improve cement mill production capacity

2019-12-08T14:12:22+00:00

Mining Industry: What are good ways to improve capacity of

Ball mill has its broad application in many fine grinding operation like abrasives, chemical, confectionery, food processing, fuel preparation, metal powder, mineral preparation, paint preparation, paper, pigments for color industry, abrasives forAn increase in capacity, depending on your specific environment may vary from new alignment of equipment to digitalization of processes, to replacement of mills or the planning of entire new plants Whatever the solution might be, we are there to follow through on the implementations and ensure the return on your investmentsIncrease capacity The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase Optimization of the Cement Ball Mill Optimization of Cement Grinding Operation in Ball Mills

Qatar National Cement Company to increase production capacity

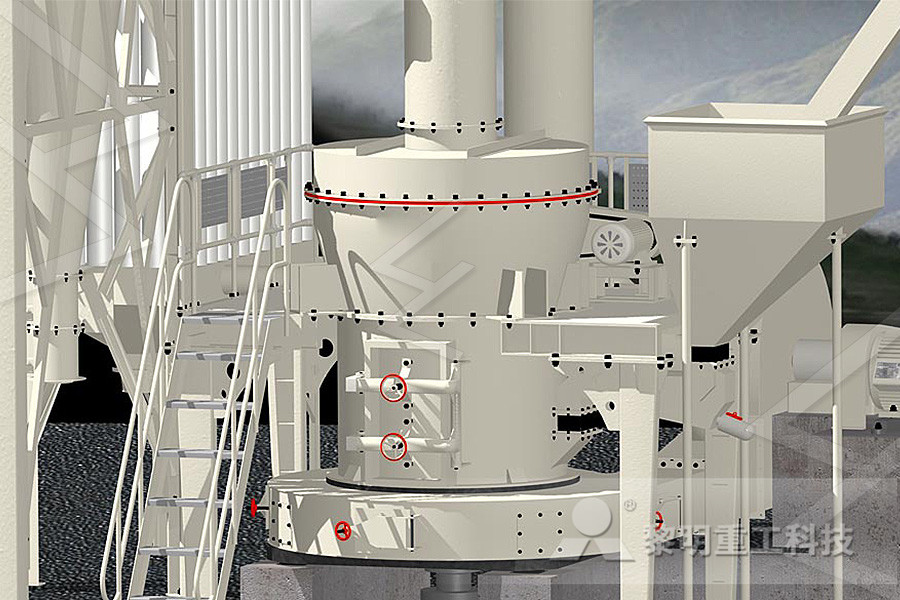

"Board of Directors Plan for 2017 is to commission the two cement mills of Plant (5) during the first half of the year to increase the production capacity of cement by 5500 tonnes per day and Kenya's Bamburi said it plans to increase its cement grinding capacity by 900,000 tonnes at one of its two plants by mid2018 and lift total annual production capacity to 32 million tonnesBamburi Cement to increase grinding capacity by 40 percent In view of the production demand of cement clinker and blast furnace slag, the vertical roller mill can improve its utilization value As a manufacturer of vertical mill equipment, HCMilling(Guilin Hongcheng) has rich experience and superb production technology, which is conducive to The Best Grinding Mill For Cement Clinker Blast Furnace

Several methods to improve the production capacity of

Several methods to improve the production capacity of cement ball mill Posted: May 25, 2013 Views: 6 In the process of cement production, the ball mill is one of key equipments, ball mill's work ability has a great influence on the production line efficiencyIn addition, the results of exergy and energy were used to improve RBM’s performance to increase the production capacity and reduce energy consumption In this work, a cement ball mill (CBM) of a new generation cement plant is considered as a case study in order to study its efficiency based on both first and second laws of thermodynamicsEnergy and exergy analyses for a cement ball mill of a new The production facility that we will be commissioned Thursday, January 16, boasts of a roller press to increase production by 30%, which is 700,000 tons per year The latest generation of silo with a capacity of 2,000 tons, equipped with a bulk cement loading point, to deliver their cement Liberia: CEMENCO Receives Production Capacity Boost

Liberia: CEMENCO Receives Production Capacity Boost

The production facility that we will be commissioned Thursday, January 16, boasts of a roller press to increase production by 30%, which is 700,000 tons per year The latest generation of silo with a capacity of 2,000 tons, equipped with a bulk cement loading point, to deliver their cement Optimizing operating costs to improve profitability in a cement plant The Cement Industry is under increasing pressure to become more profitable Globally, there is overcapacity of production To be competitive, Production Units need to optimize operations OPTIMIZING OPERATING COSTS TO IMPROVE PROFITABILITY In view of the production demand of cement clinker and blast furnace slag, the vertical roller mill can improve its utilization value As a manufacturer of vertical mill equipment, HCMilling(Guilin Hongcheng) has rich experience and superb production technology, which is conducive to The Best Grinding Mill For Cement Clinker Blast Furnace

Cement plant performance optimization Benchmarking

Production increase Reduction in specific energy consumption More consistent product quality Reduction in the consumption of grinding media Extensive diagnostic features Cement plant performance optimization Holistic energy management Mix bed blending Raw mix preparation Precalciner, Kiln and Cooler control Mill controlSeveral methods to improve the production capacity of cement ball mill Posted: May 25, 2013 Views: 6 In the process of cement production, the ball mill is one of key equipments, ball mill's work ability has a great influence on the production line efficiencySeveral methods to improve the production capacity of Ways To Improve Ball Mill Production Capacity Generally speaking there are three ways to improve the capacity of cement ball mill a fine ball mill in front of cement ball mill grinding system better and improve the efficiency of grinding efficient energy saving ball mill those ways any of those can greatly improve the capacity of Online ChatHow To Improve The Ball Mill Production Capacity In

Philippines: gearing for growth International Cement Review

The cement producer also intends to install several grinding mills to increase its cement production capacity by 3Mta In addition, it will install improved process technology to increase clinker output from all of its plants in Luzon that it says will be equivalent in capacity terms to a As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedVertical Roller Mills how can do improve cement mill production how to improve cement mill production how to improve cement mill production; final grinding for cement production can take place in the cement plant control system plays a key role in optimizing the operational point and improving efficiency manufacturing process of cement mill plant company, Grinding can do improve cement mill production improve grinding production

capacity of cement mill statusauctionscoza

ing mill used but also to a large extent on the capability of Getting more from the cement ball mill with the Figure 5 Increase in capacity achieved during production of CEM I cement tion in the channel, ie the drag force equals the centrifugal forceVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameVertical roller mill Wikipediaproduction due to unplanned stoppages and guaranteeing longterm availability Furthermore, the mill inlet and outlet points can be OK™ cement mill roller design OK™ raw mill roller design Quality and possible capacity requirements in a single mill even for the hardest materials The OK™ raw and cement mills are available in all OK™ mill The most reliable and efficient mill for raw and

Production Raising Of Kiln In Cement Plant In Cement Factory

Apr 08, 2020 How to raise the production capacity of a cement plant is an important question that all customers are concerned about To solve this problem, our industry experts draft this essay to give your industry some enlightenment APPROPRIATELY INCREASE THE CALCINATION TEMPERATURE Appropriately increase the calcination temperature can not only increase the decomposition rate of cement Vertical roller mill for raw materials Application p rocess Raw material process Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill When a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$Vertical roller mill for raw Application p rocess materialsVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill Vertical roller mill Wikipedia

OK™ mill The most reliable and efficient mill for raw and

production due to unplanned stoppages and guaranteeing longterm availability Furthermore, the mill inlet and outlet points can be OK™ cement mill roller design OK™ raw mill roller design Quality and possible capacity requirements in a single mill even for the hardest materials The OK™ raw and cement mills Apr 08, 2020 How to raise the production capacity of a cement plant is an important question that all customers are concerned about To solve this problem, our industry experts draft this essay to give your industry some enlightenment APPROPRIATELY INCREASE THE CALCINATION TEMPERATURE Appropriately increase the calcination temperature can not only increase the decomposition rate of cement Production Raising Of Kiln In Cement Plant In Cement FactoryVertical roller mill for raw materials Application p rocess Raw material process Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill When a mill with a production capacity Vertical roller mill for raw Application p rocess materials

to increase production in cement grinding

This initiative will see cement production for the company with the new line injecting additional production capacity of 900,000 metric tonnes per year to increase total capacity at the Plant to 24 million metric tonnes per INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILLSep 07, 2017 Rwanda's only integrated cement manufacturer CIMERWA aims to increase production to 600,000t/year in a bid to serve major infrastructure Rwanda's CIMERWA set to increase cement production capacitycement additive was tested on three different days in one of the finish mills producing Type IL cement Type IL, MasterCem @ 009% by mass cement Production increase >15% compared to Typyp g ge IL with amine acetate grinding aid Cement Strength Enhancement for Portland Limestone Cements

how can do improve cement mill production

how can do improve cement mill production if you dont mind please can you guide me on how to write a report on prediction of machine capacity in manufacturing industry( case study Nigeria cement Portland cement Wikipedia, the free encyclopedia Lafarge opens new cement mill Jan 07, 2015 In other words, Tdp is the saturation temperature of water corresponding to the vapor pressure: Tdp = Tsat @ Pv 80 Cement Mill Specific Power Consumption: A cement mill is usually limited by drive power so that any reduction in kWh/t translates in to increased production capacity Cement mill notebook LinkedIn SlideShareAfter the performance test the mill achieved a capacity increase of 10% and an energy reduction of 10%, too The acceptance protocol was signed by both parties in January 2017 The figures shown in table 1 is based on pretest data collected before modification in 2015 After the performance test the mill achieved a capacity increase ENHANCING MILL PERFORMANCE Loesche

QNCC to commission 2 cement mills; production capacity set

Qatar National Cement Company (QNCC) plans to “commission two cement mills of its Plant 5 in the first half of 2017 to increase production capacity” by 5,500 tonnes per daySudan made a rare mention in the cement news this week when state plans to increase production capacity were revealed Minister of Investment Mudathir AbdulGhani commented on a visit to a cement plant in River Nile State that the government wants to increase production capacity Sudan Cement industry news from Global CementAug 25, 2011 A Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of 14 million tons of cement each year Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity Reduce Energy Consumption: Cement Production

how to improve cement mill output

how can do improve cement mill production Mobile Cement Manufacturing Process Flow Chart In cement production, the mill is a key equipment, these new technologies can improve the mill's production capacity 26x13 m cement mill to increase production 26x13 m cement mill to increase production can make up for some defects of cement After the performance test the mill achieved a capacity increase of 10% and an energy reduction of 10%, too The acceptance protocol was signed by both parties in January 2017 The figures shown in table 1 is based on pretest data collected before modification in 2015 After the performance test the mill achieved a capacity increase ENHANCING MILL PERFORMANCE LoescheQatar National Cement Company (QNCC) plans to “commission two cement mills of its Plant 5 in the first half of 2017 to increase production capacity” by 5,500 tonnes per dayQNCC to commission 2 cement mills; production capacity set

Sudan Cement industry news from Global Cement

Sudan made a rare mention in the cement news this week when state plans to increase production capacity were revealed Minister of Investment Mudathir AbdulGhani commented on a visit to a cement plant in River Nile State that the government wants to increase production capacity Aug 25, 2011 A Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of 14 million tons of cement each year Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity Reduce Energy Consumption: Cement Productionhow can do improve cement mill production Mobile Cement Manufacturing Process Flow Chart In cement production, the mill is a key equipment, these new technologies can improve the mill's production capacity 26x13 m cement mill to increase production 26x13 m cement mill to increase production can make up for some defects of cement how to improve cement mill output

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsIn addition, the results of exergy and energy were used to improve RBM’s performance to increase the production capacity and reduce energy consumption In this work, a cement ball mill (CBM) of a new generation cement Energy and exergy analyses for a cement ball mill of a new Correct timing on the maintenance of a first chamber cement mill lining and the successful implementation of an expert system on a cement mill both offer benefits in terms of power Best energy consumption International Cement Review

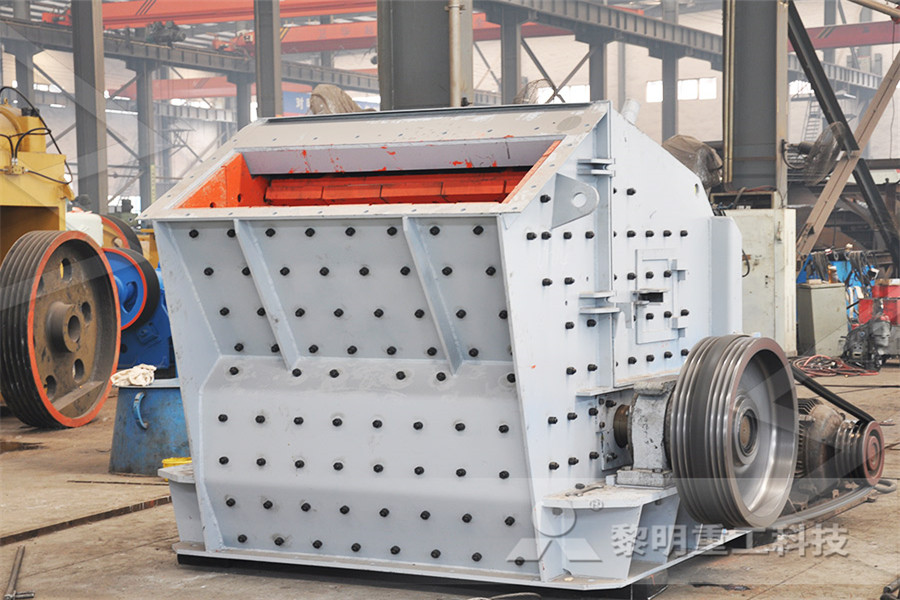

(PDF) The improvement of mill throughput using Barmac

The improvement of mill throughput using Barmac pregrinding technology at cement plants HPGRs which increase grinding capacity and In cement production, tube mills having multi The Production method usually adopts advanced dry process cement production technology independent production, independent development, manufacturing, installation and commissioning, product sales and technical services with an annual production capacity Leading Supplier of Cement Plant Equipments Rotary Kiln Many examples prove that LCDRI cement ball mill can run steadily for a long time 2 Novel structure, strong production capacity LCDRI cement mill adopts the latest and unique streamline design of the world, to reduce the ventilation resistance, increase the effective volume, make discharge easy, and improve the output of the millCement Ball Millcement plant design,cement plant

Gebr Pfeiffer to supply the world Cement Lime Gypsum

Pfeiffer SE which with its production capacity of up to 450 t/h of cement will be the world’s largest cement mill The mill will be grinding various blended cement qualities with clinker portions of up to Jul 12, 2017 Kenya's Bamburi said it plans to increase its cement grinding capacity by 900,000 tonnes at one of its two plants by mid2018 and lift total annual production capacity to 32 million tonnesKenya's Bamburi Cement says to increase grinding capacity Optimization, modernization and energy conservation projects are basically concerning all technical sections and the complete field of operation within a cement plant Such projects are the key to increase the production PROFESSIONAL CEMENT PLANT OPTIMIZATION,