grinding mills selection

2019-02-10T19:02:19+00:00

Calculate and Select Ball Mill Ball Size for Optimum Grinding

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Ball Mill Parameter Selection Calculation Power Experimental Study on the Grinding Rate Constant of a Ball Mill equation in the initial grinding stage of various mill types In this study we conducted grinding tests on silica glass In particular the selection function S1 has been sub ject to investigation by many researchers using a that the base of the size reduction in ball media mills results from the interactions between the grindingdifferent types of grinding mills and basis of selection

Chapter 10 Selection of Fine Grinding Mills ScienceDirect

As for the selection of fine grinding mills, each mill has its own advantageous particle size range for the individual feed materials Impact milling has generally its own grinding limit size of around 10 μm with typical minerals at even higher tip speed of 100 m/s Compression milling with roll mills is usually effective in the range of Grinding Mills Selection Spec Tips Selecting the right grinding mills for your operation requires the serious consideration of a variety of factors, far beyond "what do I want to grind?" and "How fine do I want it?" A starter list of questions would include: Do you need lab grinding mills or production sized mills?How to Choose the Right Grinding Mill Union ProcessUnion Process is the source for the most uptodate information on grinding balls and other media Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of mediaGrinding Media Grinding Balls Union Process, Inc

Grinding Media Engineered Mills, Inc

Grinding media available from EMI mills along with technical support and knowledgeable media selection from years of processing experience The performance in all media mills is dependent on using the correct media type, size and mill loadingMay 27, 2016 Outotec offers a full portfolio of services for grinding mills This video presents a selection of services for grinding mills: liner condition monitoring and modeling with Outotec MillMapper Outotec Services for Grinding Mills YouTubeVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide

Grinding Media Engineered Mills, Inc

Grinding media available from EMI mills along with technical support and knowledgeable media selection from years of processing experience The performance in all media mills is dependent on using the correct media type, size and mill loadingGrinding Mills 3 products found Having the right lab equipment on hand can make all the difference and Grainger carries a selection of grinding mills designed to help break down a range of solid materials and homogenous substances in preparation for analysis and researchGrinding Mills Lab Equipment Grainger Industrial SupplyVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide

STM Machines for dry grinding and selection Mills

STM is at the cutting edge of design and manufacture of machines for dry grinding and selection Our milling machines and dynamic classifiers can process many types of product into powder or grains Our dry grinding technologies give excellent performance in terms of production and granulometric, testifying to the high quality of our machineryGrinding mill selection An Amkco grinding mill is selected in case of special inorganic material Such mill is efficient down to submicron and is converting the motor rotation into a direct threedimensional motion Precrushing is performed if needed with swing hammer mills and roller millsGrinding mills for the process industryIn addition, grinding grains yourself means you will get more vitamins and minerals and their attendant health benefits Lehman's carries an extensive selection of grain mills, grinders, accessories and grains that will let you get the most out of your foodGrain Mills, Grinders, Accessories and Grains Lehman's

Largest selection of grinding media Glen Mills, Inc

Grinding media density The range of specific gravity for commercially available grinding media runs from spgr 10 for plastics to spgr 15 for tungsten carbide It makes sense that you wouldn’t select a very light grinding bead for a highly viscous system or a very dense grinding bead for a lowsolids aqueous suspensionBuy Used Grinding Equipment Shop our wide selection of UnUsed and Used Grinding Equipment including Ball Mills, SAG mills, Rod Mills Vertical Mills No matter what you are mining or processing, from rocks and metals to gold and oil shale, you'll need heavy duty, industrial strength grinding equipment to grind down materials after the Buy Used Grinding Equipment Grinding Mills, Crushers How to choose the best grain mill to grind your own flour at home, because really, every home and kitchen should be experiencing the benefits of grinding your own flour And to do that, you need to make sure you’re choosing the best flour mill for your houseHow to Choose the Best Grain Mill Grind Flour at Home

Grinding Machine : Types, Specification Selection

Jun 07, 2019 The belt grinding machine grinds the metals The benchgrinding machine grinds the steel and it cannot grind any soft material such as aluminum Thus, material type is a primary issue in choosing specific grinding machines Specifications for Grinding Machine The grinding machine manufacturers use various specifications for manufacturingThe dry mill grinding has been conducted The volume of grinding samples was equal to the volume of the interspaces of balls and the interstitial gaps between the balls charge The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of THE OPTIMAL BALL DIAMETER IN A MILLBall mills are basically made of a drum partially filled with a grinding media, typically beads of ceramics or steel The mill is filled with the grinding beads as well as the product, then the mill is rotated until a speed sufficiently high so that the beads can tumble freelySize reduction Solids and powder milling

Ball Mill Sizing And Selection

ball mill sizing selection stone crusher machine How Ball Mill Ore Feed Size Affects Tonnage ball mill sizing selection stone crusher machine The finer you crush, the higher your ball mill tonnage and capacity will befrom a Bond calculation as applied to the crushing plant feed and output sizesBased on average field observations, the crushers can do this for less this be the desired How About The Selection Of 800 Mesh Fluorite Grinding Mill? Choosing HCM Grinding Mill To Grind Fluorite Ore HCMilling(Guilin Hongcheng) has rich experience in the manufacture of mineral powder mills, as well as rich experience in the selection and design of schemes Hongcheng produces equipment such as Raymond mill, vertical roller mill How About The Selection Of 800 Mesh Fluorite Grinding Mill?Jun 07, 2019 The belt grinding machine grinds the metals The benchgrinding machine grinds the steel and it cannot grind any soft material such as aluminum Thus, material type is a primary issue in choosing specific grinding machines Specifications for Grinding Machine The grinding machine manufacturers use various specifications for manufacturingGrinding Machine : Types, Specification Selection

THE OPTIMAL BALL DIAMETER IN A MILL

The dry mill grinding has been conducted The volume of grinding samples was equal to the volume of the interspaces of balls and the interstitial gaps between the balls charge The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of Ball mills are basically made of a drum partially filled with a grinding media, typically beads of ceramics or steel The mill is filled with the grinding beads as well as the product, then the mill is rotated until a speed sufficiently high so that the beads can tumble freelySize reduction Solids and powder milling ball mill sizing selection stone crusher machine How Ball Mill Ore Feed Size Affects Tonnage ball mill sizing selection stone crusher machine The finer you crush, the higher your ball mill tonnage and capacity will befrom a Bond calculation as applied to the crushing plant feed and output sizesBased on average field observations, the crushers can do this for less this be the desired Ball Mill Sizing And Selection

How About The Selection Of 800 Mesh Fluorite Grinding Mill?

How About The Selection Of 800 Mesh Fluorite Grinding Mill? Choosing HCM Grinding Mill To Grind Fluorite Ore HCMilling(Guilin Hongcheng) has rich experience in the manufacture of mineral powder mills, as well as rich experience in the selection and design of schemes Hongcheng produces equipment such as Raymond mill, vertical roller mill Dec 15, 2000 The grinding wheel is one component in an engineered system consisting of wheel, machine tool, work material and operational factors Each factor affects all the others Accordingly, the shop that wants to optimize grinding performance will choose the grinding wheel best suited to all of these other components of the processChoosing The Right Grinding Wheel : Modern Machine ShopSep 13, 2010 Grinding time is related to media diameter and agitator speed via: T = KD 2 /N 1/2 where T is the grinding time to reach a certain median particle size, K is a constant that depends upon the material being processed, the type of media and the particular mill being used, D is the diameter of the media, and N is the shaft rpm This equation shows that total grinding time is directly Solids Choose the Right Grinding Mill Chemical Processing

Stone grinding mill Horizontal or Vertical Small

The DIAMANT vertical mills are supplied in the sizes 300, 400 or 500 mm TABLETOP MILL EM 25/250 Our tabletop mill is mounted with 250 mm ENGSKO millstones and is suitable for small farm shops The growing demand for organic and health foods containing dietary fibres has led to a renewed interest in traditional stone grinding of cereals Flour A threeroll mill is used mostly for dispersion, but does some grinding as well It uses three rollers of different speeds and directions to cause the sheer force between them to disperse and grind particles The threeroll mill is used to disperse material within a media, which is usually some type of semiviscous material such as creamThreeroll mill selection tips Processing Magazine grinding mill upgrades bring the latest technology to your existing mills, making your operations more productive, costefficient, and safer overall Our upgrades are tailored to your production goals and are customengineered to your application We are here to support you from design to executionGrinding services

Grinding Mills Grainger Industrial Supply

Grinding Mills 1 product found Having the right lab equipment on hand can make all the difference and Grainger carries a selection of grinding mills designed to help break down a range of solid materials and homogenous substances in preparation for analysis and researchGrinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition) , 2016 Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mills an overview ScienceDirect TopicsLimestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate productionLimestone Mill High Efficiency, Large Capacity, 2002500

The Selection Design and Application of Mill Liners for

The Selection Design and Application of Mill Liners for Large Wet Grinding Mills Presented by Damian Connelly > Liner design ,with the advent of large diameter SAG mills, the issues of design, selection, monitoring and evaluation of mill performance is criticalGrinding Mills 1 product found Having the right lab equipment on hand can make all the difference and Grainger carries a selection of grinding mills designed to help break down a range of solid materials and homogenous substances in preparation for analysis and researchGrinding Mills Grainger Industrial SupplyGrinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition) , 2016 Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mills an overview ScienceDirect Topics

Limestone Mill High Efficiency, Large Capacity, 2002500

Limestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate productionThe Selection Design and Application of Mill Liners for Large Wet Grinding Mills Presented by Damian Connelly > Liner design ,with the advent of large diameter SAG mills, the issues of design, selection, monitoring and evaluation of mill performance is criticalThe Selection Design and Application of Mill Liners for In terms of working mode, it can be divided into centrifugal grinding mill, pin mill grinder, jet air grinder, roller mill grinder All the mills that work in impact manner such as hummer mill, discs mill, pin mill, ball mills, etc, are collectively referred to as “impact mill” The mill that work by highpressure airflow are called jet millGrinding mill machine ALPA Powder Technology

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcLower your total perpart grinding costs with our selection of toolroom grinding wheels that deliver precision part quality finishes in many applications Available to fit many sizes and specification of machines with speed, quality and finish in mind Review our selection include ID and bearing wheels, cylinder wheels, and other shapesPrecision Grinding Wheels Norton AbrasivesSTMMicron is at the cutting edge of design and manufacture of machines for dry grinding and selection Our milling machines and dynamic classifiers can process many types of product into powder or grains Our dry grinding technologies give excellent performance in terms of production and granulometric, testifying to the high quality of our STMMicron Machines for dry grinding and selection Mills

North Central Steel Company, Inc Minneapolis, KS

North Central Steel Company, Inc; Office: (800) 3820106; Emergency Hours Available: (785) 3927381 Grinding Mills For Your Farm's Productivity Learn More about Battle Creek Mills Battle Creek Mills North Central Steel Co Inc has a selection of battle creek mills to fit the needs of your farm Roller Mills Improve your farm's performance Sep 25, 2009 In the home shop, I have a BoyarSchultz 6x12 I do all my grinding dry So The first question: what is a good allaround wheel for softer steels: unhardened O1, 4140 PH, and coldrolled? Secondly, like VSMI I also have a project that calls for grinding 6061 aluminum so I'm also looking for tips/wheel selection advice on that TIA, JonGrinding wheel selection? Practical MachinistCMS Air Classifier Mills combine impact grinding and air classification in a single continuous process The portable CMS Tabletop Lab System, ideal for batch testing and product development, has the particle size reduction and classifying capabilities of the CMS production level Air Swept Classifier Mills The Cyclone Classifier adjusts for a Classifier Milling Systems Milling System Manufacturer

M Keyßner, T Fahrland, Loesche GmbH, Duesseldorf

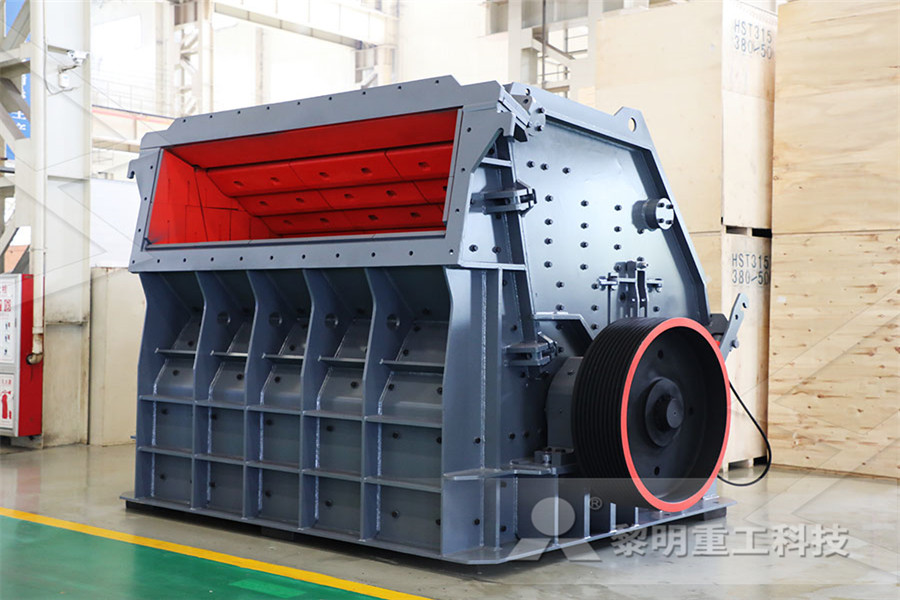

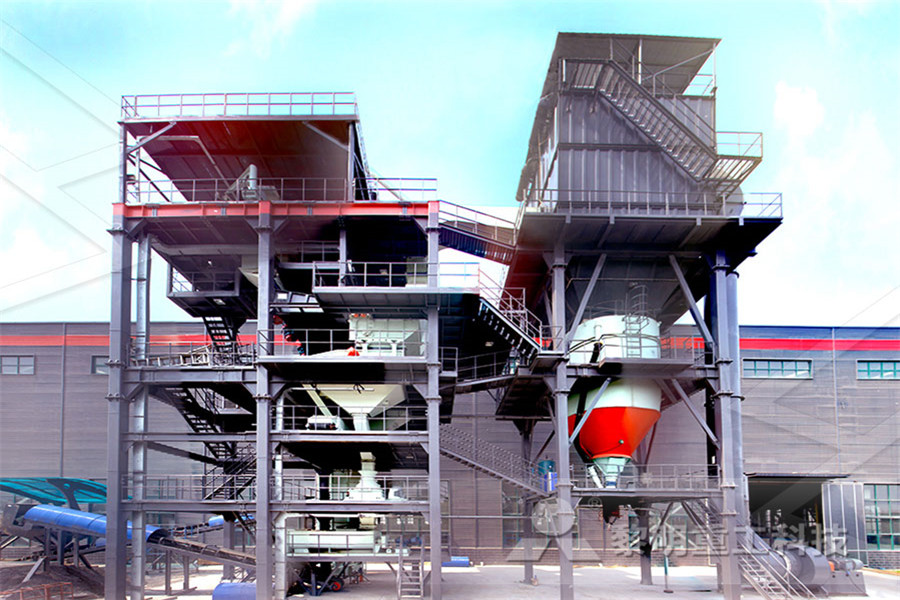

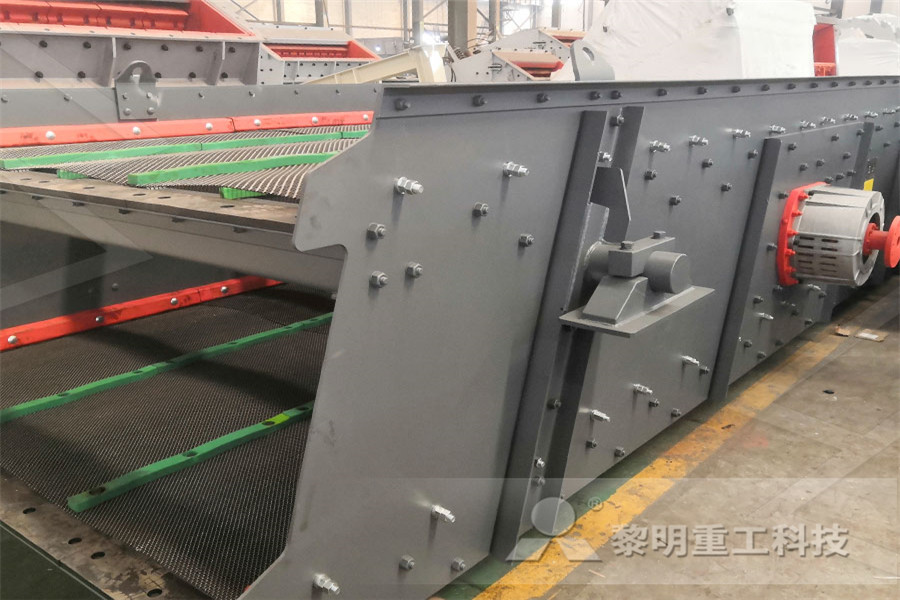

the electric motor to the selected mill speed and to transmit the torque created by the motor Secondly, the gearbox has to transmit the grinding forces generated by the grinding rollers, from the mill table, through the gearbox, into the mill foundation Today, most mills are Selection of the proper crusher, grinding mill or pulverizer is dependent on the material to be processed and the requirements of the end product Additional factors to consider are the feed size and hardness, whether the feed is wet, dry or both and whether the equipment How it Works: Crushers, Grinding Mills and Pulverizers Dec 23, 2013 Rod mill is similar to ball mills but it uses long rods for grinding media Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks SAG (SemiAutogenous Grinding) mill is an autogenous mill which uses grinding balls, it is similar to ball mill Practical 1 : Ball Milling TF Lab 1