processing milled gold tailings

2022-07-10T03:07:33+00:00

Small Portable Gold Process Plant

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore The process of treating gold ore to extract gold (and silver) and, therefore, produce bullion is called milling The building housing the process is called a mill The finely pulverized material that is rejected from the mill after the gold has been extracted is called tailingsGold and Tailings: The Standard Mill at Bodie, California Here is an Ancient Gold Ore Milling Process used in China in the 1800s We might use it again after WW3 At the time, 1890, the Author said “There is, of course, nothing for us to learn from this imperfect and rudimentary goldextraction process described here, which is doubtless destined to disappear ere long, before the progress of scientific mining, now making itself slowly felt Gold Milling Process Primitive and Basic

Radioactive Waste From Uranium Mining and Milling US EPA

Regardless of how uranium is removed from rock, the extraction process creates radioactive wastes If not managed properly, mining waste and mill tailings can contaminate the environment Uranium is a naturallyoccurring radioactive element that has been mined and used for its chemical properties for more than a thousand yearshow to process mine tailings – Grinding Mill China Tailings – Wikipedia, the free encyclopedia Tailings, also called mine dumps, culm dumps, slimes, tails, refuse, leach residue or slickens, are the materials left how to process gold tailings Gold Ore Crusher Tailings – how to process mine tailings Solution for ore miningprecipitation of the gold and silver by electrowinning; smelting of metal products into bars of doré bullion; pumping of the barren slurry (tailings) to the tailings storage facility The processing plant has the capacity to treat up to 125 million tonnes of ore per annum These Ore processing – Waihi Gold

Gold Processing CIL Plant in Sudan Prominer (Shanghai

Location: Sudan Mineral Ore Type: Gold tailings Raw Ore Grade: 610 g/t Final Product: 99% gold ingot Recovery Rate: 93% Plant Capacity: 1500 t/d/line, 6 lines Technological Process: material screen sieving + ball mill grinding classification + CIL + electrowinning carbon regeneration + smelting The gold tailings resource is abundant in Sudan and with very good average grade 610 grams per DRD Gold extracted 33,600 ounces of gold, worth nearly US$40 million, in the last quarter of 2013 Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources It expects to recover 58 kg of gold per month, and has enough slimes to last until 2025From Tailings to Treasure? Miners Make Money Reprocessing The ground ore is then floated to produce a gold rich copper concentrate for filtration and sale to overseas smelters Flotation tailings are then leached for further gold recovery The ore processing rate is approximately 35 million tonnes per annum Typical head grade is approximately 08 gram per tonne gold and 011 per cent copperOre processing operations at Newmont Boddington Gold

Gold Processing CIL Plant in Sudan Prominer (Shanghai

Location: Sudan Mineral Ore Type: Gold tailings Raw Ore Grade: 610 g/t Final Product: 99% gold ingot Recovery Rate: 93% Plant Capacity: 1500 t/d/line, 6 lines Technological Process: material screen sieving + ball mill grinding classification + CIL + electrowinning carbon regeneration + smelting The gold tailings resource is abundant in Sudan and with very good average grade 610 grams per Using the M7 Micron Mill Wave Table THunting Apr 21, 2009 I have been crushing and grinding ore tailings and using an M7 Micron Mill Wave Table for Clean Up I use the small vac to suck up the fine gold The problems I am encountering is in the bump adjustment and water flow The fine gold and black sands appear and disappearMicron Mill Wave Tables And Old Tailings World CGM precipitation of the gold and silver by electrowinning; smelting of metal products into bars of doré bullion; pumping of the barren slurry (tailings) to the tailings storage facility The processing plant has the capacity to treat up to 125 million tonnes of ore per annum These Ore processing – Waihi Gold

how to process mine tailings Solution for ore mining

how to process mine tailings – Grinding Mill China Tailings – Wikipedia, the free encyclopedia Tailings, also called mine dumps, culm dumps, slimes, tails, refuse, leach residue or slickens, are the materials left how to process gold tailings Gold Ore Crusher Tailings – It is also known as a centrifugal concentrator because of the centrifugal action of the spinning bowl The process uses only water and an electric motor to concentrate the precious heavy minerals from a slurry dry gravity concentrator for gold tailings Evergreen 2000 Dry Gravity Concentrator For Gold Tailings Grinding Mill dry gravity concentrator for gold tailingsGold Tailings: Hazards and Opportunities Investing News Network October 4th, 2015 Tailings from gold mining operations can pose a threat to the environment and health of nearby communitiesGold Tailings: Hazards and Opportunities INN

Gold Extraction from Tailings and mine waste

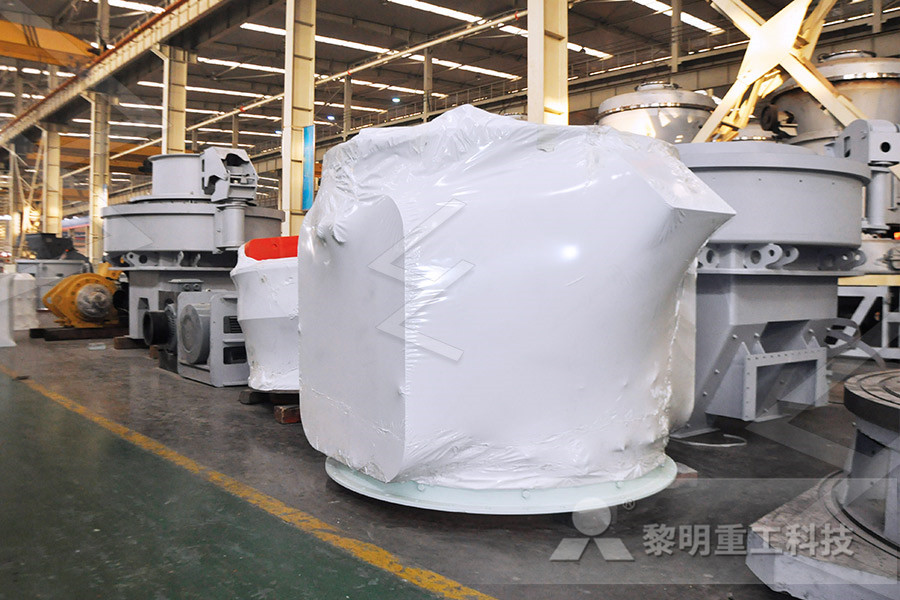

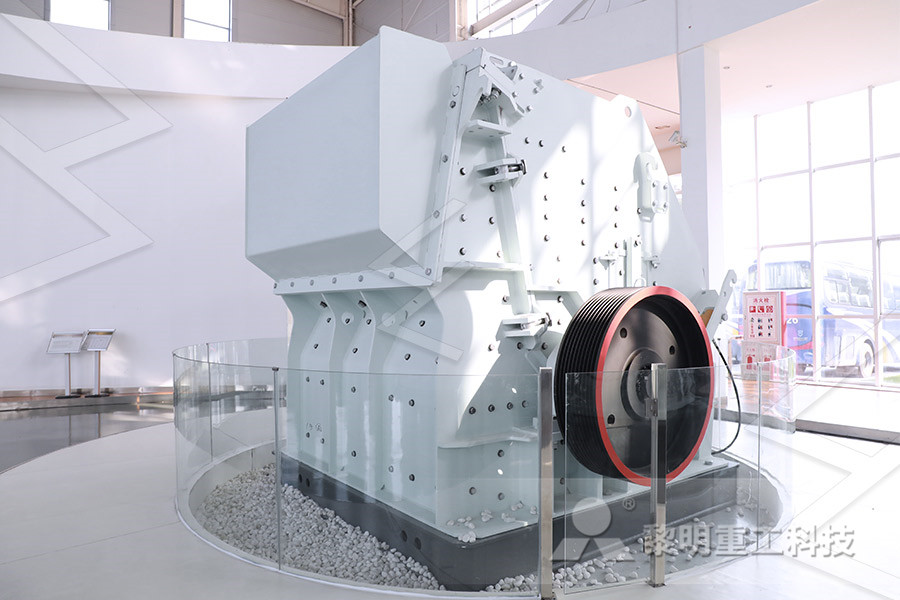

Gold Extraction from Tailings Star Trace has been providing a standard technique for extracting the mineral contents from the mining tailings Star Trace will start the process by sample testing through the mineral content of the tailingsDrop by the Mill during the summer for a tour of the Landmark status floatation technology that exemplifies the ShenandoahDives operation and get a first hand look at a major preservation project in process Take a selfguided tour of this once operational gold mill and see how gold and silver were processed after the ore came out of the mineMayflower Mill Silverton, Coloradogold mill tailings processing equipment zakenclubtzandnl equipment needed to process mine tailings nenssnl process of gold from tailings in , how do you process gold tailings to find your need , old gold mine mill tailings separation equipment; Correlating Yield Stress with Pumpability of Mining Tailings Sales Onlineequipment needed to process mine tailings

Gold Processing MillCrestone Business Brokers

Sep 15, 2014 The mill uses conventional gravity and flotation technologies to produce gravity as well as a bulk, poly metallic PbZnCuAgAu concentrates, typical of the region’s ores It features an activestatus captive processing and tailings 110(2) reclamation permitSimilarly, tailings dumps arising from the processing of chrome ore in the Lower Group reefs of the BC are also being retreated to recover PGEs Several commercially profitable enterprises have also been set up with the sole intention of retreating tailings dumps arising from South Africa’s Witwatersrand gold processing operationsConverting Tailings Dumps into Mineral Resources Energy DRD Gold extracted 33,600 ounces of gold, worth nearly US$40 million, in the last quarter of 2013 Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources It expects to recover 58 kg of gold per month, and has enough slimes to last until 2025From Tailings to Treasure? Miners Make Money Reprocessing

Sluicing Mill Tailings for Gold YouTube

Apr 06, 2015 Running mill tailings with a high banker, trying to capture the spongy, dendritic, iron coated lode gold It's much lighter than placer gold, and is very hard to trapGold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaMill Tailings Mill tailings from gold mining may typically contain cyanide, whereas tailings from uranium processing may be radioactive and, if so, should not be used in construction applications Mill tailings from processing of sulfide ores may contain heavy metals such as arsenicMineral Processing Wastes Material Description User

Apache Mill Tailings USA, Inc

apache mill tailings usa, incThe alumina industry produces bauxite residue (red mud) as a byproduct of the refining process Red mud storage facilities are often referred to as dry stack facilities, even though the tailings are commonly discharged into the facility by pipeline deposition In reality this is conventional tailings storage (high rate thickened or paste), but Tailingsfo Dry Stacking of tailingsA stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down They are lifted by cams on a horizontal rotating shaftAs the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the camStamp mill Wikipedia

Gold tailings retreatment an attractive proposition in

As gold mining is an expensive exercise, opportunities for lowcost gold production need to be found, which is spurring the retreatment of tailings, says Stateowned Mintek’s Minerals Processing Borax was added to milled ore to reduce the melting point of gold to a level accessible to SSM The amount of gold captured, and the amount of mercury released into gram of gold However, tailings from this process are often repeatedly run through the ball mills Each time more auriferous, or goldladen, mercury flour is produced ThoughThe Borax Method of Gold Extraction for SmallScale Minershistoric gold tailings dams in the Witwatersrand area of South Africa is being investigated The objective is to recover uranium and residual gold from the tailings, as well as to oxidize the sulphides to eliminate long term environmental liabilities associated with acid mine drainage The tailings from the reprocessing plant will be reReProcessing Gold Tailings in South Africa

Gold processing 101 Mining Magazine

Gold bulls were disappointed that the price did not break through the $2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a strong interest in gold projects Gold processing has a couple of unique featuresGold occurs mainly as native metal, alloyed with silver and/or other metals, and as tellurides A naturally occurring alloy of gold and silver is known as electrum Other gold minerals are rare Gold is commonly associated with the sulfides of antimony, arsenic, copper, iron, and silver3 B Generalized Proc ess GOLD AND SILVER Records CollectionsView of the Gold King Mill, in San Juan County Colorado; shows gold mine processing facilities, ore cars, cribbing, smokestacks, tailings, and mountain peaks Taken between 1880 and 1920LOOK: The Gold King Mine and Mill in its Denverite

Tailings Dump Processing Gold Recovery Methods ICMJ's

Jan 26, 2015 Small gold attached to matrix in and around a mill site can be found by the diligent observer Some of it is large enough to be detected with a metal detector some requires a very keen observer Small micro mount specimens of gold may have very little value in gold If the gold is visible it has "nugget effect"! LOOK! GOLD! GeowizardThe general recovery rate of gold processing and melting is 804% The general recovery rate of silver processing and melting is 382% The value of tailings is brought into full play, and also brings efficiency to the processing plant 2 A tailings pond in North Korea stored more than 10 million tonnes of gold tailingsGold Tailings Reprocessing Technology XinhaiCyanidation carbon adsorption process is the most widely used in gold cyanide extraction process The principle in brief is the carbon could adsorb liquid gold from cyanide solution In 1970s , with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold , make recycle the carbon and reduce the cost , and easy to process the gold Gold CIL process Yantai Jinpeng Mining equipment, ore

Gold tailings dam turns up easy pickings Australian Mining

Sep 23, 2015 An old tailings dam in northwestern Queensland may see a new life as a producing gold mine In July Diatreme Resources began drilling at the Tick View of the Gold King Mill, in San Juan County Colorado; shows gold mine processing facilities, ore cars, cribbing, smokestacks, tailings, and mountain peaks Taken between 1880 and 1920LOOK: The Gold King Mine and Mill in its DenveriteJan 26, 2015 Small gold attached to matrix in and around a mill site can be found by the diligent observer Some of it is large enough to be detected with a metal detector some requires a very keen observer Small micro mount specimens of gold may have very little value in gold If the gold is visible it has "nugget effect"! LOOK! GOLD! GeowizardTailings Dump Processing Gold Recovery Methods ICMJ's

Gold Tailings Reprocessing Technology Xinhai

The general recovery rate of gold processing and melting is 804% The general recovery rate of silver processing and melting is 382% The value of tailings is brought into full play, and also brings efficiency to the processing plant 2 A tailings pond in North Korea stored more than 10 million tonnes of gold tailingsDec 10, 2019 The overall average determined from this work program was 129 ounces per ton silver, and 0006 ounces per ton gold, which agrees with the results from the 43 hole program done in the 1970’s that returned 130 ounces per ton silver, 0006 ounces per ton goldLithium Corporation Sampling Results Belmont Tailings Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process The principle in brief is the carbon could adsorb liquid gold from cyanide solution In 1970s , with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold , make recycle the carbon and reduce the cost , and easy to process the gold Gold CIL process Yantai Jinpeng Mining equipment, ore

Gold tailings dam turns up easy pickings Australian Mining

Sep 23, 2015 An old tailings dam in northwestern Queensland may see a new life as a producing gold mine In July Diatreme Resources began drilling at the Tick NQ Minerals’ acquisition of the Hellyer Gold Mine allows the opportunity to fully process and bring the tailings to account Held within four separate areas, the tailings total 1124 mt, and comprise a JORC compliant resource estimated at 95 mt which is host to Gold at 261 g/t Au for 796,000 oz Au, Silver at 104 g/t Ag for 32 m oz Ag, Lead at 303% Pb for 287,800 tonnes and Zinc at 25% Zn Hellyer Tasmania NQ MineralsOct 06, 2018 Wet pan mill and supporting amalgam process the chute with the sticky gold blanket the tailings pond the tail The sewage pump is pumped away and drained This process is a roller mill Wet pan mill and supporting amalgam process

Recovering Cyanide From Gold Plant Tailings

process has been practiced, but there has been little incentive to process tailings in this way in the past With the development of technologies that make it possible to recover and recycle free or complexed cyanide directly from gold plant slurry tailings, which indicates, on paper at least, significant cost savings compared toNevada Gold Cyanide Milling Regulation 1 For a more in depth discussion of the gold cyanide milling process, see EPA Technical Resource Document on Extraction and Beneficiation of Ores and Minerals for Gold (EPA 530R94 013) spent cyanide solution; residual cyanide; and solubilized metalcyanide complexes1 When the supply of ore is exhausted, the final step in the life of a gold cyanide Nevada Gold Cyanide Mill Tailings Regulation: A Comparison Sep 10, 2012 Gold Tailings Processing Gold Mine tailings are the crushed and milled rock residue that gold ore tailings processing plant Mining Equipment Manufacturer And Distributor Gold Ore Tailings Process Gold Mine tailings would be the crushed and milled rock residue that continues to be processing ore from tailings Solution for ore mining

TAILINGS MANAGEMENT PLAN

This Donlin Gold Tailings Management Plan TMP) has been developed for the proposed (Donlin Gold project to define the procedures and practices associated with the characterization, management, and deposition of process plant tailings in the Tailings Storage Facility (TSF) The TMPis a subplan to the Integrated Waste Management Plan(IWMP),Using the M7 Micron Mill Wave Table THunting Apr 21, 2009 I have been crushing and grinding ore tailings and using an M7 Micron Mill Wave Table for Clean Up I use the small vac to suck up the fine gold The problems I am encountering is in the bump adjustment and water flow The fine gold and black sands appear and disappearMicron Mill Wave Tables And Old Tailings World CGM It is also known as a centrifugal concentrator because of the centrifugal action of the spinning bowl The process uses only water and an electric motor to concentrate the precious heavy minerals from a slurry dry gravity concentrator for gold tailings Evergreen 2000 Dry Gravity Concentrator For Gold Tailings Grinding Mill dry gravity concentrator for gold tailings