effect of granulated slag as sand replacement in concrete

2021-09-20T18:09:51+00:00

Effects of Ground Granulated Blast Furnace Slag in

Effects of Ground Granulated Blast Furnace Slag in Portland Cement Concrete (PCC)Wisconsin Highway Research Program WHRP 0701 Irene K LaBarca, Ryan D Foley, Steven M Cramer Department of Civil and Environmental Engineering University of WisconsinMadison January 2007 Expanded Study SPR # Gaur AS, Kumar S Effect of partial replacement of cement by groundgranulated blastfurnace slag and fine aggregate by marble slurry on properties of concrete American Journal of Engineering (PDF) Effect of partial replacement of cement by ground Download Citation Experimental Study on Effect of Ground Granulated Blast Furnace Slag of Strength and Durability of Sand Concrete Concrete used for building structures in the marine Experimental Study on Effect of Ground Granulated Blast

effect of granulated slag as sand replacement in concrete

(2006) concluded that under the high temperature effect, there has not been a of concrete in which sand was substituted by blast furnace slag and as Partial Replacement of Fine Aggregate for Preparation of Concrete A ReviewSlag Ground granulated blastfurnace slag, more commonly referred to as slag or slag cement, is a byproduct of steel production Slag is primarily composed of CaO, SiO 2, aluminum oxide (Al 2 O 3), and magnesium oxide (MgO) When used as part of a portland cement concrete, slag reacts with both the water (latent hydraulic reaction) and the Ground Granulated Blast Furnace Slag an overview Effect of Ground Granulated Blast Furnace Slag as Partial Cement Replacement on Strength and Durability of Concrete: A Review Rajesh Kr Pandey1, Abhishek Kumar2, Mohd Afaque Khan3 1Post Graduate Student, Structural Engineering, Babu Banarasi Das University, Uttar Pradesh, IndiaEffect of Ground Granulated Blast Furnace Slag as Partial

The Exploitation of Blast furnace Slag as Sand Replacement

slag as a replacement of sand in concrete mixtures The optimum percentage is between 30 % and 40 %, after those percentages there is no observed increase Keywords: Concrete; Compressive strength; Flexural properties; Ground granulated blast furnace slag, replacement as a sand I INTRODUCTION Over time waste control has become one of the The ground granulated blast furnace slag (GGBFS) is a byproduct of iron manufacturing which when added to concrete improves its properties such as workability, strength and durability This material is obtained by the heating of iron ore, limestone and coke at a temperature about 1500 degree Celsius The process is carried out in a blast furnaceGround Granulated Blast Furnace Slag in Concrete and its Slag cement, also known as ground granulated blastfurnace slag (GGBFS or GGBS), is a byproduct of the steel industry and commonly used supplementary cementitious material in concrete, either interground with Portland cement or as a partial replacement The use of slag cement in ordinary concrete is accompanied by multiple benefits, such as Effect of slag cement on the properties of ultrahigh

The Exploitation of Blast furnace Slag as Sand Replacement

Many researches used The GGBFS as a partial replacement of cement in concrete, but a few of them used it as a replacement of aggregates specially as a sandChen et al [4] investigated on mortar made up of ground granulated blast furnace, gypsum, clinker and steel slag sandMany researches used The GGBFS as a partial replacement of cement in concrete, but a few of them used it as a replacement of aggregates specially as a sandChen et al [4] investigated on mortar made up of ground granulated blast furnace, gypsum, clinker and steel slag sandThe Exploitation of Blast furnace Slag as Sand Replacement This paper investigates the effects of using Ground Granulated Blast Furnace Slag (GGBFS), Lead Slag (LS) and Zinc Slag (ZS) as replacement for sand on the strength of concrete Compressive strength, flexural strength, water absorption and density were tested at 14, 28 and 56 days In this study, a total of 40 concrete samples, including Pozzolanic Portland Cement (PPC), GGBFS, LS and ZS Effect of 30% Ground Granulated Blast Furnace, Lead and

GGBS Ground Granulated Blast Furnace Slag for Concrete!

Ground granulated blast furnace slag (GGBS) is a nonmetallic product obtained as a byproduct from the blast furnaces used to make iron Ground granulated blast furnace slag consists of silicates and aluminates of calcium and other bases The size of its particles is less than 45 microns and specific surface area is about 400 to 600 m 2 /kg/archives/V3/i2/IRJETV3I2296pdf(PDF) Effect of Ground Granulated Blast Furnace Slag as Particle Size Effect of Ground Granulated Blast Furnace Slag (GGBS) in Cement Concrete V Nagendra 1, C Sashidhar 2, S M Prasanna Kumar 3, N Venkata Ramana 4 1Civil Engineering Department, Nagarjuna College of E ngineering and Technology, Bengaluru, Karnataka, India 2Civil Engineering Department, JNTUA ,Anantapur, A P, India Particle Size Effect of Ground Granulated Blast Furnace

Ground granulated blastfurnace slag Wikipedia

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powderGroundgranulated blast furnace slag is highly cementitious and high in CSH (calcium silicate hydrates) which is a strength enhancing Effects of Grinding Process on the Properties of the Coal Bottom Ash and Cement Paste Journal of Engineering Technological Sciences, 51(1): 1 – 13 Mo, K H, Alengaram, U J, Jumaat, M Z (2015) Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concreteEffect on the Compressive Strength of Mortars Using Ground Properties And Effects Of Copper Slag In Concrete 50 CONCLUSIONS 41 Conclusions: 1 As the percentage of copper slag increases workability increases 2 Maximum Compressive strength of concrete increased by 34 % at 20% replacement of fine aggregate, and up to 80% replacement ,concrete gain more strength than normal concretePROPERTIES AND EFFECTS OF COPPER SLAG IN CONCRETE

Effect of Partial Replacement of Cement by Ground

Effect of Partial Replacement of Cement by GroundGranulated BlastFurnace Slag and Fine Aggregate by Marble Slurry on Properties of Concrete Er Arvind Singh Gaur1, Er Sachin Kumar2 1(Civil engineering, SR Group of Institution Jhansi / Dr APJ Abdul Kalam technical university, Lucknow, India)This research consists of incorporating the crushed sand (CS) in the composition of a concrete and studies the effect of its gradual replacement by the sand dune (SD) on sustainability of high performance concrete (HPC) in aggressive environments The experimental study shows that the parameters of workability of HPC are improved when the CS is partially replaced by the SD (#x3c;2/3)Influence of Local Sand on the Physicomechanical Effect of GGBFS of durability properties of concrete is discussed in this GGBS replacement (Concrete B) and silica fume plus GGBS replacement (Concrete C) The creep study was conducted at the age of 180 and the shrinkage at the age 210 days Ground Granulated Blast Furnace Slag in Concrete its AdvantagesDurability Properties of Concrete with GGBS

Performance of Copper slag and ferrous slag as partial

investigate the effect of using CS and FS as partial replacement of sand The strength characteristics of conventional concrete and slag concrete such as compressive strength, tensile strength were found Six series of concrete mixtures were prepared with different proportions of CS and FS ranging from 0% to 100% The test results of concrete wereeffect of M sand as a fine aggregate in high strength concrete and compare the results with the River sand The scope of the present investigation can be summarized as follows: ¾ To study the effect of workability and the str ength of concrete with the replacement of M sand by river sand, at an addition of silica fume with cementEffect of replacement of River sand by Msand in high Compare the strength in 40% replacement of copper slag at 7, 28, and 60 days M V Patil, YDPatil [3] investigated on Effects of copper slag as sand replacement in concrete, for this research work, M30 grade concrete was used and tests were conducted for various proportions of copper slag replacement with sand of 0 to 100% in concrete parison of The Replacement of Natural Sand by Copper

Replacement Of Sand By Steel Slag In Concrete

Many researches used The GGBFS as a partial replacement of cement in concrete, but a few of them used it as a replacement of aggregates specially as a sandChen et al [4] investigated on mortar made up of ground granulated blast furnace, gypsum, clinker and steel slag sand The Application of steel slag sand results reduced the cement clinker Apr 12, 2019 Rostami and Behfarnia studied the effect of partial replacement of slag in AAS concrete with silica fume at percentages of 5%, 10%, and 15% by weight of slag The alkaline activator solution consisted of a combination of sodium hydroxide (NaOH) and sodium silicate (Na 2 SiO 3 )A Review of Durability and Strength Characteristics of The percentage of copper slag used for replacement of river sand are 0%, 10%, 20%, 30%, 40%, 50% Cement sand mortar joint thickness of 10 and 15mm Plaster ability of use of copper slag for partial replacement material for river sand Use of copper slag as replacement material for river sand in cement concreteEXPERIMENTAL STUDY OF CONCRETE WITH COPPER SLAG

Literature review of a granulated blast furnace slag as a

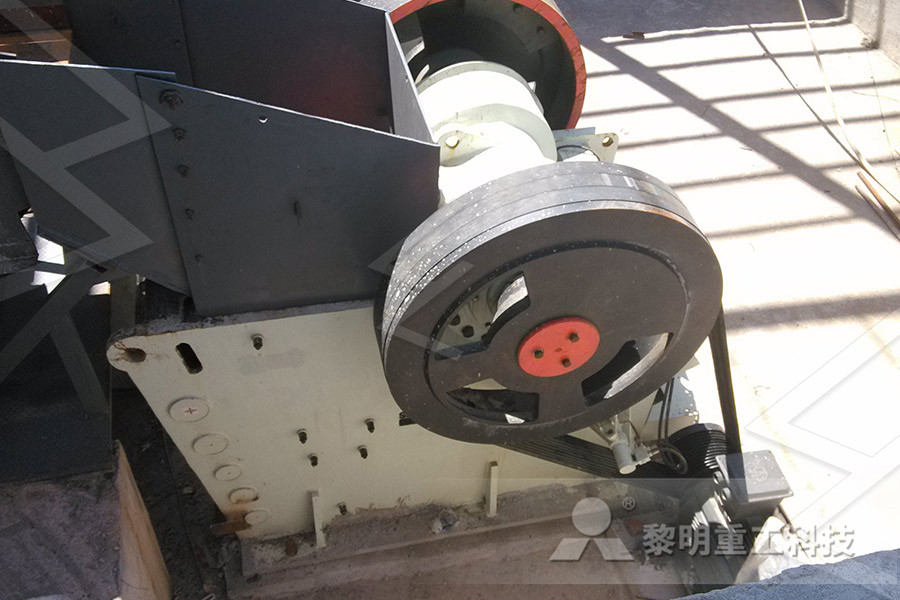

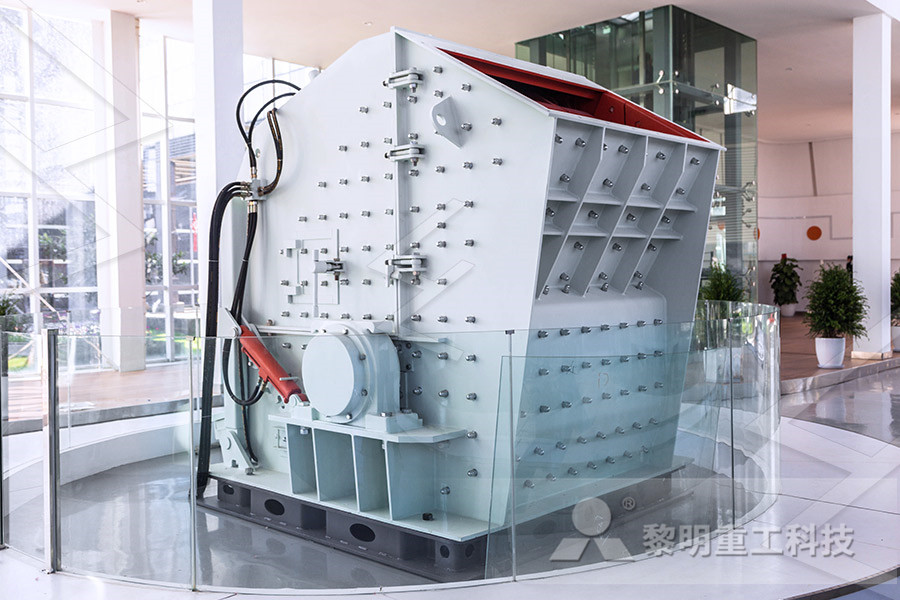

Literature review of a granulated blast furnace slag as a replacement of sand Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Literature review of a granulated blast furnace slag as a replacement of sand, quarry, aggregate, and different kinds of mineralsThe paper presents an experimental study on the effect of the replacement cement by 20%, 30%, 40%, 50% GGBFS on workability, mechanical properties and durability of sand concrete (SC) The results show SC containing 20% GGBFS had the highest compressive strength, splitting tensile strength, elastic modulus and abrasion resistanceExperimental Study on Effect of Ground Granulated Blast Steel industry results in accumulation of steel slag wastes causing severe environmental problems These wastes can be recycled and replace natural aggregates resulting in sustainable green concrete In this research, natural aggregates in selfcompacting concrete (SCC) are replaced, wholly or partly, by steel slag coarse aggregates that were produced by crushing byproduct boulders obtained Towards Sustainable SelfCompacting Concrete: Effect of

Effect of blast furnace slag powder on compressive

Compressive strength of blast furnace slag concrete with different dosage of slag was studied as a partial replacement of cement From the experimental investigations, it has been observed that, the optimum replacement of Ground Granulated Blast Furnace Slag Powder to cement without changing much the compressive strength is 15%and the desired effects on the concrete (Helmuth 1987 and ACI 232 1996) SLAG Ground granulated blastfurnace slag (Fig 35), also called slag cement, is made from iron blastfurnace slag; it is a nonmetallic hydraulic cement consisting essentially of silicates and aluminosilicates of Fly Ash, Slag, Silica Fume, and Natural Pozzolans, Chapter 3Fineness: Granulated blast furnace slag is a glassy granular material, and its particle distribution, shape, and grain size vary, depending on the chemical composition and method of production, from popcornlike friable particles to dense, sandsize grains Pelletized blast furnace slag, in contrast to aircooled and expanded blast furnace slag Blast Furnance Slag User Guideline Portland Cement

PROPERTIES AND EFFECTS OF COPPER SLAG IN CONCRETE

Properties And Effects Of Copper Slag In Concrete 50 CONCLUSIONS 41 Conclusions: 1 As the percentage of copper slag increases workability increases 2 Maximum Compressive strength of concrete increased by 34 % at 20% replacement of fine aggregate, and up to 80% replacement ,concrete gain more strength than normal concreteEffects of Grinding Process on the Properties of the Coal Bottom Ash and Cement Paste Journal of Engineering Technological Sciences, 51(1): 1 – 13 Mo, K H, Alengaram, U J, Jumaat, M Z (2015) Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concreteEffect on the Compressive Strength of Mortars Using Ground In this paper granulated blast furnace slag is used as substitute for river sand in cement mortar and concrete, to overcome the environmental problems created due to over mining In this investigation, in a cement mortar and concrete replacing natural sand by granulated blast furnace slag in a range of 20%, 40%, 60%,80% and 100%EFFECT OF GRANULATED BLAST FURNACE SLAG AS

The effect of attack of chloride and sulphate on ground

The effect of attack of chloride and sulphate on ground granulated blast furnace slag concrete Deepankar K Ashish*1,2, Bhupinder Singh3a and Surender K Verma1b 1Department of Civil Engineering, PEC University of Technology, Chandigarh160012, India 2Maharaja Agrasen Institute of Technology, Maharaja Agrasen University, Baddi , IndiaSlag cement is a hydraulic cement formed when granulated blast furnace slag (GGBFS) is ground to suitable fineness and is used to replace a portion of portland cement It is a recovered industrial byproduct of an iron blast furnace Molten slag diverted from the iron blast furnace is rapidly chilled, producing glassy granules that yield Slag Cement Benefits and Use in Concrete Slag Cement Newsdurability characteristics of concrete containing EAF slag as aggregate” Cement Concrete Composites Vol 31 pp 663671 [17] Siddique R, Kaur D (2011) “Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures” Journal of Advanced Research Vol 3 pp 4551Use of Iron Slag as Partial Replacement of Sand to Concrete

EFFECT OF USING GRANULATED STEEL SLAG IN CONCRETE

manufactured sand But in this paper only the effect of using granulated steel slag in concrete mixes as an fine agate on compressive strength and workability is discussed The properties of steel slag are also verified with the addition of GGBS (Ground Granulated Blast Furnace slag) as a replacement Aug 04, 2018 Granulated blast furnace slag ( GBFS) has been able to replace Sand to the amount of 70% GBFS is byproduct of steel industry hence this method is feasible at location where steel plant is located in close proximity Copper slag is yet another rWhich material can be used as replacement for sand in cementitious properties and produces granules similar to coarse sand This „granulated‟ slag is then dried and ground to a fine powder Although normally designated as “GGBS” in the UK, it can also be referred to as “GGBS” or “Slag cement” Concrete is basically a “Ground Granulated Blast Slag (GGBS) In Concrete – A Review”

What is slag cementany advantages or disadvantages over

Apr 17, 2017 I had practically used PPC cement in almost all projects I didn't find any problem Portland Slag Cement (PSC) Portland Slag Cement (PSC) is manufactured by either intergrinding in the Portland cement clinker, Gypsum Granulated Slag or blendinMar 01, 2020 The American Concrete Institute Founded in 1904 and headquartered in Farmington Hills, Michigan, USA, the American Concrete Institute is a leading authority and resource worldwide for the development, dissemination, and adoption of its consensusbased standards, technical resources, educational programs, and proven expertise for individuals and organizations involved in concrete Slag Topic American Concrete Instituteeffect of granulated slag as sand replacement in concrete use of blast furnace slag sand in concrete as a partial replacement for sand effect of slag on pumpability concrete manufacturer The use of slag cement slag Get Priceeffect of granulated slag as sand replacement in concrete

Blended Cement Containing High Volume Ground Dune Sand and

This paper presents the results of using ground dune sand (GDS) and ground granulated blast furnace slag (slag) as high volume cement replacement materials In this study, plain and four blended mixtures were fabricated and cured under normal and autoclave conditions For the blended mixtures, 40% GDS by weight of the total binder materials and different percentages of slag (15%, 30% and 45% The paper presents an experimental study on the effect of the replacement cement by 20%, 30%, 40%, 50% GGBFS on workability, mechanical properties and durability of sand concrete (SC) The results show SC containing 20% GGBFS had the highest compressive strength, splitting tensile strength, elastic modulus and abrasion resistanceExperimental Study on Effect of Ground Granulated Blast replacement in concrete [2 –4] In addition, there is limited literature available regarding the use of nickel slag as a sand replacement, which is only reported by [5] The subject of the current research is the effect of nickel slag as sand replacement in strength and workability of concrete 2 Materials and methods 21 CementPAPER OPEN ACCESS Effect of nickel slag as a sand

Ground Granulated Blast Furnace Slag (GGBS) Chemical

May 09, 2018 Ground Granulated Blast Furnace Slag (GGBS) The importance of Ground Granulated Blast Furnace Slag (GGBS) lies in its greener way to become a substitute in concrete material GGBS being a waste material, it needs proper method for disposal So incorporating this waste material in concrete can reduce the depletion of conventional concrete components such as cement, In this paper granulated blast furnace slag is used as substitute for river sand in cement mortar and concrete, to overcome the environmental problems created due to over mining In this investigation, in a cement mortar and concrete replacing natural sand by granulated blast furnace slag in a range of 20%, 40%, 60%,80% and 100%EFFECT OF GRANULATED BLAST FURNACE SLAG AS sand and coarse aggregates for making green concrete This research evaluates the strength of hardened concrete, by partially replacing cement by various percentages of ground granulated blast furnace slag, natural sand by CRF and coarse aggregates by river pebbles for M40 grade of concrete Green Concrete using GGBS, River Pebbles and CRF as

GGBS PPT LinkedIn SlideShare

Mar 14, 2016 Which came out to be an economical solution and partial replacement of ordinary Portland cement 6 OBJECTIVE OF THE STUDY To study the effects of Ground Granulated Blast Furnace Slag(GGBS) on the Engineering performance of black cotton soil and to check if it can be used as a soil stabilizer 6 7