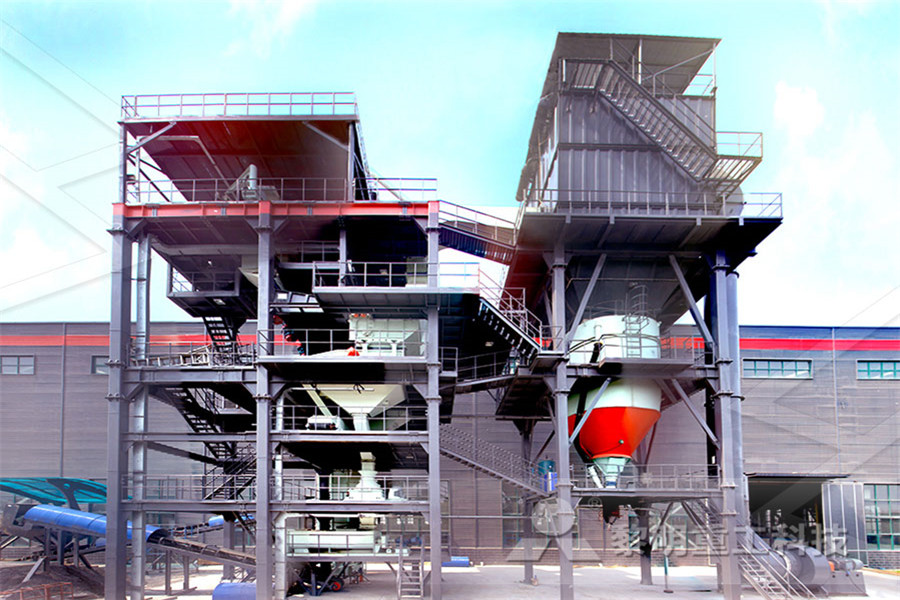

granular carbon black production process

2022-02-16T18:02:28+00:00

Continental Carbon India Carbon Black Process Flow

Carbon black gets separated from the combustible gasesIt is subsequently pelletized,dried and packed in either 25 kg paper bags or 1000 kg bulk bags The carbon black produced through the furnace process has a small granular form and is easily incorporated and dispersed in a rubber matrixCarbon black manufacturing process Carbon black is produced by combusting oil or gas with a great deal of oxygen inside large furnaces The furnace walls lined with bricks become very hot because the oxygen and oil combustCarbon black manufacturing What is carbon black Activated carbon, also called activated charcoal, is a form of carbon that has been processed to create millions of tiny pores between the carbon atoms, resulting in a dramatically increased surface area The surface area of activated carbon makes the material suitable for adsorption, a process by which impurities are removed from fluids Activated Carbon Cabot Corporation

What is Activated Carbon and How is it Made?

The Carbon Manufacturing Process How to Make Activated Carbon The production process of activated, or active, carbon exists in two forms A carbonaceous source, which can exist as coal, peat, or any organic carbonaceous material is carbonized, which means the pure carbon is extracted by a heating method known as pyrolysisThe gas furnace process for the production of carbon black was applied at the beginning of this century, but was later replaced by the cheaper oil furnace process A possible new application, the (PDF) EXTRACTION OF CARBON BLACK FROM ORGANIC Carbon black manufacturing is classified under Standard Industrial Classification (SIC) code 2895 and North American Industrial Classification System (NAICS) code Carbon black is a black, powder or granular substance made by burning hydrocarbons in a limited Carbon black process Cabot Corp 995 million lbs, 24 percent of total Economic Impact Analysis For the Proposed Carbon Black

Carbon black Wikipedia

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, or ethylene cracking tar Carbon black is a form of paracrystalline carbon that has a high surfaceareatovolume ratio, albeit lower than that of activated carbonJan 16, 2017 Granular activated carbon (GAC) is a commonly used substance for decolorization and impurity removal in sugar processing operations It can be derived from a variety of organic materials with high levels of naturally occurring carbon, including coal, peat, and/or woodUsing Granular Activated Carbon Honiron ManufacturingThe goal of this thesis is to detail a mass balance on the production of activated carbon and develop quick screening methods to observe and compare the effects of different precursor materials, chemical reagents, and process variables on this production process Activated carbon is defined as a carbonaceous material with a large internal surfaceProduction, Characterization, and Applications of

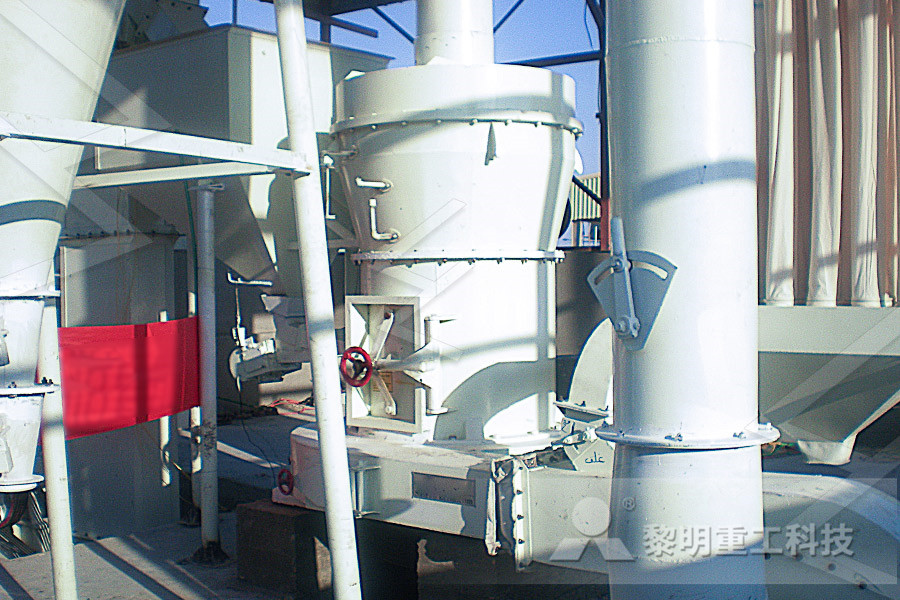

Introduction of Granular Acetylene Carbon Black

1Mature production technology: The production base of the company boasts nearly 50 years’ experience of acetylene carbon black production It’s the first professional plant producing granular acetylene carbon black in China with mature granulation production process and the annual capacity of granular acetylene carbon black of 4,000 tonsacuro offeres a range of granular activated carbon (gac) under the brand name radocarb granular activated carbon (gac) has a relatively larger particle size compared to powdered activated carbon and consequently, presents a smaller external surface diffusion of the adsorbate is thus an important factor these carbons are therefore preferred for all adsorption of gases and vapors as their Activated Carbons Granular Activated Carbon Manufacturer Activated Carbon is a porous material that removes organic compounds from liquids and gases by a process known as “adsorption” In adsorption, organic molecules contained in a liquid or gas are attracted and bound to the surface of the pores of the activated carbon Activated Carbon Calgon Carbon Corporation

Using Granular Activated Carbon Honiron Manufacturing

Jan 16, 2017 Granular activated carbon (GAC) is a commonly used substance for decolorization and impurity removal in sugar processing operations It can be derived from a variety of organic materials with high levels of naturally occurring carbon, including coal, peat, and/or woodActivated carbon remains the most common method used to decolor vinegar (Achaerandio, et al, 2002) Activated carbon can also be used to remove ethylene from fruit storage facilities, particularly if brominated (Reid, 1985) The primary use for activated carbon is the treatment of water, including potable water (24% of all use); wastewater (21%)Activated Carbon Agricultural Marketing ServiceThe goal of this thesis is to detail a mass balance on the production of activated carbon and develop quick screening methods to observe and compare the effects of different precursor materials, chemical reagents, and process variables on this production process Activated carbon is defined as a carbonaceous material with a large internal surfaceProduction, Characterization, and Applications of

What is Carbon Black? The Cary Company

manufacturing process, Carbon Black particles are formed that range from 10 nm to approximately 500 nm in size These fuse into chainlike aggregates, which defi ne the structure of individual Carbon Black grades Carbon Black is used in a diverse group of materials in order to enhance their physical, electrical and optical propertiesCarbon filters made from powdered carbon blocks are more efficient than granular activated carbon because the blocks are denser, slowing down the passage of water through them Methods for Manufacturing Activated Carbon Blocks There are two main processes used for manufacturing the carbon block known as extrusion and compression molding ExtrusionHow Are Activated Carbon Blocks Made Rajah Filter Catalysts are important for chemical and compound production Puragen Activated Carbons products are used as catalyst carriers or direct catalysts for many applications Thousands of chemicals improve our lives and the products we use Puragen Activated Carbons products are used in chemical manufacturing to enhance performance and effectivenessActivated Carbon Manufacturer Puragen Activated Carbons

Volume Of Emissions In Carbon Black Processes Emission

Aug 18, 2019 Carbon black production process descriptions Furnace Black Process The furnace black process produces carbon black from 'carbon black feedstock' (also referred to as 'carbon black oil') which is a heavy aromatic oil that may be derived either as a byproduct of the petroleum refining process or the metallurgical (coal) coke production processJul 15, 2017 Y698 Projects on Activated Carbon (Granular Activated Carbon (GAC), Activated Carbon, Activated Carbon Powder, Powdered Activated Carbon (PAC), Activated Charcoal, Activated Coal, Activated Business Ideas for Production of Activated Carbon USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords carbon black granules filler mixtures fillers Prior art date Legal status (The legal status is an assumption and is not a USA Process for the production of granules from

activated carbon production line machinery, activated

charcoal making machine/charcoal briquette carbonization furnace Raw Material of charcoal making machine/charcoal briquette carbonization furnace Welcome to contact me by cell/what's app 0086 raw material Humility carbonizing rate heating value fixed carbon wood le; 20% 3335% 60006500 6070% Wood log ge; 30% 2225% 60006500 6070% coconut shell le; 20% 3035% 1Mature production technology: The production base of the company boasts nearly 50 years’ experience of acetylene carbon black production It’s the first professional plant producing granular acetylene carbon black in China with mature granulation production process and the annual capacity of acetylene carbon black of 8,000 tonsBuy Super Carbon, Carbon Manufacturing Cheap Price Aug 18, 2019 Carbon black production process descriptions Furnace Black Process The furnace black process produces carbon black from 'carbon black feedstock' (also referred to as 'carbon black oil') which is a heavy aromatic oil that may be derived either as a byproduct of the petroleum refining process or the metallurgical (coal) coke production processVolume Of Emissions In Carbon Black Processes Emission

Business Ideas for Production of Activated Carbon

Jul 15, 2017 Y698 Projects on Activated Carbon (Granular Activated Carbon (GAC), Activated Carbon, Activated Carbon Powder, Powdered Activated Carbon (PAC), Activated Charcoal, Activated Coal, Activated USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords carbon black granules filler mixtures fillers Prior art date Legal status (The legal status is an assumption and is not a USA Process for the production of granules from charcoal making machine/charcoal briquette carbonization furnace Raw Material of charcoal making machine/charcoal briquette carbonization furnace Welcome to contact me by cell/what's app 0086 raw material Humility carbonizing rate heating value fixed carbon wood le; 20% 3335% 60006500 6070% Wood log ge; 30% 2225% 60006500 6070% coconut shell le; 20% 3035% activated carbon production line machinery, activated

Buy Super Carbon, Carbon Manufacturing Cheap Price

1Mature production technology: The production base of the company boasts nearly 50 years’ experience of acetylene carbon black production It’s the first professional plant producing granular acetylene carbon black in China with mature granulation production process and the annual capacity of acetylene carbon black of 8,000 tonsOct 13, 2018 Biochar, charcoal, and activated carbon are all made using a process called pyrolysis, in which a source material – in this case, a carboncontaining substance – is subject to elevated temperatures in the absence of oxygen so that it thermally decomposes into char, or carbonrich solids The lack of oxygen is key to the process, as Biochar vs Charcoal vs Activated Carbon: What CharGrow61 Carbon Black 611 Process Description Carbon black is produced by the reaction of a hydrocarbon fuel such as oil or gas with a limited supply of combustion air at temperatures of 1320 to 1540°C (2400 to 2800°F) The unburned carbon is collected as an extremely fine black fluffy particle, 10 to 500 nanometers (nm) in diameter The principal61 Carbon Black US EPA

Introduction to Activated Carbon FEECO International Inc

Granular Activated Carbon (GAC) Granular activated carbons generally range in particle sizes of 02 mm to 5 mm and can be used in both gas and liquid phase applications GACs are popular because they offer clean handling and tend to last longer than PACs Additionally, they offer improved strength (hardness) and can be regenerated and reused³The Manufacturing Process Unfinished, crude activated carbon arrives at the factory in bulk bags As part of the quality assurance process, samples are taken of the incoming activated carbon The carbon is then graded, crushed, sieved under vacuum for dedusting and milled to micro fine powderACT Activated Carbon Technologies FactoryClassification of carbon black by manufacturing process Carbon black is produced with the thermal decomposition method or the partial combustion method using hydrocarbons such as oil or natural gas as raw material The characteristics of carbon black vary depending on manufacturing process, and therefore carbon black is classified by manufacturing processManufacturing Process of Carbon Black

Washing Activated Carbon Mineral Processing Metallurgy

In the process of washing activated carbon, a dilute hydrochloric acid solution (3%) is circulated/pumped into the elution column The acid dissolves inorganic foulants such as calcium carbonate, magnesium and sodium salts, fine ore Minerals such as silica, and fine iron particles The carbon acid wash cycle takes about 430 hours Acid washing may also help in removing some of the Coalbased Black Granular Activated Carbon , Find Complete Details about Coalbased Black Granular Activated Carbon,Black Granular Activated Carbon,Activated Carbon,Coalbased Activated Carbon from Supplier or ManufacturerPingxiang Zhongtai Environmental Chemical Packing Co, LtdCoalbased Black Granular Activated Carbon Buy Black The black particles are 10nm to approximately 500nm big and fuse into chainlike aggregates, which define the structure of individual Carbon Black grades Depending on the production process Carbon Black types differ in size, surface chemistry, porosity and many other characteristics During the aftertreatment process the oxygen percentage Orion Engineered Carbons What is Carbon Black

(PDF) ECONOMIC ANALYSIS OF CO 2FREE HYDROGEN PRODUCTION

The paper presents the carbon black production by plasma method and the thermal–mechanical and oxidation induction time tests of LDPE and HDPE modified by changeable content of plasma carbon The paper presents the carbon black production by plasma method and the thermal–mechanical and oxidation induction time tests of LDPE and HDPE modified by changeable content of plasma carbon (PDF) ECONOMIC ANALYSIS OF CO 2FREE HYDROGEN PRODUCTION Sep 21, 2019 Granular activated carbon Biosolids Deriver Biochar generated from the Bioforcetech Pyrolysis Process a replacement for Carbon Black, carbon electrodes for Eliminating PFAS From Biosolids Is No Longer a Medium

Carbon Black Granular FactoryChina Carbon Black Granular

China Carbon Black Granular Factory Select 2020 Carbon Black Granular Factory products from verified China Carbon Black Granular Factory manufacturers, suppliers on MadeinChina