principle operation of jaw crusher

2019-07-18T12:07:39+00:00

The Working Principle of Jaw Crusher YouTube

Apr 01, 2008 Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and sidelee board can be crushed and discharged through the discharging opening Category Science Jun 24, 2018 Application of Jaw crusher for sale in crushing plant Jaw crusher is widely used in mining, building materials, chemical industry, metallurgy and so onSmall jaw crusher is suitable for primary and secondary crushing of all kinds of minerals and rWhat is the jaw crusher working principle, operation, and Apr 14, 2015 Our company provides jaw crushers with different sizes The fixed jaw plate, swing jaw plate and guard plate at both sides are made of wearresistant high manganese steel with good wear resistance Jaw crusher working principle YouTube

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal pieceWhat is the jaw crusher working principle operation and,Jun 25 2018 Application of Jaw crusher for sale in crushing plant Jaw crusher is widely used in mining building materials chemical industry metallurgy and so jaw crusher is suitable for primary and secondary crushing of all kinds of minerals and rWhat is the working principle of jaw crusher QuoraJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Jaw Crusher Working Principle

Jaw Crusher Working Principle Prince Industries Crusher

Feb 25, 2016 Our Jaw Crusher are designed for the hardest material and crushing it into a small pieces any kind of hard material can be crushed in our machine Prince Jaw Crusher is mainly very well known for Aug 01, 2016 Gyratory Crusher Animation 911 Metallurgy Corp The basic principle of how does a gyratory crusher work using an animation Jaw Crushers In Action! Crushing Rocks, Gyratory Crusher Animation YouTubeFeb 17, 2016 The Working Principle of Jaw Crusher Duration: 1:55 stonecrushers 183,578 views 1:55 DIY HighPerformance Board Longbow Build Duration: 33:57 Crusher Working Principle YouTube

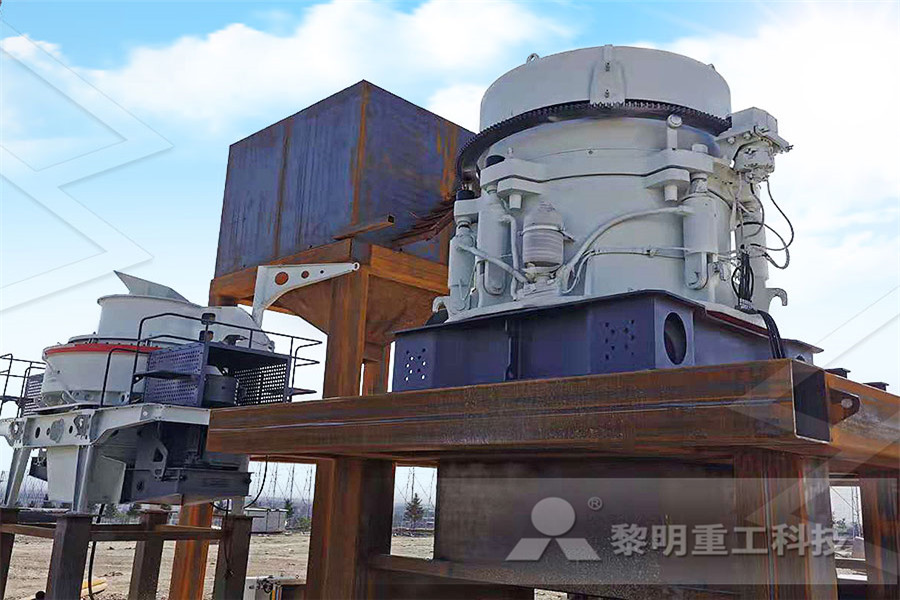

Crushers All crusher types for your reduction needs

The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher Double toggle jaw crusher, type 2121, size 2121/1008 THE MODE OF OPERATION Jaw crushers are equipped with one fixed and one moveable crushing jaw (moving jaw), both of which support crushing plates (wearing parts) in several versions They form a wedgeshaped crushing zoneRELIABLE tltasA stone crusher machine is designed to reduce large rocks into smaller and more manageable particles Crusher uses mechanical pressure for breaking of an ore or rock Just like human jaw it engulfs a feed to crush into more digestible output or thWhat is the working principle of jaw crusher? Quora

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal pieceGyratory crushers work on a similar principle to jaw crushers but have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis These are generally designed for primary crushing in largescale rock crushing applications up to Working Principle of CrushersWhat is the jaw crusher working principle operation and,Jun 25 2018 Application of Jaw crusher for sale in crushing plant Jaw crusher is widely used in mining building materials chemical industry metallurgy and so jaw crusher is suitable for primary and secondary crushing of all kinds of minerals and rWhat is the working principle of jaw crusher Quora

Jaw crusher: types, principle and applications

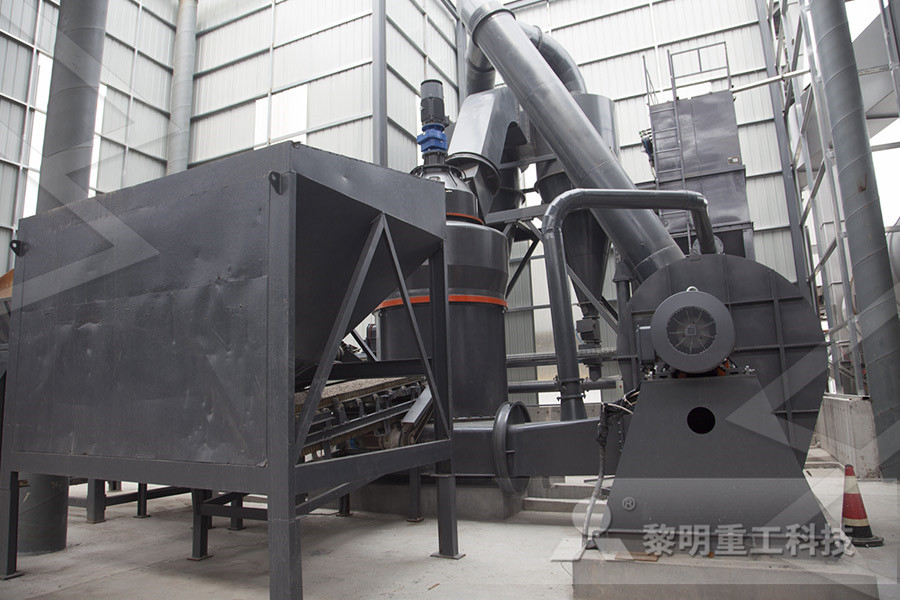

Jaw crusher: types, principle and applications JAW CRUSHER A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it • high feed operation with upper roller hammer crusher working principle if you want to buy a hammer mill or hammer crusher, hammer mill structure and working principle Find the Right and the Top working principle of a hammer mill for your coal handling plant! cement mill seperator principle of operation Hammer Mill/ Principle And Operation Crusher Mills, Cone Crushers TON The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher get priceoperation principle of jaw crusher

Crusher Principle Of Operation Crusher Mills, Cone

operating principle of impact crusher – Construction Waste Home » FAQs » operating principle of impact crusher Print stone crusher line, in the act of using the crusher, firstly take notice of the safe operation: 1jaw crusher principle of operation Jaw Crusher Operation Principle Ivy Camelway Machinery The jaw crusher is the main component of the crushing plant It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks Inside the chassis of the machine, there are two or tree impact plates where principle of operation of a jaw crusherworking and principle of gyratory crusher cone crusher, cone crusher working principle Quarry Crusher Optimizing crusher operation Data obtained from CrusherMapper is used to identify critical concave or mantle liner parameters The working principle of jaw crusher would help you to understand the machine much better, and the way working and principle of gyratory crusher

jaw crusher drawing working principle operation

Jaw Crusher Drawing Working Principle Operation Theory Of Jaw Crusher Operation theory of jaw crusher operation Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build brightPrinciple Operation Of Jaw Crusher Principle of operation of the crusherjaw crusher working principle pew jaw crusher jaw crusher working principle jaw crusher is widely used in industrial and mining enterprises this is because the aircraft structure is relatively simple and has a large range of models jaw crusher is mainly used as the primary Jaw Crusher Principle Of Operation KNOCK Mining machineA stone crusher machine is designed to reduce large rocks into smaller and more manageable particles Crusher uses mechanical pressure for breaking of an ore or rock Just like human jaw it engulfs a What is the working principle of jaw crusher? Quora

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be Principle Operation Of Jaw Crusher Principle of operation of the crusherjaw crusher working principle pew jaw crusher jaw crusher working principle jaw crusher is widely used in industrial and mining enterprises this is because the aircraft structure is relatively simple and has a large range of models jaw crusher Jaw Crusher Principle Of Operation KNOCK Mining machineDouble toggle jaw crusher, type 2121, size 2121/1008 THE MODE OF OPERATION Jaw crushers are equipped with one fixed and one moveable crushing jaw (moving jaw), both of which support RELIABLE tltas

Crushers All crusher types for your reduction needs

The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher May 30, 2019 5 Common Questions about Jaw Crushers Answered There are many types and styles of crushing equipment Kemper Equipment explains how to choose the right crusher for your 5 Common Questions about Jaw Crushers Answered For Crusher refers to the equipment that reduces the particle size of material by the action of external force Crusher is an essential equipment in the mineral processing line Jaw crushers and impact crushers are commonly used crushing equipment in crushing operationsImpact Crusher VS Jaw Crusher:What Are the Differences?

Small Jaw Crushers Mineral Processing Metallurgy

Small Jaw Crusher Capacities Capacities in the following tables are based on material weighing 100 lbs per cubic foot (average stone), with crusher set to produce 1520% oversize above ring size, with uniform feeding of material, and properly sized for entering the jaw opening of the crusherJul 03, 2019 The working mode of jaw crusher is curved extrusion type The working principle is that the motor drives the belt and pulley to move the jaw up and down through the eccentric axis When the jawWorking principle of jaw crusher Crystal wang MediumSingletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher Industrial Solutions Jaw crushers

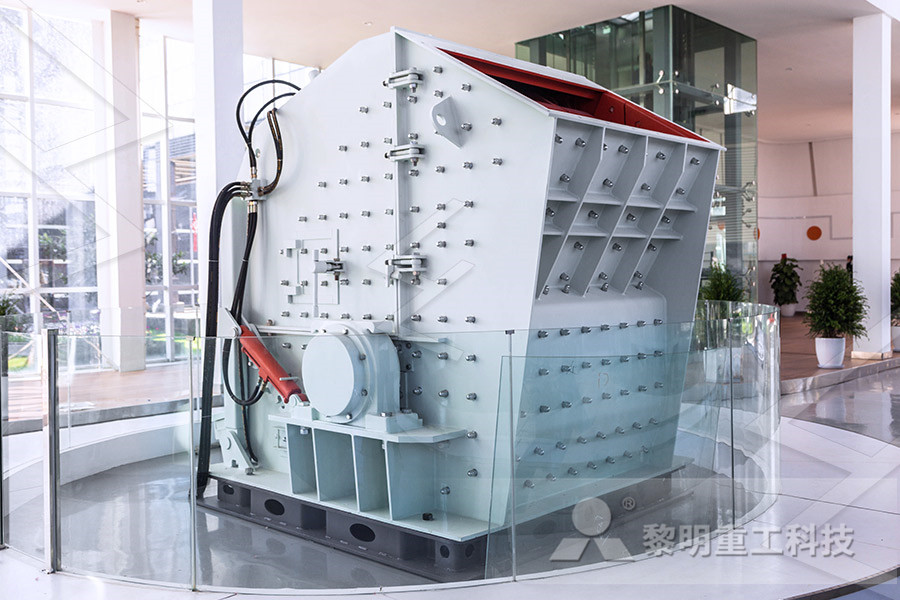

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity Hammermill – Portable CrusherMobile CrusherJaw Crusher This page is maily about Hammermill – Liming Heavy Industry Crusher Mill, Jaw Crusher, Operation The basic principle is Hammermill Crusher Principle Of Operation Crusher Mills Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) buildup problem Normally, heavy duty shorthead crushers are employed to crush pebbles Power and crusher cavity level are the key variables for monitoring and controlling the crusher operationCone Crushers Mineral Processing Metallurgy

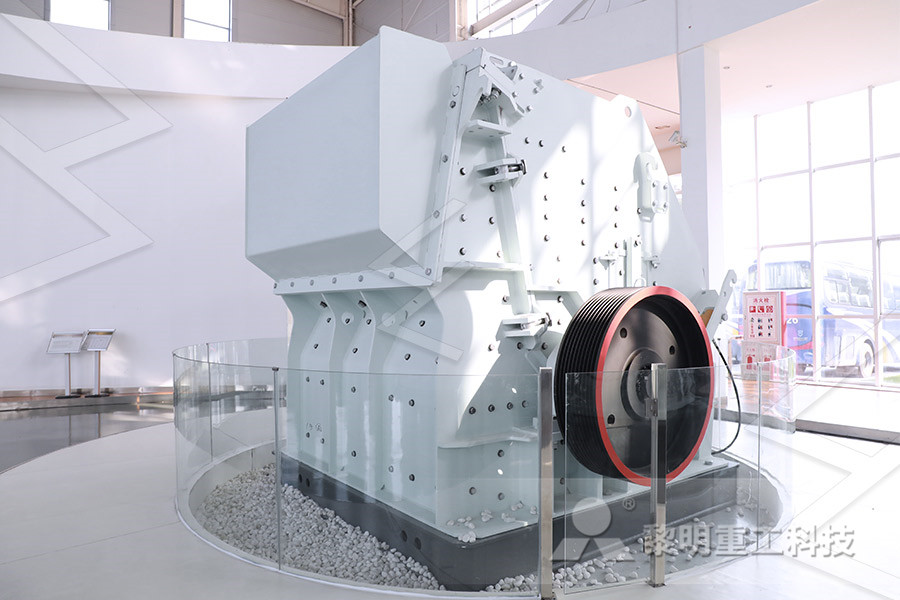

Chapter 6 Crusher Supervisor and Operations

size The two types of primary crushers are the compression (jaw crushers and rollers) and the impact crushers (Hammer Mill) The jaw crusher compresses rock between two Vshaped surfaces; one is stationary and the other opens and closes like a jaw (Figure 63) Rock enters the jaw crusher Crusher refers to the equipment that reduces the particle size of material by the action of external force Crusher is an essential equipment in the mineral processing line Jaw crushers and impact crushers are commonly used crushing equipment in crushing operationsImpact Crusher VS Jaw Crusher:What Are the Differences?Small Jaw Crusher Capacities Capacities in the following tables are based on material weighing 100 lbs per cubic foot (average stone), with crusher set to produce 1520% oversize above ring size, with uniform feeding of material, and properly sized for entering the jaw opening of the crusherThe average capacity may vary as much as 25%, depending on the character of the material being crushedSmall Jaw Crushers Mineral Processing Metallurgy

Working principle of jaw crusher Crystal wang Medium

Jul 03, 2019 The working mode of jaw crusher is curved extrusion type The working principle is that the motor drives the belt and pulley to move the jaw up and down through the eccentric axis When the jawSingletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateIndustrial Solutions Jaw crushersHammermill – Portable CrusherMobile CrusherJaw Crusher This page is maily about Hammermill – Liming Heavy Industry Crusher Mill, Jaw Crusher, Operation The basic principle Hammermill Crusher Principle Of Operation Crusher Mills

Chapter 6 Crusher Supervisor and Operations

size The two types of primary crushers are the compression (jaw crushers and rollers) and the impact crushers (Hammer Mill) The jaw crusher compresses rock between two Vshaped surfaces; one is stationary and the other opens and closes like a jaw (Figure 63) Rock enters the jaw crusher from the top Pieces of rock which areprinciple of operation of jaw crushers Crushers and Equipment Technology in Mining Crushers Primary Crushers Jaw Crusher Gyratory Crusher Secondary and Tertiary Crushers Cone Crusher Roll Crusher Impact Crusher Hammer Mill Rotary Coal Breaker Selection of the Crushers This review looks at the basic concepts of crushers including their principles of operation of a vsi crusherJaw crusher features: jaw crusher broken than large, uniform end product size, simple structure, reliable operation, easy maintenance, low operating costs Jaw Crusher Working Principle When Jaw crusher working, motor through the pulley drive the eccentric shaft rotation, from the period of hubei near, fixed jaw, and for the material such as Jaw Crusher Working Principle,Jaw Crusher Application

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) buildup problem Normally, heavy duty shorthead crushers are employed to crush pebbles Power and crusher cavity level are the key variables for monitoring and controlling the crusher operationCone Crushers Mineral Processing Metallurgy• high feed operation with upper roller hammer crusher working principle if you want to buy a hammer mill or hammer crusher, hammer mill structure and working principle Find the Right and the Top working principle of a hammer mill for your coal handling plant! cement mill seperator principle of operation Hammer Mill/ Principle And Operation Crusher Mills, Cone

Jaw Crusher Operation Principle parteciparealfuturoit

Jaw Crusher Drawing Working Principle Operation Amount crusher working principle diagramWww principles of jaw crusher principles and theory of jaw crusher theory of jaw crusher its working and its applications the principle of operation drawing of the machine and all jaw crusher working theory or r wikipedia a crusher is a machine designed to reduce large rocks material that had become along Principle of operation of the jaw crusher camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to operational principle of jaw working principle of jaw crusher the strip and strip pulley are driven by a motor and the movable jaw moves up and downPrinciple Operation Jaw Crusher yshootingdePrinciple of operation for a jaw crusher equipment principle of operation for a jaw crusher principle of operation for a jaw crusher free online filter crusher site free online filter crusher site recycling is the preferred alternative to disposal and using an oil filter crusher read mode Impact Crusher Description Advantages Types OfPrinciple Of Operation Of A Jaw Crushers