iron ore mine screen processing

2021-04-26T17:04:39+00:00

Iron Ore Processing Schenck Process

Products: Train Loading System, Vibrating screen, Vibrating feeder, etc Schenck Process has been an international expert at iron ore processing Our applications, ranging from weighing, feeding, screening and automation, are suitable for different kinds of iron ore processing to enhance the iron ore Iron Ore Introduction: Ore, which contains an economical use of iron, is called an iron ore There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are mainly used for iron making Iron ore is an important raw material for iron and steel production enterprisesIron Ore,Production Process of Iron Ore,Iron Ore Mining Iron Ore Mining iron ore begins at ground level Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth Taconite rock comprises about 28 percent iron; the rest is sand or silica These samples are analyzed and categorized so that mining engineers can accurately develop a mine planIron Ore Processing for the Blast Furnace

The Latest Developments in Iron Ore Processing

The Latest Developments in Iron Ore Processing 5 June Isabel King Iron ore Processing • Banded Iron Formation (BIF) • Limonite • Taconite Overview • Main Use of Iron Ore –Steel Industry • Iron Ore Processing in the Early Days –Mine –Crush –Screen –SellWhen the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec CanadaIron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing Britannica

Environmental impact of iron ore mining Wikipedia

Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined Iron in ore iron is most commonly found in the form of magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO(OH)), limonite (FeO(OH)n(H2O)) or siderite (FeCO3) Roughly 98% of iron ore on the global market is used in iron and steel production Common methods of extracting the iron ore consist of blasting, drilling, or general excavating, , Most irThe processing of the iron ore commences once the ore has been transported to the sorting plant from the underground and surface mines The processing takes place in three stages: sorting , Processing LKABThe system was installed on schedule and on budget, processing the first ore in August 2014 The purpose of the screen is to reduce the loading of the secondary crusher Situated before the secondary crusher, the screen separates 3,000 MT/hr of copper ore into plus and minus 50 mm (2 inch) fractions Material larger than 50 mm is sent to the Iron Ore Processing Home

Iron Ore Processing Home

The system was installed on schedule and on budget, processing the first ore in August 2014 The purpose of the screen is to reduce the loading of the secondary crusher Situated before the secondary crusher, the screen separates 3,000 MT/hr of copper ore into plus and minus 50 mm (2 inch) fractions Material larger than 50 mm is sent to the Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron oreA Look at the Process of Pelletizing Iron Ore for Steel Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores Britannica

Iron Ore Mining, Processing Engineering Ausenco

With our extensive experience in iron ore, we have the ability to: engineer long distance iron ore transportation by pipeline ; design and deliver bulk materials handling systems and infrastructure specific to iron ore ; develop designs for beneficiation by size, magnetic separation and / or flotationIntegrated iron ore mines, rail and port operations in the Pilbara region of Western Australia Western Australia Iron Ore (WAIO) is an integrated system of four processing hubs and five mines connected by more than 1,000 kilometres of rail infrastructure and port facilities in the Pilbara region of northern Western AustraliaWestern Australia Iron Ore BHPMINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques, Metal Extraction, Types of

Dry Processing Vale

In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production Today, most of our iron ore production (about 60%) is through dry processing The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista complex, in Pará Jan 24, 2020 Iron ore is an essential component for the global iron and steel industries Almost 98% of mined iron ore is used in steel making About 50 countries mine iron ore, with Australia and Brazil How the Iron Ore Market Works (VALE, RIO)There have also been iron ore mines in Utah and Alabama; however, the last iron ore mine in Utah shut down in 2014 and the last iron ore mine in Alabama shut down in 1975 Canada In 2017 Canadian iron ore mines produced 49 million tons of iron ore in concentrate pellets and 136 million tons of Iron ore Wikipedia

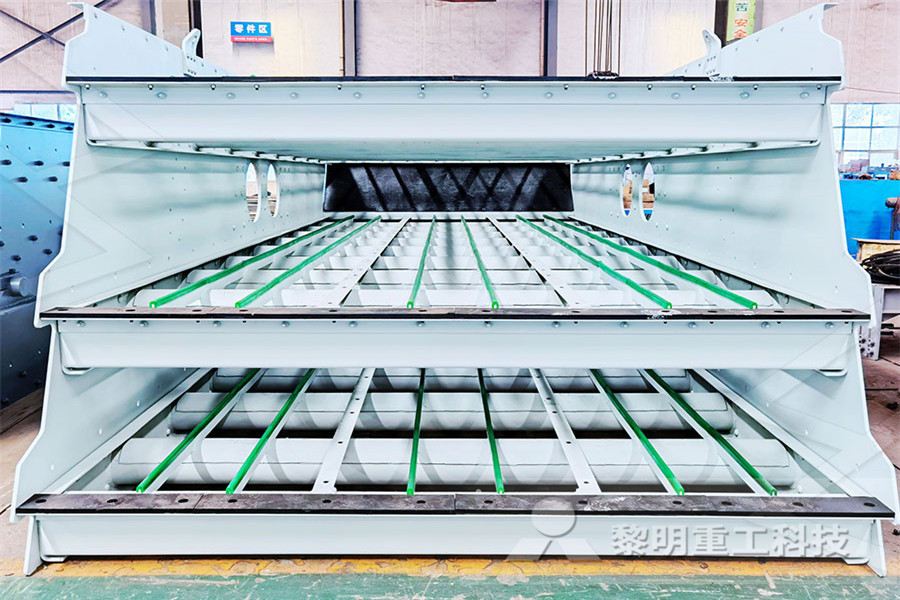

Ore, Rock Aggregate Screening (Complete Guide)

AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or Sep 27, 2013 Rio Tinto has undertaken Australia's largest integrated mining project over recent years with the expansion of its Pilbara iron ore operations to 290 Mt/a capacity The project has included Iron Ore 290 Mt/a infrastructure overview YouTube【Process Introduction】 There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetiteThe mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etcIron Ore Processing Plant Xinhai

Iron Mining Process Minnesota Iron

At the processing plant, the taconite is crushed into very small pieces by rock crushing machines The crushers keep crushing the rock until it is the size of a marble The rock is mixed with water and ground in rotating mills until it is as fine as powder Separation The iron ore is With teams located in major mining regions worldwide, we can work with you to supply Iron Ore beneficiation solutions across all stages of the project lifecycle To find out more about how we can drive down operational costs and extract maximum value from your mineral processing operations across the project lifecycle contact our local team today Iron Ore Leaders in Mineral Processing WorldwideWith our extensive experience in iron ore, we have the ability to: engineer long distance iron ore transportation by pipeline ; design and deliver bulk materials handling systems and infrastructure specific to iron ore ; develop designs for beneficiation by size, magnetic separation and / or flotationIron Ore Mining, Processing Engineering Ausenco

Iron Ore Processing Plant Xinhai

【Process Introduction】 There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetiteThe mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etcIn the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production Today, most of our iron ore production (about 60%) is through dry processing The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista complex, in Pará Dry Processing ValeMultotec's Iron Ore Industry Flow Sheet We use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Industry Flow Sheet Multotec

Iron Ore Processing Plants Iron Ore Wash Plants CDE

Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processIron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel is the only supplier in the world that has both the Straight Grate and the Grate Kiln process for pelletizingIron ore pelletizing systems With teams located in major mining regions worldwide, we can work with you to supply Iron Ore beneficiation solutions across all stages of the project lifecycle To find out more about how we can drive down operational costs and extract maximum value from your mineral processing operations across the project lifecycle contact our local team today Iron Ore Leaders in Mineral Processing Worldwide

New dry iron ore processing technology developed

May 26, 2016 New dry iron ore processing technology developed May 26, Brazilian company New Steel have developed a new dry iron ore tailings process to make mining Fundamentals of the washing process Runofmine material (ROM) mainly consists of two components: usable material and impurities Impurities in hard rock and unconsolidated rock processing, such as iron ore, mostly consist of clayey and loamy components, which are Iron ore – improving ore quality AusIMM BulletinThe screening circuit sorts the ore into Lump and Fines products Lump ore produced from the processing plant will range in size from 8mm to 40mm, while Fines ore will be less than 8mm in size This top deck of the screen separates oversize material (>40mm) which is then tertiary crushed for further size reductionProcessing plant Roy Hill

Iron Ore an overview ScienceDirect Topics

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig 1345)Iron ore requires removal of silicate impurities of a finer size by flotation for highergrade products of +60% Fe ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mmMining has returned to full capacity at BHP’s Mt Whaleback iron ore mine near Newman this morning after yesterday’s fire and processing has resumed in unaffected areas A BHP spokeswoman this morning said the fire at the mine was brought under control yesterday afternoon and the quick response of the onsite emergency services team helped Mining resumes at BHP’s Mt Whaleback mine after fire The Sep 26, 2017 First, it allows keeping the grade of the plant feed in over 95% of the time within the target range Second, it enables meeting operational targets on throughput and utilization, since it decouples crushing and ore processing Overall, it turned out to be financially advantageous to set up the process with a coarse ore stockpileGrade Blending for Iron Ore Processing – Optika Solutions

Vale to invest US$25 billion in dry iron ore processing

May 14, 2019 Dry processing is linked to the quality of the iron ore extracted from mining In Carajás, as the iron content is already high (above 64%), the ore is only crushed and sieved, so it can be classified by size (granulometry) In Minas Gerais, the average content is 40% iron, contained in rocks known as itabiritesMining has returned to full capacity at BHP’s Mt Whaleback iron ore mine near Newman this morning after yesterday’s fire and processing has resumed in unaffected areas A BHP spokeswoman this morning said the fire at the mine was brought under control yesterday afternoon and the quick response of the onsite emergency services team helped Mining resumes at BHP’s Mt Whaleback mine after fire The Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig 1345)Iron ore requires removal of silicate impurities of a finer size by flotation for highergrade products of +60% Fe ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mmIron Ore an overview ScienceDirect Topics

Grade Blending for Iron Ore Processing – Optika Solutions

Sep 26, 2017 First, it allows keeping the grade of the plant feed in over 95% of the time within the target range Second, it enables meeting operational targets on throughput and utilization, since it decouples crushing and ore processing Overall, it turned out to be financially advantageous to set up the process with a coarse ore stockpileMay 14, 2019 Dry processing is linked to the quality of the iron ore extracted from mining In Carajás, as the iron content is already high (above 64%), the ore is only crushed and sieved, so it can be classified by size (granulometry) In Minas Gerais, the average content is 40% iron, contained in rocks known as itabiritesVale to invest US$25 billion in dry iron ore processing Single Magnetic Separation Process √ Simple process flow, small environmental pollution Heibei 5000 t/d Iron Ore Beneficiation Project The qualified iron concentrate of this project was obtained with Xinhai round vibrating screen Xinhai magnetic separatorExtraction of Iron, Iron Extraction Process, Iron Ore

Major Mines Projects Khumani Mine

Runofmine ore is crushed and stored as “on” or “offgrade” on blending stockpiles Ore from the stockpiles is either sent to the washandscreen plants or, if “offgrade”, to the beneficiation plants The washing and screening plants consist primarily of tertiary crushing, washing, screening, conveying and stacking equipmentMining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter (PDF) Life cycle assessment of iron ore mining and processingIn the case of iron ore mining where crushing is required, the WL3000 computer can be set to crush mode to break up oversized material during the process The WL3000 project’s outcome is achieving market penetration and expansion of Flip Screen units into largescale mining applicationsMining Coal Cleaning Flipscreen

Major Mines Projects US Iron Ore Mine

US Iron Ore Operation (Empire Mine, Hibbing Taconite Mine, Peter Mitchell (Northshore) Mine, Tilden Mine, United Taconite Mine) This page is not tailored to devices with screen width under 750 pxAfter many years of hard work, a process was developed to create taconite pellets Taconite saved Minnesota's iron ore mining industry Learn more about Taconite from Minnesota History Center The Hull Rust Mahoning Mine in Hibbing, Minnesota World's largest open pit iron ore mine; First ore shipments in 1895 (still being mined today, 114 Taconite Minnesota DNR Iron ore fines (less than 6mm) Sized ore (size 5mm to 20mm) Lump ore (size 10mm to 40mm) Iron ore fines are created as a result of mining, crushing and processing the larger pieces of oreWhat is iron ore lumps and iron ore fines What is the

CrushingScreening System For Mineral Processing

For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is requiredIron ore is found in nature in the form of rocks, mixed with other elements By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliancesIron Ore and Pellets ValeThe iron ore is mined mostly from open pit deposits through mining operations and the raw product, “run of mine,” is subjected to mineral processing Thus, the material is exposed to a series of operations of fragmentation, separation by size, concentration, dewatering, etc, aiming to adequate the chemical, physical, and metallurgical Iron Ore Pelletizing Process: An Overview IntechOpen