ball mill design pdf download

2022-10-15T00:10:26+00:00

(PDF) Grinding in Ball Mills: Modeling and Process Control

Download fulltext PDF Grinding in Ball Mills: Modeling and Process Control Article The design of a ball mill can vary significantly depending on the size, the Design Safer Chemicals Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)Ball Milling University of Massachusetts BostonThis project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials PSP Engineering has continuously refi ned the design of its ball mills Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearingsBall Mills PSP EngBall Mill Design Handbook Pdfpdf Free download Ebook, Handbook, Textbook, User Guide PDF files on the internet quickly and easilyBall Mill Design Handbook Pdfpdf Free Download

Design, Construction and Performance Analysis of a 5

Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to120 C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 244 𝐷𝐷 02 (3) However, it is important to note that C3 =0914 vessel used in producing the ball mill was got from aOptimization of mill performance by using online ball and pulp measurements Soon after a stop, a mill is a dangerous place to enter for the personnel tasked with taking measurements or samples Crash stops are difficult to handle The mill and all feed streams should be stopped simultaneously but, often, they are stopped around about the same timeOptimization of mill performance by usingOn our download page you will find all available RETSCH brochures and flyers ready for download Click here to get to the overviewBrochures Flyers for Download RETSCH

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

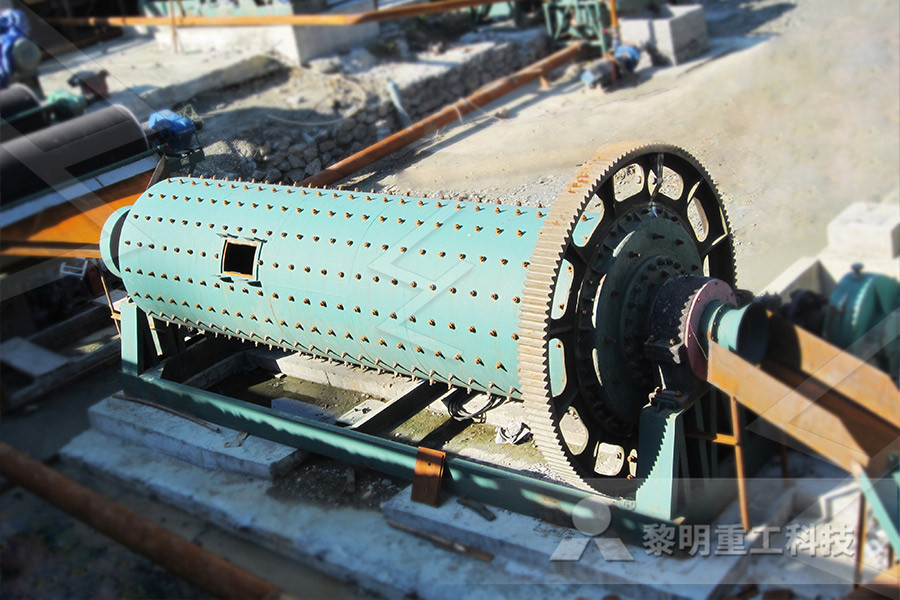

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Master of Science in Engineering Johannesburg, October 2005A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles and stainless steel ballsBall mill WikipediaMar 14, 2007 RE: Manual design of SAG/ball/rod mill foundations youngstructural (Structural) 7 Mar 07 18:27 I have a bit of a long answer here, so I'll give you a synopsis: I don't think an design can be produced manually, and I think a preliminary design could Manual design of SAG/ball/rod mill foundations

03 Ball Mill EDM Mill (Grinding) Gear Scribd

03 Ball Mill EDM Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online This poerpoint is about the ball mills involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory TRX's SiteFigure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationThe Selection and Design of Mill Liners MillTraj

Ball Mill LinkedIn SlideShare

Nov 18, 2008 We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderDownload as PDF Set alert About this page Grinding Mills so the number of mills must be decided at the design stage The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many lowgrade, hightonnage operations such as Grinding Circuit an overview ScienceDirect TopicsBallRod Mills, based on 4″ liners and capacity varying as 26 power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent This fact should be carefully kept in mind when determining the capacity of a Steel Head BallRod Mill, as this unit can carry a greater Ball Mills Mineral Processing Metallurgy

ball mill machine pdf

design and fabrication of mini ball mill (pdf download Feb 8, 2018 There is another type of ball mill machine called mini ball mill or planetary ball mill [13] Planetary ball mill is smaller than common ball mills and mainly used in the laboratories for grinding sample material like ceramic or other raw material to a very small size or powderThe design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio “length to diameter” and this ratio most frequently varies from 05 to 35 TheGrinding in Ball Mills: Modeling and Process ControlBall Mill (grinding mill) The Ball mill is a key equipment for regrindingBall mill is widely used in the field of cement, the silicate product, new type building materials, fireproof materials, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process Grinding Mill,Grinding Mill suppliers,Grinding Mill

handbook for ball mill grinding pdf Pochiraju Industries Ltd

user manual of grinding mill for cement pdf May 22, 2014 design pdf 12 Sep 2013 ball mill design handbook pdf; Ball cement ball mill design pdf 12 Sep 2013 HomeSolutions ball mill manual pdf has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your millGrinding mills for mining and minerals processing BallRod Mills, based on 4″ liners and capacity varying as 26 power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent This fact should be carefully kept in mind when determining the capacity of a Steel Head BallRod Mill, as this unit can carry a greater Ball Mills Mineral Processing Metallurgy

ball mill machine pdf

design and fabrication of mini ball mill (pdf download Feb 8, 2018 There is another type of ball mill machine called mini ball mill or planetary ball mill [13] Planetary ball mill is smaller than common ball mills and mainly used in the laboratories for grinding sample material like ceramic or other raw material to a very small size or powderThe design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio “length to diameter” and this ratio most frequently varies from 05 to 35 TheGrinding in Ball Mills: Modeling and Process ControlBall Mill (grinding mill) The Ball mill is a key equipment for regrindingBall mill is widely used in the field of cement, the silicate product, new type building materials, fireproof materials, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process Grinding Mill,Grinding Mill suppliers,Grinding Mill

handbook for ball mill grinding pdf Pochiraju Industries Ltd

user manual of grinding mill for cement pdf May 22, 2014 design pdf 12 Sep 2013 ball mill design handbook pdf; Ball cement ball mill design pdf 12 Sep 2013 HomeSolutions ball mill manual pdf has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your millGrinding mills for mining and minerals processing Addeddate 22:41:22 Identifier FanHandbookSelectionApplicationAndDesignBleier Identifierark ark:/13960/t7xm1sr40 Ocr ABBYY FineReader 90Fan Handbook, Selection, Application And Design, Bleier

Introduction to Milling Tools and Their Application

Ball end mills produce a radius at the bottom of pockets and slots Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing applications Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topicsmill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag The OK mill can contribute significantly to profitability andOK™ cement mill The most energy efficient mill for cement

Mineral Processing Design and Operations 2nd Edition

72 Design of Tubular Mills 73 Operation of Tubular Ball Mills 74 Estimation of Mill Capacity 75 Mill Power DrawMechanical Methods 76 Problems References Chapter 8: Tubular Rod Mills 81 Introduction 82 Design of Rod Mills 83 Operation of Rod Mills 84 Rod Mill Capacity 85 Rod Mill Power Draft 86 Rod Mill Drive 87 Download: Hamlets Millpdf Similar searches: Hamlets Mill Diy Mill Chainsaw Mill Rolling Mill Hamlet's Mill Power Mill Mastercam Mill Third Edition Mill Bay Treading The Mill Mastercam Mill 2d Mill On The Floss South Korea Mill Mastercam 2018 Mill 2d Mastercam 2019 2d Mill Mastercma 2020 Mill Mill Essentials Tutorial 1 Design Of Sugar Mill Ball Mill Maintenance Mastercam Mill Essentials Pdf Hamlets Millpdf Free DownloadBall Endmill EPDBE Improved compound neck design for reduced chatter and increased strength New flute shape increases resistance to breakage Details Catalog Download Download a PDF file YouTube Open in a dialog YouTube Open in a dialog EHHB Highly efficient cutting with four flutes Endmill MOLDINO Tool Engineering,Ltd North America Market

Ball Mill Design Pdf Free Download Grinding Mill China

Ball mill design calculation free download FL ball mill for cement grinding The FL ball mill is designed for compartment ball mills is of a rigid design and is More Know More design of ball mill pdf arkgroupin ball mill design pdf free download The basic parameters used in ball mill design power calculations rod mill The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball Ball Mill an overview ScienceDirect Topicsmill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag The OK mill OK™ cement mill The most energy efficient mill for cement

Mineral Processing Design and Operations 2nd Edition

72 Design of Tubular Mills 73 Operation of Tubular Ball Mills 74 Estimation of Mill Capacity 75 Mill Power DrawMechanical Methods 76 Problems References Chapter 8: Tubular Rod Mills 81 Introduction 82 Design of Rod Mills 83 Operation of Rod Mills 84 Rod Mill Capacity 85 Rod Mill Power Draft 86 Rod Mill Download: Hamlets Millpdf Similar searches: Hamlets Mill Diy Mill Chainsaw Mill Rolling Mill Hamlet's Mill Power Mill Mastercam Mill Third Edition Mill Bay Treading The Mill Mastercam Mill 2d Mill On The Floss South Korea Mill Mastercam 2018 Mill 2d Mastercam 2019 2d Mill Mastercma 2020 Mill Mill Essentials Tutorial 1 Design Of Sugar Mill Ball Mill Maintenance Mastercam Mill Essentials Pdf Hamlets Millpdf Free DownloadBall Endmill EPDBE Improved compound neck design for reduced chatter and increased strength New flute shape increases resistance to breakage Details Catalog Download Download a PDF file Endmill MOLDINO Tool Engineering,Ltd North America Market

Ball Mill Design Pdf Free Download Grinding Mill China

Ball mill design calculation free download FL ball mill for cement grinding The FL ball mill is designed for compartment ball mills is of a rigid design and is More Know More design of ball mill pdf arkgroupin ball mill design pdf free download The basic parameters used in ball mill design power calculations rod mill mills are sometimes mounted directly to the spindle nose (7) Overarm The overarm is the horizontal beam to which the arbor support is fastened The overarm, may be a single casting that slides in the MILLING MACHINE OPERATIONS HNSA

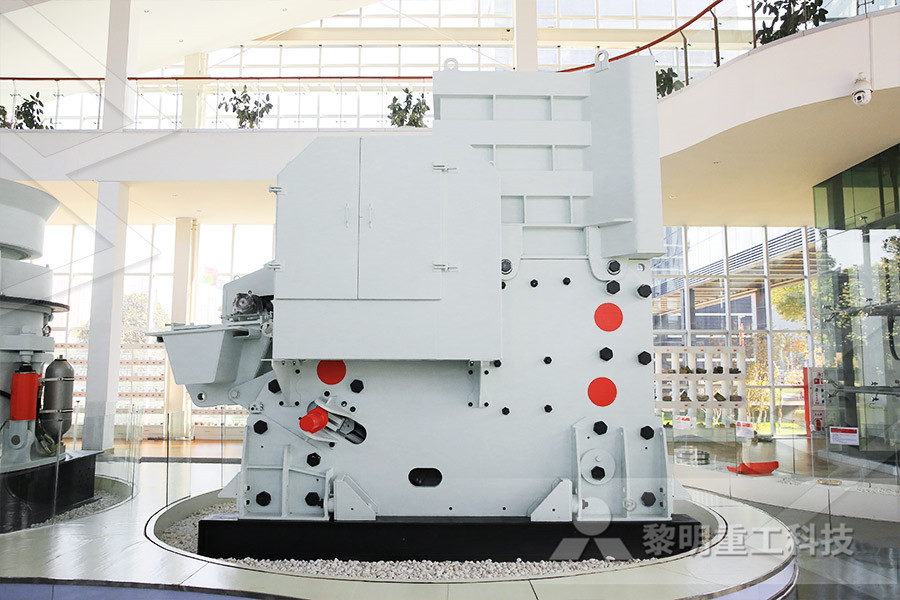

Design and Fabrication Of Hammer Mill Mechanical Project

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being The operating principle of the ball mill Primo PizzaThe grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes Cement grinding Vertical roller mills versus ball mills

Mineral Processing Design and Operation: An Introduction

Jun 26, 2006 Mineral Processing Design and Operations is expected to be of use to the design engineers engaged in the design and operation of mineral processing plants and including those Describe different types of ball mill design Describe the components of ball mill Explain their understanding of ball mill operation Explain the role of critical speed and power draw in design and process control Recognize important considerations in ball mill selection Reading Lecture In ball millsAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill This book guides readers through best practices around planning, designing, building, and implementing a design system, with insights and firsthand experiences from experts who have gone through the journey Available in ePub, PDF, audiobook and print formats Download free book What’s in the book Introducing design Design Systems Handbook DesignBetter