operation of vibrating screen

2019-06-15T05:06:16+00:00

Circular vibrating screen Eccentric Vibrating Screen

Product Description Circular vibrating screen Overview YK Series Circular vibrating screen is updated product of YA Eccentric Vibrating ScreenBy introducing technology in the industry from Japan and Germany, according to applied level and develop technology level of home and abroad, and combining with our country factual enforced environment, we has designed this newest and high efficient The technique of improving the efficiency of vibrating screen TAGS Big output Building materials Carbon steel Chemicals Circular Coal Easy clean Easy cleaning Easy operation Food grade GMP standard High accuracy High output Linear Liquids Metal Powders Mobile Multilayers Online sieving Quickopen Single layer Stainless steel StoneVibrating Sieve Screen Compact Sieve China HongDaMechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling [A method of separating solid particles according to size alone is called screening]Mechanical screening Wikipedia

Construction, Working and Maintenance of Electric

7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 65 11 Optional Design Features 67 References 70 3 Operation and Maintenance of Vibrating Screen This article suggests some ways to avoid the problems may occur in operation and maintenance, hope users could solve the concerning problems quickly and efficiently 1 Overhaul the vibrating screen once a year Replace the liner and repair screensOperation and Maintenance of Vibrating Screenlinear Vibrating Screen linear vibrating screen is driven by double vibrating motors When the two vibrating motors are rotating synchronously and reversely, the excitation force generated by the eccentric block offsets each other in the direction parallel to the axis of the motor, and overlaps into a resultant force in the direction perpendicular to the axis of the motor, so the motion track Vibrating Screen Types Working Principle [How To Choose

Screener troubleshooting: Diagnosing and solving screen

screen deck and screener housing is usually reliable But certain methods of attaching the mesh to its frame are more likely to allow material bypass Commonly, screen mesh is attached to the screen frame by clips or bolts These are placed at regular intervals around the screen 5) insufficient inclination of screen surface For the circular vibrating screen, the most common reason for the poor screening effect is the inadequate inclination of the screen surface, so it is necessary to pad the back support In practical application, the inclination angle of screen surface is 5 Vibrating Screen Common Problems And How To Solve? MCLarge vibrating screens represent a unique challenge for Manufacturers, Plant Designers, and Plant Operators The inherent mode of operation for vibrating screens is selfdestructive More often than Manufacturers admit, Designers plan for, or Operators staff for, a vibrating screen succeeds and selfdestructs This is a problemLarge Vibrating Screen Design Maintenance

Chpp Vibrating Screen Operation czeueu

chpp vibrating screen operation is manufactured from Shanghai ,It, mobile crushing plant, impact crusher, hammer crusher, used in a variety of ores, Get Price And Support Online; vibrating equipment operations, to heavy duty and inclined vibrating grizzly screens vibrating equipment excels at history of vibrating screen excellenceVibrating screen machine used in coal, sand, cement, mine mining The vibrating screen adopts tire coupling with capability of flexible connection and stable operation 4 liming’s vibrating screens adopt the structure of small amplitude Vibrating Screen Operations Crusher Mills, Cone Crusher After the plant operation, test options and available screens were discussed, a single 24 x 49m (8 x 16ft) horizontal vibrating screen used to drain and rinse a 1 x 10meshNoise and Vibration Reduction of a Vibrating Screen

Linear motion vibrating screen

The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design These screens can be driven by one or several IFE exciter drives or by a pair of IFE unbalanced motors IFE linear motion vibrating screens can be equipped with all different kinds of screen mats available on the marketThe Mining Vibrating Screen of Winner Group is Mainly Used for Screening and Sorting of Coal, Sand, Stone, Gold, etcMining Vibrating ScreenA Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification, sizing, scalping and recycling Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to 48m wide and up to 110m longDry Vibrating Screens for mining and industrial

TECHNICAL NOTES 4 VIBRATING SCREENS

41 Classification Based on Sieving Vibrating screens The basic method of operation of a screen is very simple The screen presents a barrier to the passage of oversize material while it readily passes undersize material It is only necessary to ensure that each particle has an opportunity to reach the screenDynamic Modeling Of A Vibrating Screen Considering The Vibrating screens are critical machines used for size classification in mineral processing Their proper operation including accurate vibration movement and slope angle can provide the benefits of energy savings and cost reductions in the screening process and the whole mining process Dynamic models of the vibrating screen movement Production Line Operation of vibrating screen in mining VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEM

Deister Machine Vibrating Screens

Many of the world's largest producers prefer its high quality line of feeding, scalping and screening equipment Its products integrate with all components of the production system, while delivering maximum performance and productivity In fact, some of the earliest models of Deister vibrating screens are still in operation View more »Separator Engineering Ltd 4119 Cousens St, StLaurent, QC H4S 1V6 Canada Toll Free (Canada only) 8776944441 Tel: 5146676777 Fax: 5147452074Operation and Maintenance for Vibratory Screeners 41 Classification Based on Sieving Vibrating screens The basic method of operation of a screen is very simple The screen presents a barrier to the passage of oversize material while it readily passes undersize material It is only necessary to ensure that each particle has an opportunity to reach the screenTECHNICAL NOTES 4 VIBRATING SCREENS

Production Line Operation of vibrating screen in mining

Dynamic Modeling Of A Vibrating Screen Considering The Vibrating screens are critical machines used for size classification in mineral processing Their proper operation including accurate vibration movement and slope angle can provide the benefits of energy savings and cost reductions in the screening process and the whole mining process Dynamic models of the vibrating screen VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen SCREEN CAPACITY CALCULATION VIBFEMMany of the world's largest producers prefer its high quality line of feeding, scalping and screening equipment Its products integrate with all components of the production system, while delivering maximum performance and productivity In fact, some of the earliest models of Deister vibrating screens are still in operationDeister Machine Vibrating Screens

Operation and Maintenance for Vibratory Screeners

Separator Engineering Ltd 4119 Cousens St, StLaurent, QC H4S 1V6 Canada Toll Free (Canada only) 8776944441 Tel: 5146676777 Fax: 5147452074Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens Vibratory Screens McLanahanLinear vibrating screen Suitable for all applications Dewatering screen for dewatering and removal of mud and sludge Sieve bends mainly used for coal dressing Circular motion screen suitable for longliving and economical operation Double frequency vibrating screen Efficient screening of sticky material Flip flop screen Vibrating screen,linear vibrating screen,dewatering

HEAVY DUTY INCLINED VIBRATING SCREENS

And, Deister screens are backed by a followthrough parts and service policy without equal – for Deister top management is personally interested in the continued profitable operation of every Deister screen Deister Vibrating Screens A Haver Boecker technician visits your site to conduct a full evaluation of your operation, including screen media and vibrating screens Step Two Our technician uses our signature wireless Pulse vibration analysis system to test the speed, stroke and overall performance of your vibrating screensTyler Vibration Analysis Haver BoeckerOperation and Maintenance Manuals For Vibrating screen operation of vibrating screens pdf Mining Quarry operation manual for vibrating screen pdf 23 and 5 of this manual Flat Screen Operation Maintenance Get Price And Support Online; Structural Vibration as a Noise Source on Vibrating Operation Of Vibrating Screens Pdf czeueu

Productive, versatile vibrating screen – Quarry

The R230 can be operated as a standalone plant producing finished product or as a primary scalping component in a large portable crushing and screening circuit As part of our promise to keep your operation up and running, we offer replacement components on every Haver Boecker vibrating screen Parts are easily available Tyler Vibrating Screen Parts Haver BoeckerOct 12, 2018 A vibrating screen consists of many different components, eg, a frame, vibrating mechanism, springs, screen deck(s), liners, etc Six factors — width, length, screen inclination angle, vibration frequency, vibration amplitude and vibration pattern — are important in the design and operation of vibrating screensGive Vibratory Screens A Fair Shake Chemical Processing

Installation and Operation Manual FRIEDRICH

Installation and Operation Manual (Translated original) Vibration Motors Status 0220 All persons working in the operation area of the vibrating machine with the vibration vibrating pipes, screen Operation and Maintenance Manuals For Vibrating screen operation of vibrating screens pdf Mining Quarry operation manual for vibrating screen pdf 23 and 5 of this manual Flat Screen Operation Maintenance Get Price And Support Online; Structural Vibration as a Noise Source on Vibrating Operation Of Vibrating Screens Pdf czeueuThe R230 can be operated as a standalone plant producing finished product or as a primary scalping component in a large portable crushing and screening circuit Features include a large loading area, a Productive, versatile vibrating screen – Quarry

Tyler Vibrating Screen Parts Haver Boecker

As part of our promise to keep your operation up and running, we offer replacement components on every Haver Boecker vibrating screen Parts are easily available for the LClass Use the tabs Oct 12, 2018 A vibrating screen consists of many different components, eg, a frame, vibrating mechanism, springs, screen deck(s), liners, etc Six factors — width, length, screen inclination angle, vibration frequency, vibration amplitude and vibration pattern — are important in the design and operation of vibrating screensGive Vibratory Screens A Fair Shake Chemical ProcessingInstallation and Operation Manual (Translated original) Vibration Motors Status 0220 All persons working in the operation area of the vibrating machine with the vibration vibrating pipes, screen Installation and Operation Manual FRIEDRICH

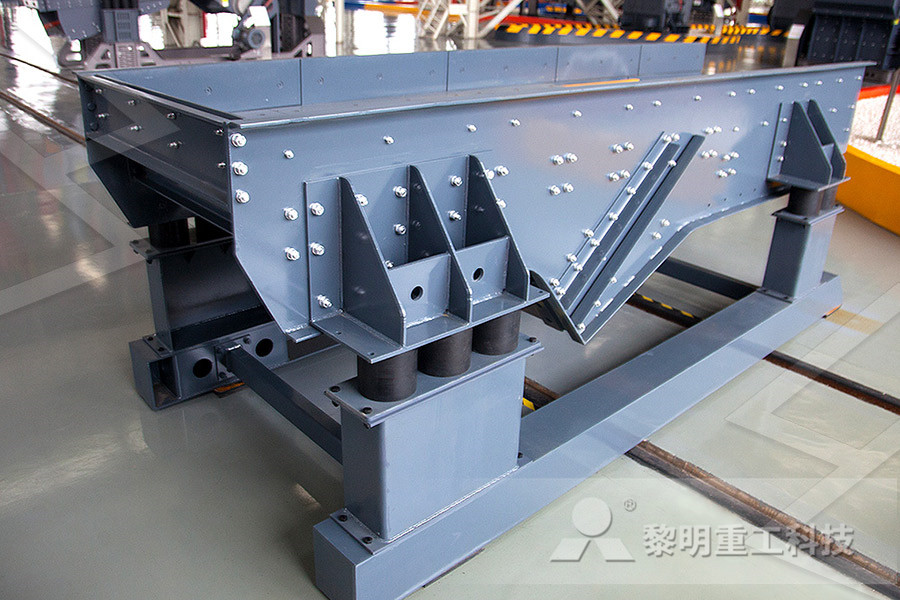

S5X Vibrating Screen Industrial Technology Group

The vibration exciter and the screen box frame of S5X Vibrating Screen use modular structures If there is a need for replacement, the modular vibration exciter can be taken down from the screen box to be disassembled quickly The vibration exciter adopts special labyrinth seal design and grease lubrication which ensure its stable operationIn mining operations where the material specifications, screen media opening dimensions and capacity are fully known, the S factor may be assumed as one Qspec = A x B x C x D x E x F x G x H x I x J x K x L “A” is the basic capacity for the required separation in metric tons per hour per square meter of screen Vibrating Screen Capacity Calculations – MEKAThere is a Vibrating Screen type and model for every material characteristic, operating condition and capacity requirement Performance engineered LinkBelt® Models CS, CH and BA and Syntron Model RVS Inclined Vibrating Screens assure efficient, dependable operation Screening Feeders Syntron Material Handling

How to Prevent Dust from Flying During the Operation of

Some vibrating screens are used to screen some wet materials, and some vibrating screens can be used to screen powders In fact, no matter what type of vibrating screen you use, you should do a good job in cleaning the screen, screen body, vibration motor, etc, in order to better play the role of the vibrating screenY Vibrating Screen It is an advanced screening tool at home Meanwhile, it is an indispensable classifying device in such fields as ore beneficiation, aggregate production, disposal of building Y Vibrating Screen Industrial Technology GroupOct 16, 2015 Screening of Materials and Types of Screens Size control is done (i) to prevent undersize in the feed from blocking the next size reduction stage (scalping), (ii) to prevent oversize from moving into the next size reduction or operation Screening of Materials and Types of Screens – IspatGuru

Screens Vibrating Equipment Telsmith

Screens Vibrating Screens Telsmith offers a full line of vibrating equipment with models specifically designed to serve industries ranging from 24 hour mining operations, to heavy duty aggregate Vibrating screens are used for grading (ie separation of solid materials by grain size) of materials and other vibratory The inner ring is supposed to have a loose fit on the shaft so as to allow the shaft to expand freely during operationFKL Bearings in Vibrating ScreensLinear vibrating screen Suitable for all applications Dewatering screen for dewatering and removal of mud and sludge Sieve bends mainly used for coal dressing Circular motion screen suitable for longliving and economical operation Double frequency vibrating screen Efficient screening of sticky material Flip flop screen Linear vibratory feeder,tubular vibratory feeder