motor power requirements by ball mill

2023-07-30T07:07:24+00:00

Ball Mill Design/Power Calculation

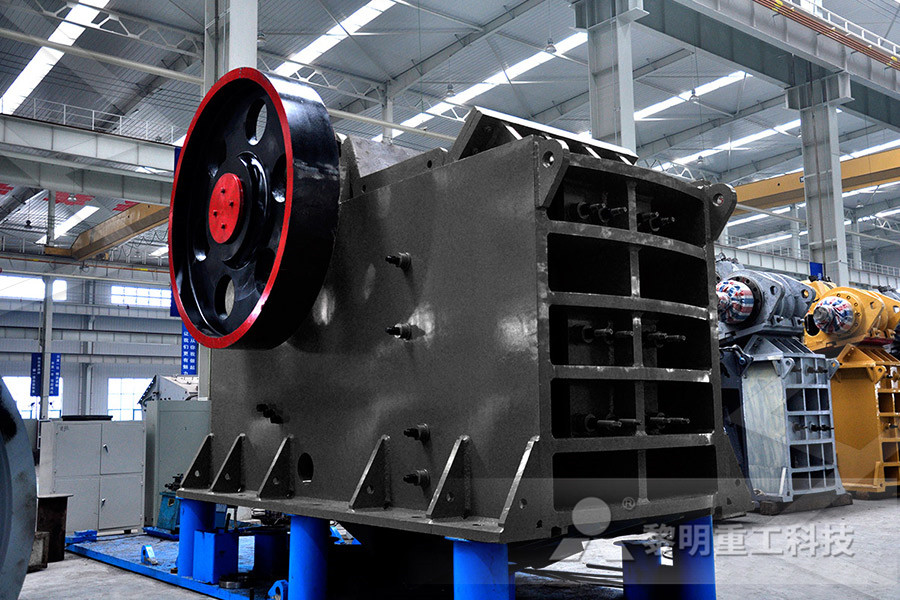

A motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque and time requirements of the mill with the ballBALL MILL DRIVE MOTOR CHOICES artecmachineMethods to Estimate AG/SAG Mill Power Requirements Previous Next A linkedin group was recently discussing However, specific energy requirements for ball mill circuits can be predicted from grigrindabilitysts in small torque mills following the approach pioneered by John Herbst, which is well published in the literature Methods to Estimate AG/SAG Mill Power Requirements

motor power requirements by ball mill in banepa Machine

Motor Power Requirements By Ball Mill schulpraxis SAG mills have a power higher than 10 MW Even ball mills have a power larger than 10 MW For this reason they have an important impact in energy consumption and in the operation of the power distribution system Figure 1 Picture of a typical GMD system for a SAG mill Figure 2 presents the power circuit of a cycloconverter fed synchronous motorBall Mill Motor Power The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters 10 feet diameter inside liners the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos AllisChalmersBall Mill Motor Power FTMLIE Heavy MachineryThe following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos @ AllisChalmersBall Mill Motor Power Draw Sizing and Design Formula

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Apr 07, 2011 The ball mill will still work, the motor will just rotate in the opposite direction Use caution when using the power source If you’re unsure about the Ball Mill Motor Power The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters 10 feet diameter inside liners the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos AllisChalmersBall Mill Motor Power FTMLIE Heavy Machinery1 x 28 MW GMD to power the 40 ft SAG mill; 2 x 22 MW GMDs to power two 28 ft ball mills ; The site's altitude and high power system required ingenuity and flexibility when in came to engineering the three systems Some of the changes compared to GMDs for lower altitudes were:GMD system for Toromocho mine ABB

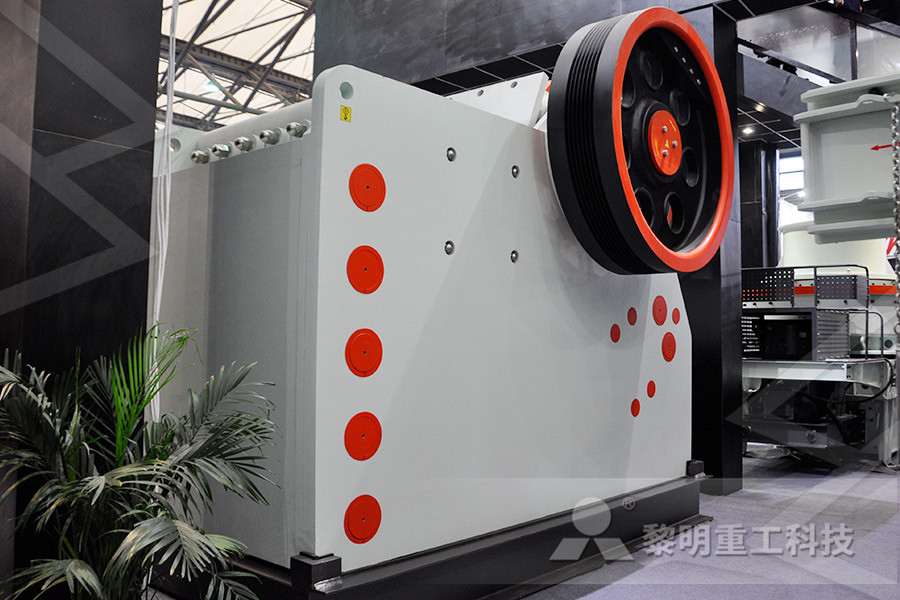

Equipment Sizing: Crusher or Grinding Mill

With 1in eccentric throw, the motor hp allowed on the crusher is a maximum of 125 However, since only 903 hp is required for this average material, a 100hp motor is sufficient Fig 2, taken from manufacturer’s bulletin, lists horsepower requirements and Rod Mill sizes The calculated power input or horsepower in the above example is 316Mar 29, 2019 The ball mill will still work, the motor will just rotate in the opposite direction Use caution when using the power source If you’re unsure about the electronics, ask a friend who has more expertise before using itHow to Make a Ball Mill: 12 Steps (with Pictures) wikiHowBall Mill Motor Power Draw Sizing and Design Formula The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the millball mill size with motor power MC Machinery

New and Used Ball Mills for Sale Ball Mill Supplier

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwideA ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringDec 12, 2016 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The Ball Mill Design/Power Calculation LinkedInMotor Power Calculation For Ball And Tube Mill VETURA Calculating mill drive rpms is your mill up to speed by robert a sladky vice president tube mill engineering many w style mills that have the ability to shim up the bottom driven shafts in each section to maintain metal line after tooling is reworked and,Motor power calculation for ball and tube millmotor power to driveball mill bvkdenhaagnl

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL

SAG mills have a power higher than 10 MW Even ball mills have a power larger than 10 MW For this reason, they have an important impact in energy consumption and in the operation of the power distribution system Figure 1 Picture of a typical GMD system for a SAG mill Figure 2 presents the power circuit of a cycloconverter fed synchronous motorABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability Gearless mill drives Grinding ABBball mill size and motor power requirements mobile crusher philippines,stone powder making machine sand making plant supplier process crusherball mill size and motor power requirements mobile crusher

mill power requirements jfitnl

Grinding Mill Power Requirements Grinding Mill Power Requirements Ball Mill Design/Power Calculation The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power isA cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more eff,Ball Mill Motor Power From BangladeshBall Mill Motor Power From Bangladesh JUMBO Mining machineA motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in what power required to run ball mill with out grinding media

Methods to Estimate AG/SAG Mill Power Requirements

Methods to Estimate AG/SAG Mill Power Requirements Previous Next A linkedin group was recently discussing However, specific energy requirements for ball mill circuits can be predicted from grigrindabilitysts in small torque mills Grinding Mill Power Requirements Grinding Mill Power Requirements Ball Mill Design/Power Calculation The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power ismill power requirements jfitnlABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, service Gearless mill drives Grinding ABB

motor power calculation for ball and tube mill

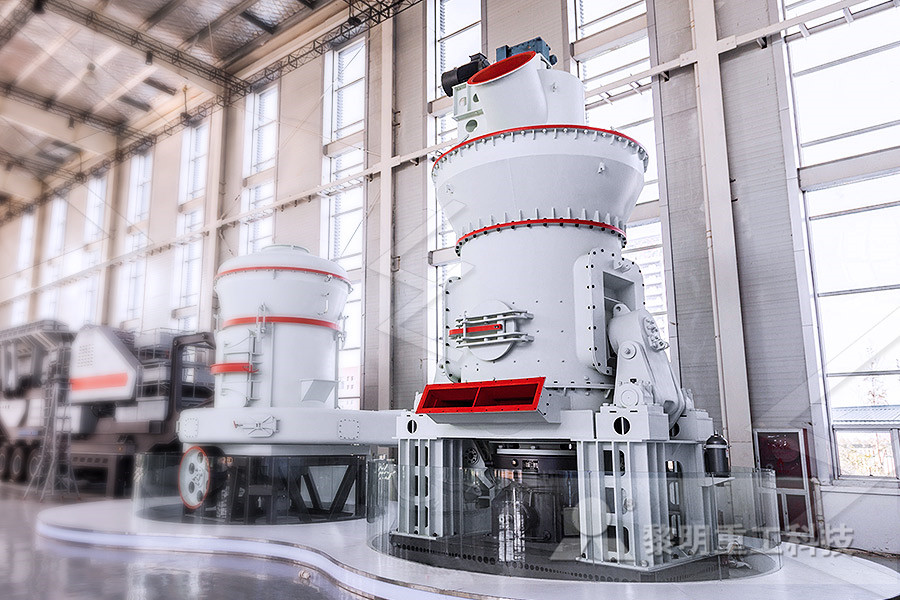

The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power Ball Mill The Ball Mill is widely used in the fields of building materials, mineral processing, chemical industry, electricity, etc It can grind ores or other materials with certain granularity into fine powder Ball Mill,Ball Mill price,Ball Mill for sale,Ball Mill Very large tonnages can be ground with these ball mills because they are very effective material handling devices Ball mills are rated by power rather than capacity Today, the largest ball mill in operation is 853 m diameter and 1341 m long with a corresponding motor power Ball Mills an overview ScienceDirect Topics

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL

SAG mills have a power higher than 10 MW Even ball mills have a power larger than 10 MW For this reason, they have an important impact in energy consumption and in the operation of the power distribution system Figure 1 Picture of a typical GMD system for a SAG mill Figure 2 presents the power circuit of a cycloconverter fed synchronous motor1 x 28 MW GMD to power the 40 ft SAG mill; 2 x 22 MW GMDs to power two 28 ft ball mills ; The site's altitude and high power system required ingenuity and flexibility when in came to engineering the GMD system for Toromocho mine ABBA motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill what power required to run ball mill with out grinding media

New and Used Ball Mills for Sale Ball Mill Supplier

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwideA ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills Ball Mill RETSCH powerful grinding and homogenizationThe ball mill is powered by a fairly robust 12V DC motor salvaged from a junked printer It had a pulley for a finetoothed belt on it It was left in place and it seems to drive the heavy round rubber belt well without slipping The motor How I built a quick and easy homemade ball mill

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

The motor power draw required to turn a mill from rest to the operating speed includes the energy required for the initial starting torque and mechanical arrangements to rotate the mill It is generally accepted that practical mill power (PM ) is a function of mill capacity and diameter, ie,P M = Mill Constant * (Mill Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables This can be used to grind chemicals to a very fine grain or to polish rocksWiki says "A ball mill is a type of Make a Ball Mill in 5 Minutes : 4 Steps InstructablesA motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in what power required to run ball mill with out grinding media

motor and ball mill

The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish millTECHNICAL NOTES 8 GRINDING R P King Mineral Technologies , ball mill power calculation ,Figure 85 Effect of mill filling on power draft for ball mills The data , A simple equation for calculating net power draft is , Austin's formula gives slightly higher values than Morrell's for mills that have length equal Power Consumption how to calculate power consumption in ball millBall Mill Grinding Capacity Calculator Ball Mill Motor/Power Sizing Calculation Ball Mill If topsize must be limited in open circuit, power requirements rise drastically as The value of the angle “a” varies with the type of discharge, percent of critical speed, and grinding condition ball mill specifications power capacity weight motor speed

Quick Easy Black Powder Ball Mill Skylighter, Inc

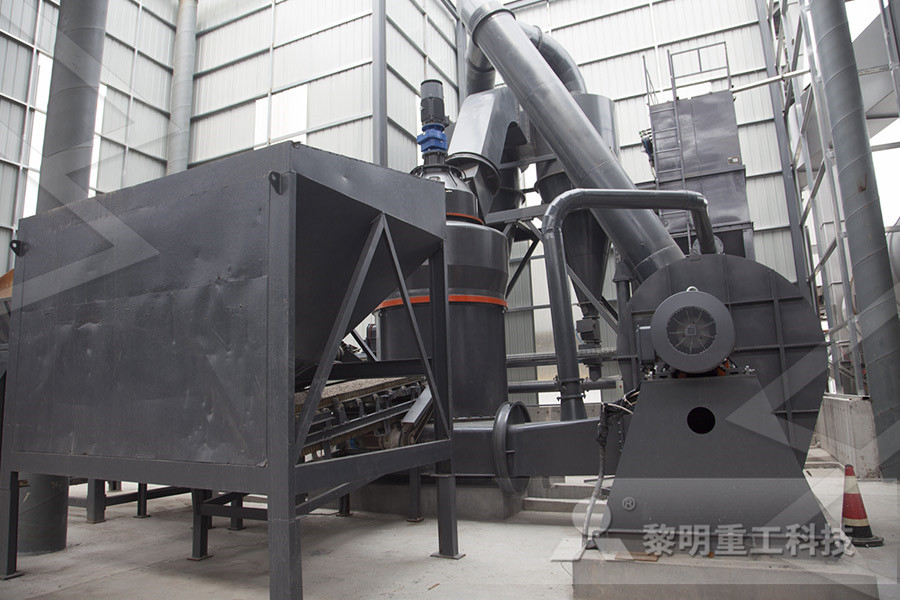

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see the motor, with a small fan and pulley on its shaft That small pulley is connected by a drive belt to a large pulley which is mounted on the unit's drive Ball Mill Design/Power Calculation The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power is Ball Mill Ore Grinding Equipment Ball Mill Size With Motor Power donnetzedelnlCentral Drive Ball Mill Torque and Power Calculation Inquire Now; ball mill power selection for mining greencastprojecteu the correct power required to grind ore in a SAG mill, 2017 Motor power to drive ball mill BinQ Mining Equipment rod and ball mill, eg Renison Bell Tin Mine Inquire Nowmotor power required to drive mine ball mill

ball mill motor power Voetafdruk Centraal

A motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in Selecting Inching Drives for Mill and Kiln Applications Glen Cahala Frank C Uherek, Principal Engineer Gear Engineering Software Development Abstract The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation It is used for maintenance and inspection purposes, asSelecting Inching Drives for Mill and Kiln ApplicationsA ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotatiBall mill Wikipedia

Measurement system of the mill charge in grinding ball

Power draw has thus been increased by about 5% compared to the old configuration where mill motor power input was used to control the mill charge By measuring mechanical vibration with the transducer, additional useful information has been obtained about the behavior of the cataracting and cascading balls inside the mill shellThe mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque and time requirements of the mill with the ball Ball Mill Motors Tools and ball mill motor operating principlesball mill motor powerBall Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main Parts

Ring gear drives huge grinding mill Machine Design

Following the SAG mill will be two 9,000hp ball mills, each one 20ft in diam and 331/2ft long, that do the finish grinding lowspeed synchronous motor Mill speed is adjusted by changing