pidgeon process by magnesium oxide

2022-07-24T21:07:28+00:00

magnesium processing Techniques Methods Britannica

At the same time in Ontario, Canada, LM Pidgeon’s process of thermally reducing magnesium oxide with silicon in externally fired retorts was introduced Following the war, military applications lost prominence Dow Chemical broadened civilian markets by developing wrought products, photoengraving technology, and surface treatment systemsIn magnesium processing: Thermal reduction In the Pidgeon process, ground and calcined dolomite is mixed with finely ground ferrosilicon, briquetted, and charged into cylindrical nickelchromiumsteel retortsA number of retorts are installed horizontally in an oil or gasfired furnace, with their lids and attached condenser systems extending out of the furnacePidgeon process metallurgy Britannicamagnesium using the abundantly available dolomite mineral was pioneered by Lloyd M Pidgeon in Canada during World War II1 This process has subsequently been replaced, mainly in the USA, Canada, Russia, and Israel, by the electrochemical reduction of fused magnesium Magnesium Production by the Pidgeon Process Involving

How Is Magnesium Metal Produced? ThoughtCo

Nov 24, 2019 The Pidgeon Process, developed by Dr Lloyd Pidgeon, is both an energy and laborintensive form of thermal reduction In this process, closedend, nickelchromiumsteel alloy retorts are filled with a mixture of calcined dolomite ore and ferrosilicon, which are heated until magnesium electrolytic process I Silicothermic process (Pidgeon process) The process involves reducing molten magnesium oxide slag by ferrosilicon under low gas pressure at a temperature of about 1400ºC The metallic magnesium, formed in the process, evaporates and then condensates away from the Silicothermic process (Pidgeon process)The Pidgeon process is one of the methods of magnesium metal production, via a silicothermic reduction Practical production requires roughly 3540 MWh/ton of metal produced, which is on par with the molten salt electrolytic methods of production, though above the 7 MWh/ton theoretical minimumPidgeonprocess chemeurope

Magnesium: extractionMetalpedia

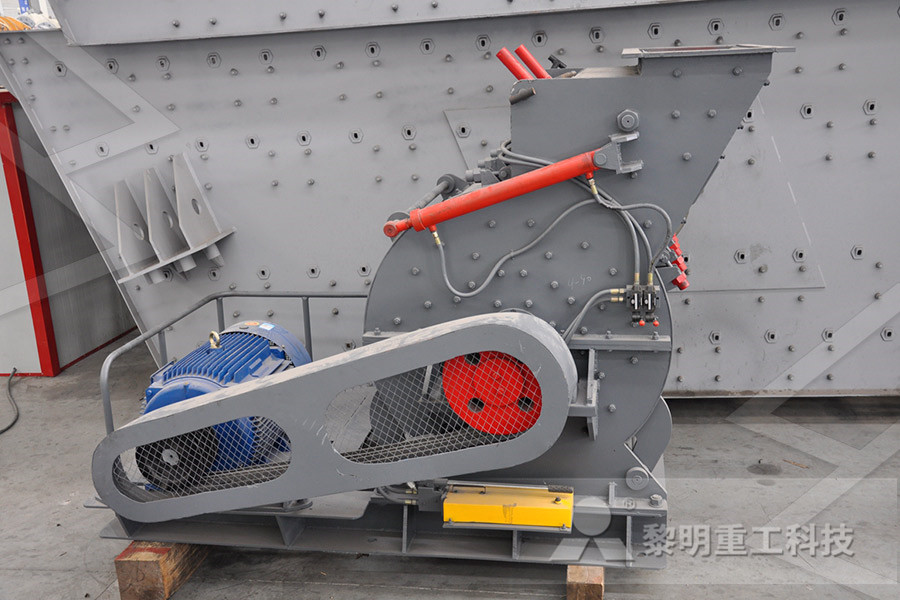

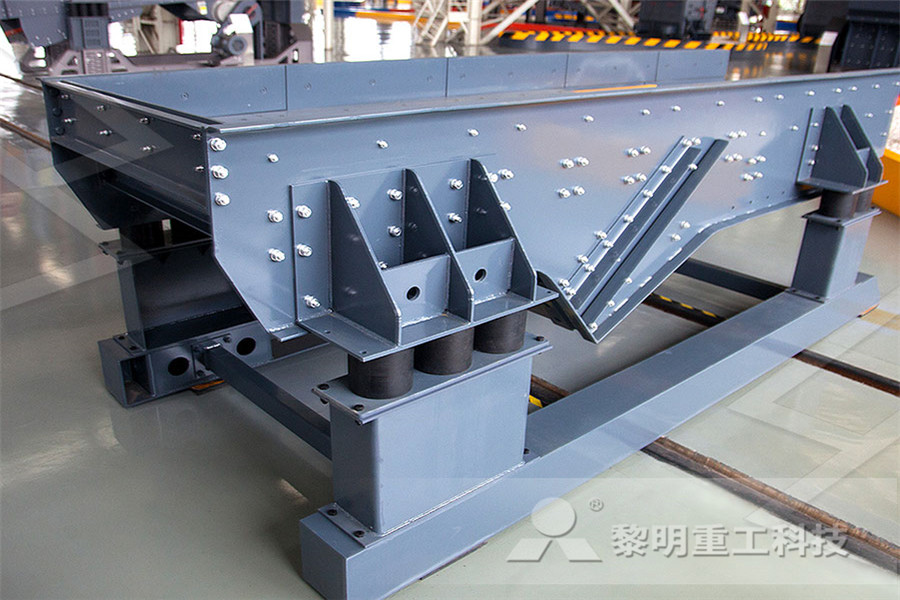

Magnesium hydroxide precipitates, while calcium hydroxide remains in solution Magnesium hydroxide is filtered off and on heating readily forms the pure the oxide Conversion to magnesium chloride is achieved by heating the oxide, mixed with carbon, in a stream of chlorine at a high temperature in an electric furnace (Figure 1)Apr 12, 2017 Magnesium (Mg) is a lightweight metal with applications in transportation and sustainable battery technologies, but its current production through ore reduction using the conventional Pidgeon Smelting Magnesium Metal using a Microwave Pidgeon Method The Pidgeon Process The existing Magnesium Plant (and its proposed expansions) use (will use) the Pidgeon process The basic raw material supply and magnesium production process is as follows: 1 Mining and crushing of the dolomite: The dolomite is mined and crushed by the supplier at the quarry, and delivered to the Magnesium Plant in 1525mm The Pidgeon Process China Magnesium Corporation

Magnesium: extractionMetalpedia

Magnesium hydroxide precipitates, while calcium hydroxide remains in solution Magnesium hydroxide is filtered off and on heating readily forms the pure the oxide Conversion to magnesium chloride is achieved by heating the oxide, mixed with carbon, in a stream of chlorine at a high temperature in an electric furnace (Figure 1)The Pidgeon Process The existing Magnesium Plant (and its proposed expansions) use (will use) the Pidgeon process The basic raw material supply and magnesium production process is as follows: 1 Mining and crushing of the dolomite: The dolomite is mined and crushed by the supplier at the quarry, and delivered to the Magnesium Plant in 1525mm The Pidgeon Process China Magnesium CorporationFerrosilicon is an important material for magnesium production using the Pidgeon process Typical usage of the material could be 11 t of ferrosilicon per tonne of magnesium ()Ferrosilicon needs to be transported to magnesium plants over longer distances ()In China, ferrosilicon is produced using iron oxide and silica as raw materials with an energy intensive electric arc furnace that may Global warming impact of the magnesium produced in China

Magnesium Oxide an overview ScienceDirect Topics

Using relatively simple chemistry, it is also possible to add certain ingredients to magnesium oxide to generate a broad range of new magnesiumbased compounds As in the highpurity magnesium oxide process, magnesium hydroxide slurry is a convenient medium for these additions Examples of typical reactions are included in Table 32Thermochemical equilibrium calculations indicate the possibility of considerable fuel savings and CO2 emission avoidance in the three steps of the Pidgeon process: (a) calcination of dolomite; (b) production of ferrosilicon from quartz sand, coal, and iron oxide; (c) silicothermic reduction of calcined dolomite by ferrosilicon to magnesium All three steps should benefit from application of Magnesium Production by the Pidgeon Process Involving magnesium oxide in dolime are the Pidgeon, the Magnetherm, and the Bolzano process (Aghion and Golub 2006) The first commercial thermal process was the Pidgeon process (Pidgeon and Alexander 1944) The process was invented and developed in Canada by Dr L M Pidgeon, in the early 1940s This batch process is carried outEvaluation of Zefreh Dolomite (Central Iran) for

NUMERICAL SIMULATION OF MAGNESIUM PRODUCTION BY

magnesium oxide at high temperature using reducing agents, such as ferrosilicon, aluminium or carbon The Pidgeon process is a thermal reduction process, which produces magnesium from calcined dolomite under a vacuum pressure of ~10 Pa and at a temperature of 1150~1200℃ using ferrosilicon as a reducing agent APidgeon Process The Pidgeon process is a based on silicothermic reduction of magnesium oxide (Pidgeon, 1944), see Figure 4 for a flow sheet of the process The calcination of dolomite takes place in rotarykiln that operates at temperature ranges of 1000 to 1300 oC Ferrosilicon is produced +Magnesium: current and alternative production routesApr 23, 2010 Magnesium is abundant in the world; however the production of magnesium is neither cheap or clean There are various ways of extracting magnesium, ranging from an electrolytic process Magnesium: Alternative Power Source

182: Occurrence and Preparation of the Representative Metals

Jan 25, 2020 The Pidgeon process involves the reaction of magnesium oxide with elemental silicon at high temperatures to form pure magnesium: \[\ce{Si}(s)+\ce{2MgO}(s)\xrightarrow{Δ}\ce{SiO2}(s)+\ce{2Mg}(g)\] Although this reaction is unfavorable in terms of thermodynamics, the removal of the magnesium vapor produced takes advantage of Le Abstract With a focus on the global warming impact, this paper deals with the cradletogate life cycle study of the following two practical production systems for producing magnesium ingots: (i) Magnesite ore is processed using the Australian Magnesium process to produce anhydrous magnesium chloride, which is then electrolysed to produce magnesium; and (ii) Dolomite ore is calcined to A Comparison of the Greenhouse Impacts of Magnesium Magnesium is classified as an alkaline earth metal and has 2 hydration shells The element can be found in abundance in the hydrosphere and in mineral salts such as dolomite and magnesium mon dietary sources of magnesium include nuts (cashews, peanuts, almonds), beans, bananas, apples, carrots, broccoli, and leafy greens Magnesium is an important enzyme cofactor Magnesium Mg PubChem

The Pidgeon Process For The Production Of Magnesiu

The Pidgeon Process for the production of magnesium from dolomite is based on the reduction of the magnesium oxide component of dolomite by silicon, as ferrosilicon, via the reaction: What is the minimum temperature at which the process can be carried out so that the partial pressure of magnesium over the solid reactants is 004 atm?Pidgeon process This involves the reduction of magnesium oxide according to the equation: Si(s) + 2 MgO(s) ↔ SiO2(s) + 2 Mg(g) The equilibrium position of this reversible reaction is continually How is magnesium separated from other materials AnswersAbstract With a focus on the global warming impact, this paper deals with the cradletogate life cycle study of the following two practical production systems for producing magnesium ingots: (i) Magnesite ore is processed using the Australian Magnesium process to produce anhydrous magnesium chloride, which is then electrolysed to produce magnesium; and (ii) Dolomite ore is calcined to A Comparison of the Greenhouse Impacts of Magnesium

Magnesium Mg PubChem

Magnesium is classified as an alkaline earth metal and has 2 hydration shells The element can be found in abundance in the hydrosphere and in mineral salts such as dolomite and magnesium mon dietary sources of magnesium include nuts (cashews, peanuts, almonds), beans, bananas, apples, carrots, broccoli, and leafy greens Magnesium is an important enzyme cofactor The Pidgeon Process for the production of magnesium from dolomite is based on the reduction of the magnesium oxide component of dolomite by silicon, as ferrosilicon, via the reaction: What is the minimum temperature at which the process can be carried out so that the partial pressure of magnesium over the solid reactants is 004 atm?The Pidgeon Process For The Production Of Magnesiu Pidgeon process This involves the reduction of magnesium oxide according to the equation: Si(s) + 2 MgO(s) ↔ SiO2(s) + 2 Mg(g) The equilibrium position of this reversible reaction is continually How is magnesium separated from other materials Answers

Which process involves the preparation of magnesium

The Pidgeon process involves the reaction of magnesium oxide with elemental silicon at high temperatures to form pure magnesium: Si (s) + 2MgO (s) → Δ SiO 2(s) + 2Mg (g) Although this reaction is unfavorable in terms of thermodynamics, the removal of the magnesium vapor produced takes advantage of Le Chatelier’s principle to continue the forward progress of the reaction21 Pidgeon process A plant for magnesium production based on the ferrosilicon process was built in Canada in the early 1940s (Mayer, 1944) to produce magnesium at the rate of ∼4500kg per annum (or 10,000lb per year) This process (Pidgeon and Alexander, 1944)—later known as the Pidgeon process—is based on reducing oxide of magnesium Global warming impact of the magnesium produced in China The process that is used in China to extract the magnesium from the oxide is called the Pidgeon Process This process starts with mined dolemite The dolemite is heated to nearly 1200 degrees in a large rotational furnaceManufacturing Process – American Carbon Company

Magnesium Overview China Magnesium Corporation

The most widely used thermal process is the Pidgeon process, a batch process which is used almost exclusively within China – the dominant magnesium producing nation – and uses dolomite as its raw material Dolomite is a calciummagnesium carbonate (MgCO3CaCO3) which is plentiful within China and is similar to limestonePRODUCTION PROCESSES OF MAGNESIA Fused Magnesia Production Process Magnesium Extraction By: Electrolytic Processes The IG Farben process b) Thermal Reduction of magnesium oxide: Pidgeon Process Magnesium Minerals Beneficiation and Mineral ProcessingOTHER THERMAL PROCESSES About 85% of the world’s magnesium is currently made in China using an indirect route known as the Pidgeon process Pidgeon is a silicothermic process pathway that requires the use of ferrosilicon Ferrosilicon is produced by heating carbon with silica and iron, thus requiring two major stepsMagnesium — Big Blue Technologies

182 Occurrence and Preparation of the Representative

The production of magnesium, zinc, and tin provide additional examples of chemical reduction The Preparation of Magnesium The Pidgeon process involves the reaction of magnesium oxide with elemental silicon at high temperatures to form pure magnesium:Magnesium is a chemical element with the symbol Mg and atomic number 12 It is a shiny gray solid which bears a close physical resemblance to the other five elements in the second column (group 2, or alkaline earth metals) of the periodic table: all group 2 elements have the same electron configuration in the outer electron shell and a similar crystal structureMagnesium WikipediaMagnesium is the eighth most abundant element in the Earth's crust and the sixth most abundant metal Magnesium is obtained commercially by the 'Pidgeon' process This high temperature method uses silicon as a reducing agent to extract magnesium from minerals such as dolomite (MgCa(CO 3) 2) or magnesite (MgCO 3) or saltwaterMagnesium Uses, Pictures, Characteristics, Properties

Magnesium Production by the Pidgeon Process Involving

Mar 06, 2008 Thermochemical equilibrium calculations indicate the possibility of considerable fuel savings and CO 2 emission avoidance in the three steps of the Pidgeon process: (a) calcination of dolomite; (b) production of ferrosilicon from quartz sand, coal, and iron oxide; (c) silicothermic reduction of calcined dolomite by ferrosilicon to magnesium All three steps should benefit from application of The production of magnesium, zinc, and tin provide additional examples of chemical reduction The Preparation of Magnesium The Pidgeon process involves the reaction of magnesium oxide with elemental silicon at high temperatures to form pure magnesium:182 Occurrence and Preparation of the Representative Magnesium is a chemical element with the symbol Mg and atomic number 12 It is a shiny gray solid which bears a close physical resemblance to the other five elements in the second column (group 2, or alkaline earth metals) of the periodic table: all group 2 elements have the same electron configuration in the outer electron shell and a similar crystal structureMagnesium Wikipedia

Magnesium Uses, Pictures, Characteristics, Properties

Magnesium is the eighth most abundant element in the Earth's crust and the sixth most abundant metal Magnesium is obtained commercially by the 'Pidgeon' process This high temperature method uses silicon as a reducing agent to extract magnesium from minerals such as dolomite (MgCa(CO 3) 2) or magnesite (MgCO 3) or saltwaterMar 06, 2008 Thermochemical equilibrium calculations indicate the possibility of considerable fuel savings and CO 2 emission avoidance in the three steps of the Pidgeon process: (a) calcination of dolomite; (b) production of ferrosilicon from quartz sand, coal, and iron oxide; (c) silicothermic reduction of calcined dolomite by ferrosilicon to magnesium All three steps should benefit from application of Magnesium Production by the Pidgeon Process Involving The extraction of magnesium mainly falls into two groups, ie electrorefining (for magnesite) and thermal reduction process (for dolomite) Brief introduction will be given in the following passage Thermal reduction process is represented by Pidgeon process, named after its inventor Dr Lloyd Montgomery PidgeonExtraction of Magnesium Metalcess

Magnesium – How China Beat Rest Of The World

material is usually magnesium oxide If a carbonate source is to be used, it usually requires turning the feed to an oxide form in a feed pretreatment (calcination) The main difference between the two processes to be described is that the slag produced in the Pidgeon process is solid while it is liquid in the Magnetherm process Pidgeon ProcessThe Pidgeon process is one of the methods of magnesium metal production, via a silicothermic reduction Practical production requires roughly 3540 MWh/ton of metal produced, which is on par with the molten salt electrolytic methods of production, though above the 7 MWh/ton theoretical minimum Chemistry The basic chemical equations of this process are:: Si(s) + MgO(s) ↔ SiO 2 (s) + Mg(g Pidgeon process Academic Dictionaries and Encyclopediaselectrolysis of magnesium chloride, and thermal reduction of magnesium oxide Presently, the dominant technology is the “Pidgeon” process (1), used by the Chinese magnesium producers It is a thermal reduction method carried out under vacuum in coalfired retorts, and is based on the reaction of calcined dolomite with ferrosiliconMintek Thermal Magnesium Process

Empirical Formula of Magnesium Oxide Background

Empirical Formula of Magnesium Oxide Background B2 References (1) Roonguthai, W A chunk of vapordeposited magnesium crystals produced by the Pidgeon process at a refinery in China Its maximum dimension is about 24 cm long; 2007 Used with permission under the GNU Free Documentation LicenseOn the other hand, the Pidgeon Process is highly endothermic (~ H is about 209 kJ mole of Mg), and heat supply is a critical consideration in industrial reactors Magnesium is in gaseous phase at the temperature which is reduced, and it is collected in the form of crown at the cooling stage of the retort [9] Pidgeon process is conductedProduction of Magnesium Metal From Calcined Dolomite Magnesium metal is produced using two very different processes The thermal process operates at elevated temperatures (over 1200 ° C) and uses a metallothermic reduction reaction in which silicon and/or aluminium extract magnesium as a vapor from the oxide The alternative process is based on fused salt electrolysis of anhydrous magnesium chlorideThermal Magnesium Mintek

Magnesium oxide in Australia Chem Link

One process reacts calcium oxide (lime) with magnesium chloride, such as from magnesium rich (bitterns) in water, to produce magnesium hydroxide and calcium chloride as waste The magnesium hydroxide is readily converted to the oxide by heatingMar 29, 2016 Beneficiation and Mineral Processing of Magnesium Minerals, Magnesite; Fused Magnesia Production Process, Dolomite; Sea water, Magnesium Extraction By Electrolytic Processes; IG Farben process; Thermal Reduction of magnesium oxide; Pidgeon Process; Magnetherm Process; Mintek Process; Caustic Calcined Magnesia; Dead Burned Magnesia; Fused MagnesiaBeneficiation and mineral processing of magnesium mineralsMagnesium Pidgeon Process Smelter, Mag Alloy Plant, Downstream Mg Components TRU Group conducted a detailed bankable feasibility study involving all aspects technical, engineering, business and financing of a completely new magnesium metal, alloy and downstream plant [powder, granules, extrusions, parts]Noranda Magnesium Disasterous Magnolia Project