heap leaching of chromium ore

2020-03-27T19:03:52+00:00

Heap leaching Wikipedia

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from oreusing a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas in situ mining lacks these liners and pulls pregnant solution up to obtain the minerals Heap leaching is widely used iHeap Leaching Of Chromium Ore We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel Heap Leaching Of Chromium OreAt 1000 °C, chromite ore reacted to a significant extent with alkali and most chromium was extracted as sodium or potassium chromate by water leaching The wt% of Cr 2 O 3 decreased from 488% in the asreceived chromite sample to 365% and 373% in the water leached residues after roasting with sodium and potassium hydroxides, parative study of alkali roasting and leaching of

Heap Leaching of Gold and Silver Ores ScienceDirect

Methods similar to heap leaching can be employed: dump leaching and vat leaching (vat leaching is the treatment of sand or crushed ore in bedded vats with rapid solution percolation) Typically, heap leaching is chosen for basic financial reasons – for a given situation, it represents the best, or safest, return on investmentMetallurgy Metallurgy Leaching: Oxides are leached with a sulfuric acid or sodium carbonate solvent, while sulfates can be leached with water or sulfuric acid Ammonium hydroxide is used for native ores, carbonates, and sulfides, and sodium hydroxide is used for oxides Cyanide solutions are a solvent for the precious metals, while a sodium chloride solution dissolves some chloridesMetallurgy Leaching BritannicaA controlled form of heap leaching may consist of the following steps: (1) crushing the ore; (2) screening the ore; (3) treatment of the fines in a separate leaching system; and (4) heap leaching the coarse, crushed ore on a prepared pad under controlled conditions of leach, ie, optimum size of particles, optimum time of leach, optimum Heap Leaching Oxide and Sulfide Copper Ores

Heap Leach: Mining's breakthrough technology

Aug 20, 2015 Copper Heap Leaching (Solvent ExtractionElectrowinning – SXEW) In 2014, more than 50 major HLSXEW operations worldwide recovered approx 3 million tonnes of copper, which represents roughly Disposal of chromium ore processing residue (COPR) is a globally widespread concern due to the risks associated with potentially harmful Cr(VI) contaminated hyperalkaline liquors leaching into the Leaching behaviour of a chromium smelter waste heap The ore is dumped, on the move, in the leaching area in such a manner that a roadway is built up to the elevation of the heap that is being built During this building process, a motor grader keeps the heap surface relatively smooth to permit the scrapers to maintain their speed and to minimize tire damageHeap Leaching Copper Ore

Heap Leach: Mining's breakthrough technology

Aug 20, 2015 Copper Heap Leaching (Solvent ExtractionElectrowinning – SXEW) In 2014, more than 50 major HLSXEW operations worldwide recovered approx 3 million tonnes of copper, which represents roughly Disposal of chromium ore processing residue (COPR) is a globally widespread concern due to the risks associated with potentially harmful Cr(VI) contaminated hyperalkaline liquors leaching into the Leaching behaviour of a chromium smelter waste heap The Bayer process is still used for Bauxite ore beneficiation Pressure leaching has been in use since 1890’s for recovery of numerous metallic ores with advances in hydrometallurgy • Heap leaching of gold ore started to gain promenence in the late 1960’s when it wasHEAP LEACHING TECHNIQUE in MINING SDIMI

Pressure acid leaching of Çaldağ lateritic nickel ore: An

After 548 days of leaching of the first heap, that was the most representative of the ore site, the recoveries of nickel and cobalt were 794% and 827%, respectively with calculated 528 kg/tonne of dry ore acid consumption (Oxley et al, 2006, Oxley et al, 2007) The resultant pregnant leach solution (PLS) was then treated to produce mixed 10 CONCLUSIONS A chromite ore processing residue (COPR) waste pile has been investigated by leachate sampling and geochemical modelling The fresh leach,ate collected after extensive cleaning of the drainage system has a pH which is compatable with the equilibrium pH of portlanditeLeaching behaviour of a chromium smelter waste heap heap leaching method is used in laboratory scale for extracting the nickel from there is hydrometalurgy called heap leaching Processing of laterite ore with low nickel concentration small amounts of nickel and chromium, and is the precursor of weathered laterite ore [8]Designing Heap Leaching for Nickel Production that

Heap leaching a stack of gold MiningFeeds

Apr 25, 2018 The barren solution, together with additional lixiviant, is recycled back to the heap Heap leaching can take anything from a couple of months to several years In the case of gold recovery, heap leaching generally requires 60 to 90 days to leach the ore, compared to the 24 hours required by a conventional agitated leach processHEAP LEACH PAD DESIGN AND CONSTRUCTION PRACTICES IN THE 21 ST CENTURY By Allan J Breitenbach, PE, SME Member Vector Colorado LLC INTRODUCTION The mining industry has been using geomembrane liners for fill structures and ponds for more than 30HEAP LEACH PAD DESIGN AND CONSTRUCTION Leach Pad Construction: After the site of this Silver Heap Leaching pad was prepared, a pad base consisting of about 15 inches of mill slimes or a fine bentonitic clay from an old nearby tailings pond was laid downThe pad was constructed slightly larger than the dimensions of the heap to go on it; ie, about 5 feet all around Subsequent experiments have shown that this base is most Heap Leaching Silver Metallurgist Mineral Processing

Leaching behaviour of a chromium smelter waste heap

Leaching behaviour of a chromium smelter waste heap Author links open overlay panel D Deakin a LJ West a DI The residual ore is unreactive and it is likely that unleached chromate is the main source of chromate within leachates, although the chemical speciation of this solid phase chromate remains unknown AHD Cheng, PF Metallurgy Metallurgy Leaching: Oxides are leached with a sulfuric acid or sodium carbonate solvent, while sulfates can be leached with water or sulfuric acid Ammonium hydroxide is used for native ores, carbonates, and sulfides, and sodium hydroxide is used for oxides Cyanide solutions are a solvent for the precious metals, while a sodium chloride solution dissolves some chloridesMetallurgy Leaching BritannicaGold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation Wikipedia

Agglomeration technique improves heap leaching process

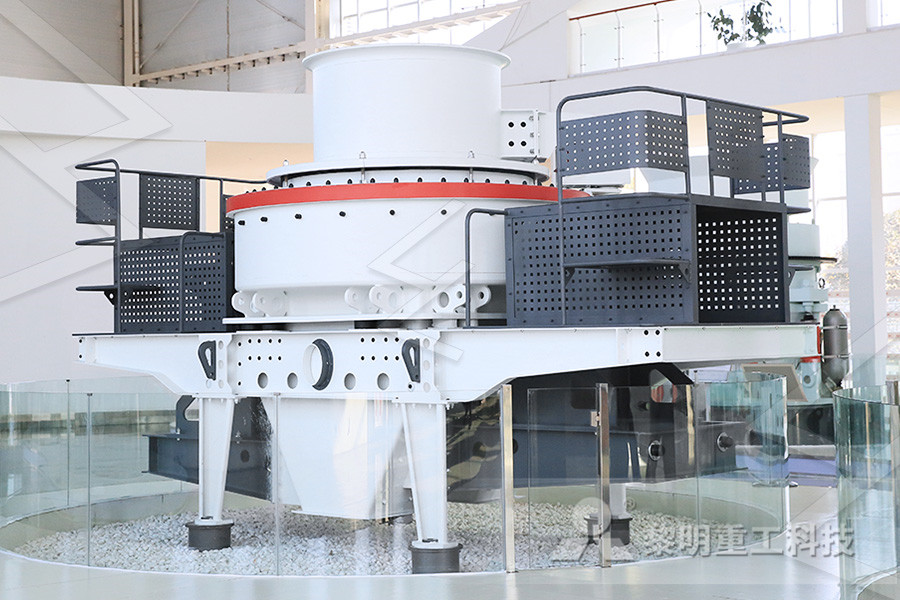

Heap leaching relies on a leaching agent moving through a bed of heaped ore to extract the metallic components: Crushed ore is stacked on a leaching pad and irrigated with the leaching agent The leaching agent chemically reacts with the metal in the ore to dissolve the copper into the solution as it percolates through the heapThe ability of Acidithiobacillus ferrooxidans to remove chromium and other metals from LD slag was examined Additionally the option to retrieve P from LD slag was evaluated Due to the facts that A ferrooxidans is a facultative anaerobic microorganism and LD slag is an alkaline and oxidic material, both oxidative and reductive bioleaching experiments were carried outBioleaching for Removal of Chromium and Associated Metals The metals are removed by passing a special leaching solution through the ore In this study, the removal of Chromium (VI) from four New Mexico soils (sand, sandy loam, and clay) using heap leaching was evaluated at a column scale The heap leaching study demonstrated greater than 99% removal of Cr(VI), using tap water as the leaching agentRemediation of Chromium‐Containing Soils by Heap Leaching

Heap leaching: Could it be an alternative to conventional

Dec 12, 2019 Heap leaching is an industrial mining process used to extract precious metals, copper, uranium and other compounds from ore using a series of Oct 03, 2018 In vat leaching the contact between matrix and solvent is facilitated by putting the ore in large vats or tanks which can be stirred Finally, heap leaching is successfully used to extract metals like gold, silver, copper, nickel and uranium and consists in piling up crushed, agglomerated ores on pads and irrigate the heap from the top with the Getting to know leaching – ChromicHeap leaching operations are often impacted by poor permeability of the ore, which may lead to uneven distribution of the leach solution and ultimately poor mineral recoveries(PDF) Agglomeration for copper heap leaching

USB1 Heap leaching of nickel containing ore

A process is provided for heap leaching ore to recover nickel The process is particularly effective for ores that have a tangible clay component (ie, greater than about 10% by weight) The process includes sizing the ore (where necessary), forming pellets by contacting ore with a lixiviant and agglomerating The pellets are formed into a heap and leached with sulfuric acid to extract the The two main types of leaching are heap and insitu leaching Heap Leaching Heap leaching is also known as acid leaching This method is most effective for the extraction of metals from difficult ores, and is one of the most tried and tested methods The preprocessing of ore before leaching involves the grinding and roasting of the oreLeaching Mining Fundamentals(2011) Ore mineralogy of nickel laterites: controls on processing characteristics under simulated heapleach conditions Australian Journal of Earth Sciences: Vol 58, THEMATIC ISSUE A tribute to the contributions of Ernie Nickel, pp 725744Ore mineralogy of nickel laterites: controls on processing

The Development of Nickel Laterite Heap Leach Projects

THE DEVELOPMENT OF NICKEL LATERITE HEAP LEACH PROJECTS By ML Steemson, PhD, RPEQ and ME Smith, PE Vector Engineering Inc, An Ausenco group company 8/2404 Logan Road, Eight Mile Plains, 4113 QLD, Australia Presented by ML (b) Heap Leaching: The ore is arranged in a big heap, which is treated with water as in slope leaching The recovery of metals and other processes are conducted just like in slope leaching (Fig 121b) (c) InSitu Leaching: This process is carried with an ore which remains in its original location in the earthBioleaching: Introduction, Methods, Application, Copper Leaching There are two main leaching methods: heap leaching and insitu leaching Heap leaching is the most common method used in the US When processing copper through heap leaching, vast quantities of ore and overburden overburdenSoil and rocks that have been moved out of the way to get to ore are called "overburden" In areas where there TENORM: Copper Mining and Production Wastes US EPA

leaching process for chromite populareducationcoza

MODELING CHROMIUM LEACHING FROM CHROMITE ORE ore processing, large amounts of chromite ore processing waste (COPW) modeling, chromium dissolution kinetics, leaching, chromium ore processing waste ore prior to material being stacked before the heap leaching process Read More A clean and efficient leaching process for chromite ore Other articles where Heap leaching is discussed: gold processing: Cyanidation: extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the goldHeap leaching industrial process BritannicaThe Bayer process is still used for Bauxite ore beneficiation Pressure leaching has been in use since 1890’s for recovery of numerous metallic ores with advances in hydrometallurgy • Heap leaching of gold ore started to gain promenence in the late 1960’s when it wasHEAP LEACHING TECHNIQUE in MINING SDIMI

Uranium Heap Leaching

After completion of the leaching process (within months to years), the leached ore is either left in place, or removed to a disposal site, and new ore is placed on the leach pad (socalled on/off scheme, or dynamic heap leaching) During leaching, the piles present a hazard because of release of dust, radon gas and leaching liquidThe heap leaching process being employed at Lomati Mine is a commonly used process to extract gold from the ore Generally, the ore is crushed into fine particles before being heaped and sprayed with a leaching solution which liquefies and separates the gold from the oreTHE MINING PROCESS LOMATI MINEBy agitation leaching at P80 75µm grind size 934 886 By heap leaching at 127mm crushed size 824 807 By heap leaching at 50mm crushed size 783 801 This report presents the results of replicate heap leaching testwork on a composite sample representing the sulphide zone of the deposit It HEAP LEACHING OF Mindoro

Bottle Roll Testing for Cyanidation of Gold Ores: Problems

Cyanide leaching of gold is a very common methodology for evaluation of low grade gold ores Despite risks associated with cyanide, the method proved to be highly effective provided that necessary precautions are taken Gold cyanidation in field scale is mainly conducted through heap leaching and tank leaching methodsThe metals are removed by passing a special leaching solution through the ore In this study, the removal of Chromium (VI) from four New Mexico soils (sand, sandy loam, and clay) using heap leaching was evaluated at a column scale The heap leaching study demonstrated greater than 99% removal of Cr(VI), using tap water as the leaching agentRemediation of Chromium‐Containing Soils by Heap Leaching (b) Heap Leaching: The ore is arranged in a big heap, which is treated with water as in slope leaching The recovery of metals and other processes are conducted just like in slope leaching (Fig 121b) (c) InSitu Leaching: This process is carried with an ore which remains in its original location in the earthBioleaching: Introduction, Methods, Application, Copper

Heap leaching industrial process Britannica

Other articles where Heap leaching is discussed: gold processing: Cyanidation: extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the goldHowever, uranium leaching from ore on a large scale is widely practiced in the USA, South Africa, Canada and India Insoluble tetravalent uranium is oxidized with a hot H 2 SO 4 /Fe 3+ solution to make soluble hexavalent uranium sulfate at pH 1535 and temperature 35°C (Crueger and Crueger, 1984)Microbial Leaching (Bioleaching, Biomining Oct 03, 2018 In vat leaching the contact between matrix and solvent is facilitated by putting the ore in large vats or tanks which can be stirred Finally, heap leaching is successfully used to extract metals like gold, silver, copper, nickel and uranium and consists in piling up crushed, agglomerated ores on pads and irrigate the heap from the top with the Getting to know leaching – Chromic

Ore mineralogy of nickel laterites: controls on processing

(2011) Ore mineralogy of nickel laterites: controls on processing characteristics under simulated heapleach conditions Australian Journal of Earth Sciences: Vol 58, THEMATIC ISSUE A tribute to the contributions of Ernie Nickel, pp 725744Aug 02, 2011 A video interview with Monash University's Dr Gavin Mudd about the proposed heap leaching expansion of Ranger Uranium Mine in Kakadu National ParkHeap Leaching Video YouTubeDec 12, 2019 Heap leaching is an industrial mining process used to extract precious metals, copper, uranium and other compounds from ore using a series of Heap leaching: Could it be an alternative to conventional

Gold CIP, CIL System, Heap Leaching, Cyanidation Process

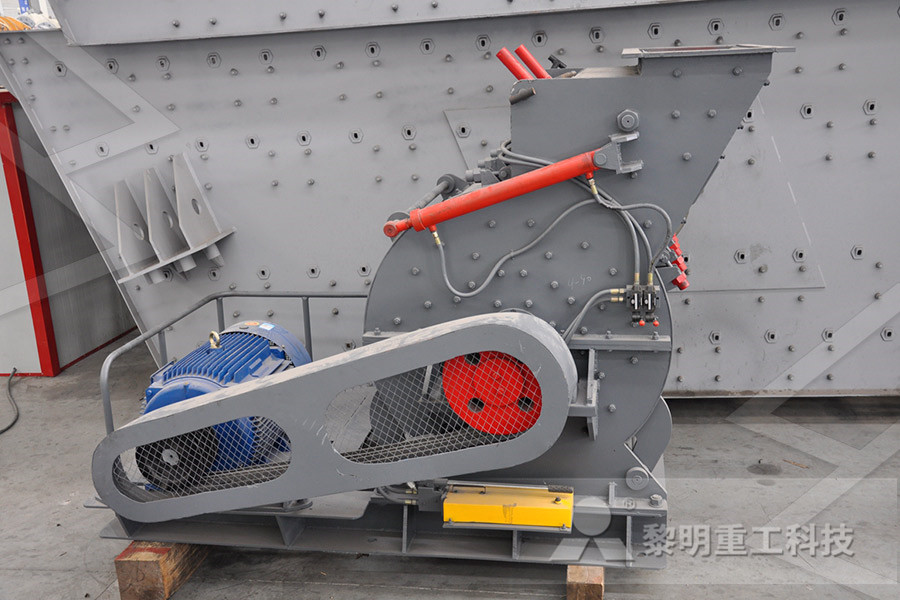

Gold Mine Heap Leaching Process Crushed by jaw crushers and cone crushers to a certain particle size (3050mm), raw ore is directly sent for heaping or granulated (to make finer particles agglomerate into coarse powder), and then transported to the ore heap site for heap construction On the laid ore heap site, the heap system is set upHeap leaching method is known as cheap method for copper extraction Presence of clay and acid consumer waste minerals are the most critical issues because they may bring out the process from economic mode For reduce acid consumption and increasing copper extraction in heap leaching method, about 3 tons sample was taken randomly from different low grade zonesInvestigation of Affecting Parameters on Heap Leaching