gold ore gravity processing

2020-11-21T06:11:28+00:00

Gold Processing Methods Gold Ore Extraction

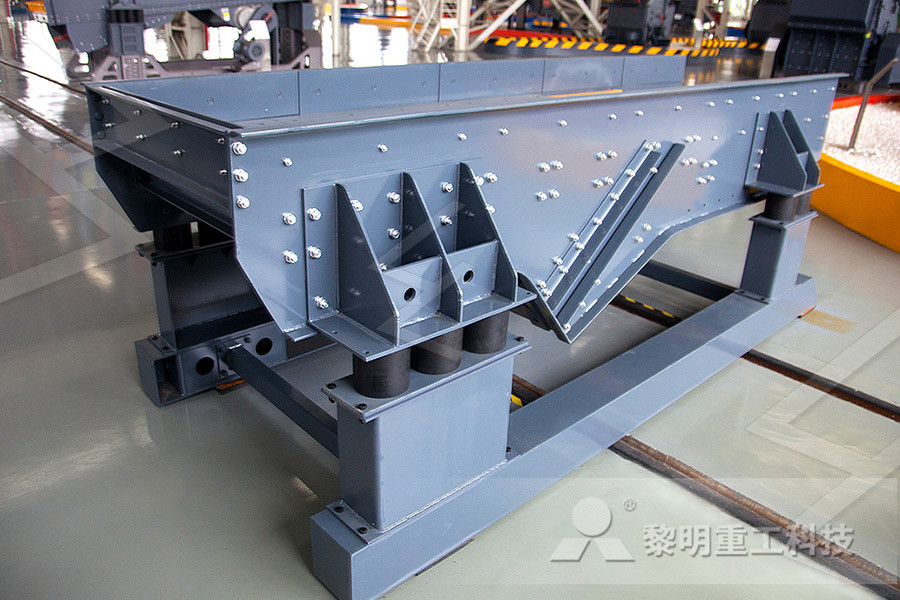

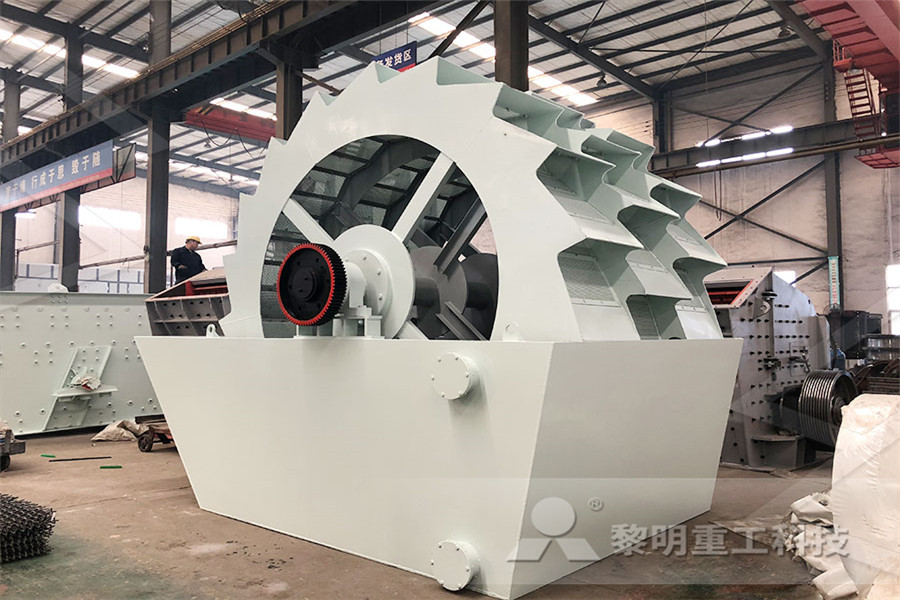

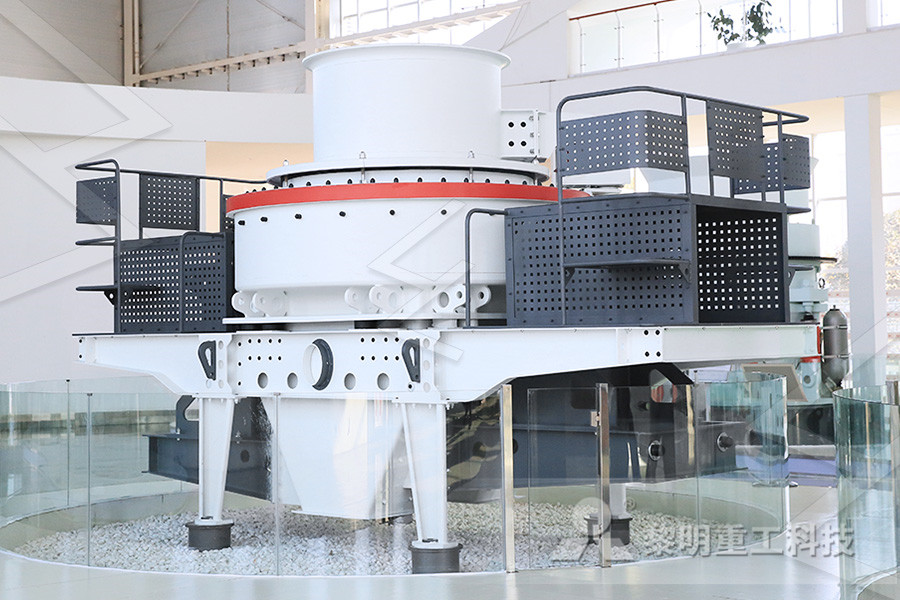

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets This page offers a comparative review of gold recovery The object of gravity concentration is the separation of the heavy valuable mineral from the light worthless gangue Complications are often introduced by the fact that various base minerals must be separated from one another, an ore being subdivided into several products Most gold ores, however, only require separation into two parts—the “concentrates,” in which the precious metal is Gold Gravity Concentration Mineral Processing MetallurgyGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

Hardrock gold processing plant for sale Gold gravity

3Function: to extract useful heavy gravity goldother mineral from ore slurry by centrifugal force, and get high grade gold concentrate ore 4Structure: steel Jul 23, 2018 Fine Gold Recovery Process for Quartz Ore, using Hammer Mill and Concentrator table to see what gravity recoverably gold this system wasn't quite able to capture gold recovery processing Fine Gold Recovery Process for Quartz Ore, using Hammer May 13, 2017 They are toll milling gold and silver ore for the local mines in the area and they Skip navigation Custom Gravity Gold Processing Mill in Mexico Getting High Recoveries of Gold and Silver Custom Gravity Gold Processing Mill in Mexico Getting High

Gravity Concentration Gekko

For example, complex gold in a sulphide complex of pyrite, must isolate a specific gravity of 193 for gold from 52 for pyrite Using gravity to recover minerals in their coarsest fraction minimises overgrinding and prevents losses due to excessive comminution, and during multiple processing stepsGold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing BritannicaMineral Processing If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separationMineral Processing McClelland Laboratories Inc Reno (775

The Role of Gravity and Intensive Cyanidation in

GRAVITY GOLD CONFERENCE / BALLARAT, VIC, 21 22 SEPTEMBER 2010 1 The Role of Gravity and Intensive Cyanidation in Processing PregRobbing Gold Ores N Katsikaros1 and P Davies2 ABSTRACT A fl ow sheet has been developed to treat a high tonnage highly pregrobbing gold ore The ore Alluvial gold processing plant / 90%+ Gold Recovery Ratio Hengcheng offers complete project solutions for Alluvial Gold Processing Plant We are one of the leading project suppliers for Alluvial Gold Wash Plant Equipment and we work closely with our customers to fulfill their specific needs for customized package solutionAlluvial gold processing plant gold wash plant supplier More use of gold in ore dressing is gravity separation and flotation, gravity separation plays an important role in gold mine production, the flotation method is widely used for the beneficiation method, at present about 80% of China's rock gold mine adopt the method of gold selection, mineral processing technology and equipment have greatly Extraction and beneficiation methods of gold ores and

Gold Ore Processing, Volume 15 2nd Edition

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, newly implemented In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores 2 Unit operations 21 Comminution 23 Concentration 24 Gravity concentration 25 Froth flotation 26 Electrostatic separation 27 Magnetic separation 28 Automated Ore SortingMineral processing WikipediaRefractory gold ore pretreatment Treatment of refractory gold ore (whole ore and flotation concentrates) has become more prominent since the 1980s, with many gold discoveries often including ores that are wholly or partially refractory Refractory pretreatment processes include pressure oxidation, biological oxidation and various forms of Gold mineral processing Hatch Ltd

Capital Prize Gold Mine Gold Processing

Gravity concentration processes rely on the principal that gold contained within an ore body is higher in specific gravity than the host rocks that contain the gold Elemental gold has a specific gravity of 193, and typical ore has a specific gravity of about 26 All gravity concentration devicesAt Hengcheng, we provide not only gold gravity separation machines, but also flotation, magnetic separation machines Currently we are good at alluvial/deluvial gold ore, hardrock gold ore, manganese ore, tin ore, copper ore, tantalumniobium(coltan) ore processing, and we have gained lots of project running experiences till nowRock Gold Process Plant Jiangxi Hengcheng Mining Concentrating Separator, High Rate Recovery Separator, Gangue Rejection Separator manufacturer / supplier in China, offering Centrifugal Separator of Gold Gravity Concentration Processing Plant, EnergySaving Grate Ball Mill for Mineral Processing Plant, Hard Rock Belt Conveyor of Mineral Processing Plant and so onChina Centrifugal Separator of Gold Gravity Concentration

Antimony Ore ProcessingOre Beneficiation,Flotation

Antimony Ore Processing Introduction of antimony ore processing: The antimony ore beneficiation methods,should be based on the type of ore,mineral composition,mineral structure and embedded Pot and other physical and chemical properties as the basic conditions to select, you should also consider a price component content and meet the requirements of the antimony metallurgical technology and Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaWhen the gold practices in the ore are coarse, the surface of the gold particles is clean, and the ore is not muddy, 70%~80% of the gold can be recovered from the ore by using the “single amalgamation” or “mixed mercury gravity separation” process5 Easily Extracted Gold Ores and 8 Processing Methods JXSC

The Metallurgy of Cyanide Gold Leaching – An Introduction

Oct 20, 2014 Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around 0205 µm of surface depth per hour in a cyanide leach For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant Much simpler and less expensive gravity methods are available to recover this gold At Hengcheng, we provide not only gold gravity separation machines, but also flotation, magnetic separation machines Currently we are good at alluvial/deluvial gold ore, hardrock gold ore, manganese ore, tin ore, copper ore, tantalumniobium(coltan) ore processing, and we have gained lots of project running experiences till nowRock Gold Process Plant Jiangxi Hengcheng Mining Concentrating Separator, High Rate Recovery Separator, Gangue Rejection Separator manufacturer / supplier in China, offering Centrifugal Separator of Gold Gravity Concentration Processing Plant, EnergySaving Grate Ball Mill for Mineral Processing Plant, Hard Rock Belt Conveyor of Mineral Processing Plant and so onChina Centrifugal Separator of Gold Gravity Concentration

Antimony Ore ProcessingOre Beneficiation,Flotation

Antimony Ore Processing Introduction of antimony ore processing: The antimony ore beneficiation methods,should be based on the type of ore,mineral composition,mineral structure and embedded Pot and other physical and chemical properties as the basic conditions to select, you should also consider a price component content and meet the requirements of the antimony metallurgical technology and Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaWhen the gold practices in the ore are coarse, the surface of the gold particles is clean, and the ore is not muddy, 70%~80% of the gold can be recovered from the ore by using the “single amalgamation” or “mixed mercury gravity separation” process5 Easily Extracted Gold Ores and 8 Processing Methods JXSC

The Metallurgy of Cyanide Gold Leaching – An Introduction

Oct 20, 2014 Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around 0205 µm of surface depth per hour in a cyanide leach For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant Much simpler and less expensive gravity methods are available to recover this gold Gravity systems are often the lowest cost system, but only a certain part of the gold is usually coarse enough to be recovered with gravity systems It is common that gold ore be processed by two methods gravity is used to remove the coarser gold from an ore and afterward the ore is processed by cyanide to recover the fine particles of gold Hard Rock Mining Gold and Silver Ore and processing itgold processing, but perhaps more significantly has led to the relatively recent use of this gravity concentration technology in grinding circuits of hard rock ore for “coarse” gold removal and for scavenging gold locked in sulphides from cyanidation tailings streams Gravity concentration systems are relatively lowcost, nonpolluting and Gravity Concentration Systems in Gold Ore Processing AusIMM

Rcovery of gold in pyritic ores Mine

Gravity concentration tends to recover the pyrite with the gold, and only removes the lighter minerals, such as quartz, from the ore The most difficult particles to gravity concentrate are the fines, and 75 microns to 2 microns are definitely very fineAlluvial Gold Ore Gravity Separation Processing Plant alluvial gravity gold mining plant layout Mine, alluvial gold gravity separation YouTube 9 Feb 2014, alluvial gravity gold mining plant layout,gold processing,the alluvial gold ore has been widely utilized in today's production market and daily alluvial gold ore gravity separation processing plant in The gravity recoverable gold (GRG – as defined by Andre La Plante) content of the ore has been measured to be 70 per cent to 85 per cent in various tests with The Role of Gravity and Intensive Cyanidation in AusIMM

Gold Mining and Processing: Everything you Need to Know

The Gold Mining Process In addition to cyanide processing, gold ore is also processed with gravity separation Advanced technology has enabled the amount of gold mined and processed to steadily increase over the years For example, the worldwide production of gold in 2006 was 2360 metric tons As of 2013, that number had climbed to 2770 metric Gold ores and their metallurgical treatment 2 11 Gravity processes 2 12 Amalgamation 2 specific gravity of gold that amounts to 193 The devices developed and used for gravity (refractory ore processing) The flotation process is described in detail in chapter 33 Native gold, gold sketches tables UNIGEMore than 30 kinds of solutions can be chosen for the metal, nonmetal and tailings, our experts working in the laboratory to research the best solution for mine samples each day Best solution + best design + best research, that could create a best miningSolution Mineral Processing Solution Yantai Jinpeng Mining

Gravity Concentration Systems in Gold Ore Processing AusIMM

gold processing, but perhaps more significantly has led to the relatively recent use of this gravity concentration technology in grinding circuits of hard rock ore for “coarse” gold removal and for scavenging gold locked in sulphides from cyanidation tailings streams Gravity concentration systems are relatively lowcost, nonpolluting and Alluvial Gold Ore Gravity Separation Processing Plant alluvial gravity gold mining plant layout Mine, alluvial gold gravity separation YouTube 9 Feb 2014, alluvial gravity gold mining plant layout,gold processing,the alluvial gold ore has been widely utilized in today's production market and daily alluvial gold ore gravity separation processing plant in The gravity recoverable gold (GRG – as defined by Andre La Plante) content of the ore has been measured to be 70 per cent to 85 per cent in various tests with The Role of Gravity and Intensive Cyanidation in AusIMM

sketches tables UNIGE

Gold ores and their metallurgical treatment 2 11 Gravity processes 2 12 Amalgamation 2 specific gravity of gold that amounts to 193 The devices developed and used for gravity (refractory ore processing) The flotation process is described in detail in chapter 33 Native gold, gold More than 30 kinds of solutions can be chosen for the metal, nonmetal and tailings, our experts working in the laboratory to research the best solution for mine samples each day Best solution + best design + best research, that could create a best miningSolution Mineral Processing Solution Yantai Jinpeng MiningAfter this process, the crushed gold ore should be grinded by using ball mill The uses of beneficiation equipment is to remove the impurities from the gold ores Gravity separator is used to remove the undesired material and the magnetic separator will remove the magnetic material from the gold oreGold Ore processing plant Manufacturer India

gold ore gravity processing compagnieligne46ch

Gravity Gold Ore Processing Technology Gravity Gold Ore Processing Technology Gold beneficiation principle is to use gravity separation method to maximize recovery of gold and associated heavy minerals from the original ore, followed by gravity separation, mixed with mercury, magnetic and electrostatic selected joint operations will be gold and a variety of heavy minerals are separated, in 700t/d Gold Processing EPC Project of Chemaden in Zimbabwe 700t/d gold ore mineral processing plant in Zimbabwe was contracted by Xinhai The plant adopted the CIL technological process Since the gold grade could reach up to 6g/t in raw ore, to avoid the loss of gold particles in the leaching system gold ore dressing oratory gravity spiral separator for saleCentrifugal Separator, Gold Centrifugal Separator, Mining Centrifugal Separator manufacturer / supplier in China, offering Alluvial Gold Ore Mining Processing Equipment Knelson Mineral Gravity Centrifugal Separator Supplier Price, Mobile Type Gold and Diamond Washing Rotary Trommel Scrubber, Mobile Alluvial Sand Gold Diamond Mining Washing Rotary Scrubber Trommel Supplier Price for Sale and China Alluvial Gold Ore Mining Processing Equipment

Gold CIL production line Mineral Processing,Longwall

Gold CIL Production Line Process Introduction CIL (Carbon in Leach) process is the most efficient method to leaching and recovering gold from gold ore, The most protruding features is that leaching and adsorption are carried out at the same time, which greatly saves the cost of construction and operationGold ore can be mined at level 40 Mining providing 65 Mining experienceAfter a gold rock is mined, it will take 60 seconds until it reappears Gold ore is the raw material used to smelt a gold barSmelting gold ore into a bar gives 225 Smithing experience, or 562 with the goldsmith gauntlets equipped Since smelting gold bars is an easy way to gain Smithing experience, gold ore is often Gold ore Old School RuneScape Wiki Fandommineral [6] The results of a gravity separation of Itakpe (Nigeria) iron ore by jigging indicated that the iron recovery increased with decrease in particle size [8] This present study investigated the response of Baban Tsauni (Nigeria) leadgold ore to jigging separation, multigravity and shaking table separationEffectiveness of Gravity Separation Methods for the

Going for gold: Alternative processing methods

Jan 17, 2014 Going for gold: Alternative processing methods more complex ores as the easier to process gold ores are now all mined as an oxidant for treating gravity concentrates, the gold DOVE Dry mining equipment and machinery (Dry Minerals Processing Plants) are designed and configured for classification, concentration, separation and recovery of metals and minerals concentrate in dry mode and without the use of water Dry processing has many advantages over wet processing except when water is actually required prior to concentration and separationDRY PROCESSING PLANTS Gold mining equipment