coal pulverizer centers

2023-04-26T08:04:42+00:00

Pulverizer Wikipedia

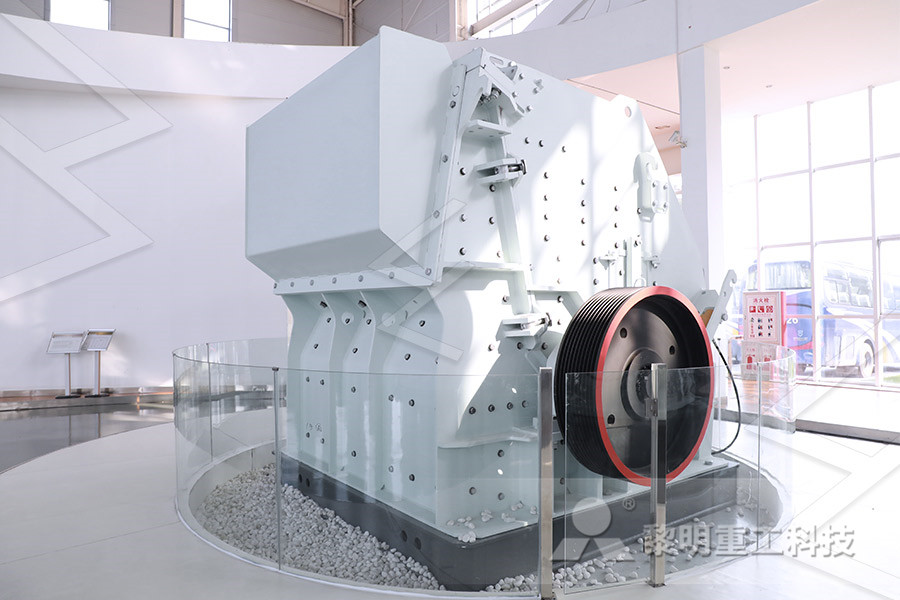

The material to be pulverized is introduced into the center or side of the pulverizer (depending on the design) As the lower ring rotates, the balls to orbit between the upper and lower rings, and balls roll over the bed of coal on the lower ring The pulverized material is carried out of the mill by the flow of air moving through itBW's pulverizers, found at power stations throughout the world From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenancePulverizers / Mills Babcock WilcoxCoal Mills Service Solutions We are a world leader in coal pulverizing and overall mill performance with a wide portfolio of services offering covering both horizontal and vertical boiler mills We are committed to key customer issues like improved coal mill and pulverizer performance, reduced maintenance costs, longer periods of operation Boiler Mill Coal Pulverizer Service Solutions GE Power

Improving Coal Pulverizer Performance and Reliability

Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal BunkerHardox Wearparts center Tuscaloosa Description of the case The coal pulverizer is applied to crush the coal to an average size of 0074 mm powder At the entrance of coal pulverizer, the temperature would be between 160 C to 393 C The blowing speed is 50 to 55 m/second When the high Cr cast steel (4858 HRC) liner plate is used, the service Coal pulverizer Hardox WearpartsWilliams Crusher leads the industry in coal pulverizer manufacturing, offering the industry’s most advanced direct fired coal and pet coke crushing system Whether you’re looking for a direct fired pulverizer, lowcapacity coal size reduction solutions, or something inbetween, you’ll find it Coal Crushers Coal Pulverizers Mills Williams Crusher

Finessing fuel fineness POWER Magazine

In my experience, about 75% of the efficiency improvements in coalfired boiler systems center on the pulverizers and closely related issues of coal fineness, fuel distribution, fuel line balance A wide variety of coal pulverizer options are available to you, There are 525 suppliers who sells coal pulverizer on Alibaba, mainly located in Asia The top countries of suppliers are China, India, from which the percentage of coal pulverizer supply is 99%, 1% respectivelycoal pulverizer, coal pulverizer Suppliers and Units 1 and 2 are Babcock and Wilcox (BW) cyclone boilers, and Unit 3 is a BW pulverized coalfired boiler The 670MW Unit 3 was designed with seven MPS89 pulverizers that have historically Improve Power Plant Heat Rate with a Pulverizer

A Comparison of Three Types of Coal Pulverizers

the pulverized coal from the pulverizer section through the coal pipes to the burners A typical arrangement of an ATRITA pulverizer system is shown in Figure 3 AT RITA pulverizers can be designed for either pressurized or nonpressurized (suction) operation Vertical Roller MillA coal pulvurizer (center) A pulverizer is a machine used to grind different types of material This is done so that the material will be able to be used or can be easily transported An example of a material that can be grinded is coal Types Pulverizer Simple English Wikipedia, the free encyclopediaWith more than a century of experience, Riley Power Inc is a highly respected manufacturer of steam boiler parts and fuel burning equipment for all types of fossil and waste fuel fired boilers, including those that fire coal, oil, gas, as well as waste fuels including refuse, wood and cellulose byproductsRiley Power Boiler Replacement Parts – Oil, Coal More

Pulverizer Training Babcock Wilcox

Eric has over 22 years of pulverizer and fuel preparation experience at BW and one patent titled “System for Controlling Coal Flow in a Coal Pulverizer” Eric spent the first eight years in Pulverizer Graphics working with designers and engineers refining the pulverizer Design of Pulverizers Every coal pulverizer is designed with a particular fuel grinding capacity, or throughput, at a certain Hardgrove grindability index (HGI), based on moisture content, a defined raw coal size, and desired fineness level These factors must all be considered and are significant in discussions of pulverizer capacityPulverizer Manufacturers Suppliers IQS DirectoryCoal Pulverizers RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering, Foster Wheeler, Babcock Wilcox, and Alstom bowl mills Our mill body wear liners, deflector liners, journal liners, and pulverizer rolls are engineered to offer the longest wear life with the lowest risk of catastrophic failureCoal Pulverizer Systems, Overlay RPM and Associates

Crushers, Pulverizers Mills Gilson Co

Crushers, Pulverizers Mills Particlesize reduction, or comminution, is often required to prepare bulk material samples for testing Crushing is often the initial step with materials such as mineral ores or aggregates using varying combinations of force, Raw coal diverter chute BW provides a raw coal diverter chute to direct the incoming coal towards the center of the pulverizer, or inboard of the grinding elements Installation of a diverter chute will reduce the inventory of coal inside the pulverizer resulting in a reduction in pressure drop and increased fineness Boltthrough housing unitsPS410 E and EL Pulverizer Modifications for Optimum Coal Pulverizer, Coal Pulverizer Mill, Coal Mill Pulverizers liming Machinery is a manufacturer of coal pulverizing equipment The four most common types of coal pulverizers are: ball pulverizer, impact pulverizer, vertical roller Coal Pulverizer Crusher Mills, Cone Crusher, Jaw Crushers

Pulverized Coal Pipe Testing and Balancing

Pulverized Coal Pipe Testing and Balancing By Richard F (Dick) Storm, PE The first step in optimizing combustion system performance is balancing the air and fuel flowing through each of the plant's coal pipes—the pipes that convey the air/fuel mix from the pulverizers to the Yamamoto et al investigated the cofiring characteristics of pulverized coal and ammonia by using a horizontal single burner with a coal feeding rate 100 kg/h Their results showed that NO x concentration in the flue gas increased by approximately 20% and UC in fly ash increased slightly, when the ammonia was injected from the center of burner Numerical investigation on ammonia cofiring in a Resource Center; Blog; Home » Industries Served » Energy Industry » Coal Pulverizers Coal Pulverizers Pulverizer gearboxes are large and come with a significant price tag Exchanging them requires a large dose of planning The spiral bevels and large Coal Pulverizers Xtek, Inc

Coal Pulverizer Monitoring and Analysis: A Case Study

This paper describes a case study of coal pulverizer monitoring and analysis It represents the partial work of a project called “Mill Advisor” which investigated the common operational and maintenance problems of the coal pulverizerCoal Pulverizer, Coal Pulverizer Mill, Coal Mill Pulverizers liming Machinery is a manufacturer of coal pulverizing equipment The four most common types of coal pulverizers are: ball pulverizer, impact pulverizer, vertical roller Coal Pulverizer Crusher Mills, Cone Crusher, Jaw CrushersPulverized Coal Pipe Testing and Balancing By Richard F (Dick) Storm, PE The first step in optimizing combustion system performance is balancing the air and fuel flowing through each of the plant's coal pipes—the pipes that convey the air/fuel mix from the pulverizers to the Pulverized Coal Pipe Testing and Balancing

Numerical investigation on ammonia cofiring in a

The combustion processes of coalfiring and NH 3 cofiring in the combustion facility under different conditions were simulated by CFD ANSYS FLUENT 150 was employed The mesh used in simulation and positions of three cross sections (face A, B, C) are shown in Fig 2The adopted submodels and reactions in the simulation of coal firing were completely the same as that of NH 3 cofiringResource Center; Blog; Home » Industries Served » Energy Industry » Coal Pulverizers Coal Pulverizers Pulverizer gearboxes are large and come with a significant price tag Exchanging them requires a large dose of planning The spiral bevels and large bearings involved require a company specially equipped to handle themCoal Pulverizers Xtek, IncImproving Coal Pulverizer Performance and Reliability Coal mill pulverizer in thermal power plants SlideShare coal pulverizer ball mill,17 Nov 2012, Coal pulverizer/mill system One of the critical power plant components that 3, Ball and race mill 8Foster Wheeler MBF Mill 9Tube Mill 10Bowl Mill Bowl mills are employed to pulverize the precrushed raw 101,Pulverizers Babcock Power, ball and race mill coal pulverizer ladonatellabe

Coal Pulverizer Monitoring and Analysis: A Case Study

This paper describes a case study of coal pulverizer monitoring and analysis It represents the partial work of a project called “Mill Advisor” which investigated the common operational and maintenance problems of the coal pulverizer• After completing traverses of all pipes on the pulverizer being tested, empty the sampling jug (which now contains pulverized coal from all of the burner lines on the pulverizer being tested) and the contents of the filter canister into a Ziploc 1 gallon freezer bag labeled with the date and all relevant pulverizer informationASME Coal Sampling Test ProcedureThe present invention is directed to, among other things, a grinding and impeller clip for attaching to a wheel assembly mounted for rotational motion within a grinding chamber of a coal pulverizer, wherein the clip has an arcuate cross sectional profile and a protective layer on its upper surfaceUSB2 Grinding and impeller clip for a coal

Coal Pulverizer Wear Parts Products Suppliers

Description: alloy Both parts are designed to bolt through the pulverizer wall, as well as to each other, giving solid attachment Pivot blocks and rolls We also offer roll pivot blocks and pivot rolls so you can rebuild with allColumbia wear parts Industry Application: Crushers Grinding MillsCOMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS NFPA 85 Code (Boiler and Combustion Systems Hazards Code), Combustion Control, Oxygen Trim, Control of Air and Coal Flow into the Boiler, Matching Boiler Firing Rate Demand to Electrical load, NOx and SOx Control, Burner Management Systems, Boiler Permissive Starting Logic and Protective Tripping Logic, and Control of Pulverized COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS CE RS Coal Mill Modernization and Performance Components Increase throughput, balance coal pipes, increase coal fineness, reduce emissions Coal Pulverizer / Mill Modernization Upgraded Components: • Entire assembly is built on the center of gravity of the Hub CE RS Coal Pulverizer Modernization and Performance

coal pulverizer for power plant lanuovaterrazzait

coal pulverizer for power plant supplier Hydraulic Motor Driving Center Thickener Tilted Plate Thickener Efficient Deep Cone Thickener Peripheral Transmission Thickener Efficient Thickener Efficient power plant coal pulverizers Coal mill pulverizer in thermal power plants 1used pulverized coal mills in stock This time, however, is dependent on various factors The heart of a pulverized coalfired boiler is the pulverizer, also known as the mill Depending on speed pulverizers are classified as lowspeed, mediumspeed, and highspeed millsused pulverized coal millsSoot formation characteristics of a labscale pulverized coal flame were investigated by performing carefully controlled laser diagnostics The spatial distributions of soot volume fraction and the pulverized coal particles were measured simultaneously by laser induced incandescence (LII) and Mie scattering imaging, respectivelySoot formation characteristics in a labscale turbulent

USB2 Grinding and impeller clip for a coal

The present invention is directed to, among other things, a grinding and impeller clip for attaching to a wheel assembly mounted for rotational motion within a grinding chamber of a coal pulverizer, Description: alloy Both parts are designed to bolt through the pulverizer wall, as well as to each other, giving solid attachment Pivot blocks and rolls We also offer roll pivot blocks and pivot rolls so you can Coal Pulverizer Wear Parts Products Suppliers COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS NFPA 85 Code (Boiler and Combustion Systems Hazards Code), Combustion Control, Oxygen Trim, Control of Air and Coal Flow into the Boiler, Matching Boiler Firing Rate Demand to Electrical load, NOx and SOx Control, Burner Management Systems, Boiler Permissive Starting Logic and Protective Tripping Logic, and Control of Pulverized COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS

CE RS Coal Pulverizer Modernization and Performance

CE RS Coal Mill Modernization and Performance Components Increase throughput, balance coal pipes, increase coal fineness, reduce emissions Coal Pulverizer / Mill Modernization Upgraded Components: • Entire assembly is built on the center coal pulverizer for power plant supplier Hydraulic Motor Driving Center Thickener Tilted Plate Thickener Efficient Deep Cone Thickener Peripheral Transmission Thickener Efficient Thickener Efficient power plant coal pulverizers Coal mill pulverizer coal pulverizer for power plant lanuovaterrazzaitused pulverized coal mills in stock This time, however, is dependent on various factors The heart of a pulverized coalfired boiler is the pulverizer, also known as the mill Depending on speed pulverizers used pulverized coal mills

Soot formation characteristics in a labscale turbulent

Soot formation characteristics of a labscale pulverized coal flame were investigated by performing carefully controlled laser diagnostics The spatial distributions of soot volume fraction and the pulverized coal Pulverizer machines can crush all types of items, including plastic, glass, aluminum, concrete, coal, rock, resin, tires, and medical waste Pulverizer machines come in a number of different forms Hammer mills, ring mills, double roll crushers, granulators, impactors, and shredders are all forms of pulverizer #1 Pulverizer Manufacturers in India Pulveriser Machine 1 Pulverized Coal Burners 11 Pulverized Coal Supply Pulverized coal from the coal pulverizers is conveyed in a stream of hot primary air from the mills to the burners where it is injected into the furnace space to be burned Generally, the air–fuel ratio of the fuel mixture leaving the pulverizers Fossil Fuel Combustion Systems Encyclopedia of Life

A CoalFired Thermoelectric Power Plant USGS

Aug 30, 2018 A large thermoelectric plant like this burns a lot of coal—in this case, about 11 million tons per year Coal that has been ground into a fine powder by a pulverizer is blown into a furnace China Coal Pulverizer, China Coal Pulverizer Suppliers and Manufacturers Directory Source a Large Selection of Coal Pulverizer Products at coal briquettes,coal gas,coal machine from China Alibaba My Alibaba Message Center China Coal Pulverizer, China Coal Pulverizer Manufacturers A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces Pulverizer Wikipedia cAesar

1 GENERAL VIEW OF FISK STREET ELECTRIC GENERATING

1 general view of fisk street electric generating station complex, looking south; in the center, behind the stack is the generating station built in 1959; the tall metalclad building contains a coal bunker, coal pulverizerCoal dust is a fine powdered form of coal, which is created by the crushing, grinding, or pulverizing of coal Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling coalIt is a form of fugitive dust Grinding coal to dust before combusting it improves the speed and efficiency of burning and makes the coal Coal dust Wikipedia