introduction on vertical roller mill in cement industry

2021-06-09T08:06:17+00:00

INVT GD5000 MV Drive for Cement Vertical Raw Mill 63KV

Keyword: GD5000 medium voltage drive, Vertical roller mill, increase raw milling production; 1 Introduction Modern urban infrastructure construction cannot leave the participation of cement, and cement production needs all kinds of equipment to work together Vertical roller mill machine is a very important device in the cement factoryVertical Roller Mill In Cement Industry Introduction Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bedVertical Roller Mill In Cement IndustryVertical Roller Mill In Cement Industry Introduction Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bedVertical Roller Mill In Cement Industry PEW Jaw Crusher

Vertical Roller Mill Operation

Vertical roller mill producted by mainly include : vertical roller mill that used in metallurgy , electric power, coal preparation of the cement industry ; vertical milling machine that applicable to nonmetallic mineral grinding ; vertical roller mill that suitable for industrial flue gas desulphurization and waste utilization ultrafine Introduction of GGBS vertical roller mill GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS) into small particles GGBS (fineness 42004500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for ready introduction on vertical roller mill in cement industry DETAILED ENERGY AUDIT AND CONSERVATION IN A INTRODUCTION The Progressive management of this cement plant has modern vertical roller grinding mills along with tube mills both for raw meal as well as coal Cement grinding is From the above pie chart it is evident that the cement mill section (37%) is the major contributor to overall SEC followed by kiln section (26%) and then byintroduction on vertical roller mill in cement industry

vertical roller mill in cement industry calculation

Jan 27, 2017 The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani and the dependent variable by using statistical analysis technologies, and the dependent variable trend can Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materialsIntroduction Around 110 years ago a Danish engineer, M Davidsen, patented a pioneering patent and started selling an improved version of this mill all over the world For the cement industry the ball mill was really an epochmaking breakthrough as for almost cement in a vertical roller millCement grinding Vertical roller mills versus ball mills

Vertical Roller Mills

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedApr 21, 2015 Gebr Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blastfurnace slag, and pozzolanaGebr Pfeiffer MVR Roller Mills working principle YouTubeImproving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice 1 Cement production is a resourceintensive practice involving large amounts of raw materials, energy, labor, and capitalIMPROVING THERMAL AND ELECTRIC ENERGY

Vertical roller mill Cement and Mining Equipment Supplier

more and more evident in the cement industry GRM series vertical roller mill is developed with the features of high efficiency, energysaving and environmental protection which is achieved after exchanging ideas with senior experts from home and abroad and making improvements based on same sector experience in the past yearsA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaApr 21, 2015 Gebr Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blastfurnace slag, and pozzolanaGebr Pfeiffer MVR Roller Mills working principle YouTube

HLM Vertical Roller Mill hcmilling

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment Jan 27, 2017 The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani and the dependent variable by using statistical analysis technologies, and the dependent variable trend can vertical roller mill in cement industry calculationChoose vertical roller mill or ball mill in Cement grinding plant News Date: 14:30:46 Vertical roller mill has become the standard for grinding raw materials in the cement manufacturing process but many cement producers are still favouring ball mill for cement manufacture when set up new integrated cement grinding plantsThe industry has failed to fully adapt to this technological Choose vertical roller mill or ball mill in Cement

Modern Processing Techniques to minimize cost in Cement

Vertical Roller Mill (VRM) The power used for the actual grinding process while grinding raw materials, depends mainly on the hardness of raw materials and the type of mill used, ie ball mill or vertical roller mill Typically, the motor of the ball mill consumes about 14 Consult Xinxiang Great Wall Machinery Co, Ltd's CHAENG(Professional Manufacturer) slag pot from China introduction brochure on DirectIndustry Page: 1/2CHAENG(Professional Manufacturer) slag pot from China Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc Application : Cement Plant, ClCement Vertical Roller Mill gwmcn

Cement ball mill chaengco

The company specializes in manufacturing tube mills, rotary kilns, vertical roller mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries It has become the mainstream equipment in the pulverizing industryVertical Roller Mill (60045μm) has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cementOK™ mill The most reliable and efficient mill for raw and

Slag Vertical Roller Mill Xinxiang Great Wall Machinery

Consult Xinxiang Great Wall Machinery Co, Ltd's Slag Vertical Roller Mill brochure on DirectIndustry Page: 1/1The company specializes in manufacturing tube mills, rotary kilns, vertical roller mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, Cement ball mill chaengcoVertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries It has become the mainstream equipment in the pulverizing industryVertical Roller Mill (60045μm)

OK™ mill The most reliable and efficient mill for raw and

has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cementConsult Xinxiang Great Wall Machinery Co, Ltd's Slag Vertical Roller Mill brochure on DirectIndustry Page: 1/1Slag Vertical Roller Mill Xinxiang Great Wall Machinery In the cement industry, vertical mills (roller mills) are being increasingly regarded as the exclusive solution for new plants In addition, roller presses are experiencing a renaissance for Market trends in vertical mills for the cement industry

Vertical Roller Mill Manufacturer NHI

Product Introduction Vertical roller mill is a kind of energyefficient grinding equipments, which is widely used in many fields such as producing raw and clinker material, grinding slag, ore, industrial silicon, calcium carbide residue, coal gangue in the cement industry Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process Descriptions Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill Vertical roller mill for cement grindingVertical Roller Mill for Cement, Clinker, Slag, etc Vertical Roller Mill for Cement, Clinker, Slag, etc From: Date: 10:28 Appliion of vertical roller mill: Vertical roller mill are suitable for Vertical Mill In Cement weerparijsnl

vertical roller mill Cement industry news from Global Cement

Thailand: Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone The cement producer previously ordered a LM 563+3 CS mill from Loesche for its Ta Luang cement Vertical Roller Mill In Cement Industry Picture Cement Grinding Vertical Roller Mills Versus Ball Mills grinding of raw materialsThe grinding efficiency of the vertical roller mill combined cement industry vertical roller millsHUAJIA(TIANJIN) INTERNATIONAL TRADE CO,LTD, is a professional global cement plant solution supplier We have been in Cement Plant project more than 15 years and The company now has over 500 sets of various machining equipments Also we can supply the relevant spare parts for daily Cement HUAJIA(TIANJIN) INTERNATIONAL TRADE CO,LTD

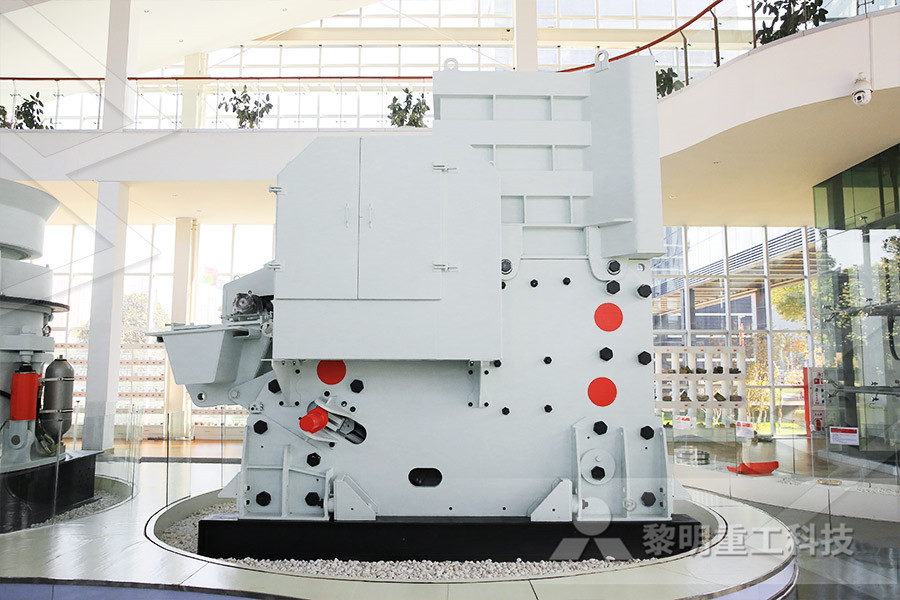

Vertical Roller Mill In Cement Industry

Vertical roller mill in cement industry has various forms, there is a cylinder, cone type, ball type, etc, and roller surface is also flat, curved, convex round noodles Applied to the grinding roller to roller HRM Vertical Roller Mill in Cement Industry As we all know that the HRM vertical roller mill is one of very important powder making machines in the cement industry Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in cement industryHRM Vertical Roller Mill in Cement IndustryHefei Zhongya Mar 01, 2016 re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams vibration vertical roller mill Page 1 of 2