lock hopper system for gasifier

2023-06-07T05:06:15+00:00

Lock Hopper an overview ScienceDirect Topics

The Lurgi dryash gasifier, shown schematically in Figure 528, is a pressurized gasifier typically operating at 30 to 35 atm Sized coal enters the top of the gasifier through a lock hopper and moves down through the bed Steam and oxygen enter at the bottom and @article{osti, title = {Coal pressurization and feeding use of a lock hopper system}, author = {Lewis, R and Santore, R R and Dubis, D}, abstractNote = {A necessary preliminary step in the Synthane highpressure coal gasification processes is to take ground coal at atmospheric pressure and feed it to the gasification system at operating pressureCoal pressurization and feeding use of a lock hopper systemDuring operation, the top valve is opened to receive coal fines into the lock hopper, while the bottom valve is maintained in a closed position After the top valve is closed, the lock hopper is brought to or above the gasifier system pressure, typically with nitrogen from the ASU Following pressurization, the bottom valve is opened, and the 12 Coal Biomass Commercial Technologies for Coal

lock hopper definition English

The lock hopper (9) is disposed to a side of the gasification furnace (3), and the slag discharge system (1A) is provided with a water flow forming means for forming a flow of the cooling water by which the slag is guided to the lock hopper (9) within the slag discharge line (7)Coal enters the top of the gasifier through a lock hopper and is handled by a rotary distributor as it begins its descent through the gasifier Steam and oxygen enter from the bottom, while ash is removed at the bottom by a rotating grate and lock hopperLurgi Dryash Gasifier netldoegovUSE OF A LOCK HOPPER SYSTEM INTRODUCTION The SYNTHANE process is a hiqh pressure coal gasification system developed by the Pittsburgh Energy Research Center of the U S Energy Research and Development Administration (ERDA), formerly a part of the U S Bureau of Mines It was designed to convert bituminous coal, subbituminous coal R D NASA

High pressure:Lock hoppers hydraulics and pneumatics

Sep 07, 2015 The lock hopper, or pressure transfer vessel, is filled from the hopper above The lock hopper is then pressurized to the same pressure as the blow tank, either by means of a pressure balance from the blow tank, which acts as a vent line for the blow tank while it is being filled, or by means of a direct line from the main air supplyA parallel lock hopper system is normally employed to allow one unit to be online, ie, discharging coal at pressure to the gasifier, while allowing the other unit to DRY BIOMASS FEED SYSTEM HighPressure Feeding Systems Another lock hopper system under development is lock hopper system for gasifier Solution for ore miningFigure 3 illustrates a lock connected to the gasifier The coal intermediate hopper mentioned already earlier and serving as storage compartment is arranged between bottom closure and coal distributor It is also evident ,hat by making a few modifications the same system is used as ash lockE Funk Frankfurt, West Germany

MOTIVA ENTERPRISES LLC DELAWARE CITY REFINERY

collect in the water sump at the bottom of the gasifier and are removed periodically, using a lock hopper system Solids collected in the quench gasifier water sump are removed by gravity and forced circulation of water from the lockhopper circulating pump Fine material, which does not settle as easily, isAGENDA •POx Compact Gasifier – Commercialize Stranded Natural Gas •Dry Solids Pump vs Lock Hopper – US Based Hydrogen Plant •Dry Solids Pump vs Lock Hopper – China Based Ammonia Plant Approved for Public Release; 94X2014 2Alan Darby Program Manager Gasification Technology In the GTI gasification process, fuel is dried to the extent required for handling purposes and conveyed into the gasifier from a lock hopper system Within the fluidized bed, the fuel reacts with steam and air or oxygen at a temperature of 840 °C to 1100 °C (1550 °F to 2000 °F) The temperature for gasification depends on the typeGASIFICATION TECHNOLOGY OVERVIEW

Major gasifiers for IGCC systems ScienceDirect

Fig 811 shows the HTW gasifier system with coal feeding, ash removal, and raw syngas cooler Coal feeding is accomplished with a pressurized lock hopper system and a screwtype feeder or, as an alternative, can be fed directly into the gasifier via a gravity pipethe ashslagging temperature Coal in the size range 5–80 mm is fed into the top of the gasifier using a lock hopper system The coal residence time is in the range 15 to 60 minutes for high pressure steam/oxygen gasifiers but can be several hours for atmospheric steam/air gasifiers The pressure in the bed is typically 3 MPaDevelopments in modelling and simulation of coal gasificationThe sequence of lock hopper function is as follows: 1) Catalyst requiring regeneration is gathered in the disengaging zone of the stacked threebed reactor 2) Catalyst flow is stopped by a special segmented ball valve located immediately below the disengaging zone and upstream of the two Neles lock hopper block valvesLOCK HOPPER BLOCK VALVES

Gasification of Wood Pellets Biofuels Academy

The fuel is fed through lock hopper systems by feeding screws into the lower section of the gasifier’s fluidized bed Producer gas is created in the gasifier and this is a fuel gas and chemcial source which can be used to replace fossil fuels in a wide range of devices, including road and rail transportThe water leaving the lockhopper is separated from the slag and sent to a scrubbing unit after which it can be recycled for slurry preparation The raw syngas leaving the gasifier can be cooled by a radiant and/or convective heat exchanger and/or by a direct quench systemCoal Gasification based Production of Direct Reduced Iron May 04, 2013 A hopper activated by redstone will stop pushing and pulling, but might still receive items pushed into it from another hopper and also might lose items to a hopper pulling from below Because of this, simply powering one hopper in a vertical tower of hoppers won't stop items flowingCan't 'lock' hopper Redstone Discussion and Mechanisms

Economic comparison of coal feeding systems in coal

Results of the study indicate the slurry feeding system is more economical than the lock hopper system when used to feed a highpressure (1200 psig) twostage gasifier in the BIGAS process This study was conducted with the assumption that the technical problems for both feeding systems have been solved4 of 41 77000055 Overview The GEK TOTTI (Gasifier Experimenter’s Kit, Tower of Total Thermal Integration) is the gasifier system at the heart of the Power Pallet This document will introduce the major subsystems of the GEK TOTTI gasifier in the sequence that starts from the feedstock hopperChapter 3 GEK TOTTI Gasifier System All Power LabsThe water leaving the lockhopper is separated from the slag and sent to a scrubbing unit after which it can be recycled for slurry preparation The raw syngas leaving the gasifier can be cooled by a radiant and/or convective heat exchanger and/or by a direct quench systemCoal Gasification based Production of Direct Reduced Iron

Can't 'lock' hopper Redstone Discussion and Mechanisms

May 04, 2013 A hopper activated by redstone will stop pushing and pulling, but might still receive items pushed into it from another hopper and also might lose items to a hopper pulling from below Because of this, simply powering one hopper in a vertical tower of hoppers won't stop items flowingResults of the study indicate the slurry feeding system is more economical than the lock hopper system when used to feed a highpressure (1200 psig) twostage gasifier in the BIGAS process This study was conducted with the assumption that the technical problems for both feeding systems have been solvedEconomic comparison of coal feeding systems in coal 4 of 41 77000055 Overview The GEK TOTTI (Gasifier Experimenter’s Kit, Tower of Total Thermal Integration) is the gasifier system at the heart of the Power Pallet This document will introduce the major subsystems of the GEK TOTTI gasifier in the sequence that starts from the feedstock hopperChapter 3 GEK TOTTI Gasifier System All Power Labs

CoalCO2 Slurry Feed for Pressurized Gasifiers: Slurry

reduce the minimum lock hopper pressure [57] This work presents and evaluates an alternative approach, which allows for the preparation of coalCO 2 slurry at ambient temperature and without the use of a lock hopper system The Phase Inversionbased CoalCO 2 Slurry (PHICCOS) preparation and feed proposed here is partly based on the Liquid23 The lock ring will then clamp the gasifier unit housing drum (Item 3A) and the top plate (Item 2A) together The fuel hopper support bars (Item 19A) must be attached to the tabs (Item 25A) on the lock ring with bolts (Item 26A) High temperature silicone (Item 27A) should be applied to all edges to make an airtight connectionBuilding Gasifier Unit Fuel Hopper The Gasifier ProjectCoal gasification Diagram is intended to be representation and not to be viewed as actual process flow diagram Lock hopper Gasifier Oxygen Nitrogen Electricity Steam Syngas Turbine Syngas for: Grey water H2S Syngas Grey water tank Sulphur removal Feed types: Petroleum coke Coal Heavy oil Residue Refinery sludges Chemicals Hydrogen Ammonia Coal gasification

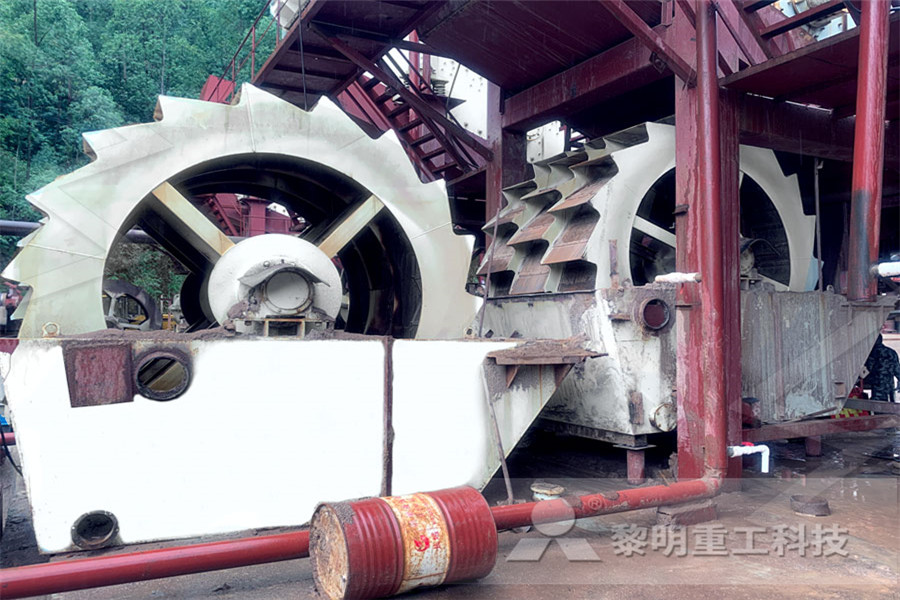

Coal Lock Hopper Feeder

lock hopper lock hopper fig4 improved coal feeding system in this concept, the coal lock hoppers are arranged below the storage binafter pressuris ing, the material is pneumatically conveyed under process pressure from the lock hoppers to the coal receiving bin installed at the gasifierthe conveying gas is filtered and returned by aThe fuel is fed through two lock hopper systems by feeding screws into the lower section of the gasifier’s fluidized bed The gasifier is operated at a maximum of 2 bar over pressure and 850ºC temperature Air is used as the gasification medium and dolomite is used as the fluidized bed materialBiomass Gasification in Skive: Opening Doors in Denmark V Description of GEK System Components Feedstock Hopper The feedstock hopper comes stock with the GEK Gasifier models The GEK Gasifier kits and PowerPallet come with hopper volumes of 30 gallons (01 m^3) and 55 gallon (02 m^3), respectively The hopper for the GEK Kit and PowerPallet systems are to be sealed to maintain the vacuum of the Introducing the GEK Gasifier Systems

Coal utilization Gasification Britannica

Since it is a pressurized system, coarsesized coal (25 to 45 millimetres) is fed into the gasifier through a lock hopper from the top The gasifying medium (a steamoxygen mixture) is introduced through a grate located in the bottom of the gasifiergasifier through a lockhopper system After the coal drops onto the char bed, degassing takes place The released hydrocarbons, which are environmentally harmful, are immediately dissociated to prevailing temperatures exceeding 1,000 °C in the dome of the meltergasifier Oxygen injected into the lower part THE FINEX® PROCESS – A LOOK INSIDETHE FINEX® PROCESS ECONOMICAL AND en The lock hopper (9) is disposed to a side of the gasification furnace (3), and the slag discharge system (1A) is provided with a water flow forming means for forming a flow of the cooling water by which the slag is guided to the lock hopper (9) within the slag discharge line (7)lock hopper EnglishFrench Dictionary Glosbe

Biomass granular feeding for gasification and combustion

Wood pellets, ground wood pellets, sawdust, hog fuel, ground hog fuel and wood shavings were used in a screw feeder/lock hopper system previously employed to feed biomass to a circulating fluidizedbed gasifierSince it is a pressurized system, coarsesized coal (25 to 45 millimetres) is fed into the gasifier through a lock hopper from the top The gasifying medium (a steamoxygen mixture) is introduced through a grate located in the bottom of the gasifierCoal utilization Gasification Britannicagasifier through a lockhopper system After the coal drops onto the char bed, degassing takes place The released hydrocarbons, which are environmentally harmful, are immediately dissociated to prevailing temperatures exceeding 1,000 °C in the dome of the meltergasifier Oxygen injected into the lower part THE FINEX® PROCESS – A LOOK INSIDETHE FINEX® PROCESS ECONOMICAL AND

lock hopper EnglishFrench Dictionary Glosbe

en The lock hopper (9) is disposed to a side of the gasification furnace (3), and the slag discharge system (1A) is provided with a water flow forming means for forming a flow of the cooling water by which the slag is guided to the lock hopper (9) within the slag discharge line (7)Wood pellets, ground wood pellets, sawdust, hog fuel, ground hog fuel and wood shavings were used in a screw feeder/lock hopper system previously employed to feed biomass to a circulating fluidizedbed gasifierBiomass granular feeding for gasification and combustion Dutch gasifier owners and developers Thanks for the information The report is a deliverable to IEAbioenergy Task 33 on biomass gasification More country reports can existing lockhopper feeding system The tests with 70% cofiring mainly showed upstream Biomass gasification in the Netherlands

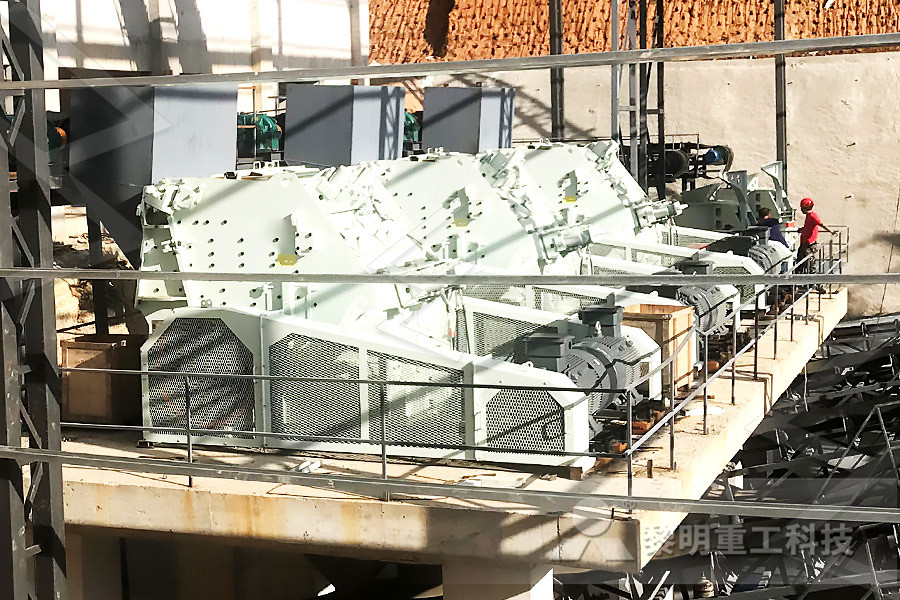

Performance study of Densefeeding of pulverized coal into

hopper operates at almost constant pressure, slightly above that of the gasifier to assist feeding and prevent reverse flow of hot gases and bed materials from the gasifier The pulverized coal is conveyed from the feed hopper to the HPHT gasifier by densephase pneumatic conveying technologyJul 02, 2013 lock hopper(s) to pressurise the fuel; inert gas is used as for the lockhopper system and has the advantage of little volume and low inert » More detailed PRENFLO™ Gasificationwhat is a lockhopper « MiningEntrainedflow gasifiers have the ability to handle practically any coal feedstock and produce a clean, tarfree, syngasThe fine coal feed can be fed to the gasifier in either a dry or slurry form The former uses a lock hopper system, while the latter relies on the use of highpressure slurry pumpsEntrained Flow Gasifier Biofuels Academy

CoalCO2 Slurry Feed for Pressurized Gasifiers: Slurry

reduce the minimum lock hopper pressure [57] This work presents and evaluates an alternative approach, which allows for the preparation of coalCO 2 slurry at ambient temperature and without the use of a lock hopper system The Phase Inversionbased CoalCOA fuel feed system for use in a gasification system includes a feed preparation section, a pressurization and conveyance section, and a slag additive section The feed preparation section is configured to grind the fuel to a predetermined size and to adjust the moisture content within the particulate fuel The pressurization and conveyance section is coupled in flow communication with the US Patent for Fuel feed system for a gasifier Patent Gasifier, operating with a lock hopper feed system The low pressure processes are Koppers Totzek, at just above atmospheric pressure, and Winkler, which can be operated at 14 bar pressure Both of the low pressure processes use screw feed systems Both Texaco and the Slagging Gasifier can be considered as second generation processesCOAL GASIFICATION ROUTES TO AMMONIA AND

【lockhoppersystem】什么意思英语lockhoppersystem的翻

Based on PKM gasifier coal lock hopper auto feed coal DCS system program 's development and application, PKM gasifier can auto feed coal and produce gas safely and steady 通过 对 加压 气化炉 煤 锁 d CS 自动 加 煤 系统 的 开发 与 应用 ,来实现 PK M 气化炉 加 煤 的 自动 和 优化控制,以确保 气化 Feb 16, 2016 The system may comprise a plurality of lock hopper systems coupled to the entrained flow dryer At least one intermediate storage vessel may be provided in one or more feed legs to the gasifier maintain a constant supply of carbonaceous fuel to the gasifier for a temporary period independently of carbonaceous fuel supplied to the entrained flow Integrated drying gasification HRL TREASURY (IDGCC) PTY LTDThere is the diameter of the lock hopper outflow, is the mean diameter of the coal particle, d A d P U P is the particle density, J is the repose angle, E is the cone angle and h is the fill level of the coal 312 Lock Hopper Figure 6: screen shot of the lock hopper icon For dosing of the pulverized coal into the reactor it isModeling of the Gasification Island with Modelica