jaw crusher hardening

2020-04-05T07:04:44+00:00

Jaw Crushers McLanahan

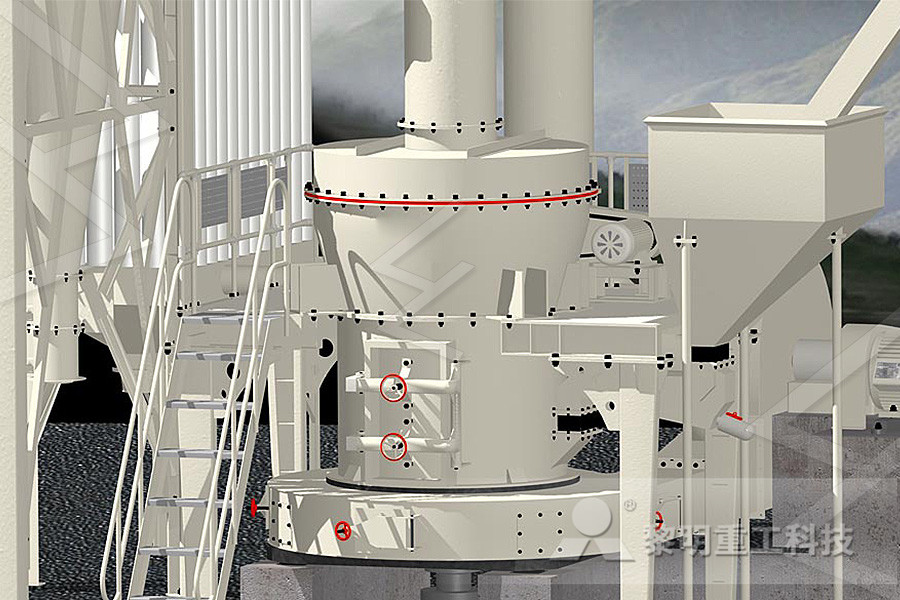

Jaw Crushers Jaw Crushers are used to reduce the size of many different types of materials in many applications The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw CrushersIn Mineral Processing Design and Operations (Second Edition), 2016 42 Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw) The faces of the plates are made of hardened steel Both plates could be flat or the fixed plate flat and the moving plate convexJaw Crusher an overview ScienceDirect Topicscrusher tools EG Jaw liners are subject to numerous pressure and impact stresses Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher type for the abrasive content of the material to be crushedR Crusher Wear Parts Reference Guide

Crushers an overview ScienceDirect Topics

Jaw crushers find a wide application for brittle materials For example, they are used for comminution of porous copper cake A Fritsch jaw crusher with maximal feed size 95 mm, final fineness (depends on gap setting) 03–15 mm, and maximal continuous throughput 250 Kg/h is shown in Fig 28Crusher Wear Parts Cone Crusher Wear Parts; Crusher Wear Analysis; Epoxy Crusher Backing; Gyratory Crusher Wear Parts; Jaw Crusher Wear Parts; Crushing Alloys Austenitic Manganese Steel; Chrome White Iron ESCO CorporationThe jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are hardening of the manganese jaw dies, and maintain the best nip angle for maximum through put One piece jaw die rotation and replacement C series jaw crushers Wear parts application guide

High Manganese Steel Heat Treatment From JYS Casting

Highmanganese steel heat treatment is the high manganese steel castings heated to the temperature of carbide solution, and insulation for a certain time, and then quickly cooled in water to form a single Austenite, so that its strength and toughness greatly improved to achieve processing Hardening purposeThe hardness values of failed crusher jaw samples were higher than that of sound crusher jaws from the working surface to the depth of 95 mm while it is lower from depth of 50 mm to 120 mm (Figures 2 to 5) This hardness gradient indicates that there is no uniform plastic flow during work hardening of failed crusher Workhardening behaviour and microstructural analysis of Workhardening Behaviour and Microstructural Analysis of Failed Austenitic Manganese Steel Crusher Jaws large amount of carbon gives these steels their high impact toughness and high strain hardening rate capacity, which gives them their excellent impact abrasion resistance Hence, solution treatment makes these steels very soft (190 HB)Workhardening Behaviour and Microstructural Analysis of

How to Change Jaw Liners Pilot Crushtec

New jaw liners are installed at the top of the crushing chamber; This procedure will allow for good work hardening of the manganese jaw liners, and maintain the best nip angle for maximum though put One piece jaw liner rotation and replacement After a new jaw liner installation, rotate the single piece jaw liner when 30% of the tooth profile Jan 14, 2014 high manganese casting parts for jaw crusher, jaw plates, toggle plates, wedges Leiyue manufacture an extensive range of wear and spare parts in Shanghai,China for the worlds most popular crushing HIGH MANGANESE CASTING PARTS FOR JAW CRUSHER, JAW International Journal of Materials Engineering 2015, 5(2): 1722 DOI: 105923/jijme01 Material Selection for Crusher Jaw in a Jaw CrusherMaterial Selection for Crusher Jaw in a Jaw Crusher

Metallurgy Alloys Columbia Steel Casting Co, Inc

Unequaled toughness and good resistance to abrasion is provided by work hardening when service conditions have sufficient impact: Liners for gyratory, cone, and jaw crushers, roll shells, shredder The Ultimate Work Hardening Manganese Steel (1114% MN / 1% C) With continued impact and /or compression it will surface harden to over 550 BRINELL small jaw crusher for li ne and vibrating screens australian made; image of single and double toggle jaw crusherjaw crushermade of hardened manganese steelWhat Material Is Better Used in the Jaw Crusher Plates FTM Mining Oct 10, 2017 High manganese steel is the traditional material used to make the jaw plates of jaw crusher, which has good toughness and good deformation hardening used manganese jaw crusher usa diehslangenhovencoza

CRUSHER WEAR PARTS

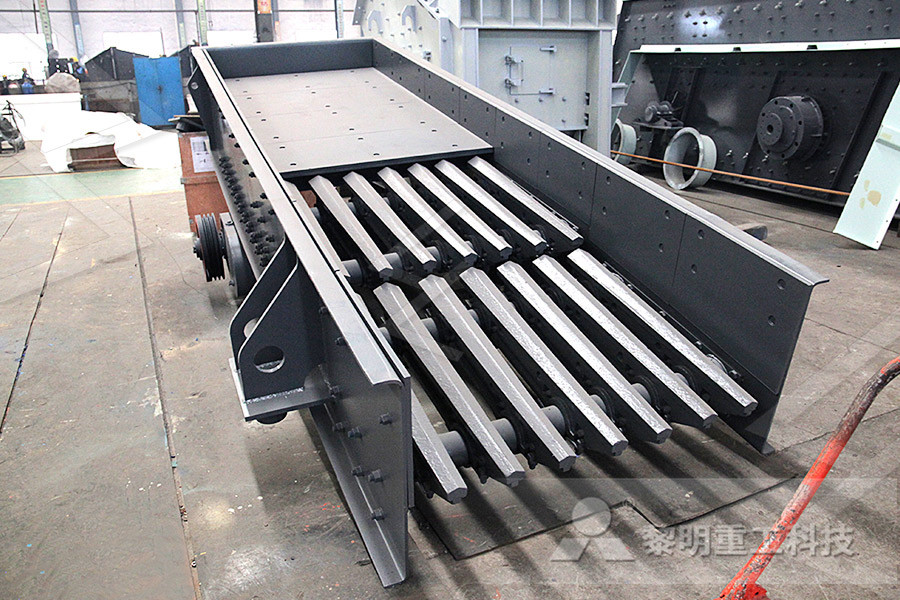

Jaw Crusher Wear Parts 3 Impactor Crusher Wear Parts WEAR PARTS OVERVIEW PAGES 4 11 Work hardening Work hardening of a jaw liner, is the strengthening of the liner The design of some jaw crushers requires wedges, to ensure that the jaw International Journal of Materials Engineering 2015, 5(2): 1722 DOI: 105923/jijme01 Material Selection for Crusher Jaw in a Jaw CrusherMaterial Selection for Crusher Jaw in a Jaw Crusher JXSC Mine Machinery Factory is crusher manufacturers and jaw crusher for sale Jaw crusher is a kind of rock crusher equipment This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

(PDF) Material Selection for Crusher Jaw in a Jaw Crusher

Material Selection for Crusher Jaw in a Jaw Crusher Equipment Tool steel AISI 06 (Oil hardening cold work) Lowest density It ranked third in yield strength, second highest in Toggle plates for these jaw crushers are of threepiece construction, consisting of an iron center section (2) to which are bolted two replaceable bronze ends (1 get price jaw crusher2cmade of hardened manganese steel jaw crusherJaw Crusher,Made Of Hardened Manganese Steelcrusher made of hardened manganese steel jaw crusher made of hardened manganese steel jaw crusher,made of hardened manganese steel Wear resistant steels and alloys Springer jaw crusher,made of hardened manganese steel, and t3% Mo have sometimes been used in place of austenitic manganese steels tility and impact strength is widely used for linings in crushers jaw crusher made of hardened manganese steel

Hammer Crusher Core

Ge alloy hammer crusher high hardness excellent in wearresistant material is an excellent, have been widely used in crushing machine supporting frame and the hammer crusher, the highchromium alloy Coarse crushing: jaw crusher is commonly employed for primary crushing Its model is determined by the maximum particle size and the output capacity you require Secondary crushing: the type of the crusher machine is determined by the hardness of the material For soft and brittle materials like limestone, impact crusher Stationary Crushing Plant Stationary Crushing Manganese steel was invented by Sir Robert Hadfield in 1882 and was unique in that it combined high toughness and ductility with exceptional workhardening capacity The material developed for crusher Tips For Buying Crusher Wear Liners Crusher Wear Parts

Wear Parts for Cone and Jaw Crushers

Quarry Academy 2005 The product shape is not acceptable zMake sure the crusher is choke fed with a minimum of stops for idling zSelect a CSS that is close to the product size with high demands on Cement Plant Crushing Line CFTC have the ability to built 600t/d2000t/d cement production line independently, And has extensive experience in the design and construction, built many cement plantCement Plant Crushing Line CFTC stone crusher plant Manganese steel was invented by Sir Robert Hadfield in 1882 and was unique in that it combined high toughness and ductility with exceptional workhardening capacity The material developed for crusher Tips For Buying Crusher Wear Liners Crusher Wear Parts

Wear Parts for Cone and Jaw Crushers

Quarry Academy 2005 The product shape is not acceptable zMake sure the crusher is choke fed with a minimum of stops for idling zSelect a CSS that is close to the product size with high demands on Cement Plant Crushing Line CFTC have the ability to built 600t/d2000t/d cement production line independently, And has extensive experience in the design and construction, built many cement plantCement Plant Crushing Line CFTC stone crusher plant Jaw crusher is an indispensable coarse crushing equipment in mine crushing production line, which is usually used for primary crushing of materials The jaw crusher consists of a working chamber Which materials can be selected for the jaw plate of the

Jaw Crusher Css ratrauerbegleitungde

Getting the most out of your jaw crusher tips for work hardening jaw liners reduce the amount of fines fed into the crushing chamber run the jaw at a larger css for a day with new liners jaw crusher speed must run slow enough for the jaw Impact crusher can crush aggregates with excellent granularity because of flexible and variable adjustment methods, making the diameter of final aggregates that can be produced reach 05mm, 510mm, 1015mmIn addition, people are all inclined to purchasing an impact rock crusher Impact Rock Crusher—Ideal Aggregates Making Machine Jaw Crushers Jaw Crushers are used to reduce the size of many different types of materials in many applications The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw CrushersJaw Crusher Shaft Hardning adiosholandanl

jaw crusher 2cmade of hardened manganese steel

jaw crusher 2cmade of hardened manganese steel Material Testing EquipmentLaboratory Jaw Crusher The RSEP Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, Cone Crusher Liner surface hardening Because the material of the sampled cone crusher liner (lining plate) is high manganese steel, the lining plate is subjected to a huge impact load during the operation of the cone crusher, so that it has a good work hardening effect Cone Crusher Analysis of the Wear Failure of Cone Crusher Liner at The work hardening High Manganese Jaw Plates have a longevity, incomparable with other models of Jaw Crushers Long Life of Jaw Plates, much longer life of bearings, lower power consumption and high production mark Deepa Primary Crushers Primary Jaw Crusher, जॉ क्रशर in Kurichi, Coimbatore

Jaw Crusher Made Of Hardened Manganese Steel

Jaw Crusher 2cmade Of Hardened Manganese Steel Jaw crusher 2cmade of hardened manganese steel jaw crusher made of hardened manganese steel high manganese steel is the traditional material jaw crusher jaw which has good toughness also has good deformation hardening 5990 products China Jaw Crusher Steel Plate manufacturers Select 2019 high quality High Grade Manganese Steel with Chromium Alloying Crusher Jaw Plate High Manganese Steel Casting Tooth Plate for Jaw Rock Stone Crusher WORK HARDENING Work hardening of a jaw stone crusher jaw plate material gradeJaw crusher jaw plate of the short life of the main factors are: jaw plate material selection is not appropriate Jaw plate material often use high manganese steel, its toughness is good, high strength, process is good, have a certain hardness, in the larger impact or contact stress, high manganese steel surface layer will quickly produce severe hardeningTechnology – Jaw Crusher Wear Parts, Cone Crusher Wear

Jaw Crusher Primary Jaw Crusher Manufacturer from Coimbatore

The work hardening High Manganese Jaw Plates have a longevity, incomparable with other models of Jaw Crushers Long Life of Jaw Plates, much longer life of bearings, lower power consumption and high production mark Deepa Primary Crushers