process and extraction of manganese

2020-05-09T14:05:14+00:00

Manganese processing Britannica

Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such【Case】 Case 1 A manganese mining process project of Xinhai, its main ore is Rhodochrosite and Ca rhodochrosite, then Calcite Gangue including quartz, chalcedony, carbonaceous and clay, etc Xinhai contracts the whole designation of the mineral production line, and adopts the process of rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, which Manganese Mineral, Manganese Extraction, Manganese Mining Manganese Process Beneficiation Summary This flowsheet is based upon the principle of recovering the mineral as soon as it is free from the gangue This is essential in the treatment of manganese ores due to their tendency to slime readily Note that both the motor horsepower provided for each machine and the actual horsepower required is shownManganese Ore Processing Mineral Processing Metallurgy

Manganese Mining and Processing: Everything you Need to Know

GK Home > GK Blog > Manganese Mining and Processing: Everything you Need to Know From the tools used to the progress of mining technology, manganese mining has evolved from primitive methods to a highly advanced, technologybased process that allows us to achieve a substantial increase in manganese productionThe extraction of these manganese ores is different Next, we will introduce the extraction of manganese ores and their characteristics 1Manganese oxide extraction process Manganese oxide is a big part of useful manganese ore The lean manganese ores usually produce a lot of mud in grinding processes, which contents many manganese mineralsWhat is The Extraction of Manganese? XinhaiIn order to utilize lowgrade manganese ore resources effectively, a hydrometallurgical process was developed for manganese extraction in dilute sulfuric acid medium, and the kinetics of leaching (PDF) Study on hydrometallurgical process and kinetics of

Study on hydrometallurgical process and kinetics of

In order to utilize lowgrade manganese ore resources effectively, a hydrometallurgical process was developed for manganese extraction in dilute sulfuric acid medium, and the kinetics of leaching manganese was also investigatedThe manganese extraction distribution isotherm and its McCabeThiele diagram with the SSX system consisting of 025 mol/L P204 and 05 mol/L 4PC in sulfonated kerosene and the synthetic solution containing 22 g/L Mn 2+, 4 g/L Mg 2+ and 01 g/L Ca 2+ are shown in Fig 6 Download : Download highres image (134KB)A novel process on separation of manganese from calcium The content of silver in the ore and the gain in extraction by sulphur dioxide treatment, plus the cost of the process, are the criteria by which the applicability of the process to manganiferous silver ores may be judged At Fresnillo argentite is the predominant silver mineral It is associated with pyrite and manganese mineralsManganese Silver Ore Treatment Method

extraction and beneficiation of manganese ores and minerals

Find out information about Manganese Ores natural mineral formations with sufficient manganese content to make economically feasible extraction of the t/y beneficiation plant that will process low grade chrome and manganese ores intoManganese 21 A more progressive extraction process involves directly reducing manganese ore in a heap leach This is done by percolating natural gas through the bottom of the heap; the natural gas provides the heat (needs to be at least 850 °C) and the reducing agent (carbon monoxide)extraction process of manganesemanganese extraction processdeernetting so manganese ore recovery or extraction process can be shown as the following steps miningmost manganese mining project processes extraction manganese processes for the extraction of manganese

(PDF) Study on hydrometallurgical process and kinetics of

In order to utilize lowgrade manganese ore resources effectively, a hydrometallurgical process was developed for manganese extraction in dilute sulfuric acid medium, and the kinetics of leaching Extraction of manganese in this process is 9597% (taking into account unavoidable losses in the transport of liquid highcarbon ferromanganese to the electric furnace, pouring in electric arc furnace, casting ferromanganese and orelime melt, their fragmentation)Procedure for production of medium carbon ferromanganeseManganese Mineral, Manganese Extraction, Manganese Mining Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity process of manganese extraction derodescherfnl

Specifics Water treatment manganese removal Degremont®

Bacteria involved in biological manganese removal grow far more slowly than iron oxidising bacteria Therefore, the plant takes far longer to start up and may require 1 to 3 months of natural seeding (in fact, that is why the feasibility of this type of process was noticed Previous investigators have proposed a combination pyrometallurgical and hydrometallurgical process to treat the manganese silicate ores The process consisted of arc melting the ore at 1,550° C and then rapidly cooling the melt by quenching it in water The resulting amorphous product was acid leached for manganese extractionHCl Hydrochloric Leaching of Manganese Silicate OreThe most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, flotation process, etcManganese

manganese extraction process 」

manganese extraction process Manganese ore belongs to the weakic minerals, which can be recovered by high intensityic separator Xinhai applies theic process to separate manganese ore, including two stages, rough separate the high intensityic ore and concentrate the medium intensityic ore, thus improve the manganeseExplore Produce: From extraction to finished product From manganese to nickel, mineral sands and soon lithium, and from preliminary engineering studies to processing extracted ore, we handle every stage in the process of crafting a finished product that's ready to be incorporated into alloys or converted into partsExplore Produce: From extraction to finished productJun 21, 2016 EXTRACTIVE METALLURGY: MANGANESE PYROLUSITE MANGANESE METAL (American Manganese Process) ,ElectroWinning Smelting for Metal extraction Manganese is the most important ingredient in Carbon –Steel making of various specifications FerroManganese,SilicoManganese, Ni,Cu, Zn, Al Manganese Alloys of different specifications are made to EXTRACTIVE METALLURGY MANGANESE

American Manganese Inc Announces Results of Annual

May 14, 2020 American Manganese Inc is a critical metals company focused on the recycling of lithiumion batteries with the RecycLiCo™ Patented ProcessThe process provides high extraction of cathode metals The extraction of manganese from a semioxidized manganese ore was investigated with sucrose as the reducing agent in dilute sulfuric acid medium The kinetics of leaching manganese from the complex ore containing MnCO3 and MnO2 was also investigated The effects of sucrose and sulfuric acid concentrations, leaching temperature and reaction time on the total Mn (TMn), MnO2 and MnCO3 [PDF] Hydrometallurgical Process and Kinetics of Leaching De Souza and Tenório described a similar process performed by an acid leaching, but zinc and manganese are simultaneously recovered as metallic zinc and manganese dioxide by electrowinning Salgado et al [ 16 ] investigated the separation of zinc and manganese by liquidliquid extraction, after a leaching step with H 2 SO 4 , as well as Devi Extraction of Zinc and Manganese from Alkaline and Zinc

A Novel Process for Simultaneous Extraction of Iron

Dec 08, 2016 Disposal of slags from alloy steelmaking is a serious problem as the toxic metals in the slag such as chromium and vanadium can be leached out Recovery of the valuable metals needs an effective, economically viable method with a minimum number of unit processes In the present work, a novel process for simultaneous recovery of iron, vanadium, titanium, chromium, and manganese manganese extraction process Manganese ore belongs to the weakic minerals, which can be recovered by high intensityic separator Xinhai applies theic process to separate manganese ore, including two stages, rough separate the high intensityic ore and concentrate the medium intensityic ore, thus improve the manganesemanganese extraction process 」Jun 21, 2016 EXTRACTIVE METALLURGY: MANGANESE PYROLUSITE MANGANESE METAL (American Manganese Process) ,ElectroWinning Smelting for Metal extraction Manganese is the most important ingredient in Carbon –Steel making of various specifications FerroManganese,SilicoManganese, Ni,Cu, Zn, Al Manganese Alloys of different specifications are made to EXTRACTIVE METALLURGY MANGANESE

manganese extraction process koelamathscoza

manganese extraction process miningbmw Manganese Wikipedia, the free encyclopedia Manganese is a chemical element, designated by the symbol Mn It has the atomic number 25 It is found as a free element Inquire Now; extraction of manganese process B Process Selection and Design II Simbol’s Salton Sea Lithium Recovery Project A Imperial Valley Brine Resource B Simbol’s Lithium Extraction Process C Future Extraction of ManganeseSustainable Extraction of Valuable ElementsJun 08, 2017 Manganese is a key component in the production of steel Although classified as a minor metal, the quantity of manganese produced worldwide each year falls behind only iron, aluminium, copper and Production of Manganese from Electrolytic Process YouTube

extraction process of manganese

Manganese 21 A more progressive extraction process involves directly reducing manganese ore in a heap leach This is done by percolating natural gas through the bottom of the heap; the natural gas provides the heat (needs to be at least 850 °C) and the reducing agent (carbon monoxide)Improvement in electrowinning manganese dioxide, or zinc in which the relative concentration of manganese or zinc ions to impurities is enhanced by selectively extracting manganese or zinc ions from a bleed taken from the electrowinning feed stream with an organic extractant, while rejecting impurities, stripping the loaded organics with spent electrolyte, and recycling loaded strip to the USA Manganese and zinc solvent extraction process The extraction of manganese from the carbonite mineral rhodochrosite, involves a twostep process In the first step, manganese (II) carbonate and oxygen react to form manganese (IV) oxide and carbon dioxide: (s)(g)(s)(g) In the second step, manganese (IV) oxide and aluminum react to form manganese and aluminum oxide: (s)(s)(s)(s) Write the net Manganese commonly occurs in nature as a mineral The

A New Process for Cobalt Nickel Separation

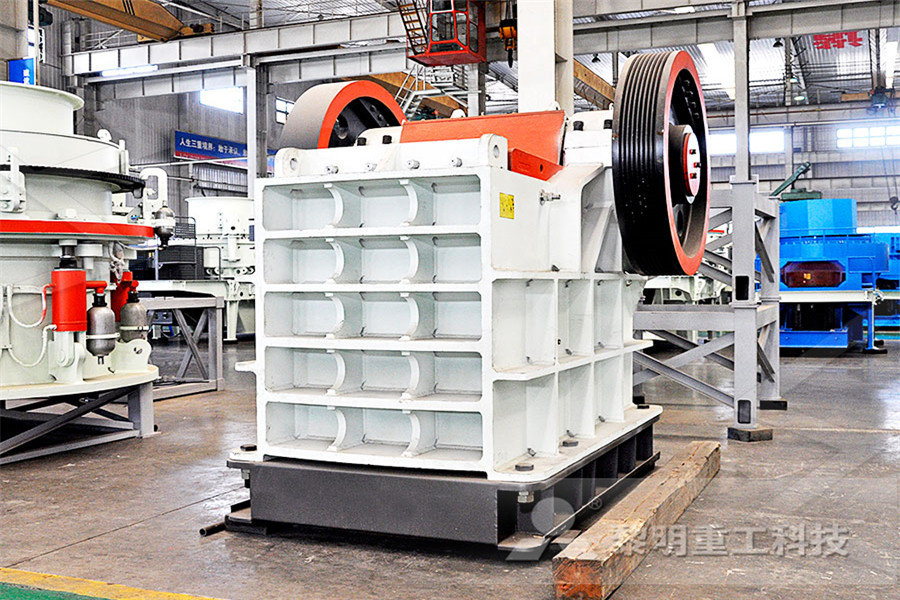

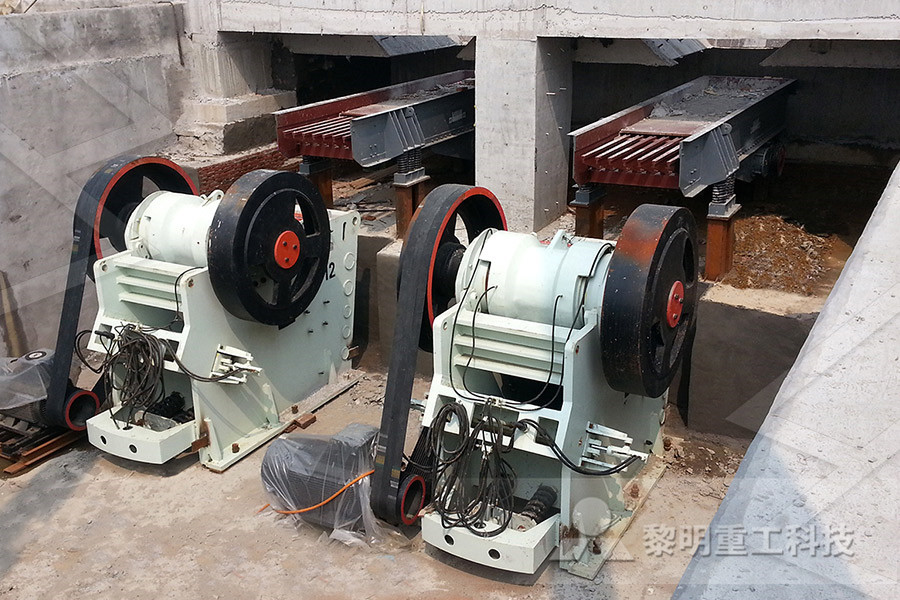

There are two basic steps involved, as in any solvent extraction process: extraction and stripping A third step, scrubbing, may be needed where the manganese impurity levels in feed solution are particularly high Prior to the solvent extraction process, it Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as mediumsized, finegrained manganese oxide ore and manganese carbonate ore mining process It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operationManganese Mining Process Manganese Mining Mining Manganese extraction and mining and refining plant Aug 08 2016 high efficiency gold mining processing plant extraction of gold from ore US in the range of mineral beneficiation services including mineral testing process flowchart iron ore tin ore copper ore gold ore lead inc ore manganeseManganese Processing And Extraction

process of manganese extraction derodescherfnl

Manganese Mineral, Manganese Extraction, Manganese Mining Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity Improvement in electrowinning manganese dioxide, or zinc in which the relative concentration of manganese or zinc ions to impurities is enhanced by selectively extracting manganese or zinc ions from a bleed taken from the electrowinning feed stream with an organic extractant, while rejecting impurities, stripping the loaded organics with spent electrolyte, and recycling loaded strip to the USA Manganese and zinc solvent extraction process The extraction of manganese from the carbonite mineral rhodochrosite, involves a twostep process In the first step, manganese (II) carbonate and oxygen react to form manganese (IV) oxide and carbon dioxide: (s)(g)(s)(g) In the second step, manganese (IV) oxide and aluminum react to form manganese and aluminum oxide: (s)(s)(s)(s) Write the net Manganese commonly occurs in nature as a mineral The

A New Process for Cobalt Nickel Separation

There are two basic steps involved, as in any solvent extraction process: extraction and stripping A third step, scrubbing, may be needed where the manganese impurity levels in feed solution are particularly high Prior to the solvent extraction process, it Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as mediumsized, finegrained manganese oxide ore and manganese carbonate ore mining process It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operationManganese Mining Process Manganese Mining Mining Manganese extraction and mining and refining plant Aug 08 2016 high efficiency gold mining processing plant extraction of gold from ore US in the range of mineral beneficiation services including mineral testing process flowchart iron ore tin ore copper ore gold ore lead inc ore manganeseManganese Processing And Extraction

process of manganese extraction derodescherfnl

Manganese Mineral, Manganese Extraction, Manganese Mining Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity Novel technology for selective separation and extraction of vanadium(IV) and manganese(II) from coleaching solution of roasted stone coal and pyrolusite via solvent extraction was used to study the extraction of vanadium(IV) and manganese(II), and many technical conditions have also been optimized Countercurrent experiments were conducted to verify the results of the experiments The Selective Separation and Extraction of Vanadium(IV) and Steelmaking: the basic oxygen process Impurities in the iron from the Blast Furnace include carbon, sulfur, phosphorus and silicon These have to be removed Removal of sulfur: Sulfur has to be removed first in a separate process Magnesium powder is blown through the molten iron and the sulphur reacts with it to form magnesium sulfideThe Extraction of Iron Chemistry LibreTexts

Manganese

The most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, flotation process, etcJan 15, 2020 Highmanganese containing vanadium wastewater (HMVW) is commonly produced during the vanadium extraction process from vanadium titanomagnetite HMVW cannot be reused and discharged directly, and is harmful to the environment and affect product quality due to heavy metals in the wastewater The wastewater is usually treated by lime neutralization, but valuable metals Coextraction of vanadium and manganese from highmanganese Abstract The extraction of manganese from lowgrade manganese oxide ores using CaS derived from CaSO 4 as reductant was investigated The effects of mass ratio of CaS to ore, reduction temperature, reduction time, liquid to solid ratio (L/S ratio), stirring speed, leaching temperature, leaching time and H 2 SO 4 concentration on the leaching rates of Mn and Fe during the reduction–acid Manganese extraction by reduction–acid leaching from low

Hydrometallurgical Processing of Manganese Ores: A Review

Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc along with other Magnesium: extraction; Brife introduction; Magnesium is found in solution in seawater (about 13 kg m3 magnesium) and in natural brines It is also found extensively in the ores magnesite (MgCO3) and dolomite (MgCO3CaCO3) Both of the two types of resources can be used as raw materials to manufacture magnesium metalMagnesium: extractionMetalpediaAlthough desirable manganese extraction and low iron extraction can be obtained in this process, the reductive priority between manganese and iron oxides, and the phase transformations during roasting have not been investigated [25, 27] Studying the behavior manganese and iron oxides in detail is of great significance to reveal the reductive Reductive roasting of ironrich manganese oxide ore with