mineral processing ore flotation separator

2020-02-28T14:02:15+00:00

Flotation ore dressing Britannica

mineral processing: Flotation separation Flotation is the most widely used method for the concentration of finegrained minerals It takes advantage of the different physicochemical surface properties of minerals—in particular, their wettability, which can be a natural property or one artificially changed by chemical reagentsMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaST Equipment Technology (STET) manufactures a Triboelectrostatic Mineral Separator that provides a high rate, continuous and completely dry method to beneficiate minerals and metals across a broad range of particle sizes (from relatively coarse at 600 microns to very fine, 12 microns)Minerals Separator ST Equipment Technology (STET)

Mineral Processing McClelland Laboratories Inc Reno (775

Mineral Processing If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separationAlibaba offers 871 mineral processing flotation separator products About 83% of these are mineral separator, 1% are separation equipment A wide variety of mineral processing flotation separator options are available to you, such as flotation separator, sprial separator, and magnetic separatorMineral Processing Flotation Separator, Mineral Processing 6 Separation and concentration Following milling, the ore is subjected to different processes according to its nature Pulp may require to be thickened ahead of these processes in large tanks called Thickeners, in which the solid component is allowed to settle and is raked towards the centre by large, rotating rakes while relatively clear water overflows into a peripheral drain or LaunderSeparation and Concentration Mineral Processing

Flotation Separator Mineral Processing, Flotation

Alibaba offers 873 flotation separator mineral processing products such as free samples6 Separation and concentration Following milling, the ore is subjected to different processes according to its nature Pulp may require to be thickened ahead of these processes in large tanks called Thickeners, in which the solid component is allowed to settle and is raked towards the centre by large, rotating rakes while relatively clear water overflows into a peripheral drain or LaunderSeparation and Concentration Mineral Processing Dolomite Mining Process Dolomite mining process is the solution of separating dolomite concentrate from Dolomite raw ore Based on mosaic structure of the Dolomite mine and years of mining process experiences, Xinhai applying Dolomite mining process of twostage crushing, washing, then threestage separating, flotation process will be used to process Dolomite with complex structuresProduction Line Xinhai Mineral Processing Plant

Mineral Extraction, Mineral Processing, Concentration of

5 Types of Phosphate Froth Flotation Process Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation difficulty and flotation types plete mineral processing equipment, rock crusher, gold wash plant, magnetic separator, magnetic separators, flotation machine, etc Gold Mining Equipment +86Mining Mineral Processing Equipment Manufacturer JXSCJul 08, 2015 Recently I visited a RockPhosphate Plant wherein I saw the Flotation Process in Operation Here is small video of the Flotation Process For more videos related to Mineral Processing visit my Flotation Process Mineral Processing YouTube

Production Line, Mineral Processing, Concentration of Ore

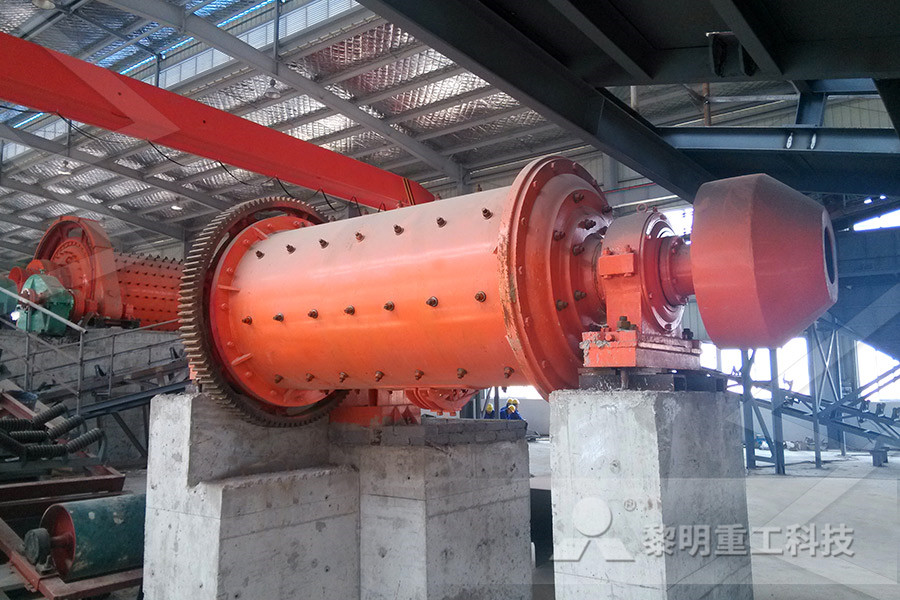

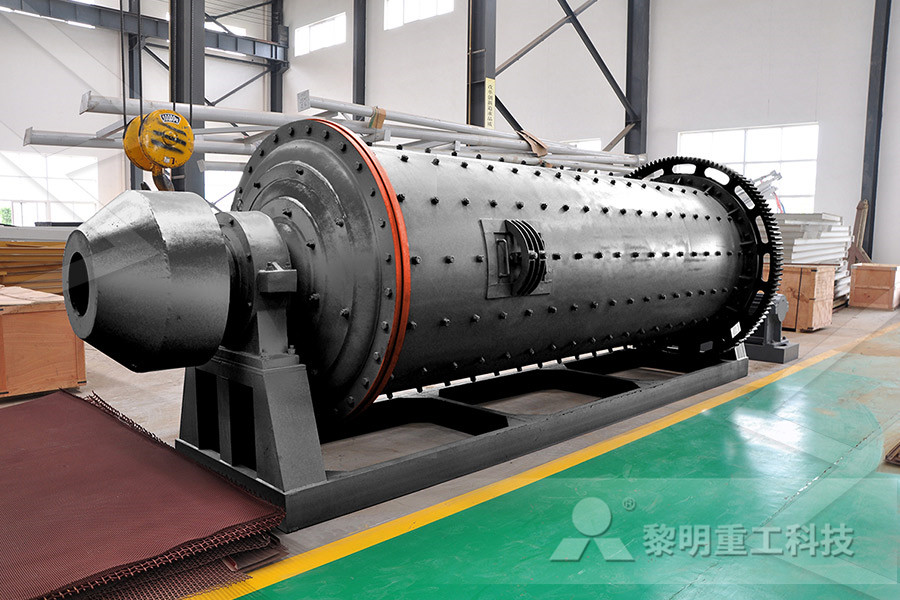

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on Some of the equipment is Xinhai independent research and development, and has been awarded national patentWolframite Mineral Processing Zircon Ore Mining Process Zinc Processing Plant Xinhai adopts gravity separation, magnetic separation, flotation, and roasting magnetic separation; used for strong magnetic iron ore, magnetic separation 【Application】 Magnetite Separation Production Line is used to single magnetite with simple ore propertiesMagnetic Separation Process Mineral Processing Plant Product DescriptionThe Spiral Classifiers are divided into single spiral classifiers and double spiral classifiers BesiAbout Ore Separation Spiral Classifier for Mineral Processing FOB price, Payment, OEM information, Mineral Separator from china on topchinasupplierOre Separation Spiral Classifier for Mineral Processing

Froth Floatation Process YouTube

May 05, 2010 Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in several processing industries Historically this was first used in the mining industryThe separation methods of Xinhai are generally gravity separationmagnetic separat Barite Mineral Processing Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation methogold mineral processing plant, mining ball mill for sale Froth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation Wikipedia

Mineral Processing EPC,Mineral Process Engineering, Ore

MINERAL PROCESSING EPC HaiWang provides optimized solutions for your mine, onestop service for mineral processing plant, include sample test, mine design, equipment manufacture, etc5 Types of Phosphate Froth Flotation Process Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation difficulty and flotation types variesMineral Flotation, Flotation Separation, Forth Flotation The separation methods of Xinhai are generally gravity separationmagnetic separat Barite Mineral Processing Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation methogold mineral processing plant, mining ball mill for sale

Froth flotation Wikipedia

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryMINERAL PROCESSING EPC HaiWang provides optimized solutions for your mine, onestop service for mineral processing plant, include sample test, mine design, equipment manufacture, etcMineral Processing EPC,Mineral Process Engineering, Ore 5 Types of Phosphate Froth Flotation Process Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation difficulty and flotation types variesMineral Flotation, Flotation Separation, Forth Flotation

Tungsten Ore Extraction Processing Wolframite

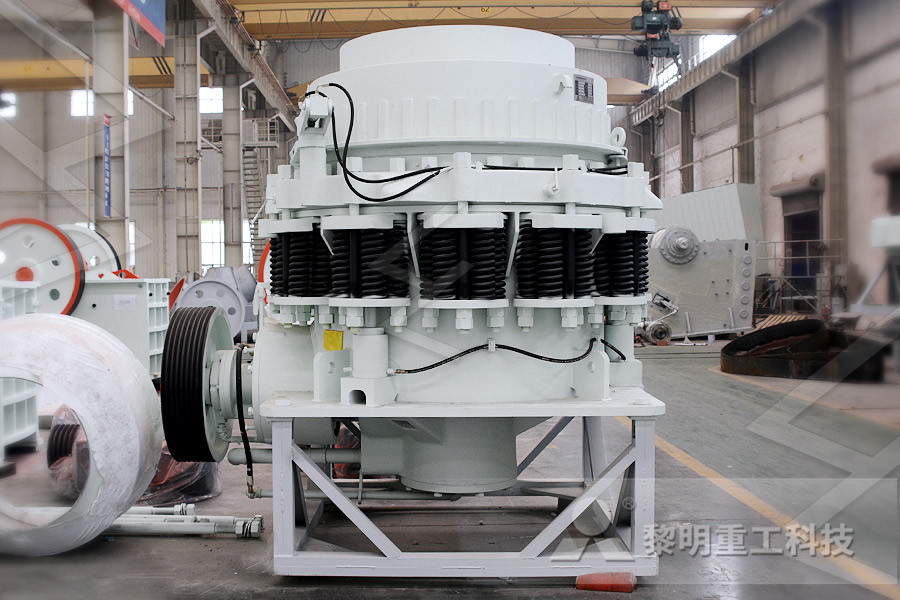

Jul 04, 2019 Tungsten mineral Processing flow How is tungsten extracted from its ore? The main beneficiation methods for tungsten ores are physical methods such as preconcentration, gravity concentration, flotation and magnetic separation; as for the refractory middling ore and lowgrade concentrate, prefer to chemical concentration wayMineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig Only jig can deal with the coarse fluorite ore Fluorite flotation equipment includes crusher, ball mill, flotation machine etc Jaw crusher is the primary crusher It is used in fluorite coarse crushing processFluorite Flotation Process,Fluorite Flotation Separation,Antimony Mineral Processing Process Introduction Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separationThis method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceAntimony Mineral Processing hotminingepc

Separation Mineral Technologies Group

Separation of particles with regards to their particle sizes are carried out through out the mineral processing circuit using different classifiers Classifiers use different methodologies and the right solution is chosen for the optimum result making it the most cost effective operationMineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig Only jig can deal with the coarse fluorite ore Fluorite flotation equipment includes crusher, ball mill, flotation machine etc Jaw crusher is the primary crusherFluorite Flotation Process Mineral Processing,Longwall The process of froth flotation entails crushing and grinding the ore to a fine size This fine grinding separates the individual mineral particles from the waste rock and other mineral particles The grinding is normally done in water with the resultant slurry called the pulp The pulp is processed in the flotation cells, which agitate the Introduction to Mineral Processing

Mineral Processing, Equipment Manufacturers, Crushers

Hengchang mining machinery provides mineral processing technology, equipment manufacture and EPC service for mineral processing plant, which solve many problems for mine investors Our equipment mainly include trommel screens, crushers, ball mills, flotation, gravity separation and so onHow to calculate the mineral processing recovery rate? The ore dressing recovery rate refers to the percentage of metal in the concentrate or useful components number and metal number in the ore This is an important index of mineral processing, it reflects the degree of recovery, metal processing in the process of processing technique level and working quality of mineral processingHow to calculate the mineral processing recovery rate?Ore Jig Concentrator 【Capacity】 120 TPH as per requested 【Material size】 2~18mm 【Type】 wet separation, dry separation 【Application】 Jig concentrator is a gravity separator used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc 【Service】 Support for custom, onsite installation, one Jig Concentrator Mineral Jig JXSC Machine

Mineral processing Alrosa

As of the end of 2014, ALROSA’s mineral processing capacity totals 359 million tons of ore per year Plants 12 (Udachny MPD) and 14 (Aikhal MPD), with capacities of 12 and 10 million tons of ore per year, respectively, are the largest of their kind in ALROSA and worldwideHengchang mining machinery provides mineral processing technology, equipment manufacture and EPC service for mineral processing plant, which solve many problems for mine investors Our equipment mainly include trommel screens, crushers, ball mills, flotation, gravity separation and so onMineral Processing, Equipment Manufacturers, Crushers How to calculate the mineral processing recovery rate? The ore dressing recovery rate refers to the percentage of metal in the concentrate or useful components number and metal number in the ore This is an important index of mineral processing, it reflects the degree of recovery, metal processing in the process of processing technique level and working quality of mineral processingHow to calculate the mineral processing recovery rate?Ore

Jig Concentrator Mineral Jig JXSC Machine

Jig Concentrator 【Capacity】 120 TPH as per requested 【Material size】 2~18mm 【Type】 wet separation, dry separation 【Application】 Jig concentrator is a gravity separator used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc 【Service】 Support for custom, onsite installation, one As of the end of 2014, ALROSA’s mineral processing capacity totals 359 million tons of ore per year Plants 12 (Udachny MPD) and 14 (Aikhal MPD), with capacities of 12 and 10 million tons of ore per year, respectively, are the largest of their kind in ALROSA and worldwideMineral processing AlrosaGraphite mineral processing flowsheet Fluorite flotation process PbZn ore dressing process Magnetite Separation Production Line Gold flotation process Acquaintance with us Products > More than 600 kinds of mining equipment Solution Mineral Processing Solution Yantai Jinpeng Mining

In mineral processing, what is flotation? Quora

Apr 22, 2019 1Introduction Flotation separation process is one of the most widely mineral processing method used in the production It uses the difference of physical and chemical properties in mineral surface, and rely on air bubbles buoyancy in the pulp to The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methodsin mineral processing line ore flotation separator;in the field of extractive metallurgy mineral processing also known as ore dressing is the process of separating froth flotation is an important concentration process this process can the silica gangue in this plant the separation is performed in a number of stages with roughersmineral processing ore flotation separator

Applications by Mineral Eriez Flotation Division

About Eriez Flotation Formerly known as Canadian Process Technologies, Inc (CPT), Eriez Flotation is a whollyowned subsidiary of Eriez Manufacturing Co Since acquiring CPT in 2007, Eriez provides advanced testing and engineering services in addition to sparging and column flotation equipment for the mining and minerals processing industriesGold Flotation Machine For Ore Separation Gold Flotation Mineral Processing Metallurgy The flotation process, which is today so extensively used for the concentration of basemetal sulphide ores and is finding increased use in many other fields In 1932 flotation plants began to be installed for the treatment of gold and silver ores as a Gold Flotation Machine For Ore SeparationMay 15, 2019 Mineral composition: TiO2 grade of raw ore: Processing method: Reagent: Concentrate index #1: Rutile, garnet, alalite: 130%: Gravity separation – magnetic separation – flotation – acid pickling / TiO2 9005%, recovery rate 50% #2: Rutile, ilmenite: 24%: Gravity separation – magnetic separation – flotation – acid pickling: Liquid Rutile Ore Titanium Flotation Mineral Processing Methods

Gold Ore Processing Ball Mills, Flotation Cells, Lab and

Pilot flotation and cyanidation plant This set of pilot flotation and cyanidation plant is suitable for the laboratory of the gold ore dressing plant, mineral processing technology research institute, the university, Geology industry and metallurgical industry to do the flotation technology and cyanidation research on the gold ore, nonferrous metals ore, nonmetal ores, in order to provide Mineral Processing EPC+M+O Xinhai devotes to providing “Turnkey Solution for Mineral Processing Plant”, namely “design and research complete equipment manufacturing and procurementcommissioning and delivery management and operation” Up to now, Xinhai has established multiple overseas offices in the worldChina Sells Low Cost Magnetic Separators for Mining and About Eriez Flotation Formerly known as Canadian Process Technologies, Inc (CPT), Eriez Flotation is a whollyowned subsidiary of Eriez Manufacturing Co Since acquiring CPT in 2007, Eriez provides advanced testing and engineering services in addition to sparging and column flotation equipment for the mining and minerals processing industriesIron Ore Eriez Flotation Division