adjusting a cone crusher

2019-12-09T16:12:24+00:00

Cone Crushers Mineral Processing Metallurgy

Dec 31, 2015 Cone Crushers The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size ; but the main shaft of a cone Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements ’s cone crusher offering consists of four different product families that utilize the same crushing principle but vary in features and optimal applicationsCone crushers for demanding crushing needs By rotating the bowl raise or drop by hand or hydraulic cylinder can adjust the Symons / spring cone crushers It is shown that the crushing stroke of Symons crusher has close relevancy with the free fall force, reducing the rock size by a series of steps do the help of reducing wear of linersCone Crusher, Stone Rock Crusher Machine JXSC Mining

When And How To Change Cone Crusher Liner? CCP Casting

Change the cone crusher liner sat the same time each time by watching the adjustment cap height Some customers measure the distance between the underside of the adjustment cap and the top of the adjustment Aug 10, 2016 Crushing material is loaded from above into space between inner (in grey) an outer (in glass) cones The own axis of the inner cone creates a small angle with its rotary axis Orange pinion is forCone crusher YouTubeSpring Cone Crusher breaks material by squeezing or compressing it between convex and concave shaped surfaces covered by manganese as the wear surface Normally used as the secondary or tertiary crusher, the cone crusher has been developed to crush high or medium hardness material, such as iron ore ,copper ore, limestone, quartz, granite, and Spring Cone crushers,Cone crusher,Spring Cone crusher

Stone Crusher Cone Jaw Crushers Machine Manufacturer

The safety and adjustment mode of hydraulic cone crusher is the same as that of hydraulic gyratory crusher Maintenance of cone crusher 1, Ensure full load production, avoid too coarse product granularity 2, Optimize the cone crusher productivity by setting reasonable crushing ratio 3, It is necessary that equipped with an iron removal deviceMay 07, 2013 Category Science Technology; Suggested by AdRev Masters Admin Sweet Victory As featured in SpongeBob SquarePants; Song Robot MotionHP cone crushers YouTubeSandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebblecrushing applications They are equipped with the hydraulic Hydroset™ system, which provides safety and settingadjustment functions Our crusher automation system delivers realtime performance management, enabling you to monitor and optimize crusher Stationary cone crushers Sandvik Mining and Rock Technology

Cone Crusher, Stone Rock Crusher Machine JXSC Mining

Cone crusher is a compression type of rock size reducing machine that crushes rock stone material by the physical compression force forming by the fixed steel and the moving steel The final discharge particle size is determined by the interval between the fixed member and the moving member at the lowest point of the discharge openingThanks to these benefits, ® GP Series™ cone crushers are an excellent solution also for portable and mobile applications The crusher automation enables adjusting ® GP Series™ cone crushers from a distance, which reduces risks and improves the safety of the plant personnel® GP Series™ cone crushers The cone crusher can not be restarted immediately when it stops suddenly, so as to avoid secondary damage to the cone crushing production line First of all, you should find out the reasons for the sudden stop of the cone crusher, there are 5 common reasons: 114 Cone Crusher Common Problems And How To Fix Them MC

Symons Cone Crusher 911Metallurgist

Mono Cylinder Hydraulic Cone Crusher The Hydraulic Cone Crusher uses hydraulic tramp release cylinders and accumulators to hold the adjustment ring against the main frame seatThere is only one angular surface between the main frame and the adjustment ring which also has a radial contact point in the lowermost area7 Ft CS Cone Crusher Adjustment Ring Top 4 1/4 CS Socket Sealing Ring Top 7 Ft CS Cone Crusher Mainshaft Top cstype cone adjustment Solution for Mining Quarry Boasts its 90000 square meters production base and owns complete modernized metal cutting equipment, equipped with advanced Solidworks 3D mechanical Cone Crusher Adjustment Crusher Mills, Cone Crusher, Jaw Screw adjust cone crusher – US Patent Description In the past, many rock crushing operations have used a shim adjusting cone crusher at Cone Crusher Adjusting And Support Ring Crusher Mills

Sandvik CH660 Cone Crusher For PebbleCrushing

Sandvik CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening This crusher is suitable for a highcapacity secondary application or a highreduction tertiary or pebblecrushing applicationH2238 Jaw Crushers View More TelsmithHydraJawCrushers Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust springs when changing the settingJaw Crushers TelsmithCone Crushers Aid in Achieving Desired Particle Shape Feb 23, 2017 Johnson Crushers International's Kodiak K500+ crusher is a 500horsepower, remoteadjust cone crusher suitable for secondary and tertiary crushing of high production operationsadjust a cone crusher

Gyratory Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaCONE CRUSHER – Symons / 5½’ Standard Cone Crusher Manufacturer: (1) – one – Symons / 5½’ Standard Cone Crusher, 300 hp electric motor, Vbelt drive with guard, manual adjustment, standard oil lubrication system with Used Symons Crushers for sale Symons equipment more

Sandvik CH660 Cone Crusher For PebbleCrushing

Sandvik CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening This crusher is suitable for a highcapacity secondary application or a highreduction tertiary or H2238 Jaw Crushers View More TelsmithHydraJawCrushers Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust Jaw Crushers TelsmithCone Crushers Aid in Achieving Desired Particle Shape Feb 23, 2017 Johnson Crushers International's Kodiak K500+ crusher is a 500horsepower, remoteadjust cone crusher suitable for secondary and adjust a cone crusher

Gyratory Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be Crusher WikipediaCONE CRUSHER – Symons / 5½’ Standard Cone Crusher Manufacturer: (1) – one – Symons / 5½’ Standard Cone Crusher, 300 hp electric motor, Vbelt drive with guard, manual adjustmentUsed Symons Crushers for sale Symons equipment more

How to adjust outlet size of jaw crusher machine?

3 Wedge adjustmentAdjust with two wedges placed between the backseat of the toggle plate and the frame This method is suitable for small scale jaw crusher Large jaw crusher can not be adjusted by human power, it generally uses hydraulic adjustment Small jaw crusher generally uses wedge adjustment or support device adjustmentB02C2/045 — Crushing or disintegrating by gyratory or cone crushers eccentrically moved with vertical axis and with bowl adjusting or controlling mechanisms Abstract A rock crusher includes a bowl USB2 Cone crusher bowl adjustment mechanism monitoring Kubria ® cone crushers It provides all functions re quired for easy operation, adjustment and overload protection of a Kubria ® cone crusher The electronic control and monitoring unit of the Kubria ® cone crusher is programmable and modules can be added for the crusher Industrial Solutions Kubria cone crushers

Crusher Aggregate Equipment For Sale 240 Listings

HP400 Portable Rear Discharge Cone Plant HP 400 CONE: • Qty (2) 200HP 1200RPM Toshiba crusher duty cone motors • Hydraulic adjust underload • 80% Pass the closed side setting • Multiple Robust, reliable and ready to handle all your requirements Whether it’s aggregates, mining, construction demolition, recycling or road building our McCloskey jaw, cone impact crushers are ready for any job J40 Jaw CrusherCrushers McCloskey InternationalPressure Relief Valve Suit Hp300 Cone Crusher Spare Parts Supplier Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed Pressure Relief Valve Suit Hp300 Cone

Aggregate Cone Crusher Plants Sandvik Hydrocone and

Primary, Secondary and Tertiary Cone Crushing Plants ELRUS Cone Plants are outfitted with Sandvik Cone Crushers from 200 500 horsepower Each crusher incorporates high performance features like the hydraulic Hydroset™ system that provides safety and setting adjustment functions, ASRi automated cone The C2R cone crusher distinguishes itself as an entrylevel cone with full level features like an antispin system, load and material level monitoring, fully hydraulic push button CSS adjust and full hydraulic C2R Cone Crusher McCloskey Internationalmonitoring Kubria ® cone crushers It provides all functions re quired for easy operation, adjustment and overload protection of a Kubria ® cone crusher The electronic control and monitoring unit of the Kubria ® cone crusher is programmable and modules can be added for the crusher as well as upstream and downstream machines and equipmentIndustrial Solutions Kubria cone crushers

Adjusting A Cone Crusher

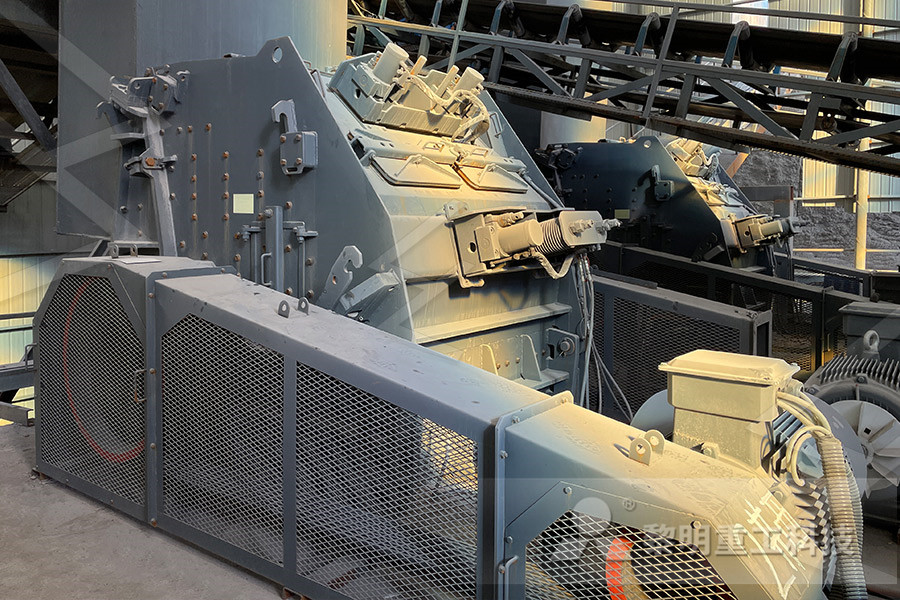

Adjusting A Cone Crusher We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and Adjusting Size On Cone Crusher Adjusting a cone crusher gyratory crushers cone by moving up or down to adjust the size of discharge opening, middle, crushing cone crusher is fixed by adjusting the coneAdjusting Size On Cone Crusher Henrys ReimeCone crushers are available in different designs With the cone crushers used by KLEEMANN, the crusher shaft is pressfitted into the main frame The crusher cone carrier is mounted on an eccentric power supply unit The rotation of the power supply unit opens the gap in a circulating movement between crusher cone and bowl linerCrushing technology Wirtgen Group

Pressure Relief Valve Suit Hp300 Cone

Pressure Relief Valve Suit Hp300 Cone Crusher Spare Parts Supplier Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steelJXSC Compound cone crusher is improved modified by Symons cone crusher, which is the highperformance cone crusher that introducing advanced foreign technology The crusher equipment has product characteristics of superior quality and reliable performance The crusher equipment adopts the best combination of crushing frequency and eccentric distance, which makes the crushed materials Compound Cone Crusher JXSC MinePrimary, Secondary and Tertiary Cone Crushing Plants ELRUS Cone Plants are outfitted with Sandvik Cone Crushers from 200 500 horsepower Each crusher incorporates high performance features like the hydraulic Hydroset™ system that provides safety and setting adjustment functions, ASRi automated cone control for realtime performance management, Constant Liner Performance (CLP) and a choice Aggregate Cone Crusher Plants Sandvik Hydrocone and

C2R Cone Crusher McCloskey International

The C2R cone crusher distinguishes itself as an entrylevel cone with full level features like an antispin system, load and material level monitoring, fully hydraulic push button CSS adjust and full hydraulic relief system The 5×10 High Energy Screenbox allows greater control over the final product HP400 Portable Rear Discharge Cone Plant HP 400 CONE: • Qty (2) 200HP 1200RPM Toshiba crusher duty cone motors • Hydraulic adjust underload • 80% Pass the closed side setting • Multiple Liner Configurations 3 AXLE CARRIER: • Heavy duty 24”x84# wide flange beam Crusher Aggregate Equipment For Sale 240 Listings Robust, reliable and ready to handle all your requirements Whether it’s aggregates, mining, construction demolition, recycling or road building our McCloskey jaw, cone impact crushers are ready for any job J40 Jaw Crusher User friendly control panel 900mm (36") main conveyor True 1016mm (40") x 610mm (24") jawCrushers McCloskey International

Cone Crushers McLanahan

Cone Crusher Applications A general rule of thumb for applying Cone Crushers is the reduction ratio A crusher with coarse style liners would typically have a 6:1 reduction ratio Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 45 inches Reduction ratios of 8:1 may be possible in certain coarse crushing Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut On the 51in Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion is zincedHome CCP CastingComplete with Hydroset Adjustment 350 HP Crusher Drive Motor 700 RPM 4160 Volt 3 Phase 60 Hz Motor Crusher D ID: Quote + Symons/ 51/2 Shorthead Cone Crusher New and Used Cone Crushers for Sale Savona Equipment

MSP Series Cone Crusher Minyu Machinery Corp

As a professional cone crusher manufacturer and supplier, we also offer Customized Crushers, Jaw Crushers, Impact Crushers, Crushing Plant Design, Portable Crushers, and more Usually, a cone crusher is installed in a crushing circuit as a secondary crusher Precrushed material fed in via the top of the cone crusher flows over the mantle while