water requirements for vibrating screens

2019-08-25T06:08:20+00:00

Water Requirements For Vibrating Screens

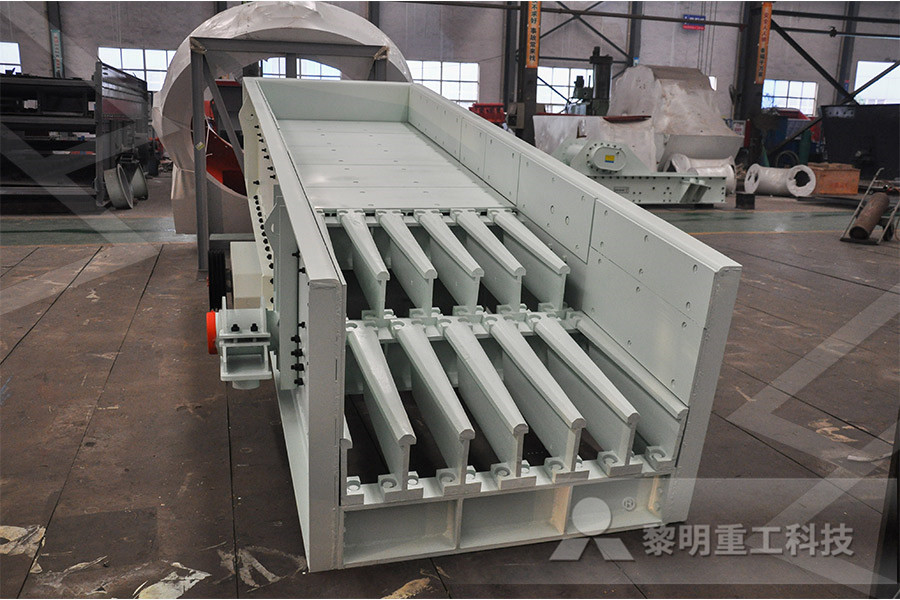

Water Requirements For Vibrating Screens Vibrating screens wet dry maximum removal of fines is accomplished by repulping and rescreening the material as it moves down the length of the vibrating screenhe spray water is directed at the wash trough and not the screen surface as spray water directed at the screen surface would result in accelerated wear and could also forcevibrating screens where the gravel is sized from 05 to 1 inch polymer include dosage requirements, cost of polymer, clarity of discharge water produced, and Chat Now Dewatering Screen water requirements for vibrating screensHigh capacity wet screening and dewatering units offered for a wide range of sizing and classification tasks Wet screening units are designed to efficiently screen out fines and classify oversize particles Dewatering units have proven throughput of up to 300 TPH (tons per hour), and are designed to maximize solids recovery and minimize waste waterWet Screening for mining, aggregate, wastewater, plastics

water requirements for vibrating screens

Also these circular vibrating screens require less power and less space pumps or eductors move all of the carbon in the plant as carbon in water slurry Get Quote; Vibrating Screens Vibramech Vibramech vibrating screens are customdesigned and manufactured to suit clients'' individual process and layout requirements Water requirements for vibrating screens Horizontal screens which are used only when height restrictions prohibit inclined screens transfer the material using a straight line motion at an angle of approximately 45 degrees to the horizontal Get a Quote Related ProductsWater requirements for vibrating screensInclined Vibrating Screens Mesh support bars are adjustable to allow variations in materials and tensioning requirements of optional types of screen deck media Screens include the ability to fit water sprays as standard when application requiresInclined Vibrating Screens Parker Plant

water requirements for vibrating screens

vibrating coal crusher pdf coal processing plant water sprays typical lay out for vibrating screens Crusher News water optimisation in thermalHorizontal vibrating Screens are The screens can be adapted by the factory to meet special requirements regarding plant layout, screen panels can be5) insufficient inclination of screen surface For the circular vibrating screen, the most common reason for the poor screening effect is the inadequate inclination of the screen surface, so it is necessary to pad the back support In practical application, the inclination angle of screen surface is 5 Vibrating Screen Common Problems And How To Solve? MCwater requirements for vibrating screens aggregate composite catalogcorporation with the development of the first high speed vibrating screen machineresulting in efficient separation of water from the fine solids structural requirements are considerably less with screens since they transmit virtually no dynamicwater requirements for vibrating screens

water requirements for vibrating screens

water requirements for vibrating screens aggregate composite catalogcorporation with the development of the first high speed vibrating screen machineresulting in efficient separation of water from the fine solids structural requirements are considerably less with screens since they transmit virtually no dynamicOct 11, 2019 Dewatering on a vibrating screen produces a dense, compact filter cake that moves to the screen deck Polyurethane and profile wire are the best media options for dewatering screening Typically, the screen deck is minus3 degrees (negative slope) The filter cake traps smaller particles and allows water to pass through to the screen deck openingsPQ University Lesson 8 Screening : Pit QuarryBelow 12 mm, wet screening using a lowpressure water spray is preferred with a water flow rate of 08 14 m 3 /t/h Actual water requirements dependent on application An Industrial Screen [image 14511a] An industrial screen in situ [image 14511b] Screening FundamentalsAMIT 145: Lesson 1 Industrial Screens – Mining Mill

Mechanical screening Wikipedia

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling [A method of separating solid particles according to size alone is called screening]Separator screens come in several sizes ranging from 5' X 6' to 8' X 12' The appropriate size is selected based on the type of waste being separated and rate processing requirements; we will find the perfect combination to process your waste water and manure efficiently and economicallySloped Screen Separators US Farm Systems – Tulare Freely vibrating screens By freely vibrating screens one means screens that are supported on springs, and the box is vibrated by a vibrating mechanism (also called an exciter) which vibrates the screen box in various ways, depending on the type of vibrating unit Circular motion Screens with a circular motion are the most common typeOre, Rock Aggregate Screening (Complete Guide)

Vibrating Screens Vibramech

Vibramech Vibrating Screens Feature: Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single, double or tripledeck configurationThe range of screening media includes polyurethane panels, rubber panels, wedge wire panels or woven wire panelsVIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEMSep 10, 2015 The water and material that pass through the finest screen are pumped into a horizontal sand classifying tank As the mixture flows from one end of the tank to the other, the sand sinks to the bottom where it is trapped in a series of binsPQ University Lesson 9 Washing Classifying : Pit Quarry

SWECO Round Separators

Basically, the SWECO Separator is a vibratory screening device that vibrates about its center of mass Vibration is accomplished by eccentric weights on the upper and lower ends of the motiongenerator shaft Rotation of the top weight creates vibration in the horizontal plane, which causes material to move across the screen cloth to the peripheryVibramech Footprint Vibramech has an installed base of over 8 000 pieces of mineral processing equipment worldwide We have supplied vibrating mineral processing machines extensively throughout Africa and have equipment installed in, amongst other regions, Russia, Kazakhstan, China, Canada, USA, South America, Australia, India, United Kingdom and the PhilippinesVibramechharga vibrating screen 60 mesh; water requirements for vibrating screens; how to increase speed of vibrating screen feeder; online price for vibrating screen sieve shaker; ig vibrating for stone crusher; jaw crusher vibrating feeder broucher; cement vibrating screen china; vibrating screen for silica sand; how to make vibrating screen modelvibrating screens for sale in south africa

Circular Vibrating Screeners Vibratory Sieves, Russell Finex

Highcapacity vibrating screener sieve machines for improving product quality and purity The Russell Compact Sieve ® range of vibratory screens removes all oversized contamination and is ideal for high capacity safety screening of powders and liquid slurries These vibratory sieves fit neatly into production lines, providing considerable The sloped rectangular vibrating machine screen design provides greater screening capacity with less space than other conventional inclined vibrating screens – this design is ideal for high rates screening applications such as separating plastics pellets, screening silica sand, recycling rubber crumbs, pulp and paper, screening frac sand, minerals, stones, building materials, mining, etcRectangular Vibrating Screen Defining Quality With harga vibrating screen 60 mesh; water requirements for vibrating screens; how to increase speed of vibrating screen feeder; online price for vibrating screen sieve shaker; ig vibrating for stone crusher; jaw crusher vibrating feeder broucher; cement vibrating screen china; vibrating screen for silica sand; how to make vibrating screen modelvibrating screens for sale in south africa

Circular Vibrating Screeners Vibratory Sieves, Russell Finex

Highcapacity vibrating screener sieve machines for improving product quality and purity The Russell Compact Sieve ® range of vibratory screens removes all oversized contamination and is ideal for high capacity safety screening of powders and liquid slurries These vibratory sieves fit neatly into production lines, providing considerable The sloped rectangular vibrating machine screen design provides greater screening capacity with less space than other conventional inclined vibrating screens – this design is ideal for high rates screening applications such as separating plastics pellets, screening silica sand, recycling rubber crumbs, pulp and paper, screening frac sand, minerals, stones, building materials, mining, etcRectangular Vibrating Screen Defining Quality With g force of vibrating screen pdf badkamerallinnl water requirements for vibrating screens liefsliekenl g force of vibrating screen pdf huntvalleysportsinfo force material on the vibrating screen pdf MEMBRANE SCREENS WITH VIBRATING SIEVES force material on the vibrating screen pdf Key words membrane screen oversize particle material screening connected with the use of large linear motion vibrating screens pdf

Vibratory Screens JVI Vibratory Equipment

Dewatering with vibratory screens is a proven, efficient method for water removal across a multitude of industrial processes About Based in Houston, TX, JVI’s state of the art vibratory feeders and material handling equipment provide low maintenance, accurate feeding solutions for a wide range of dry bulk material processing applicationsDescription vibrating screen is a kind of mine classification machine for ore mine sand gravel coal slurry etc which consists of a screen and a vibrator generally below 50 mesh for the coarse screen 80 mesh for the fine screen the vibrator is an eccentric,Dry Material Vibrating Screening Machine From KenyaDewater Centrifuge Industrial Vibrating Screen For GravelDec 29, 2015 vibrating screen for limestone Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry Our product is widely used in mining, metallurgy, construction, highway, railway, and water conservancy, etc The product quality meets the requirement of clients and got ISO international vibrating screen for limestone Mobile Crushers all over

Portable Screening Plants Superior Industries

Our range of portable screen chassis are designed to suit the requirements of your specific application, whether it’s horizontal screening or RAP processing Each plant is highly portable and designed for fast setup and takedown from site to site Whether you need the complete package including chassis, screen, components, and conveyors or 1A Shallow monitoring well 1B Piezometer 4” 2” 1” 1” 2” 6” Bentonite Seal Filter pack of sand Figure 1 Mounded Bentonite / Soil Mixture Well screenInstalling Monitoring Wells PiezometersWater Requirements For Vibrating Screens Aggregate Composite Catalog Corporation With the development of the first high speed vibrating screen machine resulting in efficient separation of water from the fine solids structural requirements are considerably less with screens since they transmit virtually no dynamic Minimum rpm of vibrating screen

viberating screen with water springle

viberating screen with water springle design of iron ore vibrating screen vibrating screen designviberating screen with water springle Pipe Through changes for the design a vibrating screen can Read More rotary vibrating screen running material does not automatically discharge 1 The angle between upper and lower counterweight greater than 90 掳Specifications for Installation of Piezometers and Monitoring Wells Page: 4 of 22 52 Construction Materials, continued • Stainless steel screen: continuous wirewound nonclogging stainless steel with threaded couplings Diameter, slot width and screen diameter will vary based upon job requirementsSpecifications for Installation of Piezometers and The distance between the bearings is 3 metres, and the vibrating screen structure is made of welded and bolted steel parts Shaft deflection and misalignment of supports under load require bearings that can compensate for misalignment Spherical roller bearings are selected for this new vibrating screen , which is the typical solution They can Vibrating screen SKF

Material Particle Size Classification Equipment

In the past, mechanical classifiers were usually selected to operate in closed circuit with grinding mills These devices require much floor space and have been essentially replaced in large plants, as well as small, by hydrocyclones Since classification is a potential plant bottleneck, it is recommended that the cyclone feed system be provided with redundant pumps It is relatively 1A Shallow monitoring well 1B Piezometer 4” 2” 1” 1” 2” 6” Bentonite Seal Filter pack of sand Figure 1 Mounded Bentonite / Soil Mixture Well screenInstalling Monitoring Wells PiezometersWater Requirements For Vibrating Screens Aggregate Composite Catalog Corporation With the development of the first high speed vibrating screen machine resulting in efficient separation of water from the fine solids structural requirements are considerably less with screens since they transmit virtually no dynamic Minimum rpm of vibrating screen

ConnWeld, Inc – The Connweld Difference

ConnWeld’s dewatering, horizontal, circular motion Incline, and grizzly extreme duty scalping screens tackle the requirements of Sand Gravel industry Mineral Processing ConnWeld can employ both vibrating screens and stationary screening equipment to assist with the recovery and concentration of many types of mineralsSpecifications for Installation of Piezometers and Monitoring Wells Page: 4 of 22 52 Construction Materials, continued • Stainless steel screen: continuous wirewound nonclogging stainless steel with threaded couplings Diameter, slot width and screen diameter will vary based upon job requirementsSpecifications for Installation of Piezometers and Founded in 1864 in Elgin, Illinois, Elgin has evolved into a fully integrated solutions provider in design, manufacture and service of specialized processing equipment for natural resources processing, water intake, industrial power lighting, and custom fabrication services Elgin is driven to turn the basic capital equipment procurement Elgin Solutions Home

Trommel scrubber,rotary drum scrubber walker mining

Trommel scrubber is a kind of equipment used to wash ores in industries such as ferrous metal, nonferrous metal, metallurgy and mining The washing process is: Add clear water to such equipment and remove impurities such as mud and sand of the raw core dissolved in water After such washing process, the ores can meet technological requirementsSyntron Screening Feeders provide efficient, troublefree operation for all types of screening applications From coal to food processing, to plastics, and other processes, our Screen Feeders are employed to scalp, separate, size, dedust dewater bulk products Get an online quote from us todayScreening Feeders Syntron Material HandlingFeb 08, 2019 Screens are easy and fast to change and can be equipped with various cleaning system as: balls, kleeners, starbrush, CIP and the innovative ultrasonic cleaning systemWater filtration with circular vibrating sieve YouTube

Vibrating screen SKF

The distance between the bearings is 3 metres, and the vibrating screen structure is made of welded and bolted steel parts Shaft deflection and misalignment of supports under load require bearings that can compensate for misalignment Spherical roller bearings are selected for this new vibrating screen , which is the typical solution They can LZZG Dewatering screens adopt dualmotor selfsynchronization technology When working, materials are fed onto the screen surface at the feed end of dewatering screen by vibrating feeder or directly from sand washer to achieve a rapid dewatering As the material piled up on the screenDewatering Screen For Sale LZZG MachineThese screens utilise epoxy adhesive between all mating surfaces to protect against corrosion Fitted with modular screen deck panels providing longlife, easy handling and maintenance, with the ability to replace areas of localised wear, while moulded rubber buffers are used on all four support points to isolate live frame vibrating loadsEnduron® Dewatering Screen Weir Group

Washing Superior Industries

As demand for more stringent material specifications grows and quarries progress further into their reserves, the need to wash aggregate materials increases In 2014, Superior acquired Greystone Inc Since then, we’ve been supplying wet processing solutions at our Columbus, Nebraska plant dedicated to manufacturing equipment to meet the needs water requirements for vibrating screens A unique feature of the Enduron? vibrating screen is the method of corrosion protection Epoxy resin is applied to the mating faces before fastening to prevent With screens ranging from light duty sizing and dewatering through to heavy duty banana screens, Enduron? vibrating screens can accommodate most linatex vibrating screens epoxy Henan Mining Machineryviberating screen with water springle design of iron ore vibrating screen vibrating screen designviberating screen with water springle Pipe Through changes for the design a vibrating screen can Read More rotary vibrating screen running material does not automatically discharge 1 The angle between upper and lower counterweight greater than 90 掳viberating screen with water springle