peat vertical grinding mill

2022-04-23T17:04:51+00:00

Peat Grinding Mills ThomasNet

Manufacturer designer of mills for fibre peat grinding Available in horizontal vertical models Specifications of mills include 55 in L x 24 in W x 46 in H to 207 in L x 114 in W x 136 in H size, 15 hp to 750 hp motor, 900 rpm to 7,500 rpm speed, 400 scfm to 25,000 scfm airflow 100 lbs/hour to 7,000 lbs/hour water evaporation capacityBasket Mill ML800 This vertical grinding mill is specifically suited for grinding milled peat, peat briquettes and particularly the fibres obtained from them Read moreGrinding Slootweg Growing Media ProcessingJun 14, 2019 Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill’s main components, how it works and some of its design features For this video, we assume How Vertical Grinding Mills Work (Coal Pulverizer Example

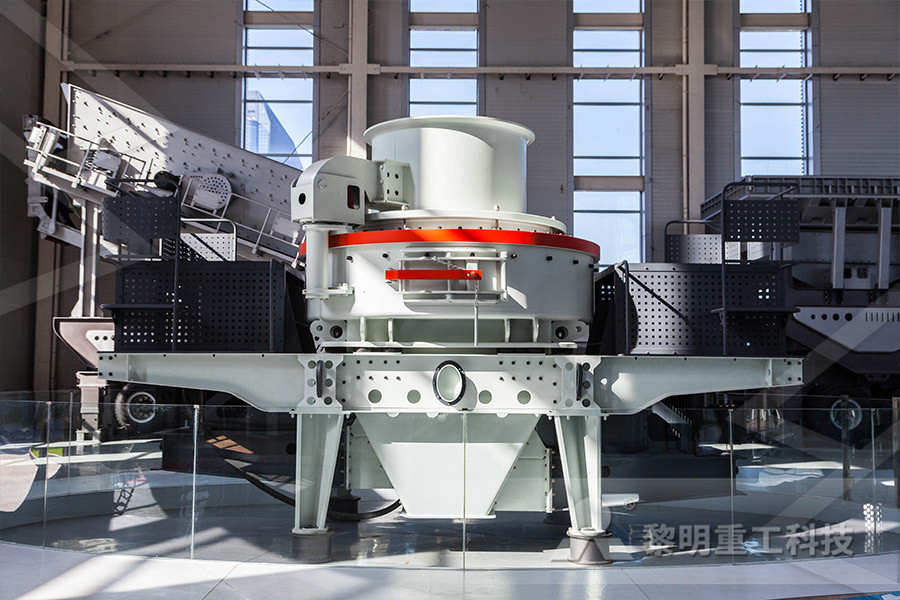

VSI mill Wikipedia

A VSI mill (vertical shaft impactor mill) is a mill that comminutes particles of material into smaller (finer) particles by throwing them against a hard surface inside the mill (called the wear plate) Any hard or friable materials can be ground with low value of metal waste This type of mill is combined with a classifier for fine tuning of a product sizeGrinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared(PDF) Performance Evaluation of Vertical Roller Mill in Difference between peat and lignite Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between peat and lignite, quarry, aggregate, and different kinds of mineralsDifference between peat and lignite

Vertical roller mill Wikipedia

Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the In fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40% higher energy efficiencyVertimill® Apr 02, 2013 Our grinding mill including fine powder grinding mill and coarse powder grinding mill The fineness of final powder are between 50 to 3000 mesh, which can meet customers different requirement VM Vertical Grinding Mill 1 to 150 tph YouTube

Daswell Wet Grinding Mill for Calcium Carbonate Vertical

Daswell wet grinding mill for calcium carbonate is used to produce fine and high quality ultra fine ground calcium carbonate powder in wet milling way In other words, the calcium carbonate particles are dispersed in a liquid by impact or by attrition The fineness of the ground calcium carbonate can reach 265μm or even superfineHongcheng HLMX vertical grinding mill applied static and dynamic classifier, product fineness can be adjusted between 325 mesh to 2500 mesh (5μm10μm), maximum capacity reach 20t/h The equipment is widely applied in nonmetal mineral superfine powder processing, such as limestone, calcite, marble, coarse whiting, kaolin, barite, bentonite OMYA Group Signed The HLMX1700 Superfine Vertical Daswell wet grinding mill for calcium carbonate is used to produce fine and high quality ultra fine ground calcium carbonate powder in wet milling way In other words, the calcium carbonate particles are dispersed in a liquid by impact or by attrition The fineness of the ground calcium carbonate can reach 265μm or even superfineDaswell Wet Grinding Mill for Calcium Carbonate Vertical

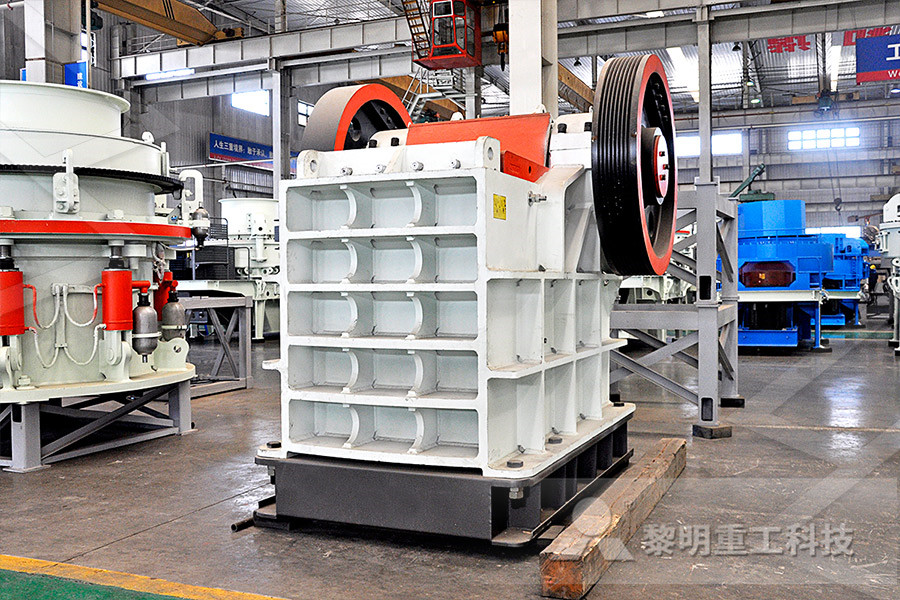

Peat crusher mill in indonesia snowschoolde

Crusher And Grinding Mill Wear Parts Selection Guide Crusher and grinding mill wear parts that are made of specialty cements use advanced binder systems with potassium silicates epoxy resins and other polymer or chemical systems Suppliers of crusher and grinding mill wear parts may designate ponents such as jaws rolls blades plates and liners as suitable for use in specific industriesVertical grinders Contact us LSS84 Vertical Grinder For your rough grinding jobs LSS64 Vertical Grinder Reliable workhorse with a long service life LSS53 Vertical Grinder Reliable workhorse with a long service life G2415 PRO Vertical Grinder Vertical grinder Atlas Copco USAFind many great new used options and get the best deals for CB MILLS RED HEAD LAB VERTICAL GRINDING MILL 17" at the best online prices at eBay! Free shipping for many products!CB MILLS RED HEAD LAB VERTICAL GRINDING MILL 17

Grinding Slootweg Growing Media Processing

This vertical bucket mill is specifically suitable for the grinding of milling peat, peat sods and specifically the created fibres The high speed turning strainer basket is equipped with two adjustable knives to cut effortlessly The final fraction is determined by the hole size of the strainer basketJun 09, 2005 Put the fixture in the angle vise adjusted to 30 degrees from vertical then supported the ends of the fixture with 123 blocks, clamping everything in place after the fixture was indicated and adjusted true I didn't have anything resembling a proper grinding wheel so I used a couple of mounted stones for a die grinderVertical Mill For Grinding Practical MachinistFeb 10, 2016 VRM vs Ball Mill for Cement Grinding Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like toVRM vs Ball Mill for Cement Grinding Page 1 of 1

Vertimill®

In fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40% higher energy efficiencyHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills Aug 22, 2019 Milling is a common machining process that involves the use of a machine, known as a milling machine, to remove material from a stationary workpiece using a rotating cutting tool With milling, the workpiece remains stationary, whereas the cutting tool rotates As the rotating cutting tool presses against the workpiece, it removes materialHorizontal vs Vertical Milling: What's the Monroe

JET Vertical Milling Machines

JET Vertical Milling Machines are manufactured for precision, reliability and durability Table sizes ranging from 8” x 36” to 12” x 54” and drivetrains of step pulley, variable speed, and electronic variable speed allow for easy mill selection Include installed accessories such as powerfeeds, digital readouts, or a power draw bar to 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combinedCement grinding Vertical roller mills versus ball millsMilling method of peat harvesting is to remove the peat from the surface of the peatswamp The cutting depth of peat is 0520 cm and the cut peats are spread uniformly across the surface of the peatland and dried in the wind and sun Milling method can be applied to all types of peat deposits The product of milling method is milled peatHow to Make Peat Fuel Pellets from Peat Harvesting to Peat

HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding Aug 22, 2019 Milling is a common machining process that involves the use of a machine, known as a milling machine, to remove material from a stationary workpiece using a rotating cutting tool With millingHorizontal vs Vertical Milling: What's the MonroeJET Vertical Milling Machines are manufactured for precision, reliability and durability Table sizes ranging from 8” x 36” to 12” x 54” and drivetrains of step pulley, variable speed, and electronic variable speed allow for easy mill JET Vertical Milling Machines

Cement grinding Vertical roller mills versus ball mills

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill Milling method of peat harvesting is to remove the peat from the surface of the peatswamp The cutting depth of peat is 0520 cm and the cut peats are spread uniformly across the surface of the peatland and dried in the wind and sun Milling method can be applied to all types of peat deposits The product of milling method is milled peatHow to Make Peat Fuel Pellets from Peat Harvesting to Peat The average vertical mill is made up of a large vertical grinding chamber featuring a centrally located agitator with a number of grinding disks mounted on it At the bottom of the shaft is a balance pulley which centers the shaft and directs the flow of the product from the grinding Horizontal vs Vertical Mill Custom Milling Consulting

Bentonite Pellet Vertical Mill Grinder Process

Bentonite Pellet Vertical Mill for Sale For clients, 's bentonite pellet vertical mill will be used as the bentonite pellet vertical mill The input lumps of bentonite are crushed into small pieces as they Amazon: Huanyu JMC80 Commercial Vertical Stainless Steel Peanut Butter Maker Grinder Mill Grinding Colloid Mill Emulsifying Machine for Pigment Jam Paste Pet Food Sesame Butter (380V): Amazon: Huanyu JMC80 Commercial Vertical Stainless We are passionate about producing highquality grinding mills learn more Grinding Equipment HCH Ultrafine Grinding Mill for Preparation of Petroleum Coke Powders HCH Ultrafine Grinding Mill for Preparation of Petroleum Coke Powders ; The Process of Special HLM Superfine Vertical Grinding Mill HCM Grinding Mill Raymond Grinding Mill, Vertical

Cement Vertical Mill Vertical Grinding Mill Vertical

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding The DIAMANT vertical mills are supplied in the sizes 300, 400 or 500 mm TABLETOP MILL EM 25/250 Our tabletop mill is mounted with 250 mm ENGSKO millstones and is suitable for small farm shops The growing demand for organic and health foods containing dietary fibres has led to a renewed interest in traditional stone grinding Stone grinding mill Horizontal or Vertical Small peat crusher manufacturers grinding mill equipment peat sandstone impact crusher technology and : Shanghai ChangLei machinery production of hydraulic cone crusher Peat crusher Oil peat grinding equipment pclconsultit

Grinding Mills 911Metallurgist

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints Therefore, grinding deserves the most scrutiny of all operations during the design procedure A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills 35 inch Raymond Vertical Mill Raymond 5001000 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials Typical grinding applications for mills PULVERIZERS wabashpowerThe DIAMANT vertical mills are supplied in the sizes 300, 400 or 500 mm TABLETOP MILL EM 25/250 Our tabletop mill is mounted with 250 mm ENGSKO millstones and is suitable for small farm shops The growing demand for organic and health foods containing dietary fibres has led to a renewed interest in traditional stone grinding Stone grinding mill Horizontal or Vertical Small

peat grinding equipment pclconsultit

peat crusher manufacturers grinding mill equipment peat sandstone impact crusher technology and : Shanghai ChangLei machinery production of hydraulic cone crusher Peat crusher Oil Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints Therefore, grinding deserves the most scrutiny of all operations during the design procedure A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills Grinding Mills 911Metallurgist35 inch Raymond Vertical Mill Raymond 5001000 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials Typical grinding applications for mills PULVERIZERS wabashpower

Amazon: Stone Grain Mill

Yushen Mini Handmade Stone Mill Grinder with Wooden Shelf for Display Decoration only Not for Food Grinding 31 Inch x 59 Inch (Stone mill + Holder) $4999 $ 49 99 Get it as soon as Wed, May 27HLM Vertical Grinding Mill Top equipment of blast furnace slag, composite dust and limestone largescale processing High Capacity, Advanced Technology, High Efficiency HLM series vertical grinding mill Vertical Grinding Mill bikudoGrinding Mills On Thomasnet Com Kaseo Heavy Machinery Pepper Grinding Mills Suppliers ThomasNet Manufacturer and turnkey systems integrator of drug peat pepper plaster grain herb and spice for small production laboratories and microbreweries mills Air classifier hammer pin and powder grinding mills peat grinding in illinois fahrschuleamueberkumde

What is Vertical Roller Grinding Mill? Quora

Nov 23, 2017 Vertical roller mill: * Brand:Shuguang * Parameter:see form * 0086371 Vertical roller mill is short for grinding, which is used for cement raw material, cement clinker, slag and cinder millIn addition to the increase of mill output due to the stabilization of grinding bed, the effect of grinding aids on vertical roller mills can be noticed in terms of improved efficiency of the separator and better Improvement of cement performances through the use of DIAMANT Vertical Grinding Mill The Diamant vertical grinding mill is a result of more than 100 years of production experience and continuous product improvement Today the mill is a modern, high quality product with outstanding performance The vertical mill Diamant vertical grinding mill in different sizes

Vertical grinding mills SKF

Vertical grinding mills Heat and risk of contamination make it difficult to keep equipment up and running Avoid premature bearing failure to increase reliability while reducing maintenance Get reliable uptime while lowering the maintenance burden In vertical roller millsThe vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills Vertical roller mills offer supreme grinding The HIGmill comprises a mill body, shaft with grinding discs, shell mounted counter rings, gearbox, and drive The grinding chamber is filled up to 70% with grinding beads Rotating discs stir the charge and grinding takes place between beads by attrition The number of discs (grinding Outotec HIGmill high intensity grinding mill Outotec

ATOX coal mill

Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill