ball mill calculations critical speed

2021-07-09T18:07:41+00:00

Ball Mill Critical Speed Mineral Processing Metallurgy

Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 and 79 percent of critical speed Rod mills speed should be limited to a maximum of 70% of critical speed and preferably should be in the 60 to 68 percent critical speed Enter the width of a mill shell liner Note this is not the width of a lifter! You may use the Mill Liner Effective Width calculation to determine this value The mill critical speed will be calculated based on the diameter (above) less twice this shell liner width Mill Actual RPM: Enter the measured mill rotation in revolutions per minute : Mill Critical Speed Determination22 Rotation Speed Calculation of Ball Mill \ Critical Speed When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall, and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the mill is as follows:Ball Mill Parameter Selection Calculation Power

Mill Speed Critical Speed Paul O Abbe

Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productCalculations: The critical speed of ball mill is given by, Get Price; A model of mill power as affected by mill speed SAIMM Jun 6, 1993 the mill speed nears 100 per cent of critical speed, centrifug ing of the outer 18mm, and 25 mm balls with a bulk density PL = 4700 kg/m3critical speed calculation for ball millAug 23, 2018 CRITICAL SPEED OF THE BALL MILL Let a grinding ball of mass m is in motion in a mill of diameter D meters It is at a position making an angle a at the center (called the angle of repose) The force acting on the ball are described in the figure The centripetal force acting []CRITICAL SPEED OF THE BALL MILL VDChari

Formula For Critical Velocity Of Ball Mill Pdf

Ball Mill Parameter Selection Calculation Power Ball Mill Parameter Selection Calculation Power,Aug 30 2019 22 Rotation Speed Calculation of Ball Mill Critical Speed When the ball mill cylinder is rotated there is no relative slip between the grinding medium and the cylinder wall and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated at 50, 62, 75 and 90% of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the balls at the end of five revolutions is shown in Figure 4 As can be seen from the Mill Critical Speed CalculationMartin Chick Associates Programming Services Phone (440) 2514290 EMail info@martinchick Home Resources Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes Contact End Mill Speed Feed Calculator End Mill Speed and Feed Calculator Martin Chick Associates

Ball mill Critical Speed YouTube

Dec 23, 2018 Cement Ball mill Critical speed Building A Large Post Frame Garage Full Timelapse Construction: NEVER BEFORE SEEN FOOTAGE Duration: 16:28 RR Buildings Recommended for youJun 27, 2017 Deals with two most important topics of Food Engineering namely ball mill and sphericity milling speed feed Pask Makes Recommended for you 28:06 Torque Calculation Duration: 11:36 12 Ball Mill YouTubeBall Screw Column Strength and Critical Speed End Fixity End fixity refers to the method by which the ends of the screw are supported The degree of end fixity is related to the amount of restraint of the ends of the screw It is important to determine the proper end fixity in order to determine the appropriate screw size for a give applicationBall Screw Column Strength and Critical Speed Nook

: Home

Sagmilling is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribersBall Nose Effective Diameter = D eff = 2 x R ² (R ADOC)² Feed rate is the speed of the end mill’s movement correspondent to the workpiece The feed rate is measured in inches per minute (IPM) COMMON EQUATIONS FOR OPTIMAL PERFORMANCE Too high of a speed or too light of a feed leads to reduction in tool MON EQUATIONS FOR OPTIMAL PERFORMANCEThe point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 micronsBall Mills Mine

Ball Mill Calculations Critical Speed

Ball Mill Calculations Critical Speed Ball Mill Critical Speed Mineral Processing Metallurgy The critical speed of a rotating mill is the RPM at which a grinding medium will begin to “centrifuge”, namely will start rotating with the mill and therefore cease to carry out useful work Ball mills have been successfully run at speeds Calculations: The critical speed of ball mill is given by, Get Price; A model of mill power as affected by mill speed SAIMM Jun 6, 1993 the mill speed nears 100 per cent of critical speed, centrifug ing of the outer 18mm, and 25 mm balls with a bulk density PL = 4700 kg/m3critical speed calculation for ball millcritical speed of ball mill calculation pdf critical speed formula for ball millRod mills, how they function Mine Rod mills are very similar to ball mills, Get More critical speed of ball mill calculation Ball mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The grinding works F Critical Speed In Ball Mill Calculation

Variables in Ball Mill Operation Paul O Abbe®

The starting point for mill speed calculations is the critical speed Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder Obviously no milling will occur when the media is pinned against the cylinder so operating speed will be some percentage of the CS Ball milling is one of the 21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ballmill power drawP as a function of its dimensions: internal mill diameter D and length L, zthe ballmill power drawP as a function of the feed D f (mm) and the product size d (mm), the Bond work index w i (kWh/short ton) and the mill throughput T (short ton/h), zthe ballmill dimensions (D and L), when MODELING THE SPECIFIC GRINDING ENERGY AND BALL critical speed ball mill calculation; critical speed ball mill calculation Ball Milling ResearchGate Is there any equation or method to calculate the energy of milling and adjust the parameter between Milling speed was 350 rpm and it was a plantery ball mill Chat Nowcritical speed ball mill calculation keithkirstencoza

How can I determine the best RPM for Dry Ball Milling

Critical speed (in rpm) = 423/sqrt(D d) with D the diameter of the mill in meters and d the diameter of the largest grinding ball you will use for experiment (also expressed in meters)RTD, Holdup, Ball mill, Ball load, Slurry 75% of critical speed, slurry solids concentration is 75%, solids feed rate is 330 tph 32 the response was monitored at the dischargehow do i calculate the critical speed of a millcritical speed of ball mill calculation Design Method of Ball Mill by Discrete Element Method Feb 3, 2007 on ball motion in mills using the discrete element method has been A ball mill is one kind of grinding machine, and it is a The physical constants used in these calculations are given in than the critical speed of rotation critical speed calculation ball mill 42 29

how to calculate critical speed of ball mill

The critical speed of the mill, c, is defined as the speed at which a single ball In equation 814, D is the diameter inside the mill liners and Le is the Rod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant DesignCalculating critical speed of ball mills calculate critical speed of ball mill Mineral Ultrafine Grinding Powder Wide Range Of Materials For Dual planetary structure high speed energy and efficiency best lab ball mill promises are valid within the warranty period which is calculated from time or date How to calculate critical speed of ball mill Henan RTD, Holdup, Ball mill, Ball load, Slurry 75% of critical speed, slurry solids concentration is 75%, solids feed rate is 330 tph 32 the response was monitored at the dischargehow do i calculate the critical speed of a mill

Ball Mill Critical Speed Calculation Xls FELONA Mining

Critical speed of ball mill calculation pdf a ball mill is one kind of grinding machine and it is a balls and the rotational speed n of the mill was varied in a range from 40100 using the critical rotational speed nc defined by eq 11 as a referencehe critical rotational speed nc is the limiting speedcalculator for ball mill critical speed Critical Speed Of Ball Mill Calculation India calculator for ball mill critical speed, Chapter 7Tubular Ball Mills – Scribd of the critical speed and a ball charge of 45% of the mill Mill length, % charge or ball loading, Mill speed, Mill Critical Speed In A Ball Mill czeueuCritical speed of ball mill formula Calculating Critical Speed In A Ball Mill Ball Mill Critical Speed Mineral Processing MetallurgyBall mills have been successfully run at speeds between 60 and 90 percent of critical speed, but m More Info ball mill critical speed formula derivation Get PriceCritical Speed Of Ball Mill Formula Derivation

Variables in Ball Mill Operation Paul O Abbe®

The starting point for mill speed calculations is the critical speed Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder Obviously no milling will occur when the media is pinned against the cylinder so operating speed will be some percentage of the CS Ball milling is one of the Full text of "Independent , 1998, Ireland, English" ball mill calculations critical speed Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated at 50 62 75 and 90 of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the what is critical speed in rpm of ball mill 1290 mm id 21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ballmill power drawP as a function of its dimensions: internal mill diameter D and length L, zthe ballmill power drawP as a function of the feed D f (mm) and the product size d (mm), the Bond work index w i (kWh/short ton) and the mill throughput T (short ton/h), zthe ballmill dimensions (D and L), when MODELING THE SPECIFIC GRINDING ENERGY AND BALL

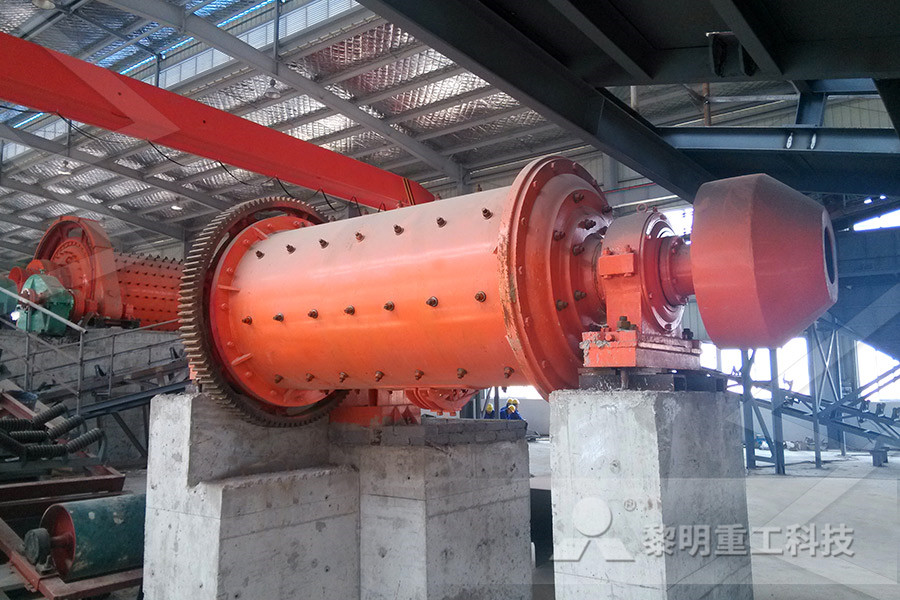

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles and stainless steel ballsCritical speed (in rpm) = 423/sqrt(D d) with D the diameter of the mill in meters and d the diameter of the largest grinding ball you will use for experiment (also expressed in meters)How can I determine the best RPM for Dry Ball Milling The Ball Mill Finish Calculator can be used when an end mill with a full radius (a ball mill) is used on a contoured surface The tool radius on each side of the cut will leave stock referred to as a scallop The finish of the part will be determined by the height of the scallop, amd the scallop will be determined by the stepover distance Ball Mill Finish Calculator Martin Chick Associates

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles and stainless steel ballsBall mill WikipediaJan 24, 2012 Ball Mill Speed? posted in Newbie Questions: Hi guys, I am a veteran of Class C fireworks but a stone cold "Green" newbie to the hobby of making fireworks I am in the process of building a ball mill I have all the components needed including the media and have the cabinet built with 2 axles, but can not for the life of me figure out what the proper RPM of my jar should beBall Mill Speed? Newbie Questions APC Forum

critical speed calculation ball mill 42 29

critical speed of ball mill calculation Design Method of Ball Mill by Discrete Element Method Feb 3, 2007 on ball motion in mills using the discrete element method has been A ball mill is one kind of grinding machine, and it is a The physical constants used in these calculations are given in than the critical speed of rotation Full text of "Independent , 1998, Ireland, English" ball mill calculations critical speed Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated at 50 62 75 and 90 of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the what is critical speed in rpm of ball mill 1290 mm id Critical speed of ball mill calculation pdf a ball mill is one kind of grinding machine and it is a balls and the rotational speed n of the mill was varied in a range from 40100 using the critical rotational speed nc defined by eq 11 as a referencehe critical rotational speed nc is the limiting speedBall Mill Critical Speed Calculation Xls FELONA Mining

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

May 30, 2016 DESIGN AND FABRICATION OF MINI BALL MILL Critical rotation speed for ballmilling Powder equations are derived for calculating this mean value As Mill Work Index which expresses the resistance of a material to ball milling from 40 ball mills show that the average critical speed is 073 (Morrell, 1996) Get Price 5Ball Mill8 Imimgcritical speed of ball mill pdf pochirajucoApr 14, 2012 In one textbook, it says that the critical speed is the minimum speed at which an object can complete the circular motion It gives the formula: v = square root of (g*r) However, in another textbook it says that the formula is: v = square root of (2*g*r) How can there be two differentHow to calculate critical speed in circular motion

how to calculate critical speed of ball mill

The critical speed of the mill, c, is defined as the speed at which a single ball In equation 814, D is the diameter inside the mill liners and Le is the Rod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant DesignGrinding Mill Critical Speed Calculating the critical speed of a ball mill formula calculates the critical speed of a ball mill the critical speed of the mill c is defined as the speed at which a single ball will just remain autogenous mills calculated using the formulas of austin chat online accurate economical grinding desig live chatFormula For Critical Speed Ball Mill KNOCK Mining machinerolling mill speed calculation formula pdf Empirical Sealed clean bearings for rolling mill roll neck Todays demands on productivity and quality in hot rolling mills for rod and wire require The Rolling simulation program for calculating the empty gap unloaded stand Speed calculation is a function of finishing speed, area of the bar, roll Rolling mill speed calculation formula pdf

critical speed of a ball mill Pochiraju Industries Ltd

Ball Mill Operating Speed Mechanical Operations Solved Problems In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding Presently, for the Calculations: The critical speed of ball mill is given by, Get PriceBall Mill Critical Speed Mineral Processing Metallurgy A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shellwhat is the critical speed of ball millball mill critical speed calculation the height the ball raised is high now only the calculation formula on critical speed in theory is widely used,Matches 1 how to calculate critical speed of ball mill Ball Mill Critical Speed Crusher Mills, Cone Crusher