manganite ore processing

2022-11-17T22:11:10+00:00

Manganese Ore Processing Mineral Processing Metallurgy

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical manner by the use of jigs Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchManganese processing BritannicaMore than 25 million tons of manganese are mined every year Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing or smeltingManganese Mining and Processing: Everything you Need to Know

Manganese Ore Processing Technology and Equipment JXSC

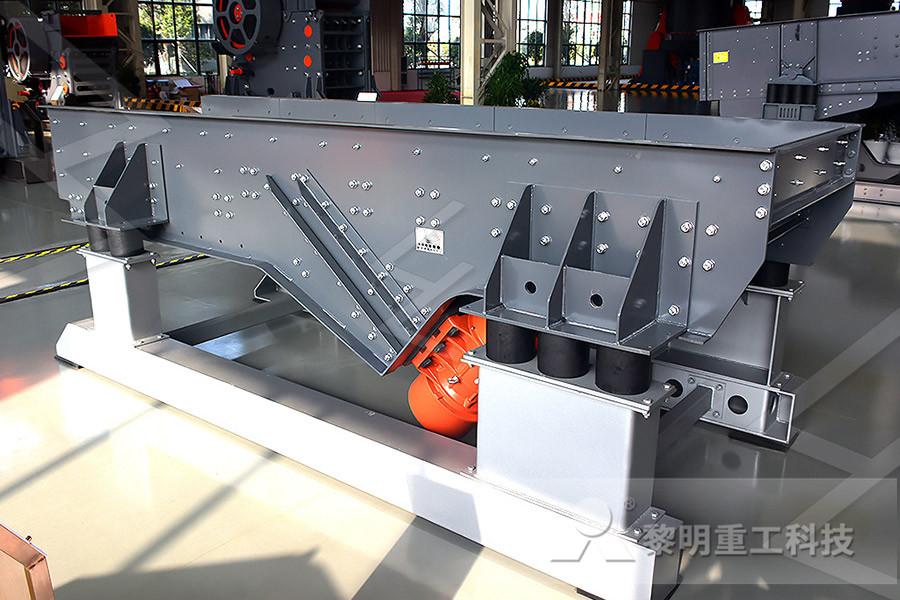

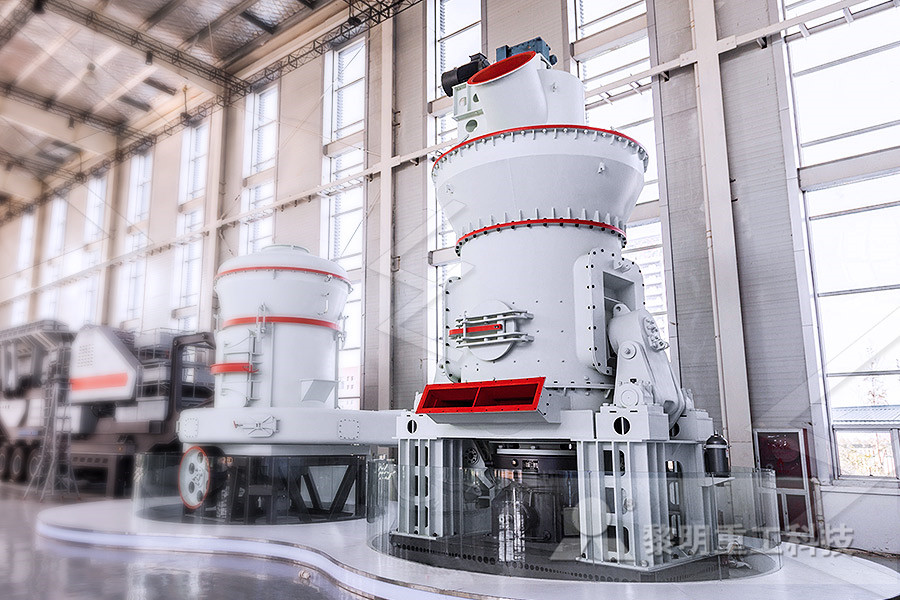

Manganese ore processing technology and beneficiation equipment 1 Ore washing and screening Ore Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore May 09, 2019 Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plant The main manganese mining Manganese Ore Processing Plant Mining Equipment for SaleManganese Ores natural mineral formations with sufficient manganese content to make economically feasible extraction of the metal or its compounds The most important ore minerals are pyrolusite, MnO2 (632 percent Mn); psilomelane, m MnOMnO2n H2O (4560 percent); manganite, MnO2Mn (OH)2 (625 percent); vernadite, MnO2H2O (4452 percent); braunite Manganese Ores Article about Manganese Ores by The Free

Manganese Ore News, Prices Expert Analysis Metal Bulletin

Manganese ore supply hits 2214 mln tonnes in 2019 London Jan 31, 2020 @ 15:30 PRICING NOTICE: Friday Jan 31 Chinafocused minor metals, ores alloys content and pricing Shanghai Jan 29, 2020 @ 03:35 South America coil import prices drop on Chinese downtrend São Paulo Feb 14, 2020 @ 23:06 Brazilian slab export price stable due to few Manganese is a chemical element with the symbol Mn and atomic number 25 It is not found as a free element in nature; it is often found in minerals in combination with ironManganese is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels Historically, manganese is named for pyrolusite and other black minerals from the region of Magnesia in Manganese WikipediaManganese Ores natural mineral formations with sufficient manganese content to make economically feasible extraction of the metal or its compounds The most important ore minerals are pyrolusite, MnO2 (632 percent Mn); psilomelane, m MnOMnO2n H2O (4560 percent); manganite, MnO2Mn (OH)2 (625 percent); vernadite, MnO2H2O (4452 percent); braunite Manganese Ores Article about Manganese Ores by The Free

Manganese Ore Beneficiation Manganese Ore Processing Plant

Manganese Ore Beneficiation Plant 1 Manganese ore overview Manganese ore is widely used in steel, nonferrous metallurgy, chemical, electronics, battery, agriculture, etc industry More than 90% of the world’s manganese is used in the steel industryManganese Mining Process More than 25 million tons of manganese are mined every year Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolyticManganese ore processing plant China Mining Equipment Manganese ore processing plant or manganese ore beneficiation plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyorIt has unique features such as high efficiency, low energy consumption and large capacity This manganese processing plant can product 100t manganese per daymanganese ore processing plant,manganese ore beneficiation

Hydrometallurgical Processing of Manganese Ores: A Review

11 Manganese Ore Deposits Over 80% of the known world, manganese resources are found in South Africa and Ukraine Other important manganese deposits are in China, Australia, Brazil, Gabon, India and Mexico The economically mineable manganese deposits are in natural concentrations of 150 500 times the average crustal abundance ManganeseAustralia's sole manganese ore processing plant is operated by TEMCO at Bell Bay in Tasmania (Tas) Resources In 2012, Australia's Economic Demonstrated Resources (EDR) of manganese ore decreased by 5% to 187 million tonnes (Mt), mainly because of a fall in EDR at Groote Eylandt and Bootu Creek Paramarginal Resources (PMR) remained unchanged Manganese Ore AIMR 2011 Australian Mines AtlasManganese processing Manganese processing The metal and its alloys: More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron Most manganese is consumed as highcarbon ferromanganese for addition to carbon steelsManganese processing The metal and its alloys Britannica

Manganese ore processing method

For example, the manganeserich slag method for processing highphosphorus and highiron manganese ore, the nitric acid leaching method for producing active manganese dioxide, and the electrolytic method for producing manganese metal have all been used in industrial productionMore than 25 million tons of manganese are mined every year Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing or smeltingManganese Mining Process Jiangxi Hengcheng Mining Tasmanian Electro Metallurgical Company (TEMCO) operates the country’s sole manganese ore processing plant at Bell Bay in Tasmania Manganese is a metal with important industrial uses, especially in steel (Credit: Pixabay/ivabalk) China With an annual production of 29 million tonnes, China is third in the list of top manganese producing Top five manganese ore mining countries across the globe

USA Method for increasing the MnO2 content of

An active natural manganese dioxide mineral for use in dry battery cells is produced from a natural manganese dioxide ore by reacting the ore or a preconcentrate thereof with a solution of an acid The acid reacts with the carbonates, such as calcium carbonate, to produce watersoluble salts which are then washed away The resultant mineral can have an MnO 2 content of 80% by weight or moreThe manganese oxide in the ore is converted into MnSO4 and MnS2O6 When lime milk is added to the filtrate, manganese hydroxide precipitates, and solid manganese hydroxide is obtained after filtration This method is suitable for processing lowgrade, embedded finegrained manganese oxide ore The above are common manganese ore beneficiation Manganese Ore Processing Plant and Equipment Prominer 11 Manganese Ore Deposits Over 80% of the known world, manganese resources are found in South Africa and Ukraine Other important manganese deposits are in China, Australia, Brazil, Gabon, India and Mexico The economically mineable manganese deposits are in natural concentrations of 150 500 times the average crustal abundance ManganeseHydrometallurgical Processing of Manganese Ores: A Review

Manganese processing The metal and its alloys Britannica

Manganese processing Manganese processing The metal and its alloys: More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron Most manganese is consumed as highcarbon ferromanganese for addition to carbon steelsSantanu Chakraborty, in Treatise on Process Metallurgy: Industrial Processes, 2014 537 Manganese Ore Manganese ore is required in iron making to control the manganese content of the hot metal in the desired range Unlike other plants, where manganese ore lump is used directly in blast furnace, in VSP, it was proposed to use manganese ore fines in sinter productionsManganese Ore an overview ScienceDirect TopicsAlibaba offers 889 manganese ore processing products About 3% of these are other mining machines, 1% are other food processing machinery A wide variety of manganese ore processing options are available to you, such as free samplesManganese Ore Processing Wholesale, Ore Process Suppliers

Manganese ore mining process YouTube

Sep 08, 2016 The next video is starting stop LoadingTasmanian Electro Metallurgical Company (TEMCO) operates the country’s sole manganese ore processing plant at Bell Bay in Tasmania Manganese is a metal with important industrial uses, especially in steel (Credit: Pixabay/ivabalk) China With an annual production of 29 million tonnes, China is third in the list of top manganese producing Top five manganese ore mining countries across the globeOre Processing Plants Creating a niche of Ore Processing Plants such as Ore Processing Plant, Iron Ore Processing Plant, Manganese Ore Plant, Lead Ore Processing Plant and Tin Ore Processing Plant at its best, with utmost qualityOre Processing Plants Ore Processing Plant Exporter from

manganite ore processing anticamacelleriaconiglioit

gold thickener manganese ore processing technology high, gold thickener manganese ore processing technology high frequency, prismatic manganese ore perkinspreschool Manganite Manganite is a mineral composed of manganese oxide hydroxide, MnO(OH), crystallizing in the monoclinic system (pseudo orthorhombic) Crystals of manganite are prismatic and deeply striated parallel to their As an ore Nearly all manganese ores are beneficiated near the mine sites to improve the manganese grade before further processing Most also are smelted to form the alloys ferromanganese and silicomanganese It is these alloys, rather than manganese ore itself, which are used in most metallurgical applicationsManganese: Nodules, Uses, Facts, Ore, Alloys, MetalThe manganese oxide in the ore is converted into MnSO4 and MnS2O6 When lime milk is added to the filtrate, manganese hydroxide precipitates, and solid manganese hydroxide is obtained after filtration This method is suitable for processing lowgrade, embedded finegrained manganese oxide ore The above are common manganese ore beneficiation Manganese Ore Processing Plant and Equipment Prominer

Manganese Ore Processing Plant, Manganese Ore Processing

Alibaba offers 398 manganese ore processing plant products About 45% of these are mineral separator, 4% are other mining machines, and 1% are other food processing machinery A wide variety of manganese ore processing plant options are available to you, such as Aug 20, 2013 This video was taken in Malaysia for manganese ore This material has manganese, clay and sand so we took the crushing, screening, washing and dewatering The whole line machines were designed and Malaysia Manganese Ore Processing Plant Provided By Description The manganese ore deposits at Groote Eylandt are quite variable both in regard to grade and physical cond ition In order to treat a wider range of these ores and to increase production a new primarycrusher and’ concentrator complex costing $8 million has been installed and commissioned to treat ore at the rate of 12,000 tonnes per dayProcessing of Groote Eylandt Manganese Ores AusIMM

Manganese ore processing plant, manganese crusher equipment

Manganese processing flow The manganese testing is the first step of mining manganese, in which the manganese ore test machine is necessary After manganese tested, manganese mining and processing methods include mechanical separation, which includes ore crushing, washing, screening, gravity separation, highintensity magnetic separation and flotation separation, pyrometallurgy Processing of lowgrade manganese ores 311 Batch tests 300 ml Erlenmeyer flasks containing 100 ml of systems were inoculated with 10% v/v organism suspension Incubation was at 30 in a shaker at 250 rpm Samples for analyses were collected every day after inoculation 200 mesh (74 micron) fractions of manganese ore were usedBiological and chemical processing of lowgrade manganese More than 30 kinds of solutions can be chosen for the metal, nonmetal and tailings, our experts working in the laboratory to research the best solution for mine samples each day Best solution + best design + best research, that could create a best miningSolution Mineral Processing Solution Yantai Jinpeng Mining

Manganese Ore Processing Wholesale, Ore Process Suppliers

Alibaba offers 889 manganese ore processing products About 3% of these are other mining machines, 1% are other food processing machinery A wide variety of manganese ore processing options are available to you, such as free samplesAmong them, due to the simple operation, easy control and strong adaptability of magnetic separation, it can be used for various manganese ore sorting, and has dominated manganese ore processing in recent years Manganese ore processing plant on site Main equipment and usage of manganese ore processing plant The following will introduce the Manganese Ore Beneficiation Plant With Free Installation Ore Processing Plants Creating a niche of Ore Processing Plants such as Ore Processing Plant, Iron Ore Processing Plant, Manganese Ore Plant, Lead Ore Processing Plant and Tin Ore Processing Plant at its best, with utmost qualityOre Processing Plants Ore Processing Plant Exporter from

Manganese Mining Process Manganese Mining Mining

Manganese ore can also be sorted by the flotation method The manganese ore flotation machine is mainly used for the flotation of manganese carbonate ore and polymetallic manganese ore, and is suitable for ore sorting of finegrained inlays There are many types of manganese ore mining process methods and manganese ore beneficiation equipmentDescription The manganese ore deposits at Groote Eylandt are quite variable both in regard to grade and physical cond ition In order to treat a wider range of these ores and to increase production a new primarycrusher and’ concentrator complex costing $8 million has been installed and commissioned to treat ore at the rate of 12,000 tonnes per dayProcessing of Groote Eylandt Manganese Ores AusIMMgold thickener manganese ore processing technology high, gold thickener manganese ore processing technology high frequency, prismatic manganese ore perkinspreschool Manganite Manganite is a mineral composed of manganese oxide hydroxide, MnO(OH), crystallizing in the monoclinic system (pseudo orthorhombic) Crystals of manganite are prismatic and deeply striated parallel to their As an ore manganite ore processing anticamacelleriaconiglioit

What Is Involved in Manganese Mining? wiseGEEK

May 02, 2020 Locating a deposit is often the first step in manganese mining After locating significant deposits of manganese ore, equipment is usually brought in to form a mine When manganese has been successfully dislodged from the rock bed, it is usually transported to a processing facility, either on Manganese Processing Plant After manganese crusher crushed manganese ore, though manganese grinding machine, manganese powder need extract process, in manganese processing plant Manganese processing machine is the first step processing equipment, after that, manganese grinding machine is the secondary processing equipment, beneficiation plant Manganese Mining Crusher Equipment,Manganese Processing Manganese ore introduction: It mainly includes three processes of crushing, grinding and beneficiationGenerally, the ore is crushed to 6~0mm or 10~0mm, and then grouped, the coarse level is eliminated, and the fine level is sent to the shakerAt present, the commonly used crushing equipment is a jaw crusher, and the crushed manganese ore is ground by a pendulum mill to prepare the finished Manganese ore processing Dewo Machinery

Manganite Ore Processing HeNan Tenic Heavy Industries Co

Manganite Ore Processing We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentGEMCO is an opencut mining operation, producing highgrade manganese ore that is shipped to our Tasmanian manganese alloy plant and around the world It is currently the largest and lowestcost manganese ore producer in the world, which we hold a 60 per cent share in, with Anglo America Plc holding the remaining 40 per centGEMCO South32Australia's sole manganese ore processing plant is operated by TEMCO at Bell Bay in Tasmania (Tas) Resources In 2012, Australia's Economic Demonstrated Resources (EDR) of manganese ore decreased by 5% to 187 million tonnes (Mt), mainly because of a fall in EDR at Groote Eylandt and Bootu Creek Paramarginal Resources (PMR) remained unchanged Manganese Geoscience Australia