max size to send to cone crusher

2022-05-22T17:05:42+00:00

Cone Crushers Mineral Processing Metallurgy

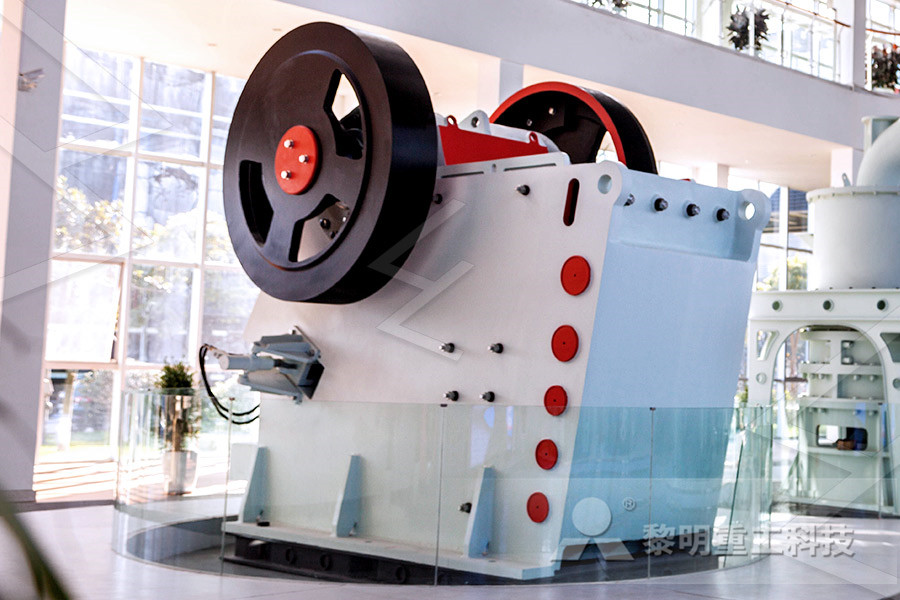

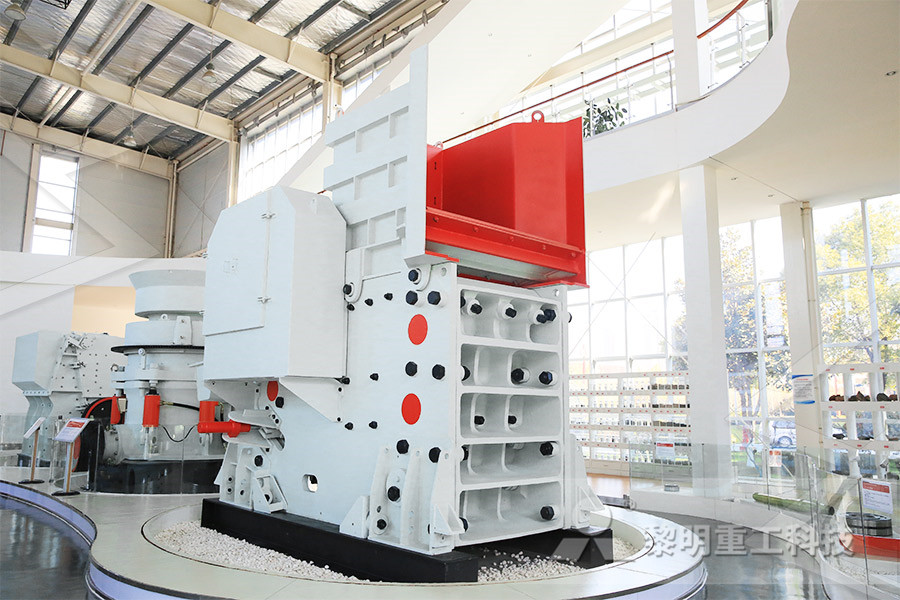

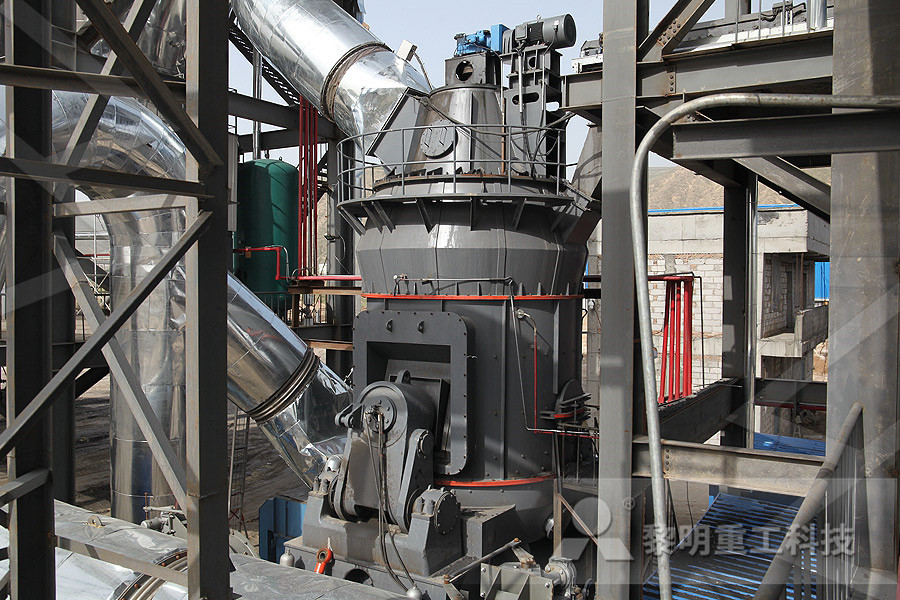

Cone Crushers The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size ; but the main shaft of a cone Cone Crusher Applications A general rule of thumb for applying Cone Crushers is the reduction ratio A crusher with coarse style liners would typically have a 6:1 reduction ratio Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 45 inches Reduction ratios of 8:1 may be possible in certain coarse crushing Cone Crushers McLanahanCrushers or rock crushers are machines used to reduce the size of rocks and stones in aggregates production, construction material recycling applications, and in mining operations has designed, engineered and manufactured crushers for more than 100 years Our offering covers different jaw crushers, gyratory crushers, cone crushers, and Crushers All crusher types for your reduction needs

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crushers crush to reduce the size by a maximum of about onetenth its size Usually, metallurgical operations require greater size reduction; hence, the products from the primary crushers are conveyed to secondary or cone crushers where further reduction in size takes place Here, the maximum reduction ratio is about 8:1Apr 28, 2017 The maximum distance from which the feed material should fall from into the top of a small to midsize cone crusher is 3 ft When the feed material drops from a much greater distance, the stones tend to slam into the Vshaped crushing cavity with such velocity that it subjects the crusher to shock loads and extremely high stress levelsMaximize your cone crusher productivity : Pit QuarryCone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingCone crusher basics in 4 minutes — Sandvik Mining and Rock

Sandvik CH660 Cone Crusher For PebbleCrushing

CH660 Cone crusher Sandvik CH660 is an advanced design with a small footprint, and has a high capacity in relation to its size This cone crusher has a hydraulically supported main shaft that is supported at both endsKey specifications; Total weight: 14300 kg / 31500 lbs: Max permitted power: 220 kW / 245 hp: Capacity: 65415 tph/td> CSS range: 844 mm / 0,31,7 in: Max feed sizeCategory: Cone Crushers – Aggregate EquipmentThe maximum feed size to an 848 Hydrocone crusher would therefore be about 5½in one way dimension The use of a wobble plate feeder, furnished as optional equipment, is recommended if the feed size is relatively large, if the crusher is to be operated in closed circuit, or if the feed to the crusher Cone Crusher Mineral Processing Metallurgy

Category: Cone Crushers – Aggregate Equipment

Key specifications; Total weight: 14300 kg / 31500 lbs: Max permitted power: 220 kW / 245 hp: Capacity: 65415 tph/td> CSS range: 844 mm / 0,31,7 in: Max feed sizeSpring Cone Crusher breaks material by squeezing or compressing it between convex and concave shaped surfaces covered by manganese as the wear surface Normally used as the secondary or tertiary crusher, the cone crusher has been developed to crush high or medium hardness material, such as iron ore ,copper ore, limestone, quartz, granite, and Spring Cone crushers,Cone crusher,Spring Cone crusher The capacity of the crusher is determined by its size The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers can produce size reduction ratios TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Symons crusher parts,Symons crusher Max feed size,Symons

Apr 25, 2017 mouldingpartsplease send inquire to:info@mouldingparts Symons Cone Crusher has features of strong crushing force,reliable Mobile Cone Crushing Plant [ Capacity ]: 10180 t/h [ Applicable Material ]: The mobile crushing plant is designed for road transportation, especially for driving to crushing sites that are difficult to access, which greatly reduce installation time compared with the stationary oneMobile Cone Crushing Plant,Cone Crusher plant,Mobile CrusherDec 05, 2016 The maximum distance from which the feed material should fall from into the top of a small to midsize cone crusher is 3 ft When the feed material drops from a much greater distance, the stones tend to slam into the Vshaped crushing cavity with such velocity that it subjects the crusher to shock loads and extremely high stress levels11 tips for maximizing cone crusher productivity

Crusher Close Side Settings Mineral Processing Metallurgy

The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under chokefeed or regulated feed conditions It is possible, when all conditions are favourable, to operate gyratory crushers, with standard throw eccentrics, at The ® 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model and features a recirculating conveyor and a doubledeck postscreen to provide a complete crushing and screening process on a single chassis The machine is designed for direct feed applications without prescreening on clean rock1000SR Mobile Cone Crusher Material Processing With a maximum diameter of 375 m (148 inches) and weight of 50,274 kg (110,833 lbs), the crusher’s size gives you flexibility for multisite crushing opportunities The Raptor 500 cone is built with a rigid threearm frame and integral countershaft box mounted inside one of its three arms which reduces your maintenance time, improves the Raptor® Cone Crusher best in class

CONE CRUSHER Bell Equipment

Medium coarse concave (max feed size 220mm) Direct cone drive via wet clutch Hopper / Feeder: Hopper capacity: 8m³ (104yd³) Belt width: 12m (48”) Metal detector Metal contaminants purge system Wear resistant liner plates Main Conveyor: Belt width: 12m (48”) High spec scraper at head drum Wear resistant liners at crusher discharge point jaw crusher out put 1 5mm max feed size 60 jaw crusher out put 1 5mm max feed size 60; stone crusher in not exceed 80% of crusher opening size Output JOYAL Jaw Crusher,Jaw Crusher Micronizer Max Output Of Stone Crusher And Size Crusher Advantages of cone crusher Working principle and main parts Working principle When cone crusher works, its motor which is driven by the belt pulley or the coupling turns around, and the transmission shaft and the cone do the swaying movement around, thus making the concave move back and forth from mantle’s surface installed in the adjusting sleeveCone Cursher In Highquality Fote Machinery(FTM)

Mobile Crusher mchinacfccc

Maxfeeding size:500800mm Application: rocks,limestone, river pebbles, cobblestone, basalt, shale, diabase and other materials that need to be relocated Mobile Impact CrusherWith a maximum diameter of 375 m (148 inches) and weight of 50,274 kg (110,833 lbs), the crusher’s size gives you flexibility for multisite crushing opportunities The Raptor 500 cone is built with a rigid threearm frame and integral countershaft box mounted inside one of its three arms which reduces your maintenance time, improves the Raptor® Cone Crusher best in class Cone crusher,rock cone crusher,Cone crushers,CS cone The China Cone Crusher is a machine used for breaking the Diameter of crushing cone(mm) Max feeding size (mm) Width of For product inquiry or order Cone Crusher Product Size Crusher Mills, Cone Crusher

1000 MAXTRAK

The high performance ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without prescreening on clean rock At its heart is the Automax® cone crusher which provides excellent reduction and product cubicity for the production of high quality aggregate and subbase materialKey specifications; Total weight: 12000 kg / 26400 lbs: Max permitted power: 132 kW / 177 hp: Capacity: 90 – 345 tph: CSS range: 19 – 54 mm / 0,752,1 inCategory: Gyratory Crushers – Aggregate EquipmentMobile Cone Crushing Plant [ Capacity ]: 10180 t/h [ Applicable Material ]: The mobile crushing plant is designed for road transportation, especially for driving to crushing sites that are difficult to access, which greatly reduce installation time compared with the stationary oneMobile Cone Crushing Plant,Cone Crusher plant,Mobile Crusher

Symons Cone CrusherZhongde Heavy Industries

Introduction of Symons Cone Crusher 1Symons cone crusher, also known as short head cone crusher and standard cone crusher, is widely used to crush the stones and ores with medium hardness and high hardness such as basalt, granite, limestone, gravel, quartz, iron ore, copper ore, gold ore and other minerals in mining, construction, road building,chemical and other fieldsBrowse our inventory of new and used EL JAY Crusher Aggregate Equipment For Sale near you at MachineryTrader Models include 45, RC45, RC54, 54 IN, 1800, 2100, and RC36 Page 1 of 1EL JAY Crusher Aggregate Equipment For Sale 10 Listings Static Cone Crusher Cedarapids cone crushers set the standard for production and efficiency Our range of powerful cone crushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systemsCedarapids Static Cone Crushers MPS

Sandvik QH331 Lonestar Crushers, LLC

Featuring the pioneering tracked chassis Sandvik CH430 cone crusher, creating one of the most flexible cone crushers on the market today This solution benefits from the CSC (cubical shape crushing) techniques Sandvik has developed to produce material of excellent shape and high quality The CH430 cone is at the heart of the QH331In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1 "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most important factors to consider when designing a crushing circuit – and How to maximize cone crusher performance Heavy Equipment hst 160 cone crusher minimum size of css and maximum auto max cone crusher 1000 MAXTRAK SPECIFICATION SCPM International , 1000 MAXTRAK SPECIFICATION CRUSHER OPTIONS CRUSHER CONCAVE MAXIMUM FEED SIZE MAXIMUM RECOMMENDED CSS 1000 Automax Medium Coarse 160mm 36mm 1000 Automax Coarse 175mm 36mm 1000 Automax Extra hst 160 cone crusher minimum size of css and maximum

Automatic Cone Crushers, Model Name/Number: Kcc 900, ID

Cone crusher can be used for primary or secondary crushing depending upon the requirement; Kingson Cone Crusher is suitable for choke feed condition with high reduction ratio crushing It gives cubical shape products and generates high proportion of fines; Cone Crushers are designed and developed for remarkable performance with maximum outputAdvantages of cone crusher Working principle and main parts Working principle When cone crusher works, its motor which is driven by the belt pulley or the coupling turns around, and the transmission shaft and the cone do the swaying movement around, thus making the concave move back and forth from mantle’s surface installed in the adjusting sleeveCone Cursher In Highquality Fote Machinery(FTM)Medium coarse concave (max feed size 220mm) Direct cone drive via wet clutch Hopper / Feeder: Hopper capacity: 8m³ (104yd³) Belt width: 12m (48”) Metal detector Metal contaminants purge system Wear resistant liner plates Main Conveyor: Belt width: 12m (48”) High spec scraper at head drum Wear resistant liners at crusher discharge point CONE CRUSHER Bell Equipment

1000 MAXTRAK

The high performance ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without prescreening on clean rock At its heart is the Automax® cone crusher which provides excellent reduction and product cubicity for the production of high quality aggregate and subbase materialMaxfeeding size:500800mm Application: rocks,limestone, river pebbles, cobblestone, basalt, shale, diabase and other materials that need to be relocated Mobile Impact CrusherMobile Crusher mchinacfcccBrowse our inventory of new and used TELSMITH Crusher Aggregate Equipment For Sale near you at MachineryTrader Models include 48S, 48FC, 18x32, 25x40, 44x48, 52SBS, H3244, T300, T400, and TI6060 Page 1 of 3TELSMITH Crusher Aggregate Equipment For Sale 52

Cedarapids Static Cone Crushers MPS

Static Cone Crusher Cedarapids cone crushers set the standard for production and efficiency Our range of powerful cone crushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systemsCone Crushers – This portable crusher design uses a spinning triangular cone to grind materials down into finer particles They can be used for anything from mining ore to environmental projects and demolishing construction materials Impact Crushers – This is where a hopper takes material into the machine to be pulverizedCrushing Plants For Sale MyLittleSalesmanIn most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1 "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most important factors to consider when designing a crushing circuit – and How to maximize cone crusher performance Heavy Equipment

C1545 Cone Crusher Home Welcome to OPS Screening

The Finlay C1545 mobile cone crusher features a high capacity aggressive cone crusher that consistently provides high output capacity and a product with excellent cubicity Specifications include: Scania DC13 331kW (450hp), TC1150 Long throw eccentric, medium coarse concave cone chamber Learn more nowThe MC1000 Modular Cone Crusher handles an allin feed for continuous crushing Its 40” (1000mm) cone has a full range of configurations for short and long throw The allroller bearing design delivers enhanced crushing efficiency Set up time and ease of operation is aided by the simplicity of The Cedarapids MC1000 Modular Cone PlantAggregate Equipment Frontline Machinery offers innovative solutions tailored to meet the unique demands of quarry, alluvial, sand, gravel or mine owners and operators alike Engineered for maximum productivity, portability, and performance, Frontline’s complete line of mobile jaw, cone, and impact aggregate crushing and screening equipment Aggregate Frontline Machinery Ltd Crushers, Screeners

Mobile Cone Crushing Plants SANME Crusher

MPC Series Mobile Cone Crusher Plants: MPC120 MPC180 MPC250 Cone Crusher: SMH120 SMH180 SMH250 Max Feed Size (mm) 160 180 260 Gap Width (mm) 932 932 951 Crushing Capacity (t/h) up to 150 up to 200 up to 350 Driving Unit Engine Cummins or CAT Cummins or CATIntroduction of Symons Cone Crusher 1Symons cone crusher, also known as short head cone crusher and standard cone crusher, is widely used to crush the stones and ores with medium hardness and high hardness such as basalt, granite, limestone, gravel, quartz, iron ore, copper ore, gold ore and other minerals in mining, construction, road building,chemical and other fieldsSymons Cone CrusherZhongde Heavy Industrieshst 160 cone crusher minimum size of css and maximum auto max cone crusher 1000 MAXTRAK SPECIFICATION SCPM International , 1000 MAXTRAK SPECIFICATION CRUSHER OPTIONS CRUSHER CONCAVE MAXIMUM FEED SIZE MAXIMUM RECOMMENDED CSS 1000 Automax Medium Coarse 160mm 36mm 1000 Automax Coarse 175mm 36mm 1000 Automax Extra hst 160 cone crusher minimum size of css and maximum

The Models And Parameters Of Cone Crusher

Symons cone crusher controls the particle size of material according to reducing the size of the discharge opening, so it is not suitable for ultrafine sand or sand making The difference in the costperformance ratio The technology of singlecylinder hydraulic cone crusher is more advanced and higher efficient to operate