process of lead concentrate from lead ore

2019-03-03T21:03:05+00:00

Lead processing Mining and concentrating Britannica

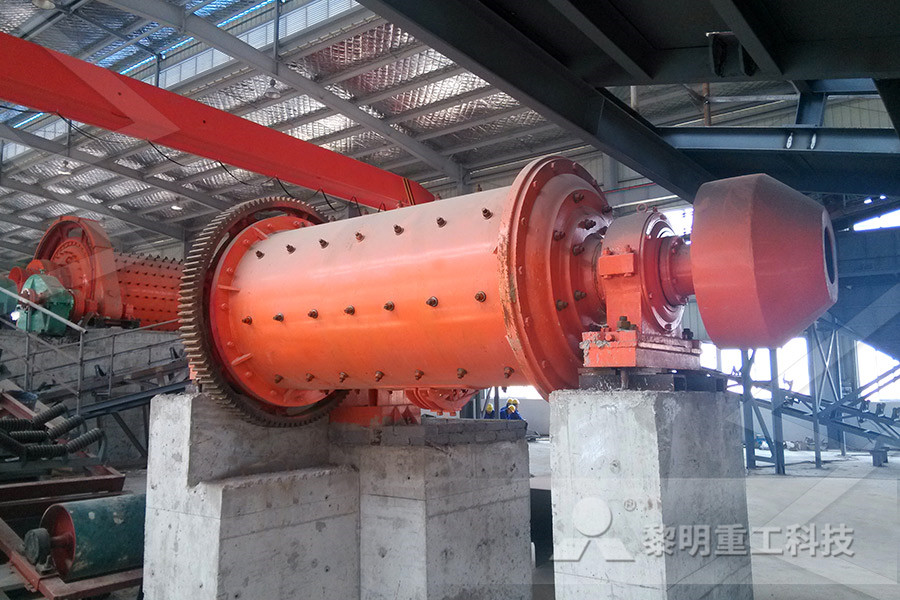

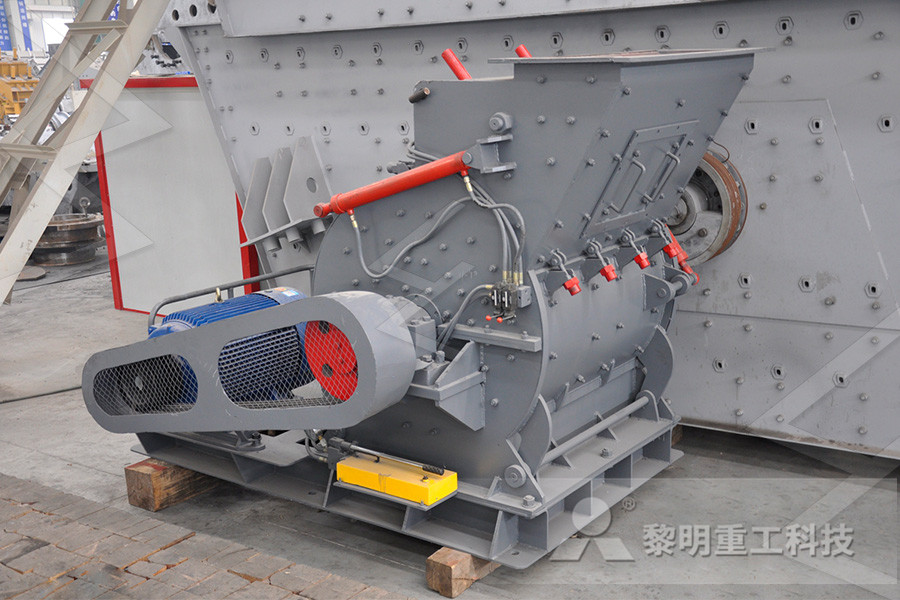

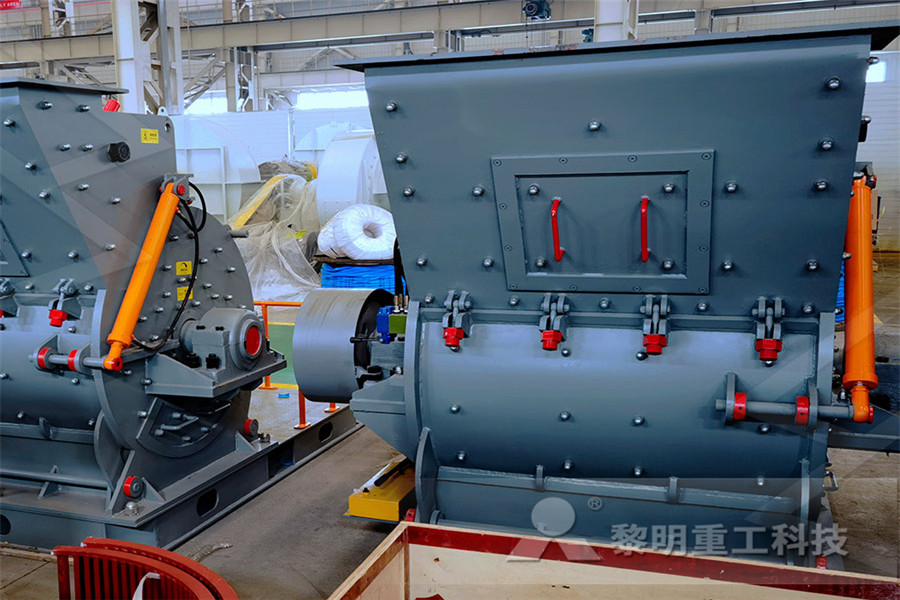

Lead processing Lead processing Mining and concentrating: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills Here the ore is finely crushed, sometimes to particle diameters of less than 01 millimetre (0004 inch), and then treated by one of several mineral The Froth flotation process separates the Lead and other minerals from the waste rock (tailings) to form a concentrate The concentrate, which can range from 50% to 60% Lead, is dried and then treated using pyrometallurgy The concentrate is sintered before being smelted in to produce a 97% Lead concentrateLead Ore / Lead Concentrate Smelting, Manufacturing Mineral extraction mining and separation of the leadrich mineral (ore) from the other extracted materials to produce a lead concentrate Primary production production of metallic lead from lead ore concentrates involves the following process steps: Smelting reacting the lead rich mineral with other ingredients, to yield impure metallic leadLEAD INDUSTRY PROFILE ILA International Lead

Lead Ore,Galena,Lead Galena,Lead Galena Buyer,Lead Ore

Mostly Lead Ore is obtained as a byproduct of metal mining (Zinc, silver) Many steps are used for obtaining the Lead from Lead Ore (Lead Ore Refining Process), these process/steps are mining the Ore, Concentrating the ore, Flotation, Filtering, Roasting the ore, Blasting, Refining, and Casting :June 12, 2015 Lead Concentrate Page 2 of 7 (H 2S) Inhalation or ingestion of concentrate dust may produce chronic health effects Possible cancer hazard due to lead, cadmium and silica content Possible reproductive hazard due to the lead content SCBA and full protective clothing required for fire emergency response personnelLEAD CONCENTRATE SAFETY DATA SHEETLead processing, preparation of the ore for use in various products Lead (Pb) is one of the oldest metals known, being one of seven metals used in the ancient world (the others are gold, silver, copper, iron, tin, and mercury) Its low melting point of 327 °C (621 °F), coupled with its easyLead processing Britannica

Lead Concentrate Sormak Mining Company

The ore concentrating process requires pine oil, alum, lime, and Potassium Amyl Xhantate Limestone or iron ore is added to the lead ore during the roasting process Coke, a coal distillate, is used to further heat the ore The manufacturing process of lead ingots 1 mining the ore 2 Concentrating the ore 3 Flotation 4 Filtering 5 Roasting the On average, lead in the feed was 36 percent recovered into a concentrate grading 55 percent lead Only 03 percent of the copper in the feed was recovered to the lead concentrate This process used MBS in the copper circuit and relatively low doses of cyanide in the lead circuitCopper Lead Concentrate SeparationDirect process In this process, lead bullion and slag is obtained directly from lead concentrates The lead sulfide concentrate is melted in a furnace and oxidized, forming lead monoxide Carbon (as coke or coal gas) is added to the molten charge along with fluxing agents The lead monoxide is thereby reduced to metallic lead, in the midst of Lead Wikipedia

Lead Essential Chemical Industry

The lead ore concentrate from the flotation tanks now contains about 50% lead and ca 01% of silver, a relatively small but valuable amount (b) Smelting Smelting is usually a twostage process as described here, although singlestage methods with lower energy use and emissions are also usedLead Concentrate is mostly used for manufacturing of Lead Metal and Lead Alloys The Lead Concentrates produced from wind Ore were processed into primary metal at two smelterrefineries Missouri and a smelter in Montana Applications: • Lead Concentrate is mostly used for manufacturing of Lead Metal and Lead AlloysLead Concentrate, Lead Concentrate Trading, Trading Lead Wanted Lead Ore And Lead Concentrate Buyer from Please provide quotation to the following requirement from importer Product Name Lead Slag, Lead Ore And Lead Concentrate Specifications (1) Lead compound = 40% Lead Slag Lead flue dust (2) Lead Ore = 40% (3) Lead Concentrate = 40% Sulfide or Oxidation all Ok As greater than 05%, Cl greater than 05%, Cd greater than 005%, Hg lead ore concentrate communales2018be

Chemistry Teacher Metallurgy of Lead Ores YouTube

Jun 08, 2018 Extraction: Lead is mainly extracted from the sulphide ore galena Galena contains lead sulphide and small quantities of silver Concentration: The ore is concentrated by froth floatation processThe one of the process which is used for getting Pure Lead is the Flotation process; this process collects the Sulfur bearing portions of the Ore, which contains the valuable metal The Liberated Lead minerals are smelted by three stage process of charge preparation (1) blending, conditioning (2) blast sintering and (3) blast furnace reductionLead Ore, Lead Ore Trading,Trading Leae Ore, Lead Ore Interested in copper ore, concentrate, Lead ore and Nickel concentrate We, a company from India, are importer and exporter of Copper ore, Concentrate, Lead ore and nickel concentrate We want Company Location: India, Chennai 295; 15012019Lead concentrate price Trade Metal Portal

Lead Concentrate Gravita India Ltd

Gravita India Limited Gravita Tower, A27B, Shanti Path, Tilak Nagar, Jaipur (Rajasthan) INDIA TEL : +91141 FAX : +91141(1) a lead concentrate, (2) a copper concentrate, and (3) a zinc concentrate It can be readily appreciated that an accurate comparison of several tests on an ore of this nature would involve a large number of factors, and that mathematical formulas to solve such problems would be unwieldy and useless if they included all of these mon Basic Formulas for Mineral Processing CalculationsPlants for the production of lead are generally referred to as lead smeltersPrimary lead production begins with sinteringConcentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metalLead smelting Wikipedia

metal distillation, vacuum distillation, nonferrous

POWBEN provide systematic solution for Lead ore, Lead battery recycling After the Lead ore or battery scrap is smelted in the furnace into crude lead (9698%), the Lead refining process will be followed to produced final qualified lead ingot (9999%) POWBEN can provide client two type of refining method: electrorefining and firerefining Lead ore minerals or lead concentrate export is the export of lead from Nigeria to international buyers located in various parts of the world It is exported in either the lead ore form or the lead concentrate form, and are further processed upon arrival at the buyer’s facility into Lead Ore Minerals Suppliers In Nigeria: Lead Ore Exporters 6122 Lead and Zinc Ore Concentration If the mineral veins separate from the rock cleanly, then processing workers can concentrate the ore by taking advantage of the greater weight mineral compared to the rock Jigging separates coarse lumps In this process, the crushed ore is agitated or shaken in water with a vertical motionLead and Zinc energygov

Lead Ore, Lead Galena buyer, Lead Ore Refining, Lead Ore

Mostly Lead Ore is obtained as a byproduct of metal mining (Zinc, silver) Many steps are used for obtaining the Lead from Lead Ore (Lead Ore Refining Process), these process/steps are mining the Ore, Concentrating the ore, Flotation, Filtering, Roasting the ore, Blasting, Refining, and Casting :The Froth flotation process separates the Lead and other minerals from the waste rock (tailings) to form a concentrate The concentrate, which can range from 50% to 60% Lead, is dried and then treated using pyrometallurgy The concentrate is sintered before being smelted in to produce a 97% Lead concentrateLead Concentrate Smelting Plant Lead Recycling Plant Mostly Lead Ore is obtained as a byproduct of metal mining (Zinc, silver) Many steps are used for obtaining the Lead from Lead Ore (Lead Ore Refining Process), these process/steps are mining the Ore, Concentrating the ore, Flotation, Filtering, Roasting the ore, Blasting, Refining, and Casting :Lead Ore, Lead Galena buyer, Lead Ore Refining, Lead Ore

Lead and Zinc energygov

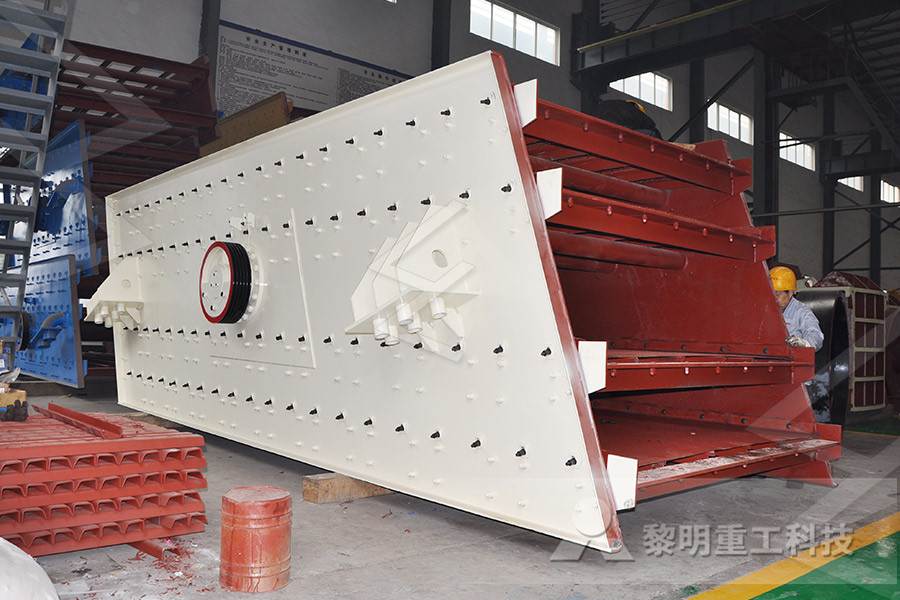

6122 Lead and Zinc Ore Concentration If the mineral veins separate from the rock cleanly, then processing workers can concentrate the ore by taking advantage of the greater weight mineral compared to the rock Jigging separates coarse lumps In this process, the crushed ore is agitated or shaken in water with a vertical motionLead ore minerals or lead concentrate export is the export of lead from Nigeria to international buyers located in various parts of the world It is exported in either the lead ore form or the lead concentrate form, and are further processed upon arrival at the buyer’s facility into Lead Ore Minerals Suppliers In Nigeria: Lead Ore Exporters The Froth flotation process separates the Lead and other minerals from the waste rock (tailings) to form a concentrate The concentrate, which can range from 50% to 60% Lead, is dried and then treated using pyrometallurgy The concentrate is sintered before being smelted in to produce a 97% Lead concentrateLead Concentrate Smelting Plant Lead Recycling Plant

CuPbZn, CopperLeadZinc Ores, Copper Lead Zinc

Process Xinhai separates two useful minerals that with similar floatability into the mixed concentrate, and then floats each concentrate That is, copper sulphide and lead ore with similar floatability are selected as mixed concentrate, and copper and lead is separated10tpd 100tpd To 20000tpd Lead Ore Concentrate,Lead Ore Concentrate Of Processing Plant , Find Complete Details about 10tpd 100tpd To 20000tpd Lead Ore Concentrate,Lead Ore Concentrate Of Processing Plant,Lead Ore Concentrate,Lead Ore Concentrate Plant,Lead Ore Concentrate Process from Mineral Separator Supplier or ManufacturerShandong Xinhai Mining Technology Equipment Inc10tpd 100tpd To 20000tpd Lead Ore Concentrate,Lead Ore Lead Mining Board on Metals Place, a free lead mining Exchange A lead mining trader's only stop Buy lead mining, sell lead mining and lead mining products on Metals Place lead mining marketplace, find lead mining producers, lead mining importers and lead mining exporters Post your ad offer free!Lead Mining Board Metals Place

LEAD ZINC EXTRACTION PROCESSES EPrints

are used for production of lead zinc depending on the type of raw material used as a charge In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentrations can be 5070%, and the sulfur content of sulfidic ores is in the range of 1520%Most ores contain less than 10% lead Ores are crushed and concentrated by froth flotation typically to 70% or more Sulfide ores are roasted, producing primarily lead oxide and a mixture of sulfates and silicates of lead and other metals contained in the ore Lead oxide from the roasting process is reduced in a cokefired blast furnacelead ore lead concentrate GalenaJan 31, 2020 Volume of lead ore and concentrate imports in India 20132018 Export and import volume of refined lead in India 20132018 Apparent consumption of refined lead in India 20132018UK: lead ore and concentrates import volume 2018 Statista

126 Primary Lead Smelting US EPA

126 Primary Lead Smelting 1261 General15 Lead is found naturally as a sulfide ore containing small amounts of copper, iron, zinc, precious metals, and other trace elements The lead in this ore, typically after being concentrated at or near the mine (see Section 1218), is processed into metallurgical lead at 4 facilities in the U SLead Ore / Lead Concentrate Smelting, Manufacturing Technique for It often contains enough silver to be mined as a silver ore The Froth flotation process separates the Lead and other minerals from the waste rock (tailings) toprocess of mining lead from ore populareducationcozaBrief About Lead Ore/Concentrate Lead is a soft, malleable, ductile, bluishwhite, dense metallic element, extracted chiefly from galena and found in ore with zinc, silver and copper Whilst it is still used for its malleability and corrosion resistance, it is now its Lead Ore Concentrate – Petevop Int Ltd

Zinc ore Mining Process

According to ore properties and a series of processing tests, Xinhai finally decided Zinc and lead mixed flotation separation mixed tailings zinc flotationflotation tailings weak magnetic separation process, so the plant also get more than 65% iron concentrate in addition to the grade high of Zinc, lead and zinc concentrateJan 31, 2020 Volume of lead ore and concentrate imports in India 20132018 Export and import volume of refined lead in India 20132018 Apparent consumption of refined lead in India 20132018UK: lead ore and concentrates import volume 2018 Statista126 Primary Lead Smelting 1261 General15 Lead is found naturally as a sulfide ore containing small amounts of copper, iron, zinc, precious metals, and other trace elements The lead in this ore, typically after being concentrated at or near the mine (see Section 1218), is processed into metallurgical lead at 4 facilities in the U S126 Primary Lead Smelting US EPA

process of mining lead from ore populareducationcoza

Lead Ore / Lead Concentrate Smelting, Manufacturing Technique for It often contains enough silver to be mined as a silver ore The Froth flotation process separates the Lead and other minerals from the waste rock (tailings) toBrief About Lead Ore/Concentrate Lead is a soft, malleable, ductile, bluishwhite, dense metallic element, extracted chiefly from galena and found in ore with zinc, silver and copper Whilst it is still used for its malleability and corrosion resistance, it is now its Lead Ore Concentrate – Petevop Int LtdAccording to ore properties and a series of processing tests, Xinhai finally decided Zinc and lead mixed flotation separation mixed tailings zinc flotationflotation tailings weak magnetic separation process, so the plant also get more than 65% iron concentrate in addition to the grade high of Zinc, lead and zinc concentrateZinc ore Mining Process

Process intrumentation for the Australian lead industry

Nov 07, 2019 The lead is separated from tailings and minerals using a flotation process Lead sulphate concentrate rises to the top and is skimmed and dried This concentrate is then sintered to form lumps and remove sulphur The remaining product is then smelted in a blast furnace, resulting in impure lead This process melts the concentrate into liquid, separating and drawing out impurities leaving only crude lead Liquid crude lead is poured and left to settle in one of six, 100 tonne kettles As it cools, the heavy molten lead with its relatively low melting point sinks to the bottom of the kettleThe mining process Zinc Mount Isa MinesList of copperconcentrate companies Over 59 in China Shaanxi Sengen Trade Co, Ltd Shaanxi Sengen trade Co, Ltd is an importer of nonferrous minerals and materials in China, it#039;s set up by MrZhangheng the year ***** Zhang has been deal with from 1998Shaanxi mainly import lead ore/concentrate;copper ore/concentrate;zinc ore/concentrate;silver List of Copper Concentrate companies in China

LEAD SMELTING PROCESS COMINCO LTD,CA

Nov 12, 1974 A process for separately recovering lead values and sulphur values from lead sulphide ores and concentrates in which ore or concentrate in particulate form in admixture with an oxygenrich gas is charged into a furnace containing a molten bath consisting of lead oxidecontaining slag or of lead and a lead oxidecontaining slag coverPlease provide quotation to the following requirement from importer Product Name : Lead Slag, Lead Ore And Lead Concentrate Specifications : (1) Lead compound = 40% Lead Slag Lead flue dust (2) Lead Ore = 40% (3) Lead Concentrate = 40% Sulfide or Oxidation all Ok As greater than 05%, Cl greater than 05%, Cd greater than 005%, Hg greater than 001%, F greater than 01% Quantity Wanted : Lead Ore And Lead Concentrate Buyer from Hong • Lead concentrate is the result of a flotation process after the ore has been mined and milled • Lead concentrate is an intermediate product used as raw material in the production of lead metal Above Products analysis regarding various minerals of mines can be changedProducts – Asia Zarin Madan Co Lead and Zinc

Selling Metal Concentrates: Payable Metal, Treatment

A typical leadzinc concentrate will be used as an example of how treatment charges and penalties are calculated First there is a deduction from the contained metal assay to compensate the smelter for processing metal losses If the concentrate grades around 50% lead and 20% zinc, then around 3% of the lead and 8% of the zinc will be deducted Furnace Process To Make Lead Sulfide Then the lead is extracted either by smelting heating in a furnace with coke or in a twostage process involving first roasting to convert lead sulfide into lead oxide lead and zinc smelting allurgical process, ore concentrate containing lead, zinc, or boProcess Of Lead Ore