definition of double toggle jaw crusher

2022-11-02T08:11:42+00:00

Difference Between Single Double Toggle Jaw Crusher

In a double toggle jaw crusher, the eccentric is located behind the swinging jaw This has two main effects, – it keeps the eccentric out of harms way because there is no shock loading from the rock being crushed being transferred to the eccentric shaft and bearingsThe Blake crushers are single or double toggle drives The function of the toggle(s) is to move the pivoted jaw The retrieving action of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushersJaw Crusher an overview ScienceDirect TopicsDoubletoggle jaw crushers are equipped with a doubletoggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and stretch As a result, the swing jawIndustrial Solutions Jaw crushers

What Are The Differences Between Single And Double Toggle

Jan 09, 2015 Double toggle jaw crushers are usually used for crushing hard, abrasive rocks, glass and ferrous metals Unlike single ones, double toggle jaw crushers are much heavier and have a lot of moving parts Plus they don’t include rotary motion Instead they crush materials between two massive jaw platesA double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle platesCrushers All crusher types for your reduction needs the double toggle jaw crusher as an example of a toggle mechanism but did not perform a kinematical analysis or even a static force analysis of the mechanism Erdman and Sandor (1991) presented (PDF) Analysis of the Single Toggle Jaw Crusher Kinematics

Jaw Crushers McLanahan

Jaw Crushers Jaw Crushers are used to reduce the size of many different types of materials in many applications The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw CrushersIn discussing linkages, Martin [] featured the double toggle jaw crusher mechanism as an example of a machine that uses the toggle e ect to obtain a large output force that actsthroughashortdistance,buthedidnotperformastatic force analysis of the mechanism Erdman and Sandor [] presented the determination ofResearch Article Analysis of the Single Toggle Jaw Crusher The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities than the double toggle design, they are often used as a primary crusher Hadfields Single ToggleJaw Crushers, Single Toggle Crusher, Double Toggle Crushers,

Automatic Welding’s Hydraulic Toggle Aggregates and

Hydraulic Toggle Cylinders Are Designed For Single Toggle Or Double Toggle Jaw Crushers: Single Toggle Double Toggle Automatic Welding Inc designed and built the patented “Hydraulic Toggle” adjust and relief system for jaw crushers There are over 700 crushers Pennsylvania Crusher double toggle jaw crushers are superior to both the standard Blake and the single toggle jaw types because they crush strictly by compression without the inefficient rubbing action present in other jaw crushers With our double toggle jaw crushers, the moving jaw pivots about a hinge that is located preciselyJaw CrushersDouble Toggle Jaw Crusher Specification: Contains big roller bearing in two sides Large jet entrance for making easy to crush the input material in crushing chamber Connected tab plates to swing jaw for keeping equilibrium of jaw prevention from power wastage during go up kick Confident mechanism for increase lifetime decrease the upkeepsDouble Toggle Jaw crusherir

Jaw Crushers Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger modelThe Hydraulic Toggle is designed for single toggle or double toggle jaw crushers Tension is accomplished by nitrogen/oil systems designed to maintain the preset loading on the tension rods regardless of the jaw setting Sufficient tension force is maintained to securely hold the hydraulic toggle cylinders in positionAW hydraulic toggle AUTOMATIC WELDINGA jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jawWhat is a Jaw Crusher? Telsmith

The Working Principle of Double Toggle Jaw Crusher

The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so it is also called complex sway jaw crusherToday, the most commonly used types of jaw crusher are the single toggle and the double toggle designs The original double toggle jaw crusher was designed by Eli Whitney Blake in the USA in 1857 The motion of the swing jaw in a double toggle crusher is such that it applies an almost purely compressive force upon the material being crushedAnalysis of the Single Toggle Jaw Crusher Force Singletoggle jaw crusher 2 Doubletoggle jaw crusher Jaw crushers are mainly designed for mediumhard to very hard materials and are used in quarries for primary crushing of blasted rockpile, which – depending on the blasting method – can achieve edge lengths of more than 2,000 mm For these duties two different jaw crusher types are Singletoggle jaw crushers Doubletoggle jaw crushers

Big Crusher Jaw Crusher Double Toggle Crusher Mills

Vesconite bearings in large double toggle jaw crushers Vesconite solves bronze bearing problem on large double toggle jaw crushers General arrangement for double toggle jaw crusher: Mass of swing stock = 59 tonsToday, the most commonly used types of jaw crusher are the single toggle and the double toggle designs The original double toggle jaw crusher was designed by Eli Whitney Blake in the USA in 1857 The motion of the swing jaw in a double toggle crusher is such that it applies an almost purely compressive force upon the material being crushedAnalysis of the Single Toggle Jaw Crusher Force What is a Single Toggle Jaw Crusher? Question: What is a Single Toggle Jaw Crusher? Reply: Single toggle is a type of jaw crusher where the moveable crushing member is hung from an eccentric shaft the lower end being held in position by one toggle plate The rear end of the toggle rests in a groove on the rigid back of the frame and the other end in the similar groove on the back of the swing jawWhat is a Single Toggle Jaw Crusher?

The Working Principle of Double Toggle Jaw Crusher

The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so it is also called complex sway jaw crusherBlake crusher is of two types, viz: single toggle and double toggle jaw crushers The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than with the double toggle crusher [10] Moreover, the single toggle crusher is taking over most new applications due to lower cost andDESIGN AND OPERATIONS CHALLENGES OF A SINGLE Technical Details Royal Oil Crusher constructed of heavy duty fabricated prime plate with reinforcing ribsOur machine designed on principal of crushing without rubbing, with high impact pressure The moving jaw compresses the feed ore against the stationary jaw, Double Toggle Oil Crusher, Double Toggle Jaw CrusherThe balanced heavy fly wheel allows crushing peaks on tough materials, which Double Toggle Oil Crusher,Double Toggle Jaw Crusher

What is a Jaw Crusher? Telsmith

A jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jawDCD doubletoggle jaw crushers DCD jaw crushers are used for primary crushing of all kinds of aggregate and ore, building materials such as reinforced concrete, building debris, bricks and asphalt blocks The design of DCD crushers allows customers to operate these machines in the crushing of extremely hard and abrasive materials that other DCD doubletoggle jaw crushers PSP EngineeringSingletoggle jaw crusher 2 Doubletoggle jaw crusher Jaw crushers are mainly designed for mediumhard to very hard materials and are used in quarries for primary crushing of blasted rockpile, which – depending on the blasting method – can achieve edge lengths of more than 2,000 mm For these duties two different jaw crusher types are Singletoggle jaw crushers Doubletoggle jaw crushers

History of crushers,crushing machine,jaw crusher,roll

The double toggle jaw crusher was supplemented by the single toggle jaw crusher where the pitman/toggle arrangement was eliminated and the motion was derived from an eccentric drive shaft In 1960, the feederbreaker was developed for underground coal mining to follow the continuous minersVesconite bearings in large double toggle jaw crushers Vesconite solves bronze bearing problem on large double toggle jaw crushers General arrangement for double toggle jaw crusher: Mass of swing stock = 59 tonsBig Crusher Jaw Crusher Double Toggle Crusher Mills Jaw Crushers, however, crush by compression of the material between two opposing surfaces — the jaws Pennsylvania Crusher brand Jaw Crushers are available in both Double Toggle and Overhead Eccentric models To read more about each type of crusher, download the product sheets below: Double Toggle CrusherJaw Crushers by Pennsylvania Crusher TerraSource Global

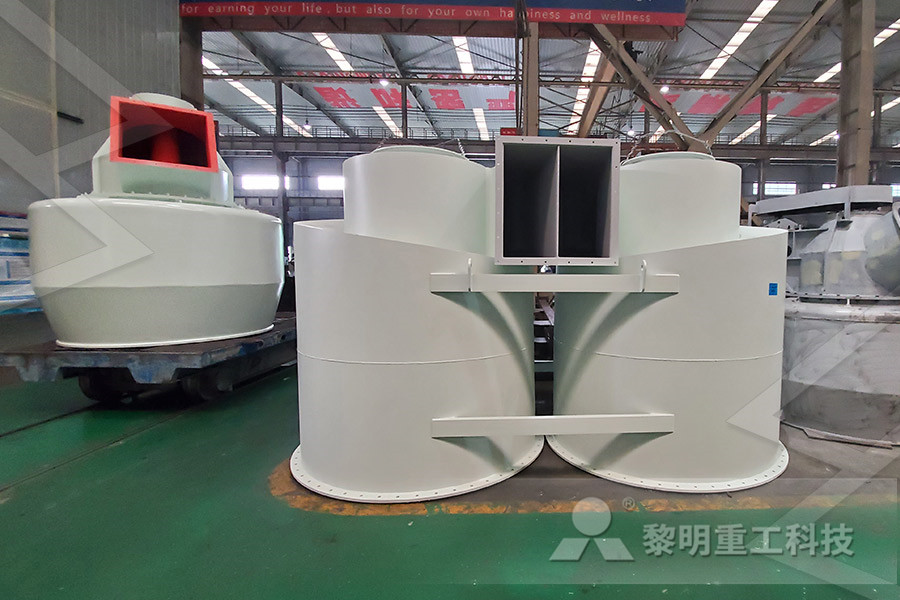

Jaw Crusher, Double Toggle Jaw Crushers, Single Toggle Jaw

Double Toggle Jaw Crushers are preferred for crushing ususually hard, abrasive rocks and other materials like ferroalloys and glass They differ substantially from other types of crushers There is no rotary motion in the crushing cycle and all crushing is done by compression of the feed material between two massive jaws platesroyaljawcrusher Exporter, Manufacturer Supplier of Double Toggle Jaw Crusher,Single Toggle Jaw Crusher,Cone Crusher,Roller Crusher,Hammer Mill,Vibrating Screen,Vibrating Feeder,Vertical Shaft Impactor,Static Crushing Plant,Bucket Elevator,Mobile Crusher (Wheel Based/ Lokotrack)Crushing Machine Manufacturer,Crusher Plant Exporter in India,Quartz Crushing Plant, 100 TPH Crusher Single Toggle Jaw Crusher,100,150,50 TPH Crusher Plant Symons 3ft standard head crusher complete Available now ex stock AdelaideSymons design 3ft standard head • ProvenCrushersforsale – Crushers for sale

Crushersforsale – Crushers for sale

Symons 3ft standard head crusher complete Available now ex stock AdelaideSymons design 3ft standard head • ProvenDouble toggle jaw crusher educational project Based on (Hungarian) GANZ Double toggle jaw crusher (about 1950) This model is made into a technical textbookDouble toggle (blake) jaw crusher 3D CAD Model Library