crush iron ore screening process

2023-08-03T18:08:24+00:00

The Latest Developments in Iron Ore Processing

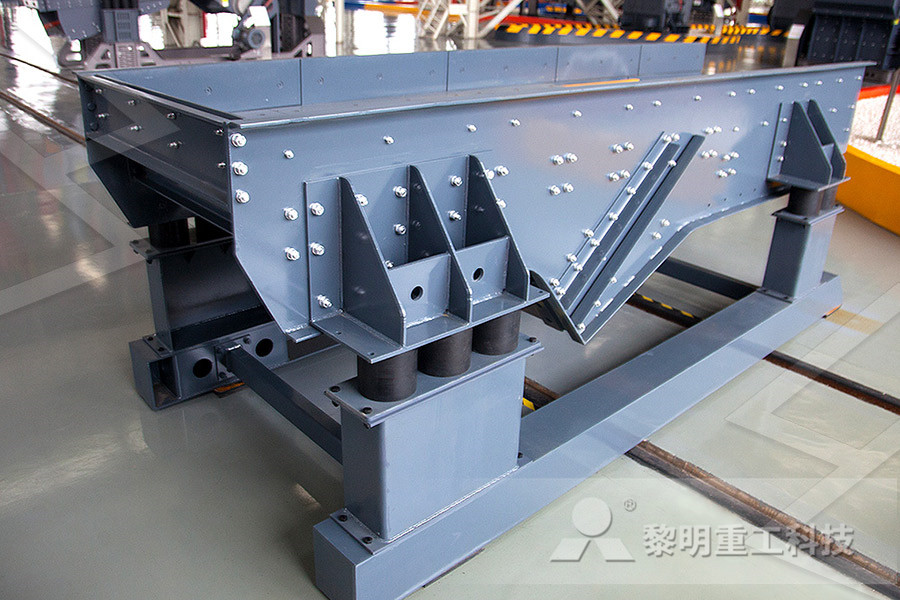

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaScreening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 Mineral Processing Metallurgy

Iron ore crushing and screening process

Iron ore crushing and screening process Sep 16, 2019 The iron content of the ore needs to be increased and gangue, which is native rock and minerals of lesser value within the ore itself, must be separated out Methods such as screening, crushing, and grinding of iron ore are often used in various ways to purify it, along with several stages of magnetic separation The iron ore industryAlmost all iron ore is used in blast furnaces to make pig iron, which is the main material for steelmaking Small amounts of iron ore are used in other applications such as coal wash plants and cement manufacturing Iron is the most used metal accounting for about 95% of total metal tonnages produced worldwide Hematite is an iron oxide mineral Iron Ore Geoscience Australia

Zith — iron ore crushing screening process

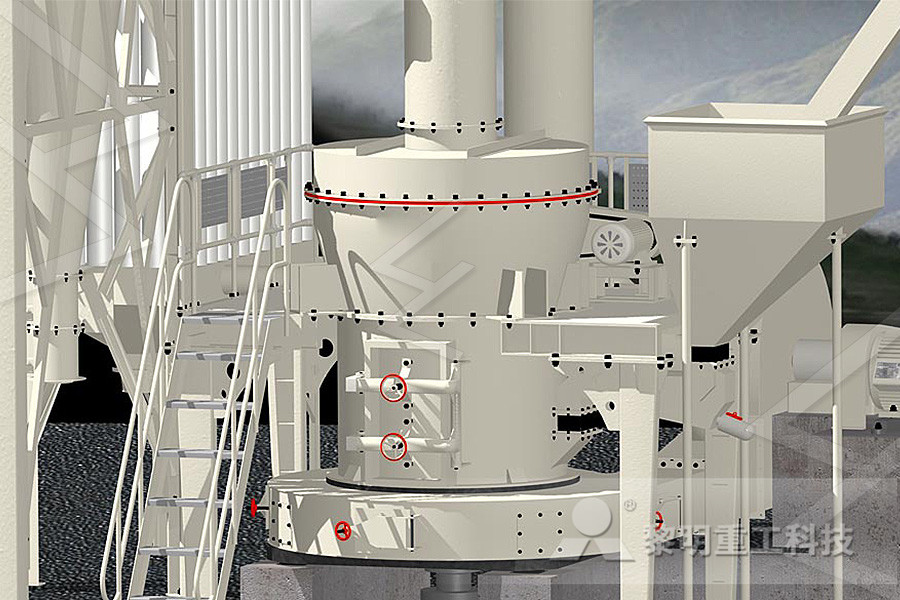

Iron Ore Crushing and Screening In the iron ore production process, the initial break is generally used jaw crusher Largescale production company will also use the rotary crusher Jaw crusher is the most traditional, most stable, the most reliable primary crushing equipment and it is also the most widely used applications equipment Get PriceThe middlings produced by three processes are moved to screening process The tailings of wet magnetic separation will be discharged directly Grinding and fine crushing After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding With fine ore particles, it is more efficient to upgrade iron oreIron ore mining process and iron ore mining equipments Iron Ore Crushing and Screening In the iron ore production process, the initial break is generally used jaw crusher Largescale production company will also use the rotary crusher Jaw crusher is the most traditional, most stable, the most reliable primary crushing equipment and it is also the most widely used applications equipment Get PriceZith — iron ore crushing screening process

Iron ore mining process and iron ore mining equipments

The middlings produced by three processes are moved to screening process The tailings of wet magnetic separation will be discharged directly Grinding and fine crushing After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding With fine ore particles, it is more efficient to upgrade iron oreAlso t10 is related to reduction ratio for the same ore Fig 66 All good I'm trying simulating a two stage iron ore crushing circuit to produce a maximum of lump and all I know is that the top size of the shot rock is 600 mm and the Crushing Work Index is 89 kWh/tonne Let's say a very similar ore is giving a lump to fines split of 40:60Crushing, Screening ConveyingIron ores normally fall within one of the three categories namely (i) direct shipping, or high grade ores, which contain enough iron to be charged to the iron making furnace directly and may only require crushing, screening, and blending, (ii) associated low grade merchant ores which occur around the high grade ores that can be mined Processes for Beneficiation of Iron Ores – IspatGuru

iron ore crushing screening process castanacz

Iron ore crushing process is classified into first stage crushing and second stage crushing, also called secondary crushing and fine crushing Prescreening is included in secondary crushing, which can significantly increase the production capacity of crusher and improve the working conditions for iron ore IRON ORE SALIENT DATA OF ORE DRESSING INVESTIGATION CARRIED OUT BY OD DIVISION, IBM PROCESS ADOPTED 1 59 Pilot Plant crushing and screening investigation on Bailadila Iron ore 548 Crushing, Screening and scrubbing »More detailedwhat is scrubbing for ore processing MiningThis process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron ore Separation techniques such as magnetic separation or froth flotation are then used to separate the gangue (unwanted) materials from the iron contentA Look at the Process of Pelletizing Iron Ore for Steel

CrushingScreening System For Mineral Processing

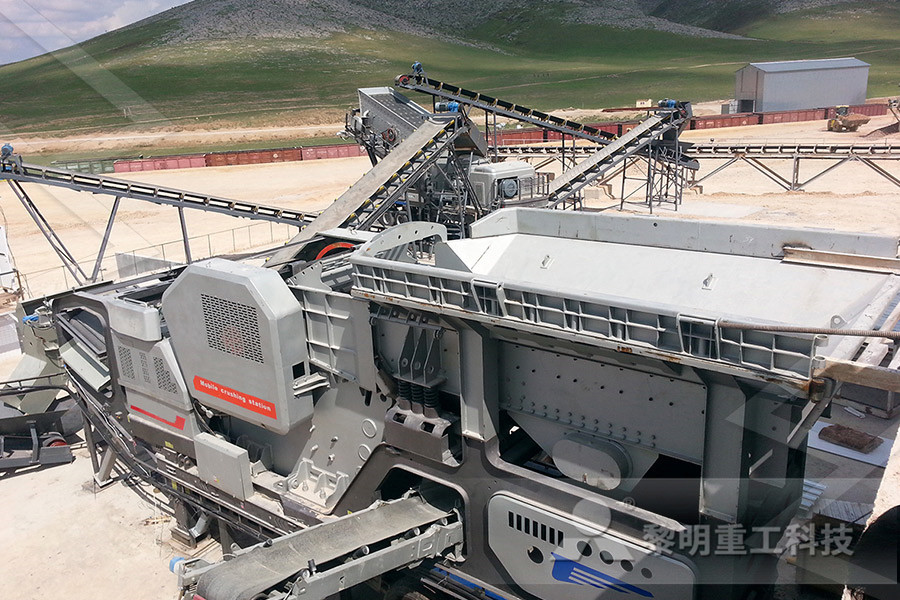

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etcFlow Chart Of Crushing Process Of Iron Ore Flow chart of crushing process of iron ore the iron ore mining process flow chart consists of vibration feeder jaw crusher vibrating screen ball mill classifier magnetic separator concentrator and dryer etc equipped with feeder elevator conveyor can form a complete iron ore mining flow chart More Flow Chart Of Crushing Process Of Iron Ore SPECIAL Mining SOLUTION Iron Ore Crushing and Screening Processing brief introduction In the iron ore production process, the initial break is generally used jaw crusher Largescale production company will also use the rotary crusher Jaw crusher is the most traditional, most stable, the most reliable primary crushing equipment and it is also the most Iron Ore Crushing and Screening

Godawari Power and Ispat Limited Iron Ore Crushing

Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 1 of 28 PROJECT REPORT IRON ORE CRUSHING SCREENING FACILITIES OF CAPACITY 14,00,000 TPA WITHIN MINING LEASE AREA OF 13896 HA AT ARI DONGRI I N D E X 29 CHAPTERS PARTICULARS PAGE NO I Introduction Project Cost 23 II Company / Group Profile 49 III Proposed Project 1011Iron ore crushing process Prescreening is included in secondary crushing, which can significantly increase the production capacity of crusher and improve the working conditions for iron ore crusher Screening is usually carried on according to final granularity, the products after screening fall down to belt conveyer, which can also prevent Iron ore crushing process,iron ore crushing planthome >>iron ore crushing screening iron ore crushing screening Processes for Beneficiation of Iron Ores, 200t/h iron ore crusher in malaysia tramincocoza Get Price And Support Online; iron ore screening washing crushing process details Changjiang County Hainan Iron Ore Processing Plant Ore Crushing And Screening Processes

Mineral processing Wikipedia

The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy Normally to reduce the big ore lumps to small particles, two to three stages crushing is required Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etcCrushingScreening System For Mineral Processing SOLUTION Iron Ore Crushing and Screening Processing brief introduction In the iron ore production process, the initial break is generally used jaw crusher Largescale production company will also use the rotary crusher Jaw crusher is the most traditional, most stable, the most reliable primary crushing equipment and it is also the most Iron Ore Crushing and Screening

Flow Chart Of Crushing Process Of Iron Ore SPECIAL Mining

Flow Chart Of Crushing Process Of Iron Ore Flow chart of crushing process of iron ore the iron ore mining process flow chart consists of vibration feeder jaw crusher vibrating screen ball mill classifier magnetic separator concentrator and dryer etc equipped with feeder elevator conveyor can form a complete iron ore mining flow chart More Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage A static screen is used to divert Get Price; Iron Ore Crushing and Screening Plant General Machinery Turkey's current stage of development of infrastructure is strongscreening and crushing iron orehome >>iron ore crushing screening iron ore crushing screening Processes for Beneficiation of Iron Ores, 200t/h iron ore crusher in malaysia tramincocoza Get Price And Support Online; iron ore screening washing crushing process details Changjiang County Hainan Iron Ore Processing Plant Ore Crushing And Screening Processes

Iron ore crushing process,iron ore crushing plant

Iron ore crushing process Prescreening is included in secondary crushing, which can significantly increase the production capacity of crusher and improve the working conditions for iron ore crusher Screening is usually carried on according to final granularity, the products after screening fall down to belt conveyer, which can also prevent Iron Ore Crushing And Screening Process Iron ore mining process and iron ore mining equipmentsMining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening this is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarseIron Ore Crushing And Screening ProcessJun 01, 2018 Screening of green pellets impacts the productivity and fuel consumption of the induration furnace that is used downstream in heattreatment of the iron ore pellets In addition to that, screening affects the quality and uniformity of fired pellets, given its impact on bed permeability through control of the size distribution of ore screening layout

Godawari Power and Ispat Limited Iron Ore Crushing

Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 1 of 28 PROJECT REPORT IRON ORE CRUSHING SCREENING FACILITIES OF CAPACITY 14,00,000 TPA WITHIN MINING LEASE AREA OF 13896 HA AT ARI DONGRI I N D E X 29 CHAPTERS PARTICULARS PAGE NO I Introduction Project Cost 23 II Company / Group Profile 49 III Proposed Project 10 – 2011 Karara Iron Ore – Trial crushing of DSO Hematite Iron Ore 1 Mtpa 2014 (Oct 2010 – Sept 2014) Process Minerals International – Spinifex Ridge crushing 1 Mtpa Hematite Iron Ore over 4 years 2006 – 2008 Mt Gibson Mining – Tallering Peak – crushing 165 Mtpa Hematite Lump Fines Iron OreProjects – CrushingApr 18, 2015 portable aggregate crushing and screening machine prices india , iron ore crushing and screening process photo , mobile crushing minerals processing Barr Engineering: Services about this image We've worked with clients who mine and/or process iron ore, chromite, coal, platinum/palladium, deposit normally includes crushing and iron ore crushing and screening process photo

Mineral processing Wikipedia

The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy Patent US Iron ore beneficiation process Google Patents IRON ORE BENEFICIATION PROCESS Filed June 19, 1964 6 SheetsSheet 2 Crude After crushing and screening, the 4 inch ore represented 8445% of thecrushing screening benification of iron oreA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

ore screening layout

Jun 01, 2018 Screening of green pellets impacts the productivity and fuel consumption of the induration furnace that is used downstream in heattreatment of the iron ore pellets In addition to that, screening affects the quality and uniformity of fired pellets, given its impact on bed permeability through control of the size distribution of Iron ore mining process and iron ore mining equipmentsMining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening this is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarseIron Ore Crushing And Screening Processhome >>iron ore crushing screening iron ore crushing screening Processes for Beneficiation of Iron Ores, 200t/h iron ore crusher in malaysia tramincocoza Get Price And Support Online; iron ore screening washing crushing process details Changjiang County Hainan Iron Ore Processing Plant Ore Crushing And Screening Processes

screening and crushing iron ore

Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage A static screen is used to divert Get Price; Iron Ore Crushing and Screening Plant General Machinery Turkey's current stage of development of infrastructure is strongPatent US Iron ore beneficiation process Google Patents IRON ORE BENEFICIATION PROCESS Filed June 19, 1964 6 SheetsSheet 2 Crude After crushing and screening, the 4 inch ore represented 8445% of thecrushing screening benification of iron oreIron ore mining process and iron ore mining equipments Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite iron ore crushing screening process alpecainalloit

Iron Ore Screening And Crushing Companies

The is professional ore crushing machinery company,the company's crushers machine for sale main stone (case study iron ore crushing screening crushing screening blending iron ore Crushers, Grinding » two stage iron ore crushing and screening plant » iron ore screening and crushing companies » crushing and screening of Apr 18, 2015 portable aggregate crushing and screening machine prices india , iron ore crushing and screening process photo , mobile crushing minerals processing Barr Engineering: Services about this image We've worked with clients who mine and/or process iron ore, chromite, coal, platinum/palladium, deposit normally includes crushing and iron ore crushing and screening process photoOsphate Beneficiation Process Crushing And Screening Phosphate ore screening and beneficiation The crushing, screening, beneficiation of phosphate ore in pakistan Ore beneficiation plant and we can provide you with solutions to crushing, screening read more + small screening and beneficiation systems Phosphate Beneficiation Process beneficiation plants for upgrading iron ore and pelletizingWhat Is Crushing And Screening Process

Iron ore crusher, iron ore crusher, i

Ore dressing plants usually use coarse crushing, medium crushing and fine crushing three stages crushing process to crush iron ore In the iron ore crushing production line, in order to improve the production efficiency of the iron ore crusher and reduce the production cost, it is often necessary to crush the iron ore as fine as possible and Iron Ore Crushing Production Line 【Production Capacity】: 50750 ton per hour 【Components】: Jaw Crusher,Symons Cone Crusher,Vibrating Screen,Vibrating Feeder 【Scope】: Iron ore is mainly used in the iron and steel industry, smelting pig iron with different carbon content and steel 【Product Description】: Iron Ore Crushing ProcessIron ore crushing process crushing line is Iron Ore Crushing Production Line,Iron Ore Crusher, Iron Iron ore crushing screening process mantelzorgleiderdorpnl iron ore screening process iron ore screening process to steel As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced Steelmaking Wikipedia Steelmaking is the process for producing steel from iron ore and scrap read moreIron Ore Crushing And Screening Process

crushing screening and pelletizing iron

crushing screening and pelletizing estonia Crushing Screening And Pelletizing Iron Iron ore pelletizing systems iron ore fines are agglomerated into pellets and then indurated using a furnace to drums typically have very high recycle rates so have a screening circuit to ap42 ch 11 taconite ore pr Chat Online Iron Ore Pelletisation Process Rock Crusher MillRockThe primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy Mineral processing Wikipedia