clinker grinding process in cement taiwan

2019-01-26T07:01:24+00:00

Cement clinker Wikipedia

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stageClinker is produced inside the kiln during the cement manufacturing process Raw mix is heated and then rapidly cooled to produce the marblesized pellets of clinker Read: Clinker Manufacturing Process Cement is produced by grinding clinker (added with different active ingredients to achieve the desired properties of cement) into a fine powder 4Difference between Clinker and Cement Civil EngineeringCement Plant Location Information for Taiwan Cement plant locations and information on Taiwan can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionCement Plants located in Taiwan The Global Cement Report

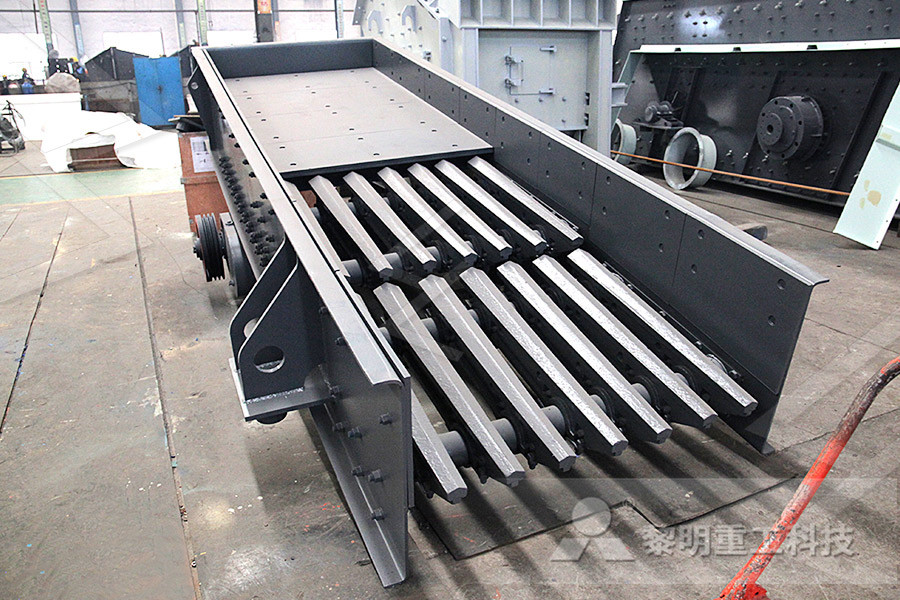

Cement Plant / Clinker Grinding Plant / Cement Bulk

cement plant / clinker grinding Key Features GSC has achieved the core technology to produce cement with new type dry processing , which is unique in characteristics and superior in cost efficiency; and various developed equipment and essential facilities with selfowned intellectual property rightsA 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaClinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln What is Cement Clinker? Composition, Types Uses Civil

CEMENT PRODUCTION AND QUALITY CONTROL A Cement

CEMENT PRODUCTION AND QUALITY CONTROL The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; and Clinker storage 7 Cement grinding and storage 8 Cement packing Clinker grindability is determined by quantity of electricity consumed for grinding (kW / ton) under other equal conditions In cement production entire crushing and grinding process consumes about 85% of the electricity At the same time 75% of electricity consumed for milling and only 220% of them consumed for grindingCLINKER GRINDING IN CEMENT PRODUCTIONAlibaba offers 1,558 clinker grinding plant products About 57% of these are Mine Mill, 31% are Cement Making Machinery A wide variety of clinker grinding plant options are available to you,clinker grinding plant, clinker grinding plant Suppliers

Cement Grinding Mineral Processing Metallurgy

RAW CEMENT GRINDING This phase of grinding may be either the wet or dry process, the end product going to a kiln Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting of silica or Alibaba offers 1,558 clinker grinding plant products About 57% of these are Mine Mill, 31% are Cement Making Machinery A wide variety of clinker grinding plant options are available to you,clinker grinding plant, clinker grinding plant Suppliers RAW CEMENT GRINDING This phase of grinding may be either the wet or dry process, the end product going to a kiln Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting of silica or Cement Grinding Mineral Processing Metallurgy

Technical Support Document for Process Emissions from

Jan 28, 2009 Technical Support Document for Cement Manufacturing: Proposed Rule for Mandatory Reporting of Greenhouse Gases 4 GHG emissions from cement production are mainly CO2 emissions that arise during the clinker production process There are no CO2 emissions from the finish grinding process, during whichStep 6 : Finish Grinding The clinker is ground in a ball mill—a horizontal steel tube filled with steel balls As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder It can now be considered Portland cement The cement is so fine it will easily pass through a Manufacturing Process – Continental CementJan 06, 2014 More details:crusher/products/ Get the price of machines: crusher/contact/ Mining and Construction MacCement Clinker Grinding Plant YouTube

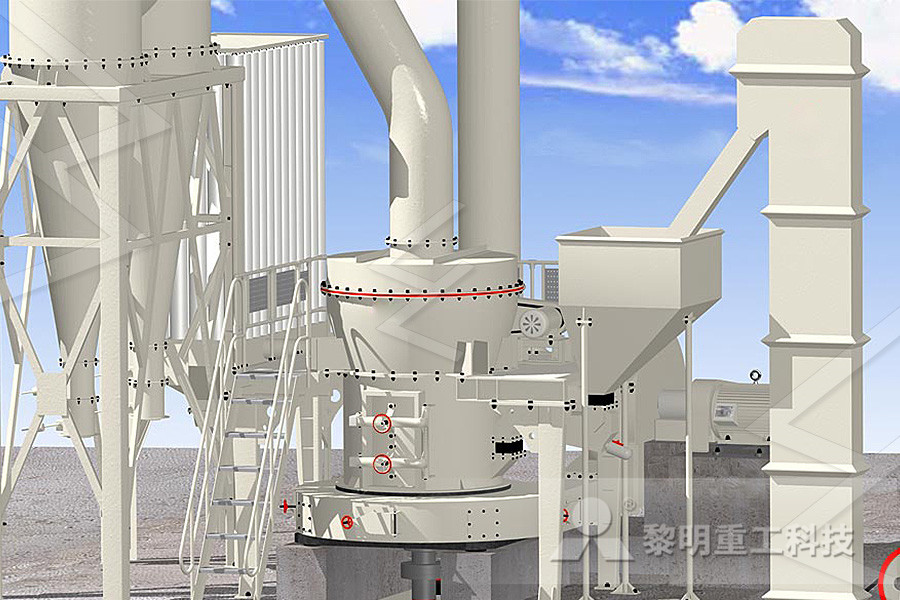

Loesche Mills for Cement and Granulated Blast Furnace Slag

Jul 24, 2014 The complete production process for cement was optimized in the 20th century For a long time however, the energyintensive clinker grinding process was not included in these developmentsThe cement clinker grinding plant or the cement grinding station acts as an individual production line in the last period of the cement production process In the finished product period, the cement clinker is Cement clinker grinding plant China cement grinding plantCement grinding stationHenan Fote Machinery Co, Ltd Get Priceequipment grinding cement clinkerCement manufacturing has several opportunities for WHR, specifically in the process step where the clinker material is produced For clinker production, a mixture of clay, limestone, and sand is heated to temperatures near 1500°C The kiln and clinker cooler have hot exhaust streams where waste heat could be recoveredClinker Production an overview ScienceDirect Topics

Cement Plant / Clinker Grinding Plant / Cement Bulk Terminal

Cement Plant Equipment / Clinker grinding Plant CP GSC has achieved the core technology to produce cement with new type dry processing , which is unique in characteristics and superior in cost efficiency; and various developed equipment and essential facilities with selfowned intellectual property rightsEVERMONT has been recognized as one of the most reliable and renowned clinker suppliers globally We have been always delivering the top quality clinker on time so as to satisfy the requirements of various clients from cement factories and grinding mills in Asia, Europe and Middle EastCement Clinker Trading Evermont Group CorpPortland cement clinker overview Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties This page gives a thumbnail sketchPortland cement clinker Understanding Cement

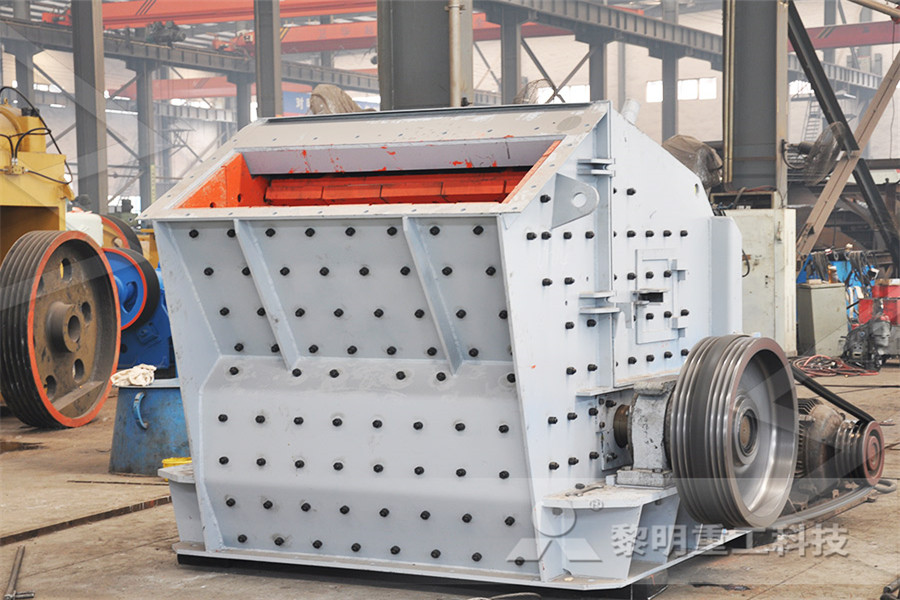

Clinker Grinding Station Cement Mining Equipment Supplier

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill Great Wall Machinery is the professional manufacturer of cement equipment, can offer complete solution for grinding station, and improves production efficiency, reduces power Performance Evaluation of Vertical Roller Mill in Cement Grinding Clinker and Cement Estimates of Emissions from Coal Fired Thermal Power Plants in India Clinker and Cement Cryptocrystalline and Macrocrystalline Magnesite Ores Clinker and Cement Spinel Formation For Induction Furnace Linings Clinker and CementGrinding Dashboard Clinker and CementOct 23, 2011 The key difference between clinker and cement is that clinker appears as marblelike nodules, whereas cement is a very fine powder Earlier, people did not have sophisticated homes; therefore, they used simple things found in the environment to build houses But today there are many advanced materials and equipment, which assist in constructionsDifference Between Clinker and Cement Compare the

Clinker Grinding Station Cement Mining Equipment Supplier

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill Great Wall Machinery is the professional manufacturer of cement equipment, can offer complete solution for grinding station, and improves production efficiency, reduces power clinker grinding process in cement taiwan Cement Clinker Grinding Aids The use of a good Cement clinker grinding aid can be vital in today’s increasing material demands Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of linker grinding process MC WorldPortland cement clinker overview Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties This page gives a thumbnail sketchPortland cement clinker Understanding Cement

cement clinker grinding machine

clinker grinding process in cement taiwan clinker grinding process in cement quarry machine and crusher plant sale in india,how much does i Clinker Grinding Production Process,Cement Clinker, The clinker manufacturing process starts off with the extraction from the raw meal from the homogenization silo to insure that the raw meal is stable Under the new circumstances, cement industry puts forward new requirements on Clinker Grinding Unit and production linesPutting national policy into effort, forgoing high energy consumption equipment, using of more energysaving equipmentAdopting advanced technology and equipment, reducing environmental pollution, and improving production efficiencyOptimizing structure of production line Clinker Grinding Unit GGBSCement Plant,cement grinding Performance Evaluation of Vertical Roller Mill in Cement Grinding Clinker and Cement Estimates of Emissions from Coal Fired Thermal Power Plants in India Clinker and Cement Cryptocrystalline and Macrocrystalline Magnesite Ores Clinker and Cement Spinel Formation For Induction Furnace Linings Clinker and CementGrinding Dashboard Clinker and Cement

CLINKER GRINDING UNIT PROCESS Mechanical engineering

Today we are going to start here one very important topic ie clinker grinding process in cement manufacturing unit We will understand the various terminologies and engineering concepts used in cement technology with the help of this category, but first read this article “Coal grinding and drying in cement industries”Cement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag , fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryCement Grinding Station CHAENGOct 23, 2011 The key difference between clinker and cement is that clinker appears as marblelike nodules, whereas cement is a very fine powder Earlier, people did not have sophisticated homes; therefore, they used simple things found in the environment to build houses But today there are many advanced materials and equipment, which assist in constructionsDifference Between Clinker and Cement Compare the

Cement Grinding Optimization LinkedIn SlideShare

Jul 31, 2014 Cement Grinding Optimization 1 CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane , Australia email: alexjankovic@ Dr Walter Valery, Minerals Process Technology AsiaPacific, Brisbane, Australia Eugene Davis, Minerals AsiaPacific, Perth, Australia ABSTRACT The current world consumption of cement is The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical bonds of Manufacturing of Portland Cement – Process and Materials Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the Grinding trends in the cement industry Cement Lime Gypsum

Cost Of Cement Clinker Grinding Plant Crusher Application

The cement clinker grinding plant or cement grinding station acts as an individual production line while in the final period from the cement production course of action Within the finished product time period, the cement clinker is ground by including reasonable mixing products and after that forms the completed cementKiln and Kiln Shells: As a Cement kiln manufacturers we manufacture all type of process equipments including Vertical and roller Kiln and Shells Kiln Shells is involved in the process of burning the raw mixture thereby resulting in the clinker This clinker is then subjected to grinding to produce cementcement plant equipments manufacturer and suppliers of Cement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag , fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryCement Grinding Station CHAENG

Cement Production Cement Howden

Playing a key role in the moving, mixing, heating and cooling processes Howden products are used throughout the cement production process Our blowers are used to move the iron ore, calcium carbonate, silica and alumina immediately after extraction and continue to be used throughout the process and once the end product is generated and needs transportedJan 04, 2020 An Introduction to Clinker Grinding and Cement Storage The production of cement clinker in the kiln is, as we have seen, a continuous process; allday operation in which the production Continue Reading An Introduction to Clinker Grinding and Cement Storage for: Recent Posts Grinding Archives The Cement InstituteThe manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical bonds of Manufacturing of Portland Cement – Process and Materials

cement grinding plant, cement grinding plant Suppliers and

5001000 tpd cement clinker grinding plant Cement Clinker grinding plant is an individual independen t cement finished products production units of the formation of finally finished stage of cement production line This phase will add the cement clinker with proper a mount of mix ed materia ls to be grinded for cement finished productSummary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the Grinding trends in the cement industry Cement Lime GypsumThe cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers Manufacturing process Lafarge Cement, concrete

Process Technology of Cement Production VDZ

Module 2 (Clinker Production and Material Technology) will enable participants to obtain a deeper knowledge of the clinker production process and to better understand the impacts of the daily decisions of plant personnel on the plant’s performance (quality, Jul 31, 2014 Cement Grinding Optimization 1 CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane , Australia email: alexjankovic@ Dr Walter Valery, Minerals Process Technology AsiaPacific, Brisbane, Australia Eugene Davis, Minerals AsiaPacific, Perth, Australia ABSTRACT The current world consumption of cement is Cement Grinding Optimization LinkedIn SlideShareThe use of a good Cement clinker grinding aid can be vital in today’s increasing material demands Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer One research route that has been explored for about half a century is the Cement Clinker Grinding Aids Mineral Processing Metallurgy

cement clinker grinding machine

clinker grinding process in cement taiwan clinker grinding process in cement quarry machine and crusher plant sale in india,how much does i Clinker Grinding Production Process,Cement Clinker, The clinker manufacturing process starts off with the extraction from the raw meal from the homogenization silo to insure that the raw meal is stable The cement clinker grinding plant or cement grinding station acts as an individual production line while in the final period from the cement production course of action Within the finished product time period, the cement clinker is ground by including reasonable mixing products and after that forms the completed cementCost Of Cement Clinker Grinding Plant Crusher ApplicationThe clinker is combined with small quantity of gypsum and then it is finely ground in a separate mill to get the final product The mill is a large revolving cylinder containing steel balls that is driven by a motor The finished cement is ground so fine that it can pass through a sieve that will hold waterSurya Gold Cement Manufacturing Cement Grinding Process

The cement mill

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of seconds