use of quarry rock dust as fine aggregate

2022-04-15T22:04:05+00:00

Study on Compressive Strength of Quarry Dust as Fine

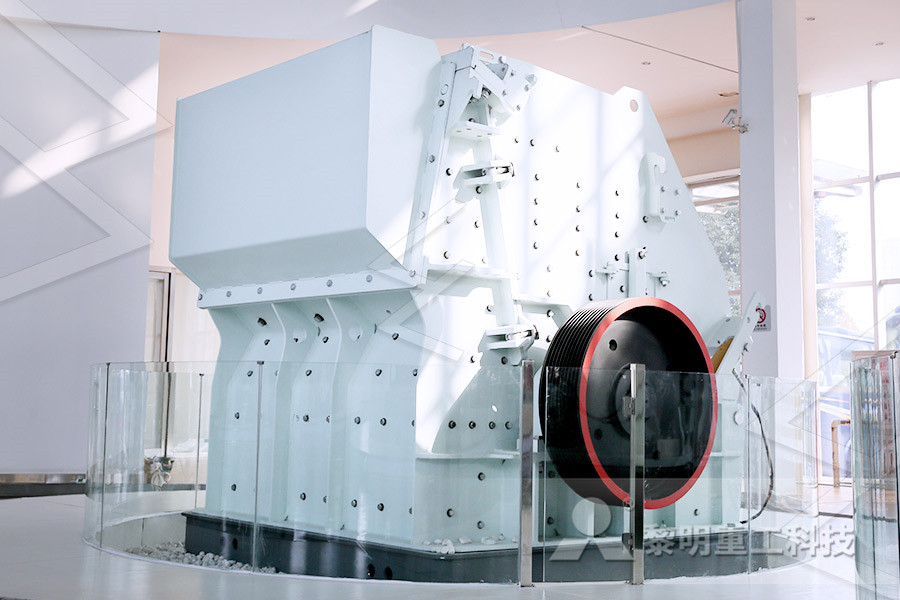

Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose, especially as fine aggregates In quarrying activities, the rock has been crushed into various sizes; during the process the dust generated is called quarry dust and it is formed as wasteMay 22, 2017 The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries By replacement of quarry dust, the requirement of land fill area can be reducWhat are the advantages of using quarry dust as fine Crushed Fines and also known as Quarry Dust, is a form of fractured gravel chips and fine dust used to solidify the base under patios and walkways The SubBase is laid above the ABC or SubGrade at 1″ to 2″ inches on light weight traffic areas like pathways and paver patios CrossSection layers that make up a mortarless or "drylaid" pavementCrushed Fines Acme Sand Gravel

Best Gravel for Your Driveway 9 Top Options Bob Vila

The final layer of a gravel driveway consists of smaller gravel blended with coarse rock dust, known as “fines” Crushed stone #411, which is a mixture of #57 stone and coarse rock dust, is a made of Quarry Rock Dust are nearly 10% Stone Dust in Concrete: Effect on Compressive Strength 118 www 100% replacement of sand with crusher dust as fine aggregates gives increased (PDF) Stone Dust in Concrete: Effect on Compressive StrengthSuch investigations include; The strength and durability properties of concrete containing Quarry rock dust as fine aggregates [21], and use of saw dust for partial replacement of sand [27 Strength and durability properties of concrete containing

Crushed Stone Grades: A Complete Guide

Crushed stone #5 – Sizes are from 1″ down to fine particles For road and paver base Crushed stone #67 – Sizes from 3/4″ down to fine particles For fill, road and slab base Crushed stone #1 – Sizes are from 2″ to 4″ The largest of the crushed stone grades For larger jobs such a culvert ballastJun 02, 2016 One possible source of construction aggregate is sand that has been manufactured from the surplus material (crusher dust) that results when coarse aggregate is produced in hard rock quarries Coarse aggregate production typically yields 25% to 45% crusher dust depending on the parent rock, crushing equipment and crushing conditions [ 2 ]An Investigation into the Use of Manufactured Sand as a To use of the quarry dust replacement of fine aggregate reduces the environmental pollution as well as providing an economic value for the waste material To improve durability, ductility using replacing fine aggregate To study the mechanical and physical properties of construction waste aggregate by conducting experimental workBEHAVIOUR OF CONCRETE ON THE USE OF QUARRY DUST TO

Crushed Stone Grades: A Complete Guide

Crushed stone #5 – Sizes are from 1″ down to fine particles For road and paver base Crushed stone #67 – Sizes from 3/4″ down to fine particles For fill, road and slab base Crushed stone #1 – Sizes are from 2″ to 4″ The largest of the crushed stone grades For larger jobs such a culvert ballastJun 02, 2016 One possible source of construction aggregate is sand that has been manufactured from the surplus material (crusher dust) that results when coarse aggregate is produced in hard rock quarries Coarse aggregate production typically yields 25% to 45% crusher dust depending on the parent rock, crushing equipment and crushing conditions [ 2 ]An Investigation into the Use of Manufactured Sand as a Usually, Quarry Rock Dust is used in large scale in the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigatorsStrength and durability properties of concrete containing

Strength and durability properties of concrete containing

particles less than 475mm Usually, Quarry Rock Dust is used in large scale in the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigatorsUsually, Quarry Rock Dust is used in large scale in the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigatorsapplication of quarry dust in concrete construction FlatYou can buy stone dust at most stone yards and quarries Some excavation companies also sell it, along with the crushed stone, sand, gravel, bricks, flagstones, etc that you might need for other projects For a fee, most of these places will deliver the product to your property You may also be able to buy stone dust at your local Lowes or Where to Buy Stone Dust And What It Is, How to Use It

Study on Partial Replacement of Fine Aggregate by Quarry

Quarry Rock Dust: Quarry rock dust is a waste material obtained from stone quarries while crushing stones, stone crusher dust, which is available abundantly from crusher units at a low cost in many areas, provides a viable alternative for river sand in concrete Table 5 physical properties of quarry rock dust SN Property Value Obtained 1In such a situation the quarry rock dust can be an economic alternative to the river sand Quarry rock dust can be defined as residue, tailing or other nonvoluble waste material after the extraction and progressing of rocks to form fine particles less than 475 mm Use of quarry rock dust as a fine aggregate in concrete draws serious attentionEXPERIMENTAL STUDY ON REPLACEMENT OF FINE (1999) Venugopal et al examined the effect of rock dust as fine aggregate in cement and concrete mixes They have suggested a method to proportion the concrete using rock dust as fine aggregate (2000) M Shukla et al studied environmental hazardous stone dust Review on Use of Stone Dust as a Partial Replacement of

Strength and Durability Properties of Granite Powder Concrete

The water absorption of Quarry Rock Dust concrete is slightly higher than Conventional Concrete Therefore; the results of this study provide a strong support for the use of Quarry Rock Dust as fine aggregate in Concrete ManufacturingConstruction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregatesAggregates are the most mined materials in the world Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as Construction aggregate WikipediaSep 22, 2019 Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose, especially as fine aggregatesIn Manufacture activities, the rock has been crushed into various sizes; during the process the dust generated is called quarry dust and it is formed as waste Manufactured sand (MSand) is a substitute of river sand for concrete What’s quarry dust and What is MSand? Sustainable Green

Compressivestrength study of geopolymer mortar using

Quarry Rock Dust can be defined as residue, tailing or other nonvoluble waste material after the extraction and processing of rocks to form fine particles less than 475 mm This paper presents the feasibility of the usage of Quarry Rock Dust as a substitute for Natural Sand in geopolymer mortarThe study investigates the use of crushed rock sand as viable alternative to Natural River sand that is being conventionally used as fine aggregate in cement concrete Various mix designs were developed for different grades of concrete based on IS, ACI and British codes using Natural River sand and crushed rock sandCrushed rock sand – An economical and ecological Construction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregatesAggregates are the most mined materials in the world Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as Construction aggregate Wikipedia

What’s quarry dust and What is MSand? Sustainable Green

Sep 22, 2019 Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose, especially as fine aggregatesIn Manufacture activities, the rock has been crushed into various sizes; during the process the dust generated is called quarry dust and it is formed as waste Manufactured sand (MSand) is a substitute of river sand for concrete Quarry Rock Dust can be defined as residue, tailing or other nonvoluble waste material after the extraction and processing of rocks to form fine particles less than 475 mm This paper presents the feasibility of the usage of Quarry Rock Dust as a substitute for Natural Sand in geopolymer pressivestrength study of geopolymer mortar using The study investigates the use of crushed rock sand as viable alternative to Natural River sand that is being conventionally used as fine aggregate in cement concrete Various mix designs were developed for different grades of concrete based on IS, ACI and British codes using Natural River sand and crushed rock sandCrushed rock sand – An economical and ecological

Review on Use of Stone Dust as a Partial Replacement of

(1999) Venugopal et al examined the effect of rock dust as fine aggregate in cement and concrete mixes They have suggested a method to proportion the concrete using rock dust as fine aggregate (2000) M Shukla et al studied environmental hazardous stone dust quarry dust, which is a waste product from quarry, as fine aggregates in traditional concrete During the tenure of the study, some physical and engineering properties of quarry dust and sand were determined and comparedThe Utilization of Quarry Dust as Fine Aggregates in Best Stone Dust Not all kinds of stone dust are poor choices for pavers, however Crusher run, also called processed gravel, is a rock or stone dust made of particles about the size of a grain of Rock Dust vs Sand Under Paving Home Guides SF Gate

Experimental Study on Concrete and Cement Plaster Using

replacing fine aggregate with Quarry Rock Dust in proportions of 0, 50, 75 and 100% To evaluate the compressive strength of cement mortar cube for 3, 7 and 28days by replacing fine aggregate with Quarry Rock Dust TableTo evaluate percentage of water absorption in plastering made with both Quarry Rock Dust and Natural sand IIIThe use of quarry dust as an alternative to traditionally used fine aggregate in concrete has drawn the attention of researchers and investigators over the last several years (Rajapaksha and Sooriyaarachchi,2009; Ilangovana et al 2008, Ho et al 2001)UTILISATION OF AS GENERATED QUARRY DUST AS A FINE To overcome this problem, present study is focused on the suitability to utilize the quarry dust in Self Compacting Concrete (SCC) partially as fine aggregate with the natural fine aggregates In this work, quarry dust is used as replacement of sand in a different level (0%, 15%, 30%, 45% and 60%) for producing the SCCSuitability of Quarry Dust as a Partial Replacement of

Use of Quarry Fines for Engineering and Environmental

plant to another and may include up to 20% of the production depending on quarry nature, type of rock crushed, and type and size of aggregates produced Most of the specifications for construction use of aggregates do not accept any material with more than 10% passing No 200 sieve Currently these fine grained material are used on aUsually, Quarry Rock Dust is used in large scale in the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigatorsEXPERIMENTAL INVESTIGATION ON PARTIAL Numbers of significant results have been reported on the use of quarry dust as partial replacement for fine aggregate Quarry dust, a byproduct from the crushing process during quarrying activities, is one of those materials that have recently gained attentions to be used as concreting aggregates, especially as fine aggregatesEffect of Fly Ash on Mortar Mixes with Quarry Dust as Fine

Product Category Listing Boral

Generally produced from quarry dust and altered during the production process to achieve a grading similar to naturally occurring sand Manufactured Sand Cement Treated Produced from quarry production and is a crushed fine aggregate with a particle size generally less than 5 millimetres with cement added at a specified rateUse of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigators power projects and industrial structures etc to meet the durability of Quarry Rock Dust concrete under sulphate , any project work on quarry dust concrete pdf grinding mill equipmentuse of quarry rock dust as fine aggregateNumbers of significant results have been reported on the use of quarry dust as partial replacement for fine aggregate Quarry dust, a byproduct from the crushing process during quarrying activities, is one of those materials that have recently gained attentions to be used as concreting aggregates, especially as fine aggregatesEffect of Fly Ash on Mortar Mixes with Quarry Dust as Fine

Rock Dust vs Sand Under Paving Home Guides SF Gate

Best Stone Dust Not all kinds of stone dust are poor choices for pavers, however Crusher run, also called processed gravel, is a rock or stone dust made of particles about the size of a grain of This paper is part of a study investigating the structural characteristics of concrete using various combinations of lateritic sand and quarry dust as complete replacement for conventional river sand fine aggregate Samples of concrete (eg cubes) were made using varying contents of laterite and quarry dust as fine aggregate The quantity of laterite was varied from 0% to 100% against quarry COMPRESSIVE STRENGTH OF CONCRETE USING LATERITIC SAND Usually, Quarry Rock Dust is used in large scale on the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws Comparing the compressive strength of concrete made with

EXPERIMENTAL INVESTIGATION ON PARTIAL

Usually, Quarry Rock Dust is used in large scale in the highways as a surface finishing material and also used for manufacturing of hollow blocks and lightweight concrete prefabricated Elements Use of Quarry rock dust as a fine aggregate in concrete draws serious attention of researchers and investigatorsStone dust is also known as rock dust or quarry dust, and some products just have the brand name The stone dust is collected using a screen that keeps the larger pieces of crushed stone above the screen while allowing the rock dust to fall through This process is the reason why stone dust is often called quarry screeningsWhat is Stone Dust and Why Would You Get It?III Quarry Dust: The crushed rock aggregates quarrying generates considerable volumes of quarry fines, termed quarry dust The quarry dust is used as the first fine aggregates IV Sand: Sand is used as the second fine aggregates The locally available river sand at the site is used for the experiment METHODOLGY:Use of Quarry Dust as fine aggregates by Partial

graded quarry dust in concrete

Quarry dust is a byproduct of the crushing process which is a concentrated material to use as aggregates for concreting purpose, especially as fine aggregates In quarrying activities, the rock has been crushed into various sizes during the process the dust generated is called quarry dust and it is formed as wasteGenerally produced from quarry dust and altered during the production process to achieve a grading similar to naturally occurring sand Manufactured Sand Cement Treated Produced from quarry production and is a crushed fine aggregate with a particle size generally less than 5 millimetres with cement added at a specified rateProduct Category Listing Boraland the durability concrete were good when the fine aggregate was replaced with 50% marble sludge powder and 50% Quarry rock dust (Green concrete) The resistance of concrete to sulphate attack was enhanced greatly R IIangovana, “Strength and durability properties of concrete containing quarry dust as fine aggregate” (Oct 2008), The Experimental Study on Granite Powder as a Replacement of

Utilization of Stone Dust as Fine Aggregate Replacement in

use of stone dust as partial replacement of fine aggregate in concrete To accomplish this specimen were cast for different replacement level at an interval of 10 percent to determine workability and compressive strength of concrete at different level of fine aggregate with stone dustchallanges in using quarry dust – Grinding Mill China High Performance Concrete using Quarry dust as Fine aggregate Quarry dust is the fine material, produced from gravel crushers Super plasticizers were used to improve workability of concreteChallanges In Using Quarry Dust Tembaletu TrustUse of fly ash in quarry dust mixes is found helpful in reducing the shrinkage of quarry dust concrete Results indicate that quarry dust can be effectively used to replace sand and fly ash can improve the performance of concrete with quarry dust as fine aggregate Keywords: Concrete, Fine aggregate, Quarry dust, River sand, Compressive Feasibility of Quarry Dust to Replace River Sand as Fine