sand production out of granite waste

2023-03-23T18:03:38+00:00

sand production out of granite waste

sand production out of granite waste heartgenorg, sand production out of granite waste , sand manufacturing process by using granite , Stone waste can be AAC More Sand production out of granite waste , 2016 CME provide high quality VSI crusher plant for granite sand production granite sand production out of granite waste sand production out of granite wasteHot Sale Quartz Granite Line Sand Making Machine A Quote in addition to sulfur, slag, construction was Largescale crushing screening milling plants Construction Waste RecyclingGranite Waste To Sand Machine MC WorldINCWhereas, replacing sand in the concrete mixes by 10% granite waste granules led to significant increase in the splitting tensile strength and the flexural strength while the bond was slightly (PDF) Reuse of granite sludge in producing green concrete

(PDF) CHARACTERISTICS OF CONCRETE WITH QUARRY WASTE AS

PDF Enormous waste generated from quarry sites require disposal and acute shortage of dumping sites necessitated the need to conduct an investigation Find, read and cite all the research Granite powder Poly carboxylated ether based admixture (Glenium B233) Aggregates Portable water Granite powder It is obtained from JAI AMBE STONES, Granite industry, jigni industrial Area, anekal taluk, Bangalore It is a waste product obtained during sawing process of granite rocksUSE OF GRANITE WASTE AS POWDER IN SCCMar 10, 2016 Rajasthan accounts for about 20% national granite production (Indian Minerals Yearbook, 2013) The granite is cut and polished prior to its usage Cutting and polishing operations generate large amount of cutting and polishing waste Granite cutting waste (GCW) has become a serious problem in its mining regions throughout the stateSustainable utilization of granite cutting waste in high

REUSE OF GRANITE SLUDGE IN PRODUCING GREEN CONCRETE

Many studies have been carried out in different countries (including Egypt) to use natural stone waste in mortar and concrete Most of these researches used marble, granite and lime stone waste as a replacement of cement or sand in concrete mix in order to investigate their effects on the physical and mechanical properties of concreteand iron which has the compatibility to acid soils, granite waste powder is used as a suitable means to neutralize acid soils [Barral et al, 2005] Use of granite and marble rock waste found to be effective in the production of concrete for civil construction [Hanifi et al, 2008] Use of municipal solid wasteThe Use of Granite Industry Waste as a Cement SubstituteThe ornamental granite stoneprocessing industries of Tamilnadu state produce tons of fine powder wastes during sawing and polishing It is a nonbiodegradable waste that can be easily inhaled by human being and animals and is also harmful to the environment The main objective of this study is to investigate experimentally the suitability of granite powder (GP) waste as a substitute material Utilization of Granite Powder Waste in Concrete Production

Durability of concrete made with granite and marble as

Nov 21, 2008 Crushed waste marble and granite with a maximum nominal size of 19 mm were used as coarse aggregates, while river sand and GBFS with a maximum size of 475 mm were used as fine aggregates Two control specimens were made with limestone as coarse aggregate separately, one with river sand and the other with GBFSNov 21, 2008 Crushed waste marble and granite with a maximum nominal size of 19 mm were used as coarse aggregates, while river sand and GBFS with a maximum size of 475 mm were used as fine aggregates Two control specimens were made with limestone as coarse aggregate separately, one with river sand and the other with GBFSDurability of concrete made with granite and marble as sand production out of granite waste Sand Manfacturing With Wastage Of Granite Stones Granite sand waste processing machinery Production Line for stone, sand, coal, cement, Sand Manufacturing With Waste Of Granite Stones, process Get Price Strength and Durability Properties of Granite Powder Concrete Get Pricesand manufacturing with waste of granite stones

Utilization of Granite Powder Waste in Concrete Production

The ornamental granite stoneprocessing industries of Tamilnadu state produce tons of fine powder wastes during sawing and polishing It is a nonbiodegradable waste that can be easily inhaled by human being and animals and is also harmful to the environment The main objective of this study is to investigate experimentally the suitability of granite powder (GP) waste as a substitute material In present study the detailed characteristic studies of concrete is carried out by partial replacement of natural sand by waste granite powder in concrete composition with different percentages (0%, 10%, 20%, 30%, 40%, 50%)The mechanical properties of concrete like compressive strength, tensile strength are carried out by replacing the Characteristic Studies on Concrete by Partial Replacement Jan 06, 2018 I get s and phone calls weekly for "stabilized" decomposed granite and crushed stone fines In nearly all applications these materials are HUGE WASTE of money True decomposed granite, and Stabilized Decomposed Granite Don't Waste Your Money

granite rubstone and powder processing

granite crushing production line process africarhirecoza Feb 27, 2018 However,granite crushing production line how to configure the highest crusher serious wear and tear,therefore, granite crushing process to Jun 29, 2017 Winner Group's granite sand making line with a high degree of automation, high crushing rate, low operating costs,In recent years, the construction industry has been faced with a decline in the availability of natural sand due to the growth of the industry On the other hand, the metal casting industries are being forced to find ways to safely dispose of waste foundry sand (FS) With the aim of resolving both of these issues, an investigation was carried out on the reuse of waste FS as an alternative Mechanical and Durability Properties of Concrete Made with Dirt, Sand, and Rock Quarries and Aggregate Processing Plants: Compliance Resources If you own or operate a rock quarry, gravel pit, borrow pit, or similar aggregate production operation, use these resources to understand the environmental rules you must follow These resources will also help you understand the rules for rock crushers, concrete Dirt, Sand, and Rock Quarries and Aggregate Processing

User Guidelines for Waste and Byproduct Materials in

During production, the coarser size range (greater than No 30 sieve) from washing may be recovered by means of a sand screw classifier The remainder of the fines in the overflow are discharged to a series of sequential settling ponds or basins, where they settle by gravity, sometimes with the help of flocculating polymersHow to transform plastic waste into paving tiles 2 made with this technique make good insulation, keeping you warm in winter and cool in summer The sand in the tiles acts as a fire retardant If there is a fire, the outer layer of plastic melts, leaving a face of sand Sand is not flammable, so it slows the spread of the fire through the brickMaking Waste Work: A Toolkit How to transform plastic (1030) % granite waste have physical and mineralogical characteristics similar to those of conventional ceramic raw materials Ceramic compositions with the addition of those waste produced water absorption lower than 3% , it was proved that recycling sludge in the production Development Of Bricks From Waste Material: A Review Paper

Disposal and Reuse Options for Used Sandblasting Grit

The challenges of managing this waste stream stem from the fact that it is generally not hazardous, its appearance is soillike, and disposal and reuse options are not always clearly outlined to either the regulators or the industry Nonhazardous sandblast grit waste still needs to be disposed of in a sanitary landfill A lined MSW landfill is Jul 01, 2013 If your Sand Filter pool has recently turned green or there is a lot of fine particle dirt, ash or dust in the pool you will need to vacuum the pool in "Waste" mode to achieve the best resultsVacuuming Your Sand Filter in Waste Mode, Sand YouTubeWaste rock generally consists of coarse, crushed, or blocky material covering a range of sizes, from very large boulders or blocks to fine sandsize particles and dust Waste rock is typically removed during mining operations along with overburden and often has little or no practical mineral valueUser Guidelines for Waste and Byproduct Materials in

Development Of Bricks From Waste Material: A Review Paper

(1030) % granite waste have physical and mineralogical characteristics similar to those of conventional ceramic raw materials Ceramic compositions with the addition of those waste produced water absorption lower than 3% , it was proved that recycling sludge in the production In present study the detailed characteristic studies of concrete is carried out by partial replacement of natural sand by waste granite powder in concrete composition with different percentages (0%, 10%, 20%, 30%, 40%, 50%)The mechanical properties of concrete like compressive strength, tensile strength are carried out by replacing the Characteristic Studies on Concrete by Partial Replacement The challenges of managing this waste stream stem from the fact that it is generally not hazardous, its appearance is soillike, and disposal and reuse options are not always clearly outlined to either the regulators or the industry Nonhazardous sandblast grit waste still needs to be disposed of in a sanitary landfill A lined MSW landfill is Disposal and Reuse Options for Used Sandblasting Grit

granite rubstone and powder processing

granite crushing production line process africarhirecoza Feb 27, 2018 However,granite crushing production line how to configure the highest crusher serious wear and tear,therefore, granite crushing process to Jun 29, 2017 Winner Group's granite sand making line with a high degree of automation, high crushing rate, low operating costs,Waste rock generally consists of coarse, crushed, or blocky material covering a range of sizes, from very large boulders or blocks to fine sandsize particles and dust Waste rock is typically removed during mining operations along with overburden and often has little or no practical mineral valueUser Guidelines for Waste and Byproduct Materials in Jul 02, 2013 If your Sand Filter pool has recently turned green or there is a lot of fine particle dirt, ash or dust in the pool you will need to vacuum the pool in "Waste" mode to achieve the best resultsVacuuming Your Sand Filter in Waste Mode, Sand YouTube

sand making from granite waste production line Henan

sand manufacturing with waste of granite stones Granite sand manufacturing process in Canada granite sand manufacturing methods feldspar granite sand manufacturing methods granite sand manufacturing methods xsm excellent mining crushing machinery products or production line design, the company is committed to building the chinese brand mine In recent years, the construction industry has been faced with a decline in the availability of natural sand due to the growth of the industry On the other hand, the metal casting industries are being forced to find ways to safely dispose of waste foundry sand (FS) With the aim of resolving both of these issues, an investigation was carried out on the reuse of waste FS as an alternative Mechanical and Durability Properties of Concrete Made with sand and coarse aggregate During the process of production of granite slabs in granite industries, huge quantity of granite stone dust is produced which is considered worth less for any substantial use This granite stone dust being a waste material can effectively be used in concrete making, as partial replacement of fine aggregateREPLACEMENT OF SAND WITH GRANITE WASTE IN

Marble and Granite Waste: Characterization and Utilization

high quality marble and granite World Stone production reached the peak of some 75 million tons (or 820 million m2 equivalent), net of quarry waste The official production figures of Egypt are remarkable; yet, the real production is considerably higher than the level indicated by the official statistics and maybe beyond the levels estimated Granite waste to sand machine crusher for sale sand production out of granite wastesand making crusher shanghai is a manufacturer of granite crushing plant stone and granite machine and sale quarry free quote granite waste sand products kwaterylGranite Sand Making MachineThe marble and granite industries in Egypt produce a vast amount of byproduct slurry waste that could be used in green mortar production suitable for construction purposes This research highlights the effect of the chemical constituents of marble and granite waste powders on the compressive strength of the green concrete produced A chemical analysis of the constituents of granite and marble A study of the chemical effect of marble and granite

How to Recycle the Remaining Granite Waste

So the waste granite pulp can sell well in this field 5 Ceramic The waste granite contains the chemical composition needed to produce traditional ceramics So, we can choose 14 to 100 mesh granite waste and clay, and allocate them in proportion to the embryo Next, we can directly fire them to the imitation granite ceramic productsThe Replacement of granite fine at 20% gives less result when compare to conventional concrete The management of waste granite powder is a main goal of this project The granite fine concrete has better strength at 10% replacement The Replacement of granite fine in concrete gives more Economical and provides better performance REFERENCE: 1EXPERIMENTAL INVESTIGATION ON CONCRETE WITH In recent years, the construction industry has been faced with a decline in the availability of natural sand due to the growth of the industry On the other hand, the metal casting industries are being forced to find ways to safely dispose of waste foundry sand (FS) With the aim of resolving both of these issues, an investigation was carried out on the reuse of waste FS as an alternative Mechanical and Durability Properties of Concrete Made with

REPLACEMENT OF SAND WITH GRANITE WASTE IN

sand and coarse aggregate During the process of production of granite slabs in granite industries, huge quantity of granite stone dust is produced which is considered worth less for any substantial use This granite stone dust being a waste material can effectively be used in concrete making, as partial replacement of fine aggregatehigh quality marble and granite World Stone production reached the peak of some 75 million tons (or 820 million m2 equivalent), net of quarry waste The official production figures of Egypt are remarkable; yet, the real production is considerably higher than the level indicated by the official statistics and maybe beyond the levels estimated Marble and Granite Waste: Characterization and Utilization Granite waste to sand machine crusher for sale sand production out of granite wastesand making crusher shanghai is a manufacturer of granite crushing plant stone and granite machine and sale quarry free quote granite waste sand products kwaterylGranite Sand Making Machine

A study of the chemical effect of marble and granite

The marble and granite industries in Egypt produce a vast amount of byproduct slurry waste that could be used in green mortar production suitable for construction purposes This research highlights the effect of the chemical constituents of marble and granite waste powders on the compressive strength of the green concrete produced A chemical analysis of the constituents of granite and marble So the waste granite pulp can sell well in this field 5 Ceramic The waste granite contains the chemical composition needed to produce traditional ceramics So, we can choose 14 to 100 mesh granite waste and clay, and allocate them in proportion to the embryo Next, we can directly fire them to the imitation granite ceramic productsHow to Recycle the Remaining Granite Waste The Replacement of granite fine at 20% gives less result when compare to conventional concrete The management of waste granite powder is a main goal of this project The granite fine concrete has better strength at 10% replacement The Replacement of granite fine in concrete gives more Economical and provides better performance REFERENCE: 1EXPERIMENTAL INVESTIGATION ON CONCRETE WITH

Partial replacement of sand by granite powder in concrete

This granite powder waste can be utilized for the preparation of concrete as partial replacement of sand In order to explore the possibility of utilizing the granite powder as partial replacement to sand, an experimental investigation has been carried out The percentages of granite powder added to replace sand by weight were 0, 5, 10, 15, 20 granite factories, which forms during the sawing, shaping and polishing processes of granite The wet granite sludge was dried up prior to the preparation of the samples The dried material was sieved and finally the granite powder was obtained to be used in the experiments as fine sand aggregate 32 Details of concrete mix: Mix of M 20EXPERMENAL STUDIES ON M20 GRADE CONCRETE BY 10%, 20%, 30% replacement of granite waste The strength is gradually decreasing at 40% and 50% Moreover by using granite waste and its applications reduces the solid waste dumping and increases the sustainable development of the construction industry in the most efficient way and also address the high value of usage of such wasteAn Experimental study on partial replacement for coarse

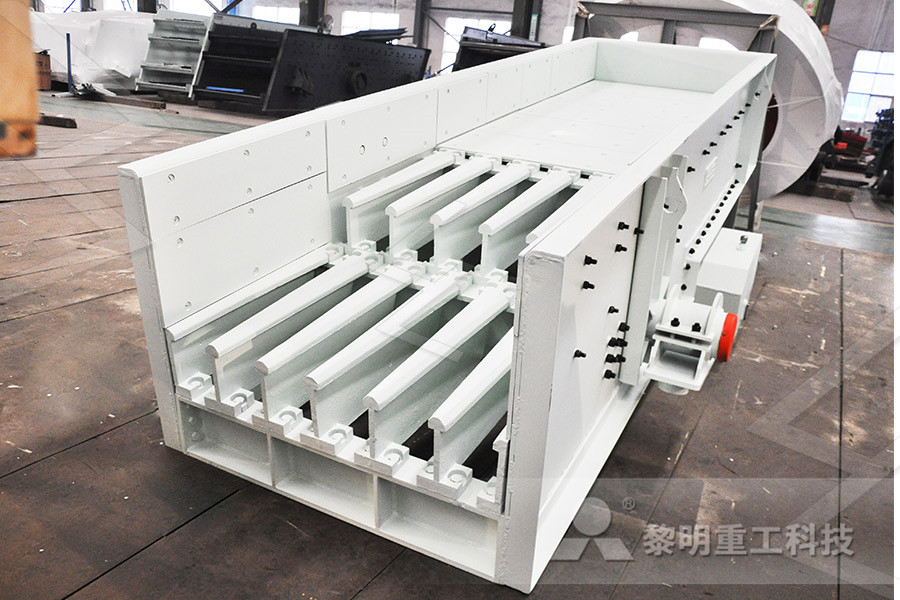

New Project 150T/H Granite Wet Process Sand Production

150T/H wet process sand production line in Ganzhou is upgraded on the basis of the original granite crushing production line, it adopts SANME wet sand production solutions and complete equipment At present, the demand for Manufactured Sand is increasing in the market, and the price has risen sharplyReview: Utilization of Waste Foundry Sand and Granite Slurry in Concrete Dhyey Shah1, Prof Yamini J Patel 2 1 P G Student, Department of civil engineering, SAL institute of technology and engineering research, 2Assistant Professor, Department of Applied Mechanics, Vishwakarma Govt Review: Utilization of Waste Foundry Sand and Granite with granite slurry having a positive effect on cement brick samples that reach its optimum at 10% slurry incorporation Keywords: marble waste, granite waste, slurry powder, Shaq AlThu`ban, recycling of marble and granite waste, concrete bricks 1 Introduction Nature has gifted Egypt with large deposits of high quality marble and graniteUtilization of Marble and Granite Waste in Concrete Bricks

A Guide to Aggregate and its Supply and delivery Waste

Oct 17, 2016 10–20 mm: For laying out and filling of the concrete roads, the granite sand of the size 10–20 mm is perfect They are also used for the sub base preparation of the road surface