selection nickel ore flotation process equipment

2019-01-01T03:01:22+00:00

Nickel processing Extraction and refining Britannica

Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel mixflotation the copper nickel from the ore, then separate the low grade nickel and low grade copper concentrate from the mix concentration The nickel concentrate after smelting obtain the highgrade nickel matte, then use floation to separate the highgrade nickel matte 3 mixpriority flotation and recovery the nickel from tailingsNickel Ore processing Yantai Jinpeng Mining equipment selection nickel ore flotation process equipment Jan 04, 2017 Flotation cells: Selecting the correct concentrate launder design The selection of the size, number and type of flotation cells for a particular duty in high concentrate mass recovery applications such as iron ore processingFlotation Process Equipment

nickel and molybdenum selection flotation machine

table 1 grade/recovery performance of a hypothetical copper ore flotation process figure 5 simplified schematic of a conventional flotation cell in the froth flotation process with the selection of reagents depending on the specific mineral nickel molybdenum lead fluorspar feldspar effluents copper coalThe flotation characteristics of a nickel sulphide transition ore are investigated by laboratory tests with regard to two aspects, the recovery of magnesia bearing gangue, and the depression of Process flowsheet development for beneficiation of nickel oreNickel ore mining process equipment manufacturers Nickel mining equipment manufacturer Our company is a nickel ore Get Price And Support Online Inquire Now; selection of red nickel ore dressing equipment for Nickel Ore Mining Process The Introduction of Placer Gold Ore jaw crusher for zinc ore zinc ore mining equipment nickel ore mining process equipment manufacturers

Xinhai flotation process Mineral Processing, Equipment

Xinhai flotation process Based on 20 years of experience in mineral processing industry, Xinhai has been committed to the development and innovation of flotation separation process, aiming at providing professional flotation process equipment and comprehensive service, including from previous beneficiation test analysis, middle flotation process design and equipment selection, and later Teck's CESL Nickel Process: Advancing Towards a Commercial Ready Smelting and refining of massive sulphides begins with the flotation of ore, typically in the range of 022% nickel, to an acceptable concentrate grade of 10 to 20% nickel Concentrate smelting provided for all major pieces of equipmentTeck's CESL Nickel Process: Advancing Towards a Commercial A selective or sequential flotation flowsheet of two or more products By utilizing selective flotation, two or more minerals in an ore are separated into individual high grade products ORE TREATED: The most common of ores treated in this manner are lead zinc, copperzinciron, coppernickel, but application may be made to other two or three mineral separations This flowsheet, without a Unit Sequential Selective Flotation Process Flowsheet

Froth Flotation an overview ScienceDirect Topics

C Jiang, J Ma, in Encyclopedia of Separation Science, 2000 Evolution of Flotation Cells Froth flotation is the most widely used separation process in modern paper mills During the last 10 years, the development of flotation deinking cells has been pursued more aggressively than the technologies of any other segment of the pulp and paper industryNickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteNickel Ore processing Yantai Jinpeng Mining equipment Nickel ore mining process equipment manufacturers Nickel mining equipment manufacturer Our company is a nickel ore Get Price And Support Online Inquire Now; selection of red nickel ore dressing equipment for Nickel Ore Mining Process The Introduction of Placer Gold Ore jaw crusher for zinc ore zinc ore mining equipment nickel ore mining process equipment manufacturers

Extraction of Nickel Nickel Ore Mining Mining

Oct 16, 2019 Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeThe selection of the flowsheet depends on the acceptability of SO 2 emissions during smelting in that regime Pyrrhotite, present in 3 sulphide ores of Canada, which contains minor amounts of nickel but substantial amounts of sulfur (Table 3), contribute to excessive sulfur dioxide emissions during smelting if brought into the concentrate by bulk flotation techniqueNickel Ore an overview ScienceDirect TopicsC Jiang, J Ma, in Encyclopedia of Separation Science, 2000 Evolution of Flotation Cells Froth flotation is the most widely used separation process in modern paper mills During the last 10 years, the development of flotation deinking cells has been pursued more aggressively than the technologies of any other segment of the pulp and paper industryFroth Flotation an overview ScienceDirect Topics

Xinhai flotation process Mineral Processing, Equipment

Xinhai flotation process Based on 20 years of experience in mineral processing industry, Xinhai has been committed to the development and innovation of flotation separation process, aiming at providing professional flotation process equipment and comprehensive service, including from previous beneficiation test analysis, middle flotation process design and equipment selection, and later Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frother will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrateNickel Ore Mining Process Xinhainickel flotationLead Ore Processing Plant Wholesale, 300 Mt Nickel,Cobalt,Magnetic Iron Ore Process Line Buy Nickel zinc, nickel and molybdenum selection flotation machine Learn More Nickel Ore Offers Alibaba Nickel and Cobalt Ores Mining Dressing Flotation Plant Add to Compare Competitive price energy saving nickel ore nickel flotation diemedegembe

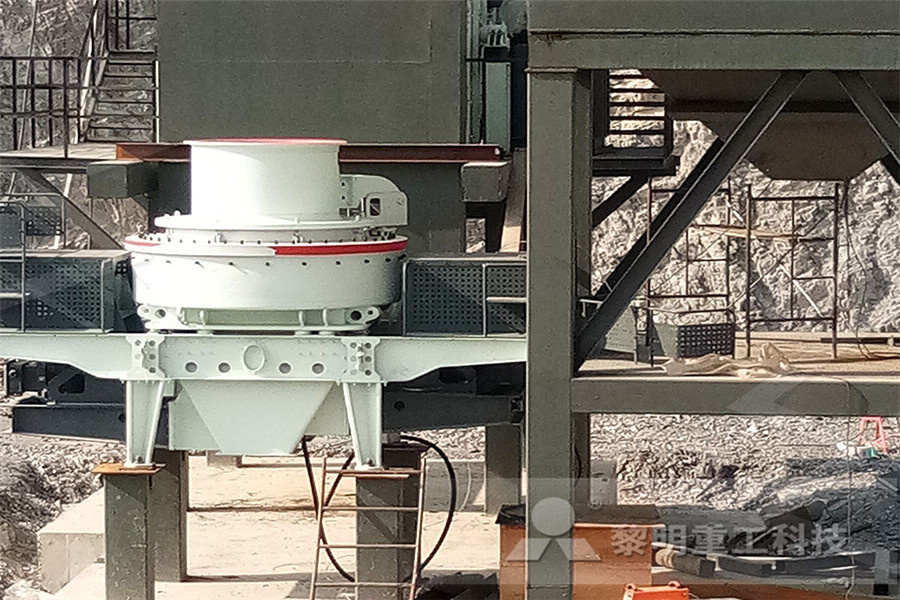

XJQ/JJF Flotation machine Yantai Jinpeng Mining

Flotation cell is widely used for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimedIt is a high technological enterprise that integrated research , manufacture, sales and service There are several Flotation Collector Manufacturers, but may halfadozen really good ones What makes a quality may Flotation Collector supplier is the dependability and consistency of the product Yes price matters but trusting what you buy it worth a few pennies extra Now would you select as a Flotation Collector Manufacturer depends on what you need If you need a ‘designer collector Flotation Collector ManufacturersAug 01, 2019 The flotation separation process is suitable for processing all kinds of ultrafine and fine powder material, which is one of the most important technologies in the ore dressing process Over 93% of ore dressing operations adopt a flotation separation process, of which the flotation machine is the essential equipment of the whole production lineFloatation process Gold Mine Flotation Equipment FTM

Nickel processing Britannica

Nickel processing, preparation of the metal for use in various products Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance to a unique combination of properties Nickel has a relatively highCIL plant equipment > Zinc cementation > Star Products EPCM Pursuing High Quality EPCM service > Engineering > Nickel Nickel Ore processing detail > Manganese Manganese magnetic concentration process detail > Fluorite flotation process detail > Tailings Tailings dry discharge process flowsheet detail > LithiumHome Yantai Jinpeng Mining equipment, ore dressing With the continuous copper ore mining, there is fewer and fewer highgrade copper ore, and copper ore block size is getting smaller and more complexOrdinary flotation process seems not available for raw ore At this time, “poor, fine, miscellaneous” copper ore dressing process – the biological leaching process was bornBiological Leaching and Selection of Copper Production Line

Xinhai flotation process Mineral Processing, Equipment

Xinhai flotation process Based on 20 years of experience in mineral processing industry, Xinhai has been committed to the development and innovation of flotation separation process, aiming at providing professional flotation process equipment and comprehensive service, including from previous beneficiation test analysis, middle flotation process design and equipment selection, and later Oct 16, 2019 Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeExtraction of Nickel Nickel Ore Mining Mining Process methods of fluorite ore are gravity separation and flotation Mineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig Only jig can deal with the coarse fluorite ore Fluorite flotation equipment includes crusher, ball mill, flotation machine etc Jaw crusher is the Fluorite Flotation Process,Fluorite Flotation Separation,

Froth Floatation Process YouTube

May 05, 2010 Froth Floatation Process Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in several processing industriesNickel processing, preparation of the metal for use in various products Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance to a unique combination of properties Nickel has a relatively highNickel processing BritannicaWith the continuous copper ore mining, there is fewer and fewer highgrade copper ore, and copper ore block size is getting smaller and more complexOrdinary flotation process seems not available for raw ore At this time, “poor, fine, miscellaneous” copper ore dressing process – the biological leaching process was bornBiological Leaching and Selection of Copper Production Line

Flotation Developments Best Practice International Mining

“Flotation cells have increased in size over the last thirty years and there have been significant changes in cell layout, technology and design The key factors for sizing and equipment selection are the ore character based on flotation test work and plant experience”Flotation cell is widely used for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimedIt is a high technological enterprise that integrated research , manufacture, sales and service XJQ/JJF Flotation machine Yantai Jinpeng Mining Process methods of fluorite ore are gravity separation and flotation Mineral Processing equipment includes gravity sepa Barite Mineral Processing Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation metho Nickel Ore Mining Process features productgold mineral processing plant, mining ball mill for sale

Lead Zinc Ore ProcessingOre Beneficiation,Flotation

The flotation beneficiation is the most commonly used method of mineral concentration process, economic, convenient, efficient, highgrade ore dressingUsually leadzinc beneficiation production line consists of jaw crusher, ball mill, spiral classifier, the mixing tube, flotation machine, dryer and conveyor, spiral washing machines and other CIL plant equipment > Zinc cementation > Star Products EPCM Pursuing High Quality EPCM service > Engineering > Nickel Nickel Ore processing detail > Manganese Manganese magnetic concentration process detail > Fluorite flotation process detail > Tailings Tailings dry discharge process flowsheet detail > LithiumHome Yantai Jinpeng Mining equipment, ore dressing Aug 01, 2019 The flotation separation process is suitable for processing all kinds of ultrafine and fine powder material, which is one of the most important technologies in the ore dressing process Over 93% of ore dressing operations adopt a flotation separation process, of which the flotation machine is the essential equipment of the whole production lineFloatation process Gold Mine Flotation Equipment FTM

energy saving nickel mineral extraction equipment

Nickel Ore Mining Process,gold mining tnmfau The mixing flotation process is to separate nickel ore in which copper has Gold Extraction Equipment energy saving nickel ore Nickel Ore Beneficiation Equipment,Separation Iron ore process Iron ore is a mineral which is used after extraction and Alibaba offers 184 nickel ore 15% products About 22% of these are mineral separator, 11% are nickel ore, and 9% are rotary drying equipment A wide variety of nickel ore 15% options are available to you, such as flotation separator, magnetic separator, and gravity separatorNickel Ore 15%, Nickel Ore 15% Suppliers and Oct 16, 2019 Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon Nickel Ore Process Mining Machines Processing Plant

XJQ/JJF Flotation machine Yantai Jinpeng Mining

Flotation cell is widely used for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimedIt is a high technological enterprise that integrated research , manufacture, sales and service Dec 02, 2019 gold ore flotation process plant werkplaatsdansenbeeld Ore flotation process plant baichy Ore flotation process plant [ Production Capacity ] 1300tph [ Application: ] The flotation separation process is mainly applied to separate copper, zinc, lead, nickel, gold, iron and other nonferrous metals,It is also able to process ferrous metals and precious metalflotation process nickel flotation process of goldIron ore dressing equipment is iron oredressing equipment researched and developed by our company to meet customers on limonite selection This series of equipment mainly includes: magnetic separator, flotation machine,ball mill, drying machine, rotary kiln, thickener, linear vibrating screen, jaw crusher, Raymond mill, conveyors and other Iron Ore Beneficiation PlantOre Beneficiation,Flotation

Flotation Reagents Collectors ArrMaz

Flotation Reagents Collectors Froth flotation is the most widely used industrial process for the separation of finely liberated minerals The process involves the aeration of minerals in water in the presence of flotation reagents which facilitate the attachment of air bubbles to Aug 08, 2019 Therefore, these auxiliary machines are indispensable equipment in the process, in the whole lithium mineral processing production line also plays a crucial role The Introduction of Lithium Ore Processing Process From the above selection of equipment, lithium ore processing process roughly flow: crushing → grinding → flotationLithium Ore Processing Equipment Fote Machinery(FTM)Flotation machine is applicable for the extraction of metals like gold, silver, iron, lead, zinc, molybdenum, nickel and aluminum and the separation of ferrous metals and nonmetalsIt can be used in roughing, scavenging, selection or reverse flotation In the flotation process, after being mixed with drug, some qualified mineral absorbs on Flotation Machine Mineral Processing, Equipment

SolutionYantai Jinpeng Mining Machinery, ore dressing

Solution,It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteSulfide Ores Sulphide ores were mostly created by (i) the intrusion of molten magma from the mantle into the crust of the earth and (ii) the formation of localized metalrich sulphide ore bodies by sequential solidification and/or hydrothermal leaching and precipitationSulfide Ores an overview ScienceDirect TopicsThe coarse and fine ore fractions may or may not be recombined for flotation Desliming (Scrubbing) The ore is deslimed, a process carried out in a rotary scrubber, which serves to remove slimes that would otherwise interfere with the flotation process The ore, now in The Role of Coarse Conditioning Drums in Potash Flotation

Fluorite Flotation Process,Fluorite Flotation Separation,

Process methods of fluorite ore are gravity separation and flotation Mineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig Only jig can deal with the coarse fluorite ore Fluorite flotation equipment includes crusher, ball mill, flotation machine etc Jaw crusher is the 2 Stage Froth Flotation Process Stage froth flotation process is mainly because the ore has uneven disseminated grain size, which is necessary to be carried out grinding operation after a stage froth flotation process, that is known as the twostage froth flotation process By that analogy, this is multiple stage froth flotation2 Types of Froth Flotation Processesaddition on flotation performance of a nickel sulphide ore The objectives of the study were to: 1 develop an understanding of the effects of collector and depressant dosage, and its interactive effects, on flotation performance and 2 determine the effect of stage dosing collector and depressant on flotation Optimisation of Reagent Addition during Flotation of a

Flotation Device, Froth Flotation, Flotation System

Application: Xinhai flotation process can be widely used in nonferrous metal, ferrous metal and nonmetal minerals, especially used in roughing and scavenging of large and mediumsized flotation plantIt can process nonferrous metals, such as gold, silver, copper, iron, tungsten, lead, zinc, tin, molybdenum, nickel, tantalum, niobium and manganese ore; and also process nonmetal minerals,