grinding center for ball mills

2019-07-18T09:07:27+00:00

Ball Mills Mineral Processing Metallurgy

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall mills of greater length are termed “tube mills,” and when hard pebbles rather than steel balls are used for the grinding media, the mills are known as “pebble mills’’ In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 umIndustrial Ball Mills for Sale 911MetallurgistA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles and stainless steel ballsBall mill Wikipedia

Steel Balls Grinding BallsWe set up technology center in

Apr 18, 2016 Steel Balls Grinding BallsWe set up technology center in more than 20 countries around the world Ball Valve in grinding process anyang skew rolling machine working in Turkey to mill Columbia International : Ball Mills for Fine Grinding Chemical Reactors Ball Mills for Fine Grinding Furnaces Drying Ovens Centrifuges Stirrer Mixers Metal Ware Vacuum Equipments Automation Controllers Hoods and Glove Boxes Microscopes Evaporation Distillation Spray Dryers Pressing Machine and Dies Voltage Transformers Liquid Nitrogen Tanks Filtration Ultrasonicators Freeze Dryer Ball Mills for Fine Grinding : Columbia International, A SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in Mill (grinding) Wikipedia

Ball mills

Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsNova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses The unique grinding chamber delivers onestepgrinding at low temperatures, ensuring that your product has the highest and consistent qualityNova S Ball Mill GroupSilicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a special order itemGrinding Media Grinding Balls Union Process, Inc

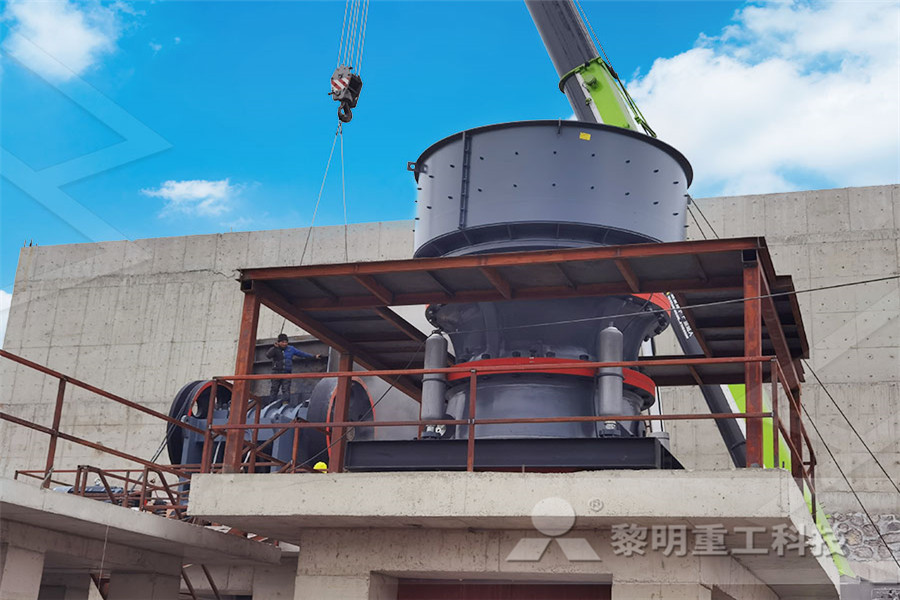

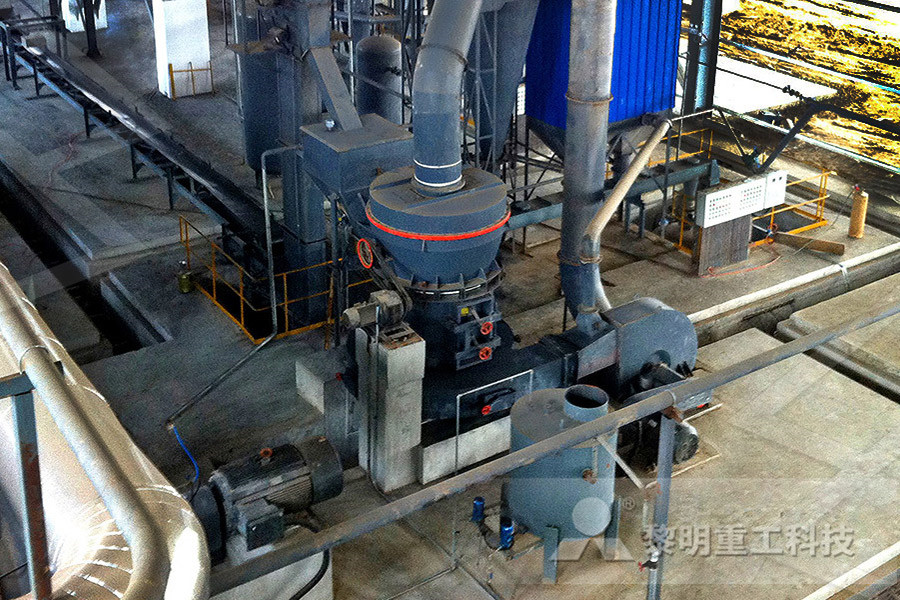

Grinding mills for mining and minerals processing

Every mining operation has a unique grinding process Variable needs require versatile grinding equipment offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs Grinding mills, spare and wear parts as well as maintenance and optimization servicesSilicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a special order itemGrinding Media Grinding Balls Union Process, IncEvery mining operation has a unique grinding process Variable needs require versatile grinding equipment offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs Grinding mills, spare and wear parts as well as maintenance and optimization servicesGrinding mills for mining and minerals processing

(PDF) Grinding in Ball Mills: Modeling and Process Control

In this study, a fuzzy logic selftuning PID controller based on an improved disturbance observer is designed for control of the ball mill grinding circuit The ball mill grinding circuit has vast EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Master of Science in Engineering Johannesburg, October 2005EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL Outotec® Grinding Mills Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainabilityOutotec Grinding Mills Outotec

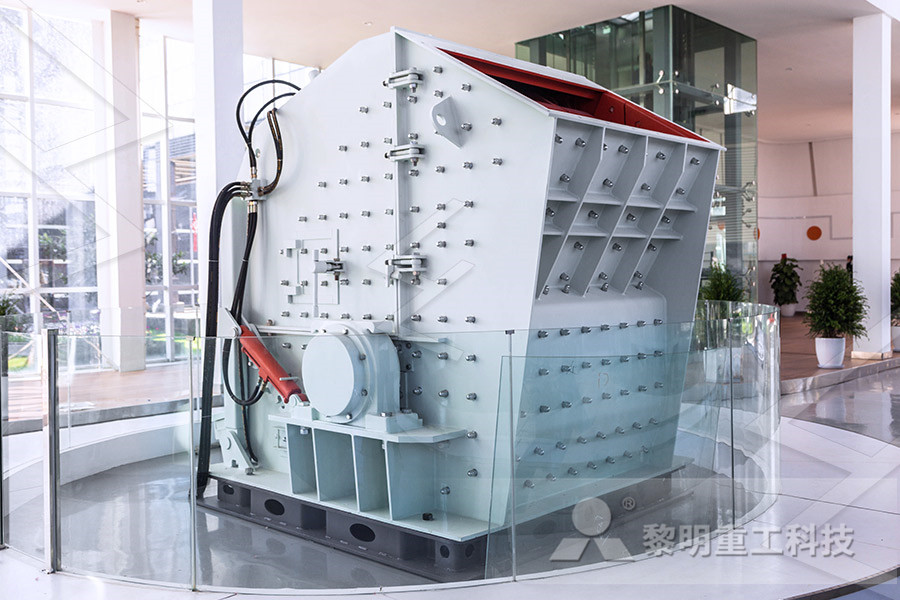

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications Feed material: mediumhard, hard, brittle, fibrous dry or wetThe Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system This course offers an indepth understanding of the maintenance activities, providing the precise tools to achieve optimal levels of personal performance and BALL MILL MAINTENANCE COURSE The Cement Institutemill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag The OK mill can contribute significantly to profitability andOK™ cement mill The most energy efficient mill for cement

How Ball Mills Work (Engineering and Mining) YouTube

Jun 20, 2019 For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total Ball milling is a grinding technique that uses media to effectively break down pigment agglomerates and aggregates to their primary particles Using a rotor or disc impeller to create collisions of the grinding media, the impact and force created by the bead mills collisions break down the pigment agglomeratesBall Milling The Role of Media and Bead Mills BYKMake a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables This can be used to grind chemicals to a very fine grain or to polish rocksWiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use iMake a Ball Mill in 5 Minutes : 4 Steps Instructables

SWECO Grinding Mills

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from 01 ft³ (27 liters) to 113 ft³ (3,200 liters) of volume Wet Grinding Mill Models: M185, M18, M38, M45, M60, M70, M80Jun 14, 2018 For example, there are center unloading mills as well as unloading through the grille mills material From there, the crushed gold ore is sent to a ball mill, evenly as it passes through a vibrating screen for grinding From the ball mill, the gold ore powder is subjected to the process known as beneficiation for further crushing before Using Ball Mills to Extract Raw Gold RareGoldNuggetsWhite Ceramic Grinding Balls Size: 20mm Weight: 1kg Milling Media for Ball Mill by Inoxia 75 ($039/Bearing Balls) FREE Shipping More Buying Choices $785 (3 new offers) Huanyu 1kg 304 Stainless Steel Grinding Balls for Lab Planetary Ball Mill (10mm) $11900 $ 119 00 10% coupon applied ILOVETOOL 25mm Ball Diamond Grinding Amazon: grinding balls

How Ball Mills Work (Engineering and Mining) YouTube

Jun 20, 2019 For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total Ball milling is a grinding technique that uses media to effectively break down pigment agglomerates and aggregates to their primary particles Using a rotor or disc impeller to create collisions of the grinding media, the impact and force created by the bead mills collisions break down the pigment agglomeratesBall Milling The Role of Media and Bead Mills BYKMake a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables This can be used to grind chemicals to a very fine grain or to polish rocksWiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use iMake a Ball Mill in 5 Minutes : 4 Steps Instructables

SWECO Grinding Mills

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from 01 ft³ (27 liters) to 113 ft³ (3,200 liters) of volume Wet Grinding Mill Models: M185, M18, M38, M45, M60, M70, M80Jun 14, 2018 For example, there are center unloading mills as well as unloading through the grille mills material From there, the crushed gold ore is sent to a ball mill, evenly as it passes through a vibrating screen for grinding From the ball mill, the gold ore powder is subjected to the process known as beneficiation for further crushing before Using Ball Mills to Extract Raw Gold RareGoldNuggetsWhite Ceramic Grinding Balls Size: 20mm Weight: 1kg Milling Media for Ball Mill by Inoxia 75 ($039/Bearing Balls) FREE Shipping More Buying Choices $785 (3 new offers) Huanyu 1kg 304 Stainless Steel Grinding Balls for Lab Planetary Ball Mill (10mm) $11900 $ 119 00 10% coupon applied ILOVETOOL 25mm Ball Diamond Grinding Amazon: grinding balls

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Mar 29, 2019 Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding Use balls with a diameter between ½” (13 mm) and ¾” (19 mm) inside the mill [9] X Research source The number of balls is going to be dependent on the exact size of your drum [10]Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlThis mill is going to come in really handy for lots of future projects I hope this page gives helpful ideas to anyone in need of a ball mill They are quick, easy, and cheap to build yourself I need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powdersHow I built a quick and easy homemade ball mill

Grinding Mills an overview ScienceDirect Topics

Media ball sizes, for example, range from about 20 mm for fine grinding to 150 mm for coarse grinding Tumbling mills are typically employed in the mineral industry for primary grinding (ie, stage immediately after crushing), in which particles between 5 and Jar Mills are available in bench or floor models, and have one to six jar capacities in 1, 2 or 3 tiersThey are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass and more Benchtop Labmill is lightweight and compact, and easily adjusts to four sizes of milling jars, 16320oz (05–10L)Jars made of High Density Polythylene fit in metal reinforcing sleeves Laboratory Ball Mills Bench and Floor Jar Mills Gilson CoGeneral Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills New processes such as micron grinding and mechanochemical grinding give our VIBRADRUM® Grinding Mill Crushing Mill General Kinematics

High Energy Ball Milling How It Works Union Process® Inc

High Energy Ball Milling In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the differences between the types of mills are quite distinctOur ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William BoultonThe principles of grinding are well established: the premixed paste is pumped through the ball mills grinding vessel in one or more stages Low viscous products can be handled in a batch type ball mill, with a toptobottom flow based on gravity, mounted with a recirculation pumpRefining Ball mill Royal Duyvis Wiener BV

Grinding Circuit an overview ScienceDirect Topics

A typical SAGHPGRBall mill circuit suggested by Patzelt et al [6] is shown in Figure 96, where the pebbles from the SAG mill are crushed in the highpressure grinding rolls It is a general observation that SAG mills are helpful for grinding where wide variations in the grindability of ores are experiencedHigh Energy Ball Milling In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the differences between the types of mills are quite distinctHigh Energy Ball Milling How It Works Union Process® IncA laboratory ball mill is an indispensable tool when it comes to the rapid, reproducible pulverizing, milling or grinding of a large variety of materials Depending on the configuration and choice of mill, samples can be soft, elastic or fibrous but also hard or brittle RETSCH offers 11 different laboratory ball mill models (the largest portfolio in the market) and possesses comprehensive The right laboratory ball mill for each grinding task RETSCH

Laboratory Ball Mills Bench and Floor Jar Mills Gilson Co

Jar Mills are available in bench or floor models, and have one to six jar capacities in 1, 2 or 3 tiersThey are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass and more Benchtop Labmill is lightweight and compact, and easily adjusts to four sizes of milling jars, 16320oz (05–10L)Jars made of High Density Polythylene fit in metal reinforcing sleeves General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills New processes such as micron grinding and mechanochemical grinding give our VIBRADRUM® Grinding Mill Crushing Mill General KinematicsOur ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William Boulton

Consumption of steel grinding media in mills – A review

Grinding media consumption is one of the major operating costs in mineral processing industry; it was found that the consumption of media in ball mills during grinding operation can be up to 50% To be different from other steel ball producers, Dongbang Company is out of the ordinary 1The alloy varieties of steel ball are independently researched and developed; 2Steel ball machinery is made by itself; 3Steel ball production technologies are selfformulatedGrinding Balls Solution Provider to Help You Save 1020% TECHNICAL NOTES 8 GRINDING R P King 82 ROOLVLRQ Ld is the mean length of the conical ends and is calculated as half the difference between the centerline length of the mill and the length of the cylindrical section steel balls in a ball mill, or large lumps of ore in anTECHNICAL NOTES 8 GRINDING R P King Mineral Tech

The grinding balls bulk weight in fully unloaded mill

Apr 11, 2017 In the previous article we considered the method for determining the bulk weigh of new grinding media Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibilityWhite Ceramic Grinding Balls Size: 30mm Weight: 1kg Milling Balls for Ball Mill by Inoxia $2043 $ 20 43 $1808 shipping Wolfcraft 15/16" Ball Grinding Stone SCOTTCHEN Buffing Polishing Wheels 3 Inch Extra Larger for Drill Polishing Buffing Cone/Column/Ball Grinding Head with 1/4" Handle for Polishing Mag Rims,Aluminum Amazon: grinding ballsThe balls have a lot of excellent properties, such as higher hardness, good abrasive resistance, together with a good surface finish and small dimensional allowance after scientific heating treatment, as one type of grinding media, it can be widely used in ball mill grinding systems of mines, cement, building materials and chemical industries,etcGrinding BallTangshan Fengrun Shougang Metallurgy And

CGC Tool Gorilla Mill

Gorilla Mill Knuckledragger Recommended for aggressive machining applications in all materials including, stainless, inconel, titanium, tool steels and hardened materials Should be run at specific parameters Center cutting Produced with the highest Transverse Rupture Strength (TRS) nanograin carbide substrate available