extraction of molybdenum from its ore

2022-12-31T15:12:50+00:00

Molybdenum: mining and processingMetalpedia

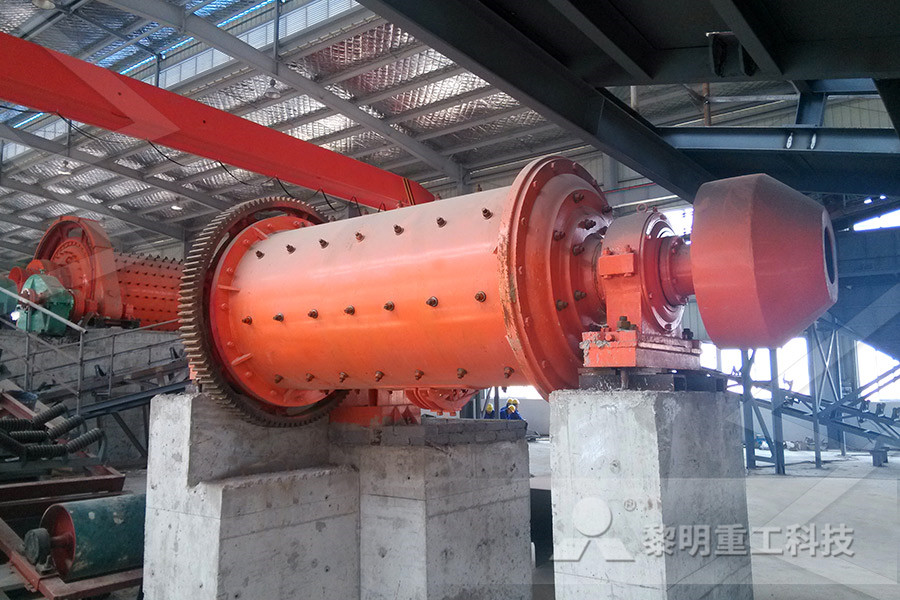

Molybdenum mines are classified into three groups according to the minerals contained in the ore body and their quality: •Primary mines, where the extraction of molybdenite is the sole aim •Byproduct mines, where the extraction of copperbearing ores is the primary aim, and molybdenite extraction provides additional economic valueExtraction of Molybdenum from its Ore Previous Next View Larger Image Molybdenum Flotation By L D Michaud T19:31:3204:00 March 10th, 2016 Categories: Flotation, Flowsheets Flowcharts Tags: Molybdenum Flotation, Small Process Equipment Comments Off on Extraction of Molybdenum from its Ore Related Posts Extraction of Molybdenum from its Ore1 Introduction The extraction of molybdenum (VI), which is one of the major fission products found in spent nuclear fuel, is of great importance due to its strong tendency to form precipitates during the course of the PUREX reprocessing process (Zilberman et al, 2015)Molybdenum is a firstchoice element in the manufacture of heat and corrosionresistant alloys, a base metal in Extraction of molybdenum (VI) from nitric acid medium and

Molybdenum processing Britannica

Molybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficientFor low grade oxide ore, use sulfuric acid to leach, ion exchange and extraction method to extract pure molybdenum trioxide from solution Application overview of molybdenum Molybdenum is used in the leading position in the iron and steel industry, accounting for about 80% of the total consumption of molybdenum, followed by chemical industry How is Molybdenum Extracted SAMaterialsMolybdenum Ores natural mineral formations containing molybdenum in quantities that make its extraction economically feasible The reserves of molybdenum in ores in developed deposits range from a few thousand tons to millions of tons The average molybdenum content in the ores of large deposits ranges from 006 to 030 percent, and in small deposits Molybdenum Ores Article about Molybdenum Ores by The

(PDF) Extraction of molybdenum and nickel from

More than 998% of the molybdenum (VI) was extracted in a fourstage counter current extraction using an organic system consisting of 30% (v/v) P507 and 70% (v/v) sulfonated kerosene and a Molybdenum Ores natural mineral formations containing molybdenum in quantities that make its extraction economically feasible The reserves of molybdenum in ores in developed deposits range from a few thousand tons to millions of tons The average molybdenum content in the ores of large deposits ranges from 006 to 030 percent, and in small deposits Molybdenum Ores Article about Molybdenum Ores by The USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords ore solution sodium molybdenum wulfenite Prior art date Legal status (The legal status is an assumption and USA Process for extracting molybdenum from

Extraction of Tungsten JXSC Machine

Extraction of tungsten has a different method, include gravity separation, magnetic separation, flotation process It can only constant testing to determine the best way to the extraction of tungsten from its ore 1 Description of tungsten ore Tungsten minerals are tungstateMolybdenum extraction of 952 percent was achieved on a laboratory scale from an ore containing 035 percent molybdenite Corresponding power consumption was 24 kilowatt hours per pound of molybdenum extracted with a base consumption of 45 Pounds of sodium carbonateNIOSHTIC2 Publications Extraction of Liu et al (2011) reported the extraction of molybdenum from lowgrade Nimolybdenum ore in sodium hypochlorite solution under mechanical activation The Extraction of molybdenum from lowgrade Ni–Mo ore in

Extraction molybdenum

The extraction of molybdenum Molybdenum comes from a sulphide ore called molybdenite First, the ore must be crushed into a powder and then the copper sulphide must be separated from the rest What is left is molybdenum sulphide and that is roasted Now there is molybdenum concentrate and that is then made into molybdenum oxideOres Niobium occurs mostly as an oxide and has a strong geochemical coherence with tantalum Major minerals of niobium are pyrochlore [(Na, Ca) 2 Nb 2 O 6 F] and columbite [(Fe, Mn)(Nb, Ta) 2 O 6], consisting of niobate, tantalate, iron, and manganesePyrochlore occurs usually in carbonatites and in pegmatite derived from alkalic rocks, commonly in association with zirconium, titanium niobium processing History, Ores, Mining, Extraction Molybdenum is contained in various minerals, but only molybdenite (MoS 2) is suitable for the industrial production of marketable molybdenum productsMolybdenite can occur as the sole mineralization in an ore body, but is often associated with the sulphide minerals of other metals, notably copperMolybdenum Mining

Process for extracting chromium from chromium ores

Jun 15, 1976 I claim: 1 A process for extracting chromium in the form of a chromate from ore or concentrate by the suspension oxidation thereof to the chromate state which comprises suspending finely crushed ore or concentrate containing the chromium in a molten liquid bed of an alkali metal salt in the ratio of 1 part by weight of ore to 5 to 20 parts by weight of salt; subjecting the suspension to ABSTRACTTertiary amine N235 diluted with sulphonated kerosene containing secoctyl alcohol as a phase modifier was used to directly extract molybdenum from the acidic leach solution of Ni–Mo ore The results indicated that the extraction of molybdenum can reach more than 88% using a solvent extraction system consisting of 10 vol% N235 and 10 vol% secoctyl alcohol in sulphonated Extraction of molybdenum from acidic leach solution of Ni Molybdenum is a chemical element with the symbol Mo and atomic number 42 The name is from NeoLatin molybdaenum, from Ancient Greek Μόλυβδος molybdos, meaning lead, since its ores were confused with lead ores Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of other metals Molybdenum Wikipedia

Solvent extraction of molybdenum from acidic leach

May 30, 2013 A P204 (D2EHPA) diluted with sulfonated kerosene was used for the selective extraction of molybdenum from an acidic Ni–Mo ore leach solution that was reduced using sodium thiosulfate The results indicate that P204 (D2EHPA) is an effective extractant for the extraction of molybdenum The extraction of Mo is more than 90 % at pH of 05, contact time of 10 min, and organictoaqueous Material adapted from: Hudson, TL, Fox, FD, and Plumlee, GS 1999 Metal Mining and the Environment, p 7,2027,3135,3839 Published by the American Geosciences Institute Environmental Awareness Series Modern mining operations actively strive to mitigate potential environmental consequences of extracting metals, and such operations are strictly regulated in the UnitedHow can metal mining impact the environment? American ABSTRACTTertiary amine N235 diluted with sulphonated kerosene containing secoctyl alcohol as a phase modifier was used to directly extract molybdenum from the acidic leach solution of Ni–Mo ore The results indicated that the extraction of molybdenum can reach more than 88% using a solvent extraction Extraction of molybdenum from acidic leach solution of Ni

Molybdenum Wikipedia

Molybdenum is a chemical element with the symbol Mo and atomic number 42 The name is from NeoLatin molybdaenum, from Ancient Greek Μόλυβδος molybdos, meaning lead, since its ores were confused with lead ores Molybdenum May 30, 2013 A P204 (D2EHPA) diluted with sulfonated kerosene was used for the selective extraction of molybdenum from an acidic Ni–Mo ore leach solution that was reduced using sodium thiosulfate The results indicate that P204 (D2EHPA) is an effective extractant for the extraction of molybdenum The extraction Solvent extraction of molybdenum from acidic leach Material adapted from: Hudson, TL, Fox, FD, and Plumlee, GS 1999 Metal Mining and the Environment, p 7,2027,3135,3839 Published by the American Geosciences Institute Environmental Awareness Series Modern mining operations actively strive to mitigate potential environmental consequences of extracting How can metal mining impact the environment? American

Molybdenum Article about molybdenum by The Free Dictionary

In addition to molybdenum ores, some molybdenumbearing copper and copperleadzinc ores are used to produce molybdenum The extraction of molybdenum is increasing rapidly Physical and chemical properties Molybdenum The milled ore/gangue powder is mixed with a liquid and aerated in the flotation step The less dense ore rises in the froth to be collected, while the gangue sinks to be discarded Flotation separates the metallic minerals from the gangue this way and – in the case of copper/ molybdenum ores Molybdenum Processing IMOA: International Molybdenum Jul 31, 2018 Due to the added energy consumption, chemicals, and materials involved in extracting lithium from mineral ore, the process can run twice the cost of brine recovery, a factor that has contributed to its smaller market share The process for recovering lithium from ore What is Lithium Extraction and How Does It Work?

Gold extraction Wikipedia

Gold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores Series Molybdenum, China Series Molybdenum Suppliers Lead Separator, Lead Separator Suppliers and Manufacturers at antimony separation machine antimony jig separation and flotation Mo Molybdenum Sputtering Targets Vacuum Engineering and (PDF) Microwave irradiation effects on vermicasts potency Copper Ore Chinese Centrifuge Extraction Equipment For Mo/MolybdenumPrecious metals can be found in ore deposits along with sulfur, and are known as sulfides Cadmium, cobalt, copper, lead, molybdenum, nickel, silver, zinc, and gold and platinum group metals can be found in sulfide forms These concentrated ore How to Extract Precious Metals From Sulfides Sciencing

What is a word equation for the extraction of tin from tin

Whereas for zinc it is extracted from its ore chemically by reduction using carbon When an ore is reduced you are taking the oxygen out of the metal, this is because carbon can only take the Extracting copper from its ores The method used to extract copper from its ores depends on the nature of the ore Sulfide ores such as chalcopyrite (\(CuFeS2\)) are converted to copper by a different method from silicate, carbonate or sulfate ores Chalcopyrite (also known as copper pyrites) and similar sulfide ores are the commonest ores The Extraction of Copper Chemistry LibreTextsThe solvent extraction followed by the stripping technique was found to be excellent as the concentration of vanadium and molybdenum enriched from 055 to 19 M and 00448 to 108 M, respectivelyEvaluation of molybdenum recovery from sulfur removed

Processes and Procedures in the Extraction of Iron

The extraction of iron from its ores is quite a technical process The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high Whereas for zinc it is extracted from its ore chemically by reduction using carbon When an ore is reduced you are taking the oxygen out of the metal, this is because carbon can only take the What is a word equation for the extraction of tin from tin Extracting copper from its ores The method used to extract copper from its ores depends on the nature of the ore Sulfide ores such as chalcopyrite (\(CuFeS2\)) are converted to copper by a different method from silicate, carbonate or sulfate ores Chalcopyrite (also known as copper pyrites) and similar sulfide ores are the commonest ores The Extraction of Copper Chemistry LibreTexts

Evaluation of molybdenum recovery from sulfur removed

The solvent extraction followed by the stripping technique was found to be excellent as the concentration of vanadium and molybdenum enriched from 055 to 19 M and 00448 to 108 M, respectivelyThe extraction of iron from its ores is quite a technical process The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high Processes and Procedures in the Extraction of Iron Extracting iron from iron ore using a Blast Furnace The common ores of iron are both iron oxides, and these can be reduced to iron by heating them with carbon in the form of coke Coke is produced by The Extraction of Iron Chemistry LibreTexts

Processes extraction, mining, smelting, refining

The most abundant ores are chalcopyrite and bornite, which contain both copper and iron sulphides These account for about 80% of the world’s known ores Copper Mining The following gives an overview of how copper is extracted from its ore and converted into pure metal Mining The ore search hints: Porphyry copper – Nazca subduction – Global volcanism smithsonian Copper can be extracted from its ore by: Underground: sinking a vertical shaft into the Earth to an appropriate depth and driving horizontal tunnels into the ore Open pit: 90% of ore Copper Mining and Extraction Sulfide OresGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold Copper Mineral, Extraction of Zinc, Extraction of Copper

Bismuth: extractionMetalpedia

Bismuth: extraction; Brife introduction; Bismuth is extracted from its ores by dry, wet, or electrometallurgical methods, the choice depending upon the composition of the ore and economic Copper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors Extraction process of molybdenum extraction copper sulfate from copper molybdenum sunfit oreJul 20, 1993 This invention relates to the removal of molybdenum from uraniumbearing solutions Typically these solutions contain high concentrations of uranium and low concentrations of molybdenum Extraction of uranium from its ores is commonly carried out by processes which include leaching the ore Removal of molybdenum from uraniumbearing solutions

How Is Gold Extracted From Gold Ore? Sciencing

Gold is usually found alone or alloyed with mercury or silver, but can also be found in ores such as calaverite, sylvanite, nagyagite, petzite and krennerite Most gold ore now comes from either open pit or underground mines The ores Apr 17, 2009 Can anyone describe the process of Tungsten being extracted from any of its ores After having written an account on the extraction of Sodium and titanium from their ores I can postulate what the equations for this extraction process would be so can anyone simply describe what goes on in the industrial extraction process of Tungsten from its ore and ALSO what are the main uses of Tungsten Extraction of Tungsten from its ore? Yahoo AnswersAug 06, 2019 This is the introductory video to the lesson titled “Extraction of Metals from its Ore” in Form 3 Science To see the full lesson featuring more animations and interactive exercises, go to Form 3 Science PT3 Extraction of Metals from its Ore