cement rotary kiln indonesia

2022-09-04T14:09:04+00:00

Cement kiln Wikipedia

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant11 rows The 35X54m rotary kiln has been used as rotary kiln, whose end is fitted with fivestage Cement rotay kilnHenan Hongji Mine Machinery Co, LtdCement Rotary Kiln Indonesia cement rotary kiln indonesia manolopoulos cement rotary kiln indonesia metropackers Rotary Kiln Cement supplier cementkilns Rotary Kiln Cement is the main equipment to be used to calcine the Get Price And Support Online; Cement kiln Wikipedia The cement kiln system is designed to accomplish Cement Rotary Kiln Indonesia czeueu

The cement kiln

The original rotary cement kilns were called 'wet process' kilns In their basic form they were relatively simple compared with modern developments The raw meal was supplied at ambient temperature in the form of a slurry A wet process kiln may be up to 200m long and 6m in diameter It has to be long because a lot of water has to be evaporated Innovation in cement kilns Our newest kiln, the ROTAX2® rotary kiln for cement plants, has a twobase design that helps cut down construction time It never needs kiln axis alignment And the ROTAX2® rotary kiln has an innovative design that suspends the kiln Explore our marketleading cement rotary kilns, kiln sealsCement Rotary Kiln Indonesia From Kenya Preheater cyclone in cement plant as a global leading manufacturer of products and services for the mining industry our company can provide you with advanced rational solutions for any sizereduction requirements including quarry aggregate grinding product,Cement Rotary Kiln Indonesia From KenyaCement Rotary Kiln Indonesia From Kenya TENIC Mining machine

Wet Process Cement Rotary Kiln System Manufacturer

The energy consumption accounts for 1/21/3 of the cost of cement, which is higher than that of the vertical kiln and dry rotary kiln Because of the high heat consumption, high energy consumption, large water consumption, and water resources consumption in wet production, wet cement production has been listed as a type of kiln that restricts Indonesia Cement Clinker Rotary Kiln Plant Export , Find Complete Details about Indonesia Cement Clinker Rotary Kiln Plant Export,Indonesia Cement Clinker Rotary Kiln Plant Export,Indonesia Cement Clinker Rotary Kiln,Indirect Rotary Kiln Price from Cement Making Machinery Supplier or ManufacturerZhengzhou Jiangtai Heavy Industrial Machinery Co, LtdIndonesia Cement Clinker Rotary Kiln Plant Export Buy Company website Rotary Kiln Services Australasia Our general products and services include: Supply and installation of new rotary vessels [Kilns, Calciners, Dryers, Coolers, Roasters] Supply and installation of new Grinding Mills [ Ball Mills and Vertical Mills] Supply and replacement of kiln shell sections Supply and replacement of kiln tyres, tyre supporting blocks and guides Supply and Rotary Kiln Services Australasia International Cement Review

Rotary Kiln an overview ScienceDirect Topics

A A Boateng, in Rotary Kilns (Second Edition), 2016 11 The Rotary Kiln Evolution Rotary kilns have been synonymous with cement and lime kilns probably because of the history of their evolution and development It has been reported that cement deposits characterized by Israeli geologists in the 1960s and the 1970s place cement making at 12,000,000 BC when reactions between limestone and oil Indonesia Cement Clinker Rotary Kiln Plant Export , Find Complete Details about Indonesia Cement Clinker Rotary Kiln Plant Export,Indonesia Cement Clinker Rotary Kiln Plant Export,Indonesia Cement Clinker Rotary Kiln,Indirect Rotary Kiln Price from Cement Making Machinery Supplier or ManufacturerZhengzhou Jiangtai Heavy Industrial Machinery Co, LtdIndonesia Cement Clinker Rotary Kiln Plant Export Buy The rotary kiln, originally designed as a British cement kiln in 1877, was born in England, grew up in the United States and was completed in France in the 1900s and has been developed and used in various fields such as ore extraction, metal smelting and waste disposalROTARY KILN Plant Engineering Company Vietnam SAMSHIN

Rotary Kilns KHD International

The KHD PYRORAPID® rotary kiln with a length to diameter ratio of approx 11:1 to 12:1 fulfills high availability, considerable flexibility and costeffectiveness The threestation kiln from KHD Humboldt Wedag is a classic kiln which has been thoroughly tried and tested over the pany website Rotary Kiln Services Australasia Our general products and services include: Supply and installation of new rotary vessels [Kilns, Calciners, Dryers, Coolers, Roasters] Supply and installation of new Grinding Mills [ Ball Mills and Vertical Mills] Supply and replacement of kiln shell sections Supply and replacement of kiln tyres, tyre supporting blocks and guides Supply and Rotary Kiln Services Australasia International Cement ReviewThe global cement industry is pursuing the harmonious coexistence of environmental protection and cement production Using cement rotary kiln to treat municipal solid waste synergistically has always been the common goal of the industry to achieve the ultimate reuse of waste resourcesCement Rotary Kiln Coprocessing Waste Treatment LCDRI CN

Rotary Kiln Part 2 YouTube

Jun 23, 2019 #RotaryKiln #cementtechwithnic #cementplant #cement All Part's Of Rotary Kiln 1 Girth Gear 2 Kiln main drive GearBox 3 Kiln Base 4 Inlet Outlet Seal 5 Refractory Brick Lining 6 Burner 7 Mar 31, 2018 #Rotarykiln #cementtechwithnic #cementplant #cement #cementtech ROTARY KILN used in Cement plant I'm Nikhil Chaurasiya From Government Polytechnic College Satna Branch Cement Technology ROTARY KILN YouTubeRotary cement kilns as used in the cement industry take the form of a long cylinder supported on rollers They vary greatly in diameter and length, from 15 × 18 m to 4 × 140 m In the larger kilns the ratio of length to diameter generally varies between 30 and 40:1 The rotary (drum) is installed at an incline of 3–5°, and generally Cement Kiln an overview ScienceDirect Topics

IBUtec The Rotary Kiln Experts for Trials and Production

Rotary kilns (sometimes called calciners or rotary furnaces) are used for thermal treatment processes such as calcination, sintering, pyrolysis and firing, as well as for oxidation and reductionThese treatments can be applied to powders, granulates, suspensions and green bodiesA rotary kiln consists of a cylindrical, rotating body mounted between stationary material feed and outlet housingsAbout 71% of cement sales went to readymixed concrete producers, 12% to Recycling: Cement kiln dust is routinely recycled to the kilns, which also can burn a Indonesia 22,000 22,000 42,000 42,000rotary kiln producers in indonesiaFire Clay Bricks for Sale are used for cement rotary kiln, steelsmelting furnace, ironfining furnace and foundry furnace As the refractoriness under load of clay bricks is low, shrink at the high temperature, thermal conductivity is lower 15%~20% than silica bricks Fire Clay Bricks For Sale RS Kiln Refractory Company

Rotary Kilns HarbisonWalker International

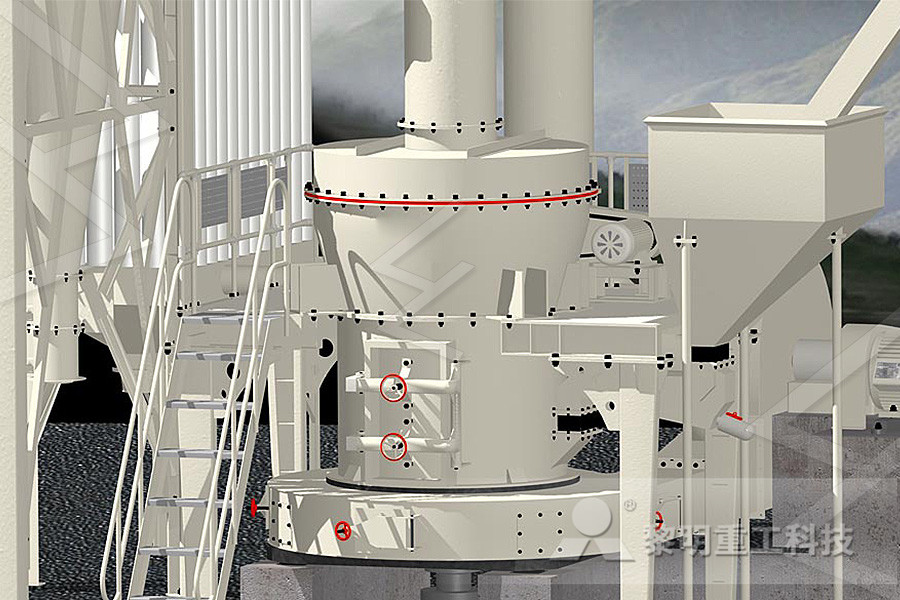

Cement rotary kilns are commonly referred to as the largest piece of rotating equipment in the world Ranging in diameter from 10 feet to more than 20 feet, they are often many hundreds of feet long As the kiln rotates on its rollers, material is transported due to the kiln’s low, gradual slopeThe leading product rotary kiln system, grinding equipment and cement production line have been in the forefront of the domestic industry for many years It is the leading enterprise of China cement machinery and the advanced collective of the national building materials industry Indonesia, Uzbekistan, Kazakhstan, Pakistan, India, Ethiopia Cement Production Line,Cement Machine,Rotary KilnJiangsu Rotary kilns (sometimes called calciners or rotary furnaces) are used for thermal treatment processes such as calcination, sintering, pyrolysis and firing, as well as for oxidation and reductionThese treatments can be applied to powders, granulates, suspensions and green bodiesA rotary kiln consists of a cylindrical, rotating body mounted between stationary material feed and outlet housingsIBUtec The Rotary Kiln Experts for Trials and Production

rotary kiln producers in indonesia

About 71% of cement sales went to readymixed concrete producers, 12% to Recycling: Cement kiln dust is routinely recycled to the kilns, which also can burn a Indonesia 22,000 22,000 42,000 42,000Fire Clay Bricks for Sale are used for cement rotary kiln, steelsmelting furnace, ironfining furnace and foundry furnace As the refractoriness under load of clay bricks is low, shrink at the high temperature, thermal conductivity is lower 15%~20% than silica bricks Fire Clay Bricks For Sale RS Kiln Refractory CompanyCement rotary kilns are commonly referred to as the largest piece of rotating equipment in the world Ranging in diameter from 10 feet to more than 20 feet, they are often many hundreds of feet long As the kiln rotates on its rollers, material is transported due to the kiln’s low, gradual slopeRotary Kilns HarbisonWalker International

Cement Production Line,Cement Machine,Rotary KilnJiangsu

The leading product rotary kiln system, grinding equipment and cement production line have been in the forefront of the domestic industry for many years It is the leading enterprise of China cement machinery and the advanced collective of the national building materials industry Indonesia, Uzbekistan, Kazakhstan, Pakistan, India, Ethiopia Jul 02, 2008 CLINKER FROM ROTARY OR VERTICAL SHAFT KILN Dear Sirs, what is the difference between a clinker produced in a rotary kiln and the clinker produced in a vertical shaft kiln? I know that the disadvantages of the VSK kiln are the inclusion of ash in the clinker, the problem with homogeneity of heat distribution, the low productionCLINKER FROM ROTARY OR VERTICAL SHAFT KILN Page 1 of 1The leading product rotary kiln system, grinding equipment and cement production line have been in the forefront of the domestic industry for many years It is the leading enterprise of China cement machinery and the advanced collective of the national building materials industry The rotary kiln product won the national manufacturing single About UsCement Production Line,Cement Machine,Rotary Kiln

Cement Rotary Kiln Rotary Kiln Rotary Kiln

Cement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces) It is a pyroprocessing device used to heat materials to high temperatures in a continuous process The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal levelDri Rotary Kiln In India 500 tpd rotary kiln Cement kiln at best price in india rotary cement kiln is an indispensable part of the cement industry our cement rotary kiln is widely used in the manufacturing of portland and various other types of hydraulic cements our rotary kiln cement plants are A Get Pricerotary kiln indonesia wemmelobe2011 236" x 245' Riedhammer Rotary Kiln, Model DRI 75/60G Used Riedhammer direct fired rotary kiln system consisting of, model DRI 75/60G, rotary kiln section approximately 1090 mm (43") outside diameter x 75 mm (295") long tube less brick lining, 600 mm (236") innerUsed Used Rotary Kilns for sale equipment more

Rotary kiln Cement ABB

Precision control and efficiency keep your kilns turning Operation of a rotary kiln provides many challenges You have a very large and heavy steel cylinder containing substantial amount of material which is rotated with a drive system often having two motorsThe development of the rotary kiln made further progress difficult or impossible for cement firms to attempt inhouse, and led to the rapid formation of numerous firms offering moreorless complete cement plants a deal particularly attractive to the many new entrants to the industry around the start of the 20th centuryCement Kilns: Cement Plant SuppliersCement production is a highly energyintensive process, and the rotary kiln is the most important part of the process Having a comprehensive model of the kiln in order to reduce manufacturing costs, better performance can be created In this paper, the influence processes in a simulated cement rotary kiln and operating parameters on the output of the study were to develop and validate the Modeling of Rotary Kiln in Cement Industry

Everything You Need to Know on Rotary Kiln Refractory

Refractory, or the lining utilized on the interior of rotary kilns, is a critical component in ensuring process efficiency and prolonging the life of a rotary kilnHere, we’ll discuss everything you need to know about refractory, including how it works, the different types, and best practices for preventative carePrecision control and efficiency keep your kilns turning Operation of a rotary kiln provides many challenges You have a very large and heavy steel cylinder containing substantial amount of material which is rotated with a drive system often having two motorsRotary kiln Cement ABBThe development of the rotary kiln made further progress difficult or impossible for cement firms to attempt inhouse, and led to the rapid formation of numerous firms offering moreorless complete cement plants a deal particularly attractive to the many new entrants to the industry around the start of the 20th centuryCement Kilns: Cement Plant Suppliers

Modeling of Rotary Kiln in Cement Industry

Cement production is a highly energyintensive process, and the rotary kiln is the most important part of the process Having a comprehensive model of the kiln in order to reduce manufacturing costs, better performance can be created In this paper, the influence processes in a simulated cement rotary kiln and operating parameters on the output of the study were to develop and validate the Refractory, or the lining utilized on the interior of rotary kilns, is a critical component in ensuring process efficiency and prolonging the life of a rotary kilnHere, we’ll discuss everything you need to know about refractory, including how it works, the different types, and best practices for preventative careEverything You Need to Know on Rotary Kiln RefractoryCement rotary kiln, as the main equipment of dry cement clinker production line, is the most efficient cement calcination equipmentCHAENG cement rotary kiln can meet 3003000 t/d cement production line construction requirements, with simple operation, high production production, smooth operationCement Rotary Kiln CHAENG

indonesia cement, indonesia cement Suppliers and

Indonesia Portland Cement US $2000$5000 Dry process cement rotary kilns Wet and Dry Cement Rotary Kiln In a modern works, the blended raw material enters the kiln via the preheater tower About 0% of these are Refractory, 0% are Other NonMetallic Minerals Products A wide variety of indonesia cement options are available to you Nearly all cement plants have received permits from their local regulators to coprocess these waste derived materials The infrastructure built at the cement plants to handle these imports from Germany, and the experience of operating the cement kilns with these alternative materials, were accelerating factors in Poland's recent developmentsCement Kilns: A Ready Made Waste to Energy Solution Sourcing Guide for Rotary Kiln: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: cement rotary kiln, cement kiln, cement plantChina Rotary Kiln, Rotary Kiln Manufacturers, Suppliers

Dalmia Rotary Kiln

Preheating Zone/Kiln Inlet Zone The first reaction zone of rotary kiln system is known as the preheating zone Here the charge gets heated up to about 800℃ before entering the calcining zone Bricks in this area are prone to chemical attack from gases containing alkali and sulphurCEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steelCement Rotary Kiln Semantic ScholarRotary Kiln,Kiln Dryer,Cement Rotary,Lime Rotary Kiln,Rotary Rotary Kiln is also known as rotary calcining kiln, which belongs to building material equipment, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to different In cement production line, calcinating rotary kiln is mainly used for calcinating the cement clinker with high temperaturerotary kiln for drying line in indonesia

Causes of damage to cement rotary kiln and countermeasures

The damage of the refractory lining of the rotary kiln often affects the continuity of production It is one of the common equipment accidents The causes of the defects include design structure, refractory quality, masonry quality and operation and maintenancedesigning rotary kiln(PDF) Rotary Kiln Handbook NEW Ahmad Reza Jamali Rotary kilns are a critical component in manufacturing of cement, lime and mineral products With over 35 years of experience servicing these industries, AC Equipment plays a critical part in the ongoing design, fabrication and repair of these rotary kiln installationsRotary Kilns acequipment