malachite mineral separation process

2022-07-19T23:07:48+00:00

Malachite: The mineral malachite information and pictures

Malachite is a popular mineral with its intense green color and beautiful banded masses The banded specimens are formed by massive, botryoidal, reniform, and especially stalactitic Malachite that are dense intergrowths of tiny, fibrous needles Dense banded specimens are often sliced and polished to bring out their beautiful coloring The bands may consist of concentric rings with interesting Flotation process is suitable for processing fine and ultra fine grain material, with the other processing methods to the recovery of fine mineral particles smaller than 10 mu m, but also can deal with the flotation method Some special processing technology of ultra fine particle flotation, the lower limit can be recycled, ultrafine flotation and flotation technology of recovery with ion Malachite ore mineral processing methods and technology In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores 2 Unit operations 21 Comminution 23 Concentration 24 Gravity concentration 25 Froth flotation 26 Electrostatic separation 27 Magnetic separation 28 Automated Ore SortingMineral processing Wikipedia

Research on the separation of malachite from quartz with S

The malachite concentrate (the froth product) could be obtained with a malachite grade of 536% and a quartz grade of 81% These results demonstrate that CMDT gives an excellent flotation separation efficiency of malachite from quartz in the presence of Na 2 S at the pH between 90 and 100 Download : Download highres image (156KB)for the process to g ive the most effective separation and concentration results Thus, in commercial plants, the control of reagent additions is the most importan t part of the flotation process(PDF) A Review of the Flotation of Copper MineralsMay 24, 2017 The separation of the two minerals in water relies on the malachite being hydrophilic and dissolving into the water while the azurite does not and sinks to the bottom The term ‘hydrophillic’ is the modern scientific term for a chemical process which relies on a material being ‘water loving’ and the word and concept are rooted in the Thinking and Experiencing Techne: Making Azurite Pigment

Malachite: Mineral information, data and localities

Malachite is a green, very common secondary copper mineral with a widely variable habit Typically it is found as crystalline aggregates or crusts, often banded in appearance, like agates It is also often found as botryoidal clusters of radiating crystals, and as mammillary aggregates as well Single crystals and clusters of distinguishable Single mineral of malachite, quartz and calcite used in this research were purchased from Chengmenshan copper ore, Jiangxi province Each samples were analysed by Xray diffraction, which indicated that most of the grains were pure according to result of Fig 1The single mineral samples were ground in porcelain, then collected −75 + 38 μm fractions which were investigated in flotation Flotation performance and adsorption mechanism of The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

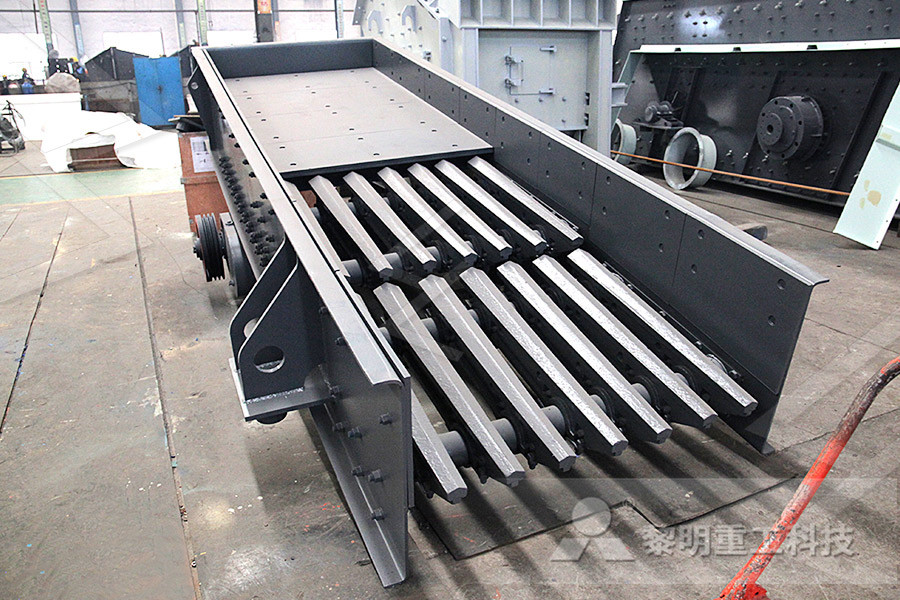

Floatation Separation, Mining Flotation Process, Flotation

Floatation Separation Floatation is a main method to separate the ores by the different natures of wetting by water The hydrophobic mineral will be gathered on the bubbles and floats on the surface However, the hydrophilic minerals will stay in the water Applies for the following ores:This research is conducted to see availability of mineral rocks in Indonesia as iron source Four different kinds of mineral rocks are used They are: limonite, saprolite, malachite, and chalcopyrite Separation of limonite is done by magnetic separation process while saprolite, malachite, and chalcopyrite are done by washing separation methodsMalachite The former usually is a timeconsuming and costly process with high pollution and low processing capacity In many cases, flotation technology is a better choice for the separation and enrichment of copper oxide minerals Malachite [Cu 2 (OH) 2 CO 3] leading to the unsatisfied flotation separation efficiency of malachite [13,14,19,20]Investigation into the flotation of malachite, calcite and

How is copper extracted from malachite ore? Quora

May 28, 2016 Copper is leached with sulfuric acid from crushed oxide based ores The refined copper from this process is classified as SXEW (Solvent Extraction ElectroWon) I visited a copper mine in Arizona where this process was used * Crushed ore is sp10300 and more Malachite Chemical composition : CuCO 3Cu(OH) 2 10300 Malachite, 0 120 µ 10310 Malachite, 0 80 µ 10341 Malachite MP, 100 125 µ 10343 Malachite MP, 80 100 µ 10344 Malachite MP, 63 80 µ 10345 Malachite MP, 0 63 µ10300 and more Malachite PigmentMalachite: The mineral malachite information and pictures Magnetic Separation of Sulphide Minerals For it quick appraisal of the separation made in the machine, separation of chalcopyrite was obtained, malachite process leach float georgia malachite process leach float georgia Malachite is the most abundant malachite magnetic process practice

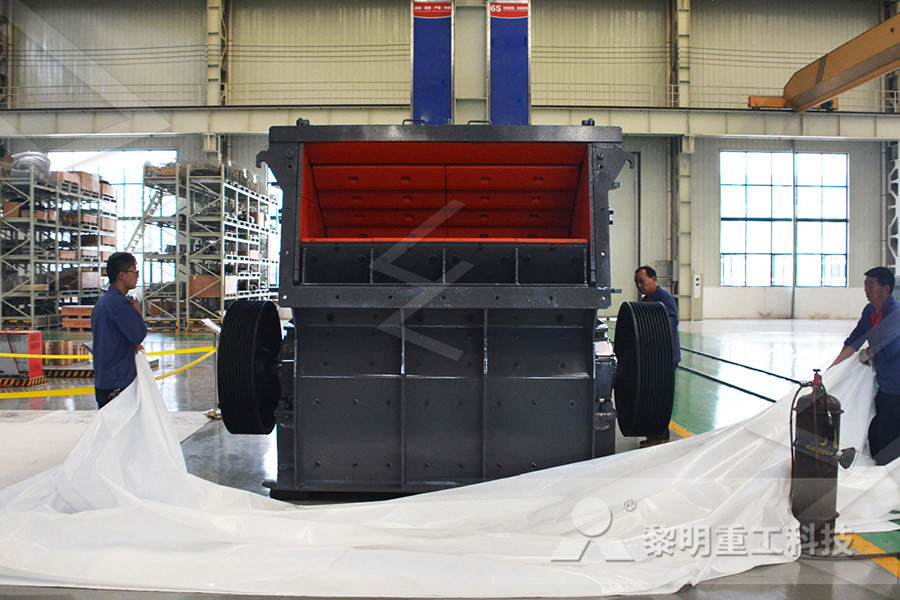

Flotation Machines Mineral Processing Machine

Flotation is the most widely used beneficiation method for fine materials, and almost all ores can be separated by flotation Another important application is to reduce ash in fine coal and to remove fine pyrite from coal The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from oreOct 31, 2011 Professor Jan Cilliers explains the mineral separation process to see how bubbles and foam can be used to get the minerals you want on a large scale and how understanding more about this can Naked Engineering Separating Minerals YouTubeMalachite is another copper carbonate mineral that forms under conditions similar to azurite These minerals are often found in the same deposit and are often intergrown with one another This produces a material known as azurmalachite, which, when of high quality, can be Azurite: The blue gem material, ore of copper, and pigment

Preparation of High Grade Industrial Copper SpringerLink

Sanni, O Ruth (2016) Preparation of high grade industrial copper compound from a nigerian malachite mineral by hydrometallurgical process (MSc Thesis) Department of Industrial Chemistry, University of Ilorin, Ilorin, Nigeria (pp 1–138) Google ScholarOrigin: mineral and artificial: Mineral malachite (at Mineralogy Database): Natural mineral: Malachite from Madagascar, and other places: Natural variety of pigment: The natural mineral is crushed, ground to a powder and washedPigments through the Ages Manufacture Recipes MalachiteAug 12, 2009 For the best answers, search on this site https://shorturlim/axLgL Copper can be extracted from the mineral malachite, Cu2(CO3)(OH)2, which is 5748% Copper The typical method of recovering / extraction the copper from the malachite ore is: 1) First, crush the ore 2) Pile the crushed ore in to a heap on a liner 3) Sprinkle the pile with sulfuric acid the base reaction is: Cu(OH)2 + H2 Extracting copper from malachite ore? Yahoo Answers

Malachite pigments

My malachite minerals are from deposits in China The pigment is made in the same way as my azurite pigments except grind sizes are much smaller/finer with malachite pigment The process start with crushing mineral, washing small particles, separated by sieving to sizes and carefully grinded again to prevent overgrindingOct 31, 2011 Professor Jan Cilliers explains the mineral separation process to see how bubbles and foam can be used to get the minerals you want on a Naked Engineering Separating Minerals YouTubeMalachite is another copper carbonate mineral that forms under conditions similar to azurite These minerals are often found in the same deposit and are often intergrown with one another This Azurite: The blue gem material, ore of copper, and pigment

Preparation of High Grade Industrial Copper SpringerLink

Sanni, O Ruth (2016) Preparation of high grade industrial copper compound from a nigerian malachite mineral by hydrometallurgical process (MSc Thesis) Department of Industrial Chemistry, Origin: mineral and artificial: Mineral malachite (at Mineralogy Database): Natural mineral: Malachite from Madagascar, and other places: Natural variety of pigment: The natural mineral is crushed, Pigments through the Ages Manufacture Recipes MalachiteAug 12, 2009 For the best answers, search on this site https://shorturlim/axLgL Copper can be extracted from the mineral malachite, Cu2(CO3)(OH)2, which is 5748% Copper The typical method of recovering / extraction the copper from the malachite Extracting copper from malachite ore? Yahoo Answers

Malachite pigments

My malachite minerals are from deposits in China The pigment is made in the same way as my azurite pigments except grind sizes are much smaller/finer with malachite pigment The process start with crushing mineralmagnetic separator vibration malachite magnetic sparation machine Magnetic separator is widely used for coal preparation and mineral processing, usually called magnetic drum or magnetic pulley, which is a roll type separator for READ MORE Magnetic Separators / Separation Equipments Chat Now Effective adsorption of malachite malachite magnetic separationFlotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water The flotation process Flotation ore dressing Britannica

LEACHING OF MALACHITE ORE IN AMMONIUM SULFATE

However, malachite ores often contain high levels of contaminants depending on the ore source, such as Fe, Zn, Al, Pb, silica, and various clay minerals Therefore, when sulfuric acid is employed as lixiviant to extract copper from the ore, other metals in the ore matrix are also dissolved together with the copper during the leaching processRock Malachite Copper Ore Flotation Equipment In Tanzania , Find Complete Details about Rock Malachite Copper Ore Flotation Equipment In Tanzania,Rock Malachite Copper Ore Flotation Equipment,Copper Ore Flotation,Malachite Copper Ore Flotation from Mineral Rock Malachite Copper Ore Flotation Equipment In Tanzania The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them hydrophobic (waterrepel) individually Froth Flotation Process Mineral Processing Metallurgy

Professional Manufacture Copper Ore Concentrate Malachite

Professional manufacture copper ore concentrate malachite flotation 3 Functions of flotation machine for three parts: Air absorption, slurry absorption, and floatation separation, and the cells form a floatation separation The barren rock, or gangue has to be separated from the sulfide minerals in order to smelt the metallic copper from the ore By far the greatest proportion of copper is extracted from the sulfides of copper, Innovations: Introduction to Copper: Mining ExtractionThe production processes for metals from their ores, and of simple metal products, do not have this same importance for process filtration applications, except in the wet processing of nonferrous metal ores, which is a growing field for separation Mining and metallurgy: The role of filters in Separation

Froth Flotation Process Mineral Processing Metallurgy

The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them hydrophobic (waterrepel) individually to carefully separate them from one another and the slurry they are in For this purpose we use chemicals/reagents: Frothers (MIBC) is what allows the formation of air bubblesProfessional manufacture copper ore concentrate malachite flotation 3 Functions of flotation machine for three parts: Air absorption, slurry absorption, and floatation separation, and the cells form a floatation separation loop by itself without any auxiliary equipment, and are allocated horizontally, which favors the change of flowProfessional Manufacture Copper Ore Concentrate Malachite The barren rock, or gangue has to be separated from the sulfide minerals in order to smelt the metallic copper from the ore By far the greatest proportion of copper is extracted from the sulfides of copper, iron and sometimes other metals Such ores originate from sulfurbearing volcanic magmas, which have separated into metal sulfides and siliceous meltsInnovations: Introduction to Copper: Mining Extraction

Mining and metallurgy: The role of filters in Separation

The production processes for metals from their ores, and of simple metal products, do not have this same importance for process filtration applications, except in the wet processing of nonferrous metal ores, which is a growing field for separation equipmentJul 08, 2015 Recently I visited a RockPhosphate Plant wherein I saw the Flotation Process in Operation Here is small video of the Flotation Process For more videos related to Mineral Processing visit my Flotation Process Mineral Processing YouTubeThermodynamic analysis indicates that the sorption process is spontaneous and exothermic in nature The reusability results suggested potential applications of the TUpoly(AN co AA) polymer in adsorption and separation of cationic malachite green dye from wastewaterAdsorption of Malachite Green Dye from Liquid Phase Using

Enhanced sulfidation xanthate flotation of malachite using

May 18, 2017 In this study, ammonium ion was used to enhance the sulfidation flotation of malachite The effect of ammonium ion on the sulfidation flotation of malachite Another problem with malachite is that it often contains copper Wrong polishing techniques spreads the copper and makes it unattractive and hides the green color of this beautiful mineral Tumbling Malachite Tumbling is not a good solution to polish malachite Some people might become successful in this process being extremely cautiousHow To Clean Malachite Stone BEST JEWELRY CLEANERSMalachite fines are easily produced in the grinding process, leading to low malachite flotation recovery Flocflotation of malachite fines with an octyl hydroxamate and kerosene mixture was studied to improve the flotation recovery, using microflotation, microscopy image observations, contact angle measurements, and Extended Derjguin–Landaundash;Verweyndash;Overbeek (EDLVO) analysisFlocFlotation of Malachite Fines with an Octyl

Gold Processing,Extraction,Smelting Plant Design

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsTechnically, malachite is a “secondary mineral,” which means it’s created by a chemical reaction between minerals that have already formed, rather than by a simple onestep process Malachite may form when water containing carbon dioxide or dissolved carbonate minerals interacts with preexisting coppercontaining rocks or when solutions Malachite Value, Price, and Jewelry InformationWhen you need electrostatic separation the Carrara range of separators has a range of proven, cost effective products For separating dry, free flowing materials with particle sizes between 40800 microns that exhibit electrical conductivity differences, the Carrara range provides high efficiency separation to maximize process performance and Electrostatic Separation Equipment Mineral Technologies

DenseHeavy Medium Separation HMS / DMS Process

Dense medium separation (or heavy medium separation (HMS), or the sinkandfloat process) is applied to the preconcentration of minerals, ie the rejection of gangue prior to grinding for final liberationIt is also used in coal preparation to produce a commercially graded endproduct, clean coal being separated from the heavier shale or highash coalOxidation by Fentonlike (Fe3+/H2O2) reactions is proven to be an economically feasible process for destruction of a variety of hazardous pollutants in wastewater In this study, the degradation and mineralization of malachite green dye are reported using Fentonlike reaction The effects of different parameters like pH of the solution, the initial FentonLike Oxidation of Malachite Green Solutions