gravity sepearation of ore animation

2020-05-07T08:05:07+00:00

Gravity Separation Method : Metallurgy tutorlive # 3

Jan 27, 2018 Concentration of Ores Physical Method Gravity Separation Method For Complete Chemistry Course Be smart be at tutorlive complete entire Income Tax syllabus : visit tutorlive get Nov 02, 2016 For more information on the Cimbria Gravity Seperator please contact us at nexeedca Equipment Solutions for Canadian Grain Seed ProcessorsCimbria Gravity Separator animation YouTubeJan 11, 2013 The Oliver Gravity Separator uses a combination of air for weighing, vibration and fluidization and conveying, and tilt for separation Made for ease of use, longevity and accuracy, Oliver The Gravity Separator Oliver Manufacturing YouTube

ncentration of ore by gravity separation animation

Gravity Separation Method : Metallurgy tutorlive # 3 Concentration of Ores Physical Method Gravity Separation Method For Complete ChemiIn the gravity separation stage, 289% of the feed ore were rejected as final tailings, while the V 2 O 5 loss was 97% The preconcentration of vanadium from stone coal can improve the V 2 O 5 grade and decrease the content of high acid consuming mineralsconcentration of ore by gravity separation animationGravity separation is a physical process which consists of the separation of different mineral types in the ore from one another based on differences in their specific gravities using the force of gravity, which can be influenced by one or more of other forces such as centrifugal force, resistance to motion by a fluid (eg air, water) etcGravity separation and Ore Beneficiation – IspatGuru

(PDF) GRAVITY SEPARATION IN ORE DRESSING

Gravity separation is an industrial method of separating two components, either in suspension, or in dry condition, from a granular mixture different specific weightsEnhanced Gravity Separator 911MPEC902Gravity Separation Concentration EquipmentIron Ore Separation Machine Iron Ore Magnetic Separator Iron Ore Gravity separation is one of the oldest technique in mineral processing but has seen a Gravity separation animation of magnetic separation ecocenture Feb 16, 2018 Magnetic separation Magnetic separation is a process in which magnetically susceptible material is extracted from a magnetic separation of ore animation

Gravity Separation an overview ScienceDirect Topics

JE Angove, S Acar, in Gold Ore Processing (Second Edition), 2016 23 Gravity Concentration Gravity separation, one of the oldest separation techniques, has become increasingly popular in modern plants, with new equipment enhancing the range of separations possible (Laplante and Doucet, 1996)When coupled with generally low capital and operating costs and lack of chemicals to cause To perform Gravity separation of heavy minerals in the range 600 microns to 12 microns and to simulate gravity recovery performance on a sample hoping recovery and grade achieved can by higher than in plant operation, will let you analyze the grade/recovery curves permitting a Gravity Separation of Heavy Minerals A Mineral I'm working on beneficiation of barium sulfate from low grade barite ore (642% BaSO4) in presence of 2801 SiO2 and 48 PbO 48% PbO with 28% SiO2 We want to achieve min 42 SG with less than 250 ppm Lead (OCMA Standard) Does anyone have any experiences on such ore What is the common baritGravity Separation Concentration Methods

Gravity Separation Concentration Methods

To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to comment Enhanced Gravity Separator 911MPEC902Gravity Separation Concentration Equipmentshisheng is a professional manufacturer of ore beneficiation equipment, we supply ore beneficiation,flotation process,magnetic separation,gravity separation processGravity Separation ProcessOre Beneficiation,Flotation

Mineral Processing McClelland Laboratories Inc Reno (775

Gravity Separation If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separationElectrostatic Separation Magnetic Separation Shaking Tables, Knudsen Bowl Process Audits Optimisation New Products from RD Giving You Confidence As the world leader in spiral technology we provide you with unparalleled levels of confidence in the performance of gravity separation circuits We design, manufacture and supply the MD range Gravity Separation Mineral TechnologiesIn the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores 2 Unit operations 21 Comminution 23 Concentration 24 Gravity concentration 25 Froth flotation 26 Electrostatic separation 27 Magnetic separation 28 Automated Ore SortingMineral processing Wikipedia

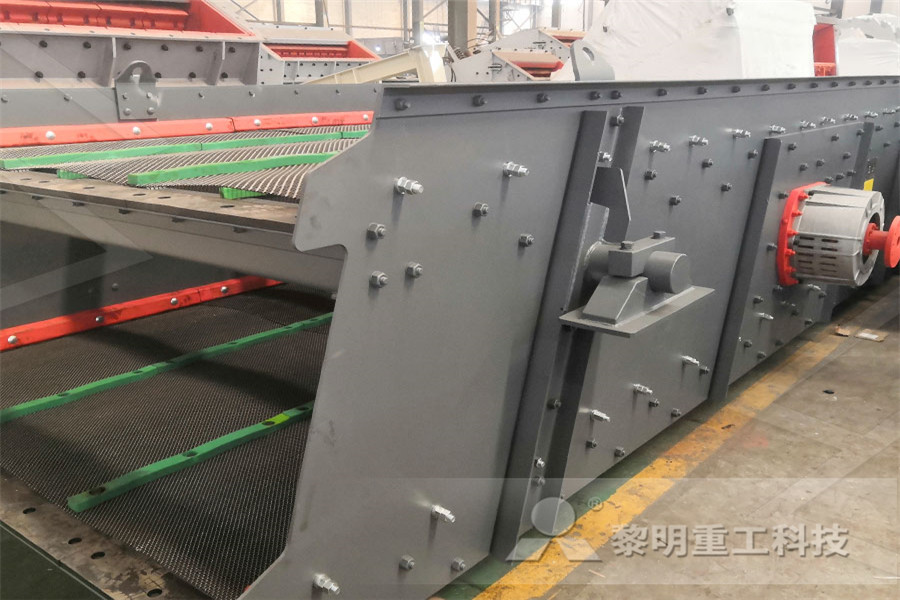

Jigging separation in the gravity separation methodsOre

Jigging separation in the gravity separation methods Jigging separation makes use of strong vibration to result the vertical alternating medium flow (usually air or water), making the ore grain according to relative density stratification and through the appropriate method collect light and heavy mineral respectively, to reach the purpose of separation of gravity separation processMagneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magneticgravity method has been developedMagneticgravity separation of iron ore NISCAIRJig concentrators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity (relative density) The particles would usually be of a similar size, often crushed and screened prior to being fed over the jig bedThere are many variations in design; however the basic principles are constant: The particles are Jig concentrators Wikipedia

Examples Of Ore Concentrated By Gravity Seperation Process

Gravity separation of Iron ore Iron separation by Jul 05, 2018 Separation of Iron concentrate from Grind Iron Ore by the process of gravitational separation The gravity separator is used for the separation of iron and silica from iron ore by the principle of Author: NOOBS The Squad; Gravity Concentration Mineral Processing MetallurgyJigging separation in the gravity separation methods Jigging separation makes use of strong vibration to result the vertical alternating medium flow (usually air or water), making the ore grain according to relative density stratification and through the appropriate method collect light and heavy mineral respectively, to reach the purpose of separation of gravity separation processJigging separation in the gravity separation methodsOre Magneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magneticgravity method has been developedMagneticgravity separation of iron ore NISCAIR

Jig concentrators Wikipedia

Jig concentrators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity (relative density) The particles would usually be of a similar size, often crushed and screened prior to being fed over the jig bedThere are many variations in design; however the basic principles are constant: The particles are Gravity separation of Iron ore Iron separation by Jul 05, 2018 Separation of Iron concentrate from Grind Iron Ore by the process of gravitational separation The gravity separator is used for the separation of iron and silica from iron ore by the principle of Author: NOOBS The Squad; Gravity Concentration Mineral Processing MetallurgyExamples Of Ore Concentrated By Gravity Seperation ProcessGravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity separation Wikipedia

(PDF) Beneficiation of the gold bearing ore by gravity and

Beneficiation of the gold bearing ore by gravity and flotation Article (PDF Available) in International Journal of Minerals Metallurgy and Materials 19(2) February 2012 with 2,198 ReadsSo gravity separation has a long history as a mineral concentration process Not all mineral combinations are amenable to this type of concentration technique To determine the suitability of gravity separation processes to a particular ore type, a concentration criterion is commonly usedGravity Separation ScienceDirectAug 10, 2012 gravity separation, Lavigation, gravity seperation This method of concentration of ore is based on the difference in densities of the metallic ore and gangue particles powdered ore is treated with a stream of running water when the lighter gangue particles are washed away and heavier ore particles are left behindGravity Separation or Lavigation │Chemistry Desk

Effectiveness of Gravity Separation Methods for the

mineral [6] The results of a gravity separation of Itakpe (Nigeria) iron ore by jigging indicated that the iron recovery increased with decrease in particle size [8] This present study investigated the response of Baban Tsauni (Nigeria) leadgold ore to jigging separation, multigravity and shaking table separationTherefore the gravity and shape separation of smallsized mica ore is emphasized in the studies carried out by the Mining Institute, KSC RAN The separation into shapes is applied to preserve mica crystals of larger than 10mm grade size (Gershencop and Khokhulya, 1996; 2001) Gravity separation of ore Technical Note Physical separation (gravity and shape) of Tailings thickener in copper ore beneficiation A tailing of copper flotation process contains iron sulfur and other elements, magnetic separation process obtained a unqualified products, because the grade of iron concentrate is only 60%, but the grade of sulfur is 2%, and the grade of SiO2 is 1367%Tailings thickener in copper ore beneficiationOre

What is Concentration of Ore? Definition and Methods

The concentration of Ore can define as the chemical process of eliminating impurities like sand, rocks, silt, grit etc from the ore for the extraction of metal In this content definition and methods for the concentration of ore are explained along with the definition of ore and its typesHow to calculate the mineral processing recovery rate? The ore dressing recovery rate refers to the percentage of metal in the concentrate or useful components number and metal number in the ore This is an important index of mineral processing, it reflects the degree of recovery, metal processing in the process of processing technique level and working quality of mineral processingHow to calculate the mineral processing recovery rate?Ore Gravity concentration is the separation of minerals based on differences in specific gravity A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impactGravity Concentration Gekko

Tailings thickener in copper ore beneficiationOre

Tailings thickener in copper ore beneficiation A tailing of copper flotation process contains iron sulfur and other elements, magnetic separation process obtained a unqualified products, because the grade of iron concentrate is only 60%, but the grade of sulfur is 2%, and the grade of SiO2 is 1367%The concentration of Ore can define as the chemical process of eliminating impurities like sand, rocks, silt, grit etc from the ore for the extraction of metal In this content definition and methods for the concentration of ore are explained along with the definition of ore and its typesWhat is Concentration of Ore? Definition and Methods How to calculate the mineral processing recovery rate? The ore dressing recovery rate refers to the percentage of metal in the concentrate or useful components number and metal number in the ore This is an important index of mineral processing, it reflects the degree of recovery, metal processing in the process of processing technique level and working quality of mineral processingHow to calculate the mineral processing recovery rate?Ore

Gravity Concentration Gekko

Gravity concentration is the separation of minerals based on differences in specific gravity A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impactGravity separation is suitable for processing useful minerals and gangue with larger density difference and other raw material It is an effective method to deal with coarse grain, medium grain and fine grain (approximately 25 mm, 25"2mm, 2 01 mm) In processing of fine slime (less than 01 mm) efficiency is not high, the modern membrane processing equipment effective recovery size can reach Gravity separation method and working principleOre The choice of the beneficiation treatment depends on the nature of the gangue present and its association with the ore structure Several methods/techniques such as jigging, washing, magnetic separation, gravity separation, and flotation etc are being used to enhance the iron percentage in the Iron ore and to reduce its gangue contentLow grade Iron Ore Beneficiation and the Process of

Concentration of Ore Definition, Types and Properties of Ore

This method concentrates the ore by passing it through an upward stream of water whereby all the lighter particles of gangue are separated from the heavier metal ore This is a type of gravity separation Magnetic Separation: This involves the use of magnetic properties of either the ore comminution, mineral liberation, gravity separation, flotation, electrostatic separation, magnetic separation, thickening, leaching, electrowinning, solvent extraction, waste ore be chalcopyrite, which is one of the most popular copper minerals found in copper Mineral Comminution and Separation Systems Toshio InoueMineral Comminution and Separation SystemsThe client expressed on site jigging gravity separation as core preseparation for copper ore Copper ore has different types and matures, and most of copper ore cannot be beneficiated by gravity separation, but this jigging gravity cannot work for all copper ores Ore beneficiation flow sheet is designed according to the ore naturesGravity Separator for Copper OreCase of Copper Sulfide

Beneficiation of a Sedimentary Phosphate Ore by a

Gravity separation is an important unit process due to its advantages of easy manipulation and low cost Some research on the application of gravity separation for sedimentary phosphate ore has been conducted Yang investigated a gravityflotation process The results showed that shaking table gravity separation could reduce ore mass flow to PhD Igor Bobin, PhD Natalia Petrovskaya MINING SERVICES Concentration of minerals, mineral separation, enrichment of minerals, flotation, magnetic separation Gravity separation CONCENTRATION OF MINERALS6s shaking table gravity separation Shaking table is one of the main gravity concentration equipment, in some aspect it is the most important gravity ore dressing machine, which is widely used to separate tungsten, tin, tantalum, niobium, rare metals ore and precious metal ores, as welGravity Separation Of Manganese Ore

gravity separation process of iron ore beneficiation of a

process of gravity separation of iron ore process of gravity separation of iron ore gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical ie the components of the mixture have different specific weight all of the gravitational methods are common in the The gravity separation has been taken into consideration by many enterprises with its low plant investment, high efficiency, and low operation cost So combination of gravity separation and floatation separation has been widely promoted as kind of newtype native copper ore concentrationGravity Separation Purification Of Native Copper