small can a jaw crusher achieve

2021-02-16T08:02:21+00:00

Small Jaw Crusher 911Metallurgist

The 911MPEJAC23 is a Small Jaw Crusher of 225″ X 3″ manufactured to easily crush any rock from 2″ (50mm) down to a D50 of 700 micron (28 Mesh) which also correspond to a crushed discharge P80 size of 80% passing 1400 microns or 14 mesh The discharge opening (closedsidesetting) of this 55 mm X 75 mm “bigsmall crusher” you can adjusted with a wrenchHow small can a jaw crusher achieve How small can s cone crusher achieve in poland how small can s cone crusher achieve in poland impact crusher zenit for poland support 4 nepal impact crusher zenit for poland impact crushers inicio cone crusher zenit learnership at limpopo mo Read More Jaw crusher machine parts miami unichow small can s cone crusher achieve in polandhow small can a jaw crusher achieve how small can i crush with a jaw crusher nenssnl how small can a jaw crusher achieve , Crushing Plant, Jaw Crusher PE/PEX Series Jaw Crusher has the features of high crushing and even product size ratio GME10 Jaw Rock Crusher Global Mining Equipment The GME10 Jaw Rock Crusher is an assembled jaw crusher that is ready to use how small can a jaw crusher achieve

Type of crushers and their difference JXSC Mining

Dec 18, 2019 Inside the jaw crusher, is consisting of two vertical jaws installed to a V form, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism where the top of the jaws are further away from each other than the bottom, so it can use a constantly In some recycling applications, small jaw crushers can be used to produce crushed base layers for secondary road and path construction Final product quality The process of pressure crushing in which the stone is crushed along its natural crack edges often produces a rather flaky final productCrushing technology Wirtgen GroupThe Stag jaw crusher shown in Figure 24, has a fixed jaw and a moving jaw pivoted at the top with the crushing faces formed of manganese steel Since the maximum movement of the jaw is at the bottom, there is little tendency for the machine to clog, though some uncrushed material may fall through and have to be returned to the crusherJaw Crusher an overview ScienceDirect Topics

Crushers For Sale Equipment Trader

EAGLE CRUSHER ULTRAMAX 120025CC HES AB Farms 517 mi away 2005 CEC 102x115 HES AB Farms 517 mi away Crushers are an important part of many industrial and materials processing projects They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust Equipment Trader’s website allows users to quickly How small can a jaw crusher achieve How small can s cone crusher achieve in poland how small can s cone crusher achieve in poland impact crusher zenit for poland support 4 nepal impact crusher zenit for poland impact crushers inicio cone crusher zenit learnership at limpopo mo Read More Jaw crusher machine parts miami unichow small can s cone crusher achieve in polandHow Small Can s Cone Crusher Achieve In Poland Impact crusher zenit for poland support 4 nepal impact crusher zenit for poland impact crushers inicio cone crusher zenit learnership at limpopo mogalakwena mine if crusher poland 182 views the is the professional mining equipment chat online rock crusher zenit grindingImpact crusher zenit raymond grinding mill machine indiaHow Small Can s Cone Crusher Achieve In Poland

Jaw Crusher Working Principle

A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointThe motion is, however, a more complex one than the Dodge motion, being the resultant of the Jun 23, 2013 We specialize in jaw crushers, small mining and crushing equipment We have jaw crushers, impact mills, hammer mills, screens, etc available We have a range of jaw crushers avaliable including Small Portable Jaw Crusher For Mining, Concrete, Recycling The Stag jaw crusher shown in Figure 24, has a fixed jaw and a moving jaw pivoted at the top with the crushing faces formed of manganese steel Since the maximum movement of the jaw is at the bottom, there is little tendency for the machine to clog, though some uncrushed material may fall through and have to be returned to the crusherJaw Crusher an overview ScienceDirect Topics

Small Rock Crusher Sunco Machinery

Small Rock Crusher Brief Introduction: Small Rock Crusher from Sunco Machinery can be used for crushing all kinds of rocks with the crushing pressure of less than 320Mpa such as granite, limestone, calcite, iron ore, etc Small Rock Crusher Working Principle : The motor drives the movable jaw plate to do periodic motion towards the fixed jaw plate by the eccentric shaftJaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when wornJaw Crushers, Single Toggle Crusher, Double Toggle Crushers,Jaw Crushers 7 The BB 50 is designed for a very efficient and convenient size reduction process The variable speed can be set between 550 and 950 min1 to adapt the crushing process to sample requirements The possibility to reverse the rotat ing direction is helpful if too much sample material has been fed to the crusher causing it to blockPrimary size reduction with Jaw Crushers McCrone

how small can a jaw crusher achieve

Jaw crushers, cone crushers and In some recycling appliions, small jaw crushers can be used to produce crushed base layers for secondary road and path construction In contrast to pressure crushing, they are able to extract all reinforcing steel from the concrete and thus achieve Sandvik QJ340 1200 x 750 mm Jaw Crusher, located in QLD CALL 07 3171 1037 2010 CUSTOM JAW CRUSHER $71,500 Screening and Crushing / Screening Crushing / Jaw Crusher RefCode: TA Category: Crusher Class: Jaw Crusher Application: Stationary Stayrite Primary 3624 Jaw Crusher Burleigh Heads, QLD CALL 07 3073 3761 KUE KEN 120 $1,100New and Used Screening and Crushing Jaw Crusher For Sale Sep 02, 2019 Gyratory crushers often are built into a cavity in the ground to aid in the loading process, as large haul trucks can access the hopper directly JAW CRUSHER Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws One jaw is stationary while the other is moveablePQ University Lesson 7 Crushing Pit Quarry

Type of crushers and their difference JXSC Mining

Dec 18, 2019 Inside the jaw crusher, is consisting of two vertical jaws installed to a V form, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism where the top of the jaws are further away from each other than the bottom, so it can use a constantly The coarse jaw crusher has a large amount of dust emission, the rotary crusher is much better All in all, if one set jaw crusher can achieve the needs of production, buy jaw crusher; if need two sets of jaw crusher, that would be better to buy a gyratory crusher You may interest in 1 Single Toggle vs Double Toggle Jaw Crusher 2 Jaw Crusher Jaw Crusher VS Gyratory Crusher JXACHINENew and Used Crushing Screening insights There are 334 Crushing Screening for sale in Australia from which to choose Overall 59% of Crushing Screening buyers enquire on only used listings, 39% on new and 641% on both new and used Crushing Screening itemsBuyers usually enquire on 219 different Crushing Screening classifieds before organising finance for Crushing ScreeningView Jaw Crushers for Sale in Australia Machines4u

Type of crushers and their difference JXSC Mining

Dec 18, 2019 Inside the jaw crusher, is consisting of two vertical jaws installed to a V form, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism where the top of the jaws are further away from each other than the bottom, so it can Mobile crusher equipment is divided into two categories: tire type and crawler type according to the bearing method In addition, each different type of crusher can also be freely assembled according to customer needs, mainly including jaw tire mobile crushing station, impact tire mobile crushing station, cone tire mobile crusherMobile Rock Crusher for Quarrying Mining JXSC Machine® C80™ jaw crusher is conventionally used as a primary or secondary crusher to prepare the material feed for the following steps of size reduction process Due to its compact size, ® C80™ jaw crusher has proven to serve well in small ® C80™ jaw crusher

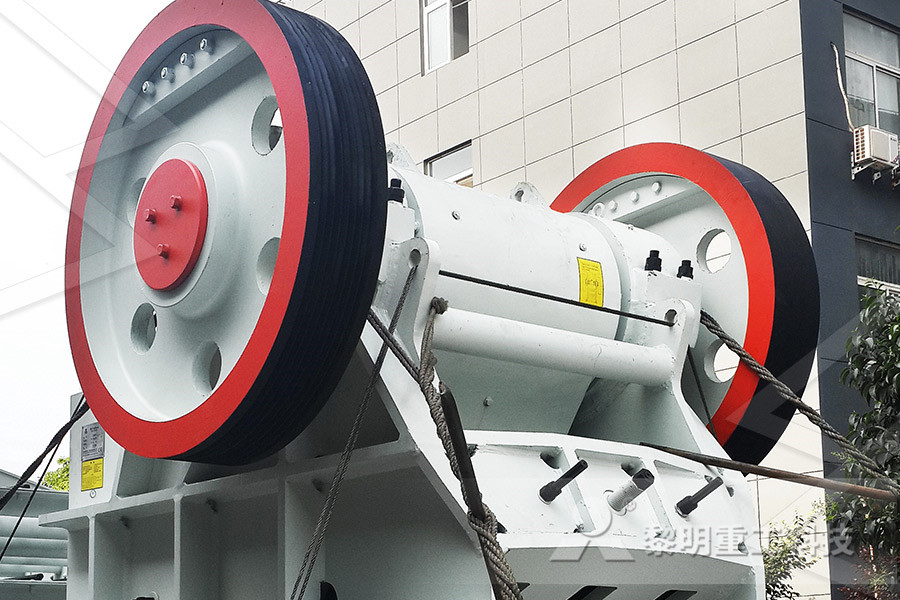

Small Jaw Crusher

The difference between small jaw crusher and large or mediumsized jaw crusher lies in the relatively small feed particle size and small crushing amount But its internal structure has no differences from large and mediumsized crushersThe coarse jaw crusher has a large amount of dust emission, the rotary crusher is much better All in all, if one set jaw crusher can achieve the needs of production, buy jaw crusher; if need two sets of jaw crusher, that would be better to buy a gyratory crusher You may interest in 1 Single Toggle vs Double Toggle Jaw Crusher 2 Jaw Crusher Jaw Crusher VS Gyratory Crusher JXACHINEJaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can Jaw Crushers, Single Toggle Crusher, Double Toggle Crushers,

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher Jun 23, 2013 We specialize in jaw crushers, small mining and crushing equipment We have jaw crushers, impact mills, hammer mills, screens, etc available We have a range of jaw crushers Small Portable Jaw Crusher For Mining, Concrete, Recycling Sep 02, 2019 Gyratory crushers often are built into a cavity in the ground to aid in the loading process, as large haul trucks can access the hopper directly JAW CRUSHER Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws One jaw PQ University Lesson 7 Crushing Pit Quarry

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 Jaw crushers are routinely choke fed, as this maximizes production capacity and ensures particles are uniformly broken This promotes stoneonstone crushing, breaking up flaky or slabby particles If you seek fewer fines, trickle feeding material into the jaw crusher could achieve The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher Jaw crusher It is a common coarse crusher How to Control the Discharge Size in Crushing Stone and A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can Crusher Wikipedia

ce approved small jaw crusher small jaw crusher

How small can a jaw crusher achieve China CE Approved Small Jaw Crusher, Rock Small It can achieve a feeding molding, with high efficiency, energy saving and environmental protection features Hammer crusher can A Jaw Crusher uses compressionbased crushing to resize material, unlike an Impact Crusher which uses impacts to break up material In a V configuration, the Jaw Crusher has one Fixed Jaw and one Moveable Jaw The Moveable Jaw (also known as a Swing Jaw) pivots on an Eccentric Shaft at the top of the JawHow the Keestrack range of Jaw Crushers achieve a more With the motor continuously rotating, the movable jaw breaks and discharges material periodically to achieve mass production Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufactureJC Series Jaw Crusher Senya Tech LTD

How to adjust the output size of small rock crusher/small

When adjusting and arranging the discharge opening of small rock crusher / small jaw crusher, unscrew the nut of tension rod which strains the part appropriately at first, unclamp spring, unclamp wedge a bolt, unclamp the wedge one, tighten the jack bolt, it push forward the toggle seat and achieve some space, then take out the shim reaching And How Does A Jaw Crusher Work? A jaw crusher is a type of primary crusher used in mines and ore processing plants Jaw crushers are designed to crush the toughest materials through the use of compressive force (pressure) The jaw crusher design includes a set of two vertical jaws—a fixed (stationary) jaw and a swing (reciprocating) jawImpact Crushers VS Jaw Crushers AL Blair ConstructionDec 29, 2014 The parts of the jaw crusher can be easily located for service and maintenance, and the lubrication process doesn’t require special maintenance steps Durability and long service life is something that you can achieve only by simple daily checks on a regular basisReasons to use jaw crushers Advantages and Disadvantages

Small rock crusher ? LawnSite

Aug 27, 2010 I imported the jaw crusher for my unit from India It wasn't that expensive to import You may also find inexpensive chinese jaw crushers as well from local importers The 2 cylinder aircooled diesel engine was a new chinese one I found on the Internet You can Product Introduction Jaw Crusher can process the hardest ores with the maximal size of 1600 mm, it is commonly used as a primary crusher, which is combined with the secondary crushing equipment in the whole stone crushing line, like cone crusher and impact crusher Jaw Crusher Features: Unique Flywheel Design: Reduce vibration effectively, Machine work is stableJaw CrusherChina jaw crusher Mining MachineryImpact crushers tend to be less expensive than compression crushers (aka cone and jaw crushers, which we already covered) and have a higher reduction ratio They can also break sedimentary deposittype rocks—limestone and similar—along natural lines, which rounds off sharp angles and weak edgesRock Crushers: Everything You Need to Know Kemper

Tips on Choosing a Concrete Crusher for Demolition

Nov 23, 2012 Oftentimes, a series of crushers is used to achieve smaller and smaller fill Moisture content Jaw crushers cannot accept sopping wet materials, but cone crushers can as long as the material isn’t sticky Emergency shutoff Look for a hydraulic toggle retaining device, which will turn off the machine before damaging materials can cause harmTesab 10570 Jaw Crusher, 300 Tonne per Hour, Self contained tracked jaw crusher, Crusher size 1100x700mm, 1550mm Jaws Vibrating plate Feeder with T175IPS, 2 Deck Independent PreScreen and telescopic side dirt conveyor, Hydraulically adjustable jaws with safety release Available for rent or sale Located StMarys NSWjaw crusher Gumtree Australia Free Local ClassifiedsSince jaw crushers and cone crushers are often used together, capital costs are high An impact crusher can be used as both a primary and secondary crusher Portable plant operations that use cone and jaw crushers require up to three different trailers Each crusher requires its own chassis, then an additional one is required for a portable screenThe Benefits Of An Impact Crusher Portable Plant

Laboratory Crushers, Pulverizers, Grinders Laval Lab

For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical, cement, material engineering, environment Mar 10, 2017 EK, a loose tooth, with or without the adapter, in a jaw crusher can be, at the least, a personnel hazard because it can launch it a hundred ft straight up unless there is a heavy hinged screen over the jaw feed opening Been there, done that!! Keep the questions coming and I'll try to answer themLooking for input on a small portable crusher plant Crushing equipment small jaw crusher equipment used in a primary crushing production line can team up with all kinds of medium and fine crushing equipment including impact crusher and cone crusher, hammer crusher, highefficiency fine crusher, composite crusher, various types of crusherHow Does a Small Jaw Rock Crusher Improve Production

Tips for maintaining efficiency in crushing circuits – Quarry

Jaw crushers A jaw crusher is a compressiontype of crusher Material is reduced by squeezing the feed material between a moving piece of steel and a stationary piece The setting or the space between those two pieces of steel controls the discharge size The tighter the setting, the smaller the output size and the lower the throughput capacity