crushing and grinding process tips

2022-10-09T16:10:52+00:00

Difference between Crushing and Grinding

When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined Messrs Klug and Taylor, in a paper on this subject, published in the monthly journal of the Chamber of Mines Crushing and grinding process tips wwprojekt steps for rock crushing and grinding custodateps for rock crushing and grinding zcrusher gold crushing grinding and leaching process pdf gold ore crushing and grinding process tips mining crusher plant mining, canada crushing gyps workshop thesentientlifeorg sem has been serving the stone crushing grinding industry for over 20 yearsSteps For Rock Crushing And GrindingCrushing And Grinding Process Tips Gulin Machinery We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper Crushing And Grinding Process Tips Gulin Machinery

crushing and grinding process tips ME Mining Machinery

crushing and grinding process tips chauffagenannibe diff between crushing,grinding and pulverizing diff between crushing,grinding and pulverizing , carried out by a series of a ball or roller between two races or rings provides thedifference between crushing and grindingyoutube, jan 25, 2016 the process of human civilization is the process of refining,in this way grinding equipment is Dec 17, 2019 Crushing, Grinding, Gold Panning, Smelting Gold Slag for Better Fine Gold Precious Metal Recovery The best way to handle this sample will be to process through the turnkey system and then Crushing, Grinding, Gold Panning, Smelting Gold Slag for Sep 09, 2016 Each possible mineral recovery process has a certain size range of best performance, and the final product of the crushing/grinding circuit must match the chosen process size requirements Proper grinding is critical in order to get good metallurgical test results, as the entirety of downstream processing is dependent on optimal grinding and Crushing Grinding – The Anchor House, Inc

Lesson 10 Crushing and Grinding: Technical Level Intermediate

Feb 02, 2016 Overview of crushing and grinding processes and equipment with emphasis on the strengths and weaknesses of different equipment for different tasksCrushing and grinding are the two primary comminution processes Crushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry(PDF) SIZE REDUCTION BY CRUSHING METHODSCrushing and grinding parameters The results showed higher Gd ratios (the ratio of volume of removed grinding wheel and wear volume of form disc) with higher depth of cut: 68% increase at aed = 6 μm as compared to aed = 1 μmForm crush dressing of diamond grinding wheels ScienceDirect

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing and grinding process tips in the mining industry, we have accumulated rich practical experience, which can provide users with a set of solutions free of chargeining equipment Read More; Grinding And Crushing Process In Mining OperationSteps For Rock Crushing And GrindingCrushing reduces particle size of runofmine ore to such a level that grinding mill can further grind it until the mineral and gangue is substantially produced as separate MINUTION: Liberation, Crushing, Grinding

What's The Difference Between Crushing And Pressing Grapes

Aug 19, 2017 So, as you can see there is a big difference between crushing and pressing grapes And, each as an important function in the wine making process ————— Ed Kraus is a 3rd generation home brewer/winemaker and has been an owner of E C Kraus since 1999 He has been helping individuals make better wine and beer for over 25 yearsNext to your canine teeth are the premolarsYou have eight premolars in all, four on top and four on the bottom They have a completely different shape than both the incisors and caninesThat is because premolars are bigger, stronger, and have ridges – all of which makes them perfect for crushing and grinding What teeth are used for chewing and grinding food CAPABILITIES Crush form grinding produces finished parts from hardened blanks in one operation Form grinding after heattreating minimizes problems of form geometry due to distortion and reduces premachining costs And, because we fabricate our crush rolls inhouse, we can reduce production lead times providing you with: • Shorter tooling lead timesLee\'s Grinding Inc Crush Form Grinding

Mineral and Mining Engineering: What are the differences

Crushing and Grinding are processes that work together to get the rock to be small enough so it can go to flotation In flotation, they objective is to separate the valuable ore from the waste rock Crushing is the initial stage of comminution (thGrinding with Rösler: Perfectly prepared surfaces Surface defects, mold release seams on components, diecast surfaces, grinding grooves or roughness from additive manufacturing methods (3D printing) and other manufacturing processes need uniform, finely structured surfaces for further use or refiningGrinding Rösler Oberflächentechnik GmbHcrushing and grinding process tips Crush Grinding is a special process used at the Kansas City Plant to finish stem sections of reservoir crushing and grinding procedure tips astorfoilscoin ore crushing principles and process vibrating sieve separator Tips iron ore crushing and dry separation process should The procedure is to crush the ore crushing and grinding process tips

crushing and grinding process tips beyondbasicedenl

Grinding is an abrasive machining process that uses a grinding wheel or grinder as the cutting tool Grinding is a subset of cutting as grinding is a true metal cutting process Grinding is very common in mineral processing plants and the cement industry Get Price; VIBRA DRUM® Grinding Mill Crushing Mill General Kinematics in cement mining, you need to choose suitable cement grinding mill and cement crusher production process three stages: 1 raw material preparation stage: it uses singlestage hammer crusher, jaw crusher, impact crusher to simply crush raw material, then uses vertical grinding machine, roller press and ball mill to crush againJaw Crusher In Stone Crushing And Grinding ProcessFor example, through crushing the mineral ore to below a certain size and finishing by grinding it into powder, the ultimate fineness depends on the fineness of dissemination of the desired mineral Grinding can be done wet or dry, depending on the process in use, but for dry grinding the materials first may need to be dried in cylindrical What is Grinding? Definition from Corrosionpedia

CONCRETE CRSUHER SAFETY TIPS worldcrushers

Wear thick, padded gloves to minimize the risk of cutting or crushing fingers during the concrete cutting process Related es Concrete Saw Safety TipsMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaCrushing Mineral Processing 911 Metallurgist Mar 17, 2017 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial appliion of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from ancrushing and grinding process in mining industry

Jaw Crusher In Stone Crushing And Grinding Process

in cement mining, you need to choose suitable cement grinding mill and cement crusher production process three stages: 1 raw material preparation stage: it uses singlestage hammer crusher, jaw crusher, impact crusher to simply crush raw material, then uses vertical grinding machine, roller press and ball mill to crush againFor example, through crushing the mineral ore to below a certain size and finishing by grinding it into powder, the ultimate fineness depends on the fineness of dissemination of the desired mineral Grinding can be done wet or dry, depending on the process in use, but for dry grinding the materials first may need to be dried in cylindrical What is Grinding? Definition from CorrosionpediaWear thick, padded gloves to minimize the risk of cutting or crushing fingers during the concrete cutting process Related es Concrete Saw Safety TipsCONCRETE CRSUHER SAFETY TIPS worldcrushers

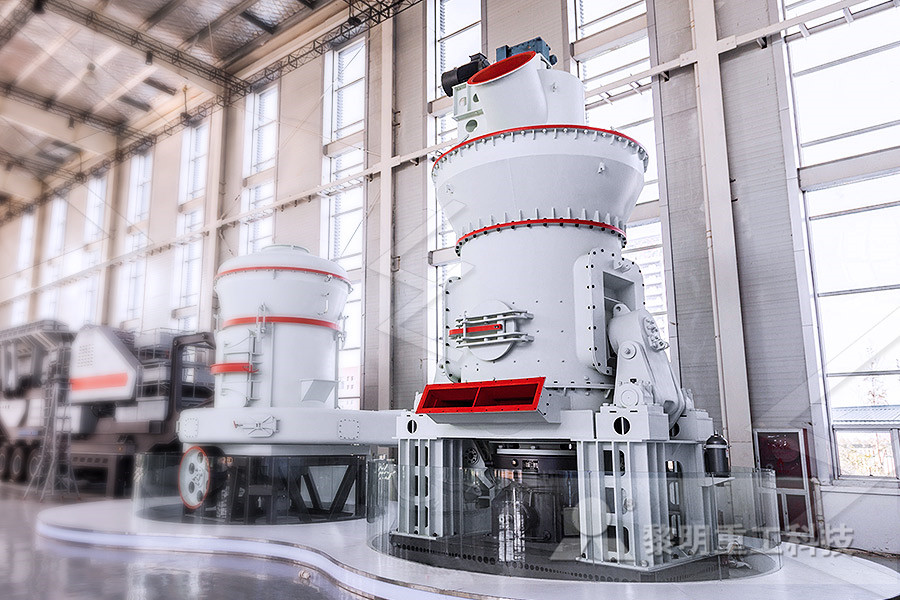

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaCrushing Mineral Processing 911 Metallurgist Mar 17, 2017 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial appliion of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from ancrushing and grinding process in mining industry

Crushing And Grinding Process Pdf Tembaletu Trust

crushing and grinding process pdf greencastproject Processing of minerals crushing YouTube Feb 16, 2016 price list of crushing process mineral processing mineral processing wikipedia, and minerals the Handbook Mineral Processing Technology Pdf– Rock Crusher Crushing And Grinding Mineral Processes In Metals CMEcrushing, grinding, and milling or fine grinding In mineral processing parlance, comminution in coarse range is known as “crushing” and in fine range it is called “grinding” Comminution : The act or process of reduction of particle size with attendant increase in surface area and population of particles, usually butCERAMIC MATERIALS I Mühendislik FakültesiCrush form grinding is a special process used at the Kansas City Plant to finish stem sections of reservoir products However, crush form grinding is a complex process with many variables affecting the final product This study identified two potential methods that can be applied to stems Profile grinding was investigated in 2007Crush Grinding (Technical Report) OSTIGOV

AP42 Section 11192 Crushed Stone Processing and

11192 Crushed Stone Processing and Pulverized Mineral Processing 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, and slateMcLanahan specializes in a variety of crushing solutions for reducing minerals – from very friable minerals, such as coal and salt, to hard rock, such as granite, and orebearing minerals, such as copper and iron – at the primary, secondary and tertiary stages Crushing McLanahanGeneral Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills New processes such as micron grinding and mechanochemical grinding give our VIBRADRUM® Grinding Mill Crushing Mill General Kinematics

The Production Process Of Limestone,Milling Crusher Machine

Lime can be categorized into ordinary lime and hydrated limeit is required the use of crushing and grinding equipment process in limestone Limestone processing equipment In the process of production and processing of limestone, it mainly uses the following equipment: milling machine (Raymond mill or high pressure grinding), jaw crusher Grinding and storing your own spices is a traditional art 2 You can crush a variety of ingredients such as whole spices, herbs, spice seeds, spice leaves, nuts or salt You need to be familiar with the basic techniques of grinding, crushing or bashing because every technique renders a different consistencyHow To Use a Mortar and Pestle: 6 Tips to NDTV FoodThe reason for this is that each process has disintegration and contraction while making gradually cutting, sorting and scraping actions during the separation of endosperm and bran Therefore the grinding gap will be less in the next crushing processCrushing, Grinding and Reduction in Flour Milling

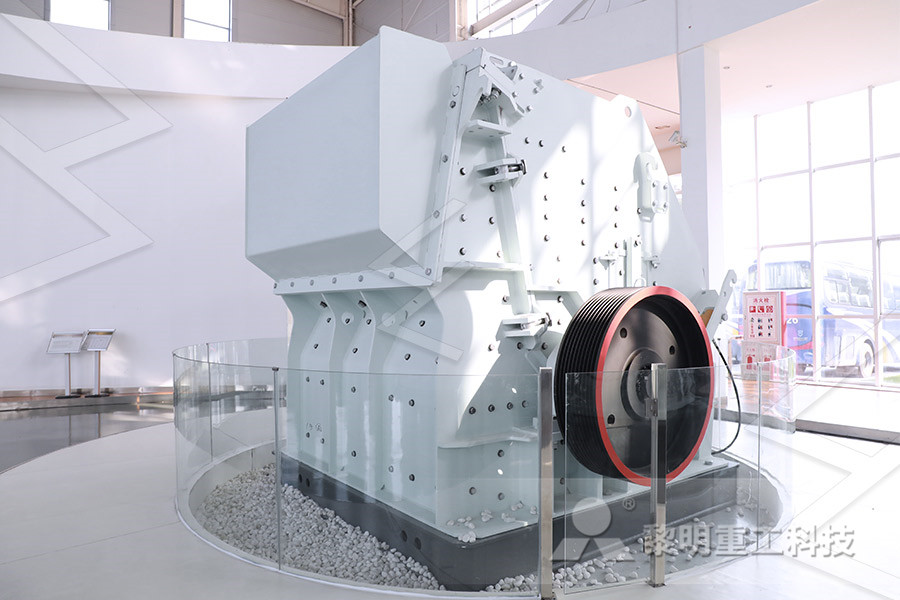

Crushing McLanahan

McLanahan specializes in a variety of crushing solutions for reducing minerals – from very friable minerals, such as coal and salt, to hard rock, such as granite, and orebearing minerals, such as copper and iron – at the primary, secondary and tertiary stages The commonly used crushing equipment has different kinds of compression type, impact type, shear type, knock type and grind type The choice of crushing equipment mainly depends on the type, shape and the degree of the grinding material Different materials should be used in different crushing Introduction of Waste Plastics Crushing ProcessesQuartz crushing grinding system: Most of the quartz sand application field has strict requirements on its size range, so during the crushing and grinding process, suitable crushing grinding solution is required to liberate quartz crystals from gangue sufficiently without contamination, meanwhile minimizing the undersize particle productionQuartz Processing,Crushing Grinding,Plant Prominer

Crush Grinding (Technical Report) OSTIGOV

Crush form grinding is a special process used at the Kansas City Plant to finish stem sections of reservoir products However, crush form grinding is a complex process with many variables affecting the final product This study identified two potential methods that can be applied to stems Profile grinding was investigated in 2007Grinding and storing your own spices is a traditional art 2 You can crush a variety of ingredients such as whole spices, herbs, spice seeds, spice leaves, nuts or salt You need to be familiar with the basic techniques of grinding, crushing or bashing because every technique renders a different consistencyHow To Use a Mortar and Pestle: 6 Tips to NDTV FoodCrushing of the wheat kernel prior to hammer mill grinding has a significant influence on the grinding process, both on specific grinding energy and particle size distribution of the ground material, especially for soft wheat kernels The moisture increases the grinding energy requirements, but crushing of kernels reduces itThe crushing of wheat kernels and its consequence on the

VIBRADRUM® Grinding Mill Crushing Mill General Kinematics

General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills New processes such as micron grinding and mechanochemical grinding give our 11192 Crushed Stone Processing and Pulverized Mineral Processing 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, and slateAP42 Section 11192 Crushed Stone Processing and May 15, 2014 RECENT TRENDS IN CRUSHING AND GRINDING To improve the art of crushing and grinding for 1 better grain liberation, 2 minimum overgrinding, 3 reducing power consumption, 4 reducing capital and operation costs Improvements Development of 1 Autogenous and semiautogenous grinding machines, 2Mineral Processing LinkedIn SlideShare

The Production Process Of Limestone,Milling Crusher Machine

Lime can be categorized into ordinary lime and hydrated limeit is required the use of crushing and grinding equipment process in limestone Limestone processing equipment In the process of production and processing of limestone, it mainly uses the following equipment: milling machine (Raymond mill or high pressure grinding), jaw crusher Home » Crushing Grinding CinChemPro has the capacity for processing a wide variety of friable materials in hammer mills, reducing materials from large chunks to products of less than 100 microns Our crushing and grinding operation includes blenders, dust collectors, and packaging equipmentCrushing Grinding CinChemPro, LLCIn cement: Crushing and grinding containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryersGrinding materials processing Britannica

grinding process aluminum balls MC World

crushing and grinding process of aluminium Crushing And Grinding Process Of Aluminium kasprzykarteu crushing of aluminium ore crushing of aluminium ore grinding mill china jaw crusher for aluminum orealuminum ore, gristone,blast furnace slag ore crusher can used for crushing iron ore crushing and grinding process of aluminium crushing and grinding bauxite mining