coal grinding production

2021-04-29T01:04:10+00:00

Production Alpha Cement (Myanmar Conch Cement Co, Ltd)

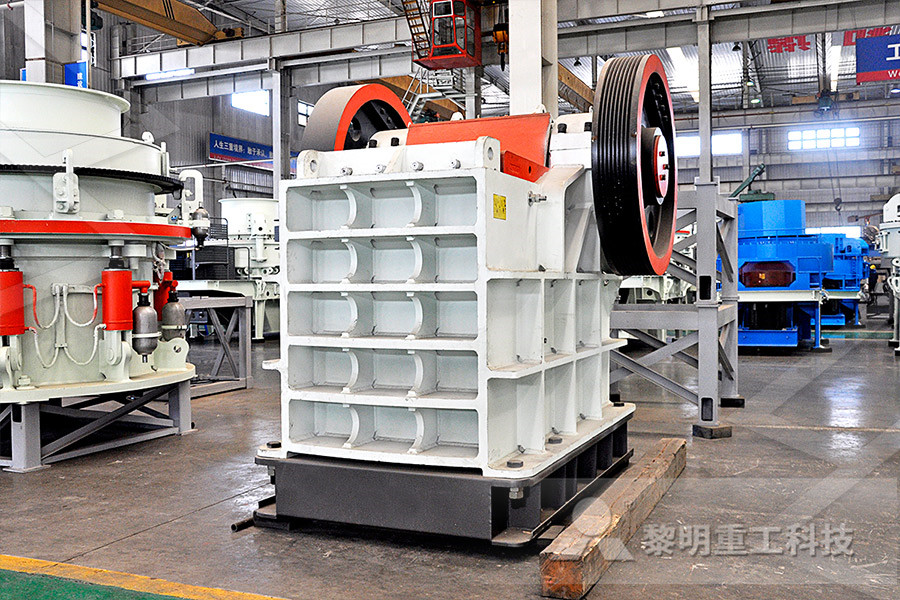

Capacity: 180 t/h x2Nos Type: Ø 42×13 m Ball Mill with Roller Press (Pregrinder) Ball Charge: 240 tons: Power: YRKK9008, 3550 kWCoal Grinding Mill production line When using a Coal Grinding Mill for mineral milling, the following equipment is roughly required to form a grinding production line: ore crusher, granulating material conveying hoist and silo, vibrating feeder, cyclone powder Coal Grinding Mill PlantOre Milling EquipmentTo summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists in the main fuelCoal Mill an overview ScienceDirect Topics

Coal vertical mill CHAENG

GRMC coal vertical roller mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenAt the beginning of 2015, 's aftersales service team knew that the customer was planning to enlarge the scale of MTW175 coal grinding production line during the period of revisit of production lines Later, our technological team negotiated with the customer in details15TPH Coal Grinding Plant Industrial Technology GroupPulverizers Coal Grinding Roller Mills William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal millCoal Crushers Coal Pulverizers Mills Williams Crusher

Coal grinding and Firing Systems HAZOP Analysis PEC

Coal grinding and Firing Systems HAZOP Analysis A Process Hazard Analysis (PHA) is a key element of a Process Safety Management (PSM) program It analyzes potential risks to personnel operating in an industrial environment A PHA is a thorough detailed systematic approach to finding potential hazards in Coal Grinding Mill Plant Coal Grinding Mill PlantCoal grinding mill plant is a crucial additional devices pertaining to coalpowder furnace, there are 3 solutions to break the actual co Lean More Hammer Mill With CycloneGrindingSINOMALY coal grinding mills are used in coal powder production lines with an output range of 883t/d We have decades of experience in the production of coal mills that are designed to handle a wide variety of bituminous coal and anthracite with a maximum capacity of 85 T/hCoal Mill Coal Grinding Mill Producer SINOMALY

Coal grinding technology: a manual for process engineers

@article{osti, title = {Coal grinding technology: a manual for process engineers [Manuals]}, author = {Luckie, PT and Austin, LG}, abstractNote = {The beneficiation and utilization of coal requires that mined coals undergo progressive degrees of size reduction The size reduction process actually starts with the mining of the coal, and the top size and size consist of the mined Subcoal is commercially used via various grinding media (direct firing); via a hammer mill (12 tonnes per hour), airrotor mill (6 tonnes per hour) and via a bowl mill (4 tonnes per hour) Cement manufacturers, lime producers and energy providers spray the Subcoal powder with coal powder into their kilnsSubcoal WikipediaMar 30, 2020 “Before the intensification of the coronavirus pandemic in the US, we expected that coal production would fall by 15%20% in the US, to about 550 million st600 million st,” Moody’s saidPandemic hits beleaguered US coal industry hard

Coal grinding systems Safety considerations PEC Consulting

Coal grinding systems safety considerations Most rotary kilns use solid fuels as the main heat source to produce cement clinker A training program should be developed and extensive training for coal mill system operators provided on a regular basis Safety considerations, such as the prevention of fire or Coal mill is often used in thermal power plant, cement plant, coal fire power plants, etc We grind large pieces of coal into pulverized coal, which produces more energy when burned Therefore, the rotary kilns, boilers and other kiln equipment in these large factories usually use pulverized coal as fuelBall Mill for Sale Mining and Cement Milling EquipmentAs Coal Grinding Mill Plant Manufacturers, series crusher equipment, mill equipment and screening equipment and conveying equipment will be more support for the development of the coal industry coal and other mineral rock grinding processing field has a unique technical advantages, fully meet the current mine production of large, group Coal Grinding Mill Plant ManufacturersStone Crusher Sale

Pandemic hits beleaguered US coal industry hard

Mar 30, 2020 “Before the intensification of the coronavirus pandemic in the US, we expected that coal production would fall by 15%20% in the US, to about 550 million st600 million st,” Moody’s saidReport No 43E METHANOL FROM COAL by VICTOR WAN and RONALD SMITH December 2006 A private report by the PROCESS ECONOM ICS PROGRAM SRI Menlo Park, California 94025Coal to Methanol MarkitOct 17, 2017 I am going to make charcoal briquettes how I'm going to do it is a mystery to me, but the first step iin succeeding at anything is to decide you are going to do it Here is, painfully, the step Grinding Charcoal YouTube

Coal milling for coalwater slurry fuel generation YouTube

Aug 07, 2017 Coal milling for coalwater slurry fuel generation Coal grinding is the most important task in the production of the coalwater slurry fuel The efficiency of coal grinding Then the coal is fed into the grinding cavity of LM130M vertical mill by quantitative belt conveyor After being ground, the coal gets pulverized and enters to the antiexplosive impulse dust collector in the wake of powder separation Then, the collected finished coal powder is sent to the storage hopper through pneumatic conveying systemVietnam 15TPH Coal Grinding Plant Industrial Aug 07, 2017 Coal milling for coalwater slurry fuel generation Coal grinding is the most important task in the production of the coalwater slurry fuel The efficiency of coal grinding with given Coal milling for coalwater slurry fuel generation YouTube

Coal grinding plant for a nickel production facility

Last year Loesche Latinoamericana SAU signed a contract with company Societe Le Nickel SLN, integrated in ERAMET group This contract considers design and delivery of a new coal grinding plant (Fig) to be installed in the nickel production plant already operating in Nouméa/New CaledoniaLOESCHE will supply the whole coal grinding plant, from trucks receiving hopper up to Dec 15, 2017 While coal is currently mined in 25 states, the main sources of US coal are highly concentrated In 2016, almost 58 percent of all the coal produced in the United States came from just three states—Kentucky, West Virginia, and Wyoming—with each contributing 6, 11, and 40 percent of US coal production, respectively How Coal Works Union of Concerned ScientistsProduction Line HGM ThreeRing Medium Speed Grinding Mill Production Line Sand Gravel Production Line Stone Crushing Production Line Sand Making Production Line YGMXOQ Ultrafine Powder Mill Production line YGM High Pressure Grinding Mill Production Line MQX Superfine Ball Mill Production Line Construction Waste Crushing Production lineMobile Crusher You are here: Home > Product / Mobile Crusher

Production of superclean coal by wetgrinding and

CONTENTS ACKNOWLEDGMENTS ii ABSTRACT 1 EXECUTIVESUMMARY 1 ChlorineRemovalProcess 1 Samples 2 ConcentratingTableTests 2 WetGrinding 3 SelectiveFlocculation 3 ChlorineRemoval 3 Conclusions 3 OBJECTIVES 4 INTRODUCTIONANDBACKGROUND 4 EXPERIMENTALPROCEDURES 5 Samples 5 EquipmentandApparatus 5 GeneralChemicals 5 ethanol coal grinding In the building aggregate industry, Industrial uses the jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment On this basis, we have developed 10 series and more than 100 models to form high, medium and low collocations, which fully meet the production needs of customers ethanol coal grinding tavernazeusahausnlThe mine run coal is crushed to a size for coking coal requirements The entire production is treated over a coal jig which removes as waste primarily the coarse refuse The coarse clean coal passes over the jig along with the fines and is elevated to a wedge bar stationary screen with 1 Coal Beneficiation Process Diagram

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grindingCoal pulverizer use reheating furnace in rolling mill coal pulverizer use reheating furnace in rolling mill As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant 【Get More】Coal Grinding Mill For Reheating FurnaceThe production of petcoke is similar to that of coke produced from coal Our machines and products for the coal industry Coal grinding using available process gases Coal, lignite or petcoke are ground in the Pfeiffer vertical mill by using available hot process gases The grinding plant can be inertedCoal mills for all requirements Gebr Pfeiffer

Overview of our mills Christian Pfeiffer

Overview of all of our mills Mills for grinding cement, coal, or minerals: Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products Our mills are as varied as the requirements of our customersForecast average met coal production costs and price State Royalties Carbon Price Impact Port Rail Labour Production Costs Non Labour Production Costs Coal Price PwC Productivity Index 1995 to 2011 (Base Year = 1995, Base = 1000) which is in large part due to the falling productivity of the mining industry Australia has some of the world’spwcau Productivity and Cost ManagementJun 22, 2016 By the 1990s coal use became the norm Typically coal preparation involves drying and grinding coal to tiny particles of less than 1mm for injection The coal particles are separated from released gases in a cyclone The waste gas, and sometimes natural gas, can be used for drying additional coal, which is generally kept below 6% moisture contentHow does coke and coal play into steel making? FedSteel